Draining device and method for deep foundation pit pool construction in thermal power plant confined space

A technology for drainage devices and deep foundation pits. It is applied in the direction of infrastructure engineering and construction. It can solve the problems of many impurities in foundation pit water, single drainage method, and inability to effectively prevent them, so as to improve stability, realize back-and-forth conversion, and avoid The effect of water clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

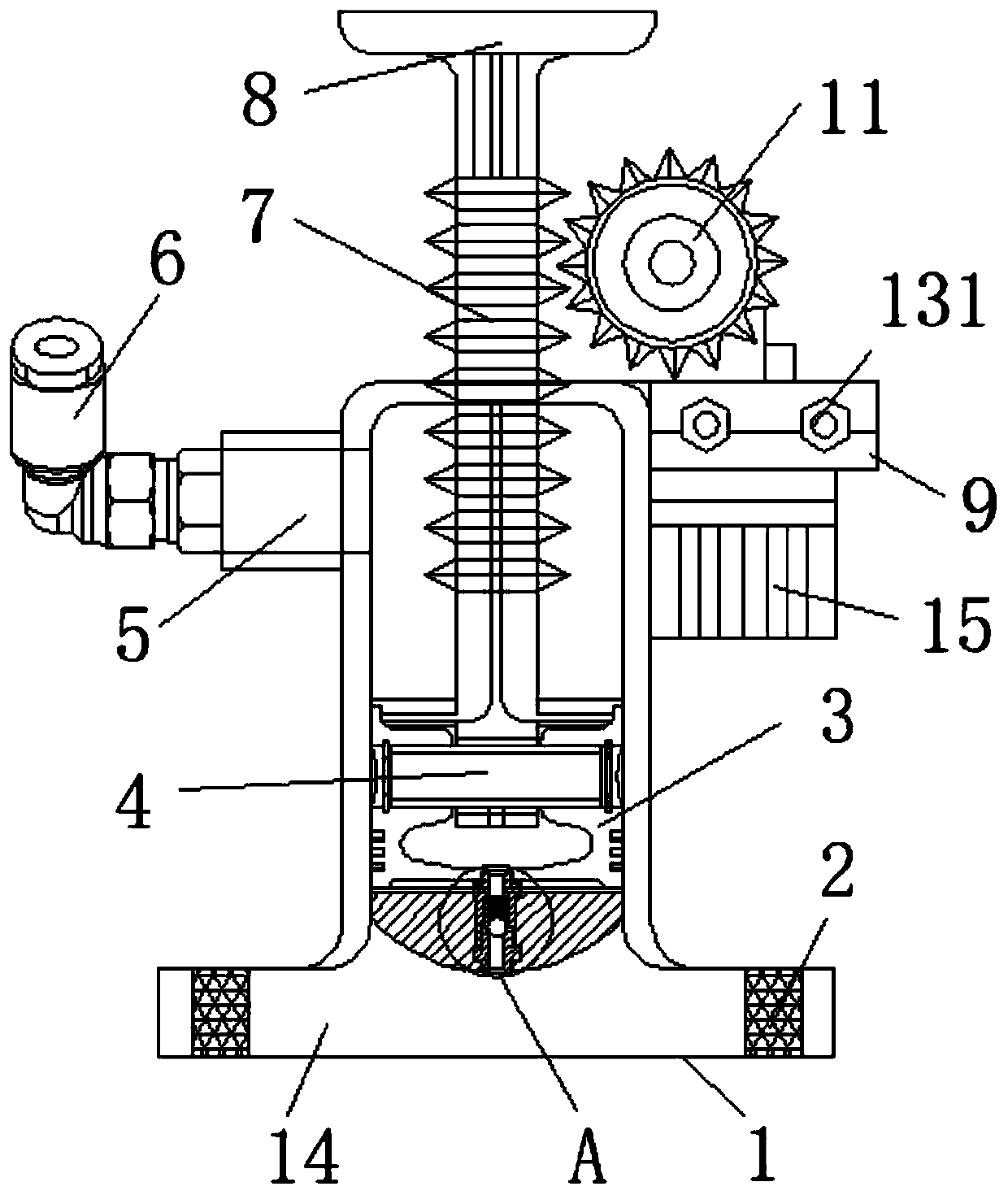

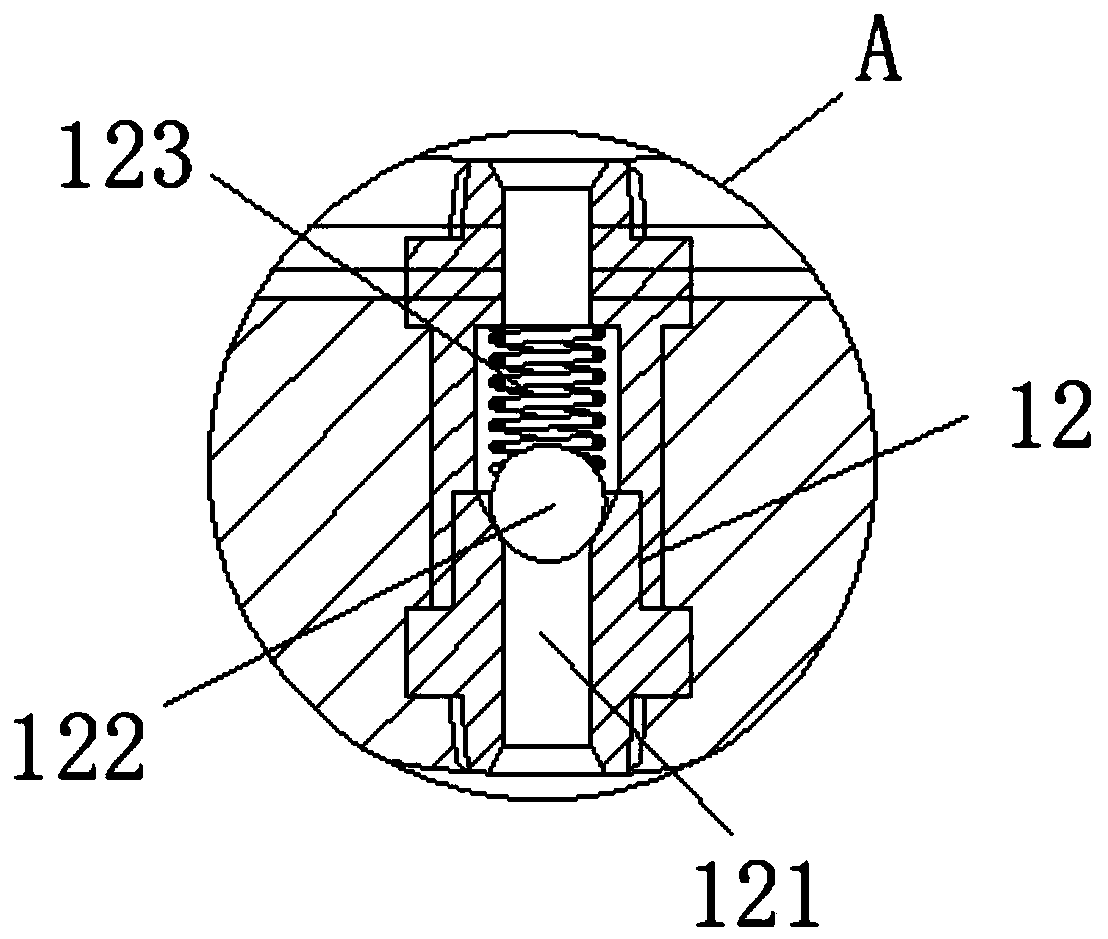

[0033] A drainage device for construction of a deep foundation pit pool in a confined space of a thermal power plant, including a housing 1, a transmission mechanism, a plug body 3, a one-way valve 12 and a power source, the bottom of the housing 1 is provided with an opening, and the opening passes through the one-way valve 12 Connect the water inlet pipe 14, the T-shaped connection between the water inlet pipe 14 and the shell 1, the water inlet pipe 14 is installed with the filter screen 2, the worm 7 extends from the top outside of the shell 1 to the inside of the shell 1, and the end of the worm 7 is connected The plug body 3, the housing 1 below the plug body 3 is equipped with a one-way valve 12, and the one-way valve 12 can close the housing 1; the power source is connected to the worm gear 11 and the worm screw 7 assembly. In this embodiment, the power source is a motor 10 , and the transmission mechanism is a worm gear 11 and a worm 7 mechanism, including the meshing ...

Embodiment 2

[0048] Embodiment 2 discloses a drainage method for construction of a deep foundation pit pool in a confined space of a thermal power plant, which specifically includes the following steps:

[0049] Select manual mode and electric mode;

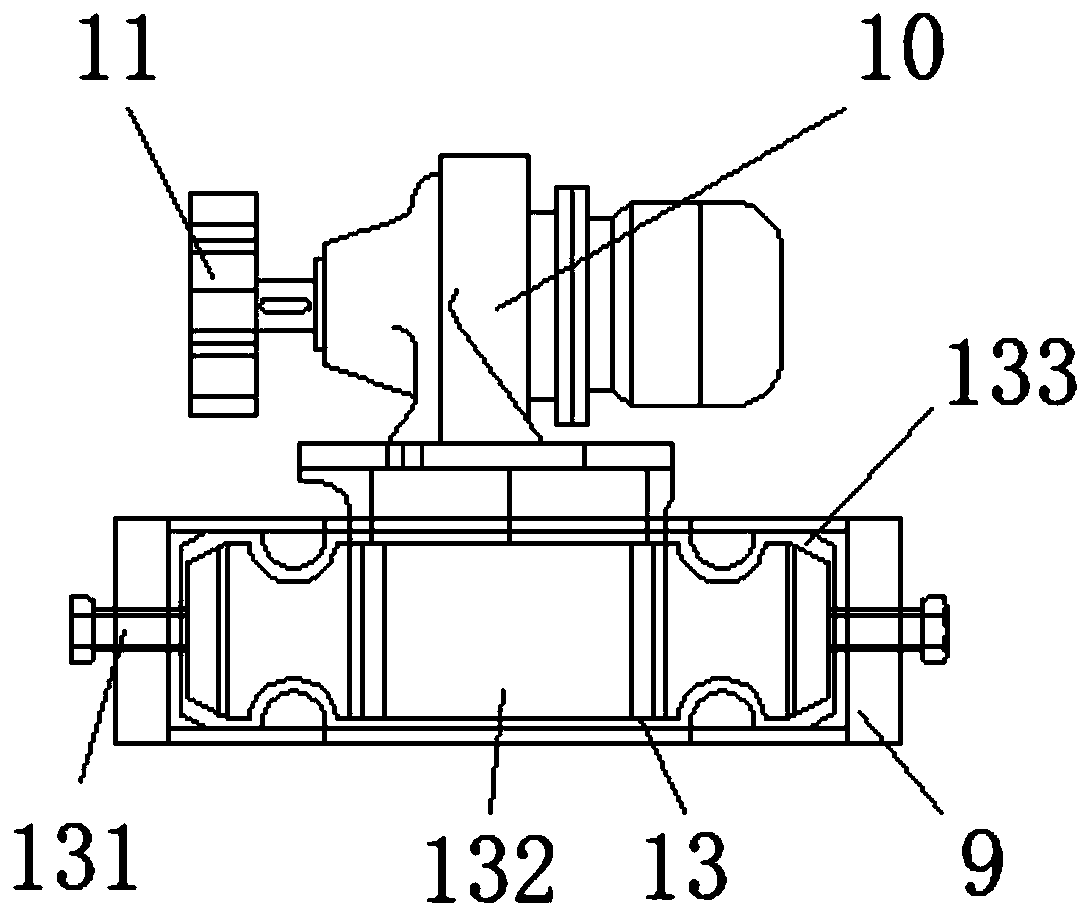

[0050] When the electric mode is selected, the slider 132 is pushed, and the slider 132 slides in the slide rail 133 to drive the motor 10 to move, so that the worm wheel 11 on the output shaft of the motor 10 and the worm 7 can be engaged with each other, and through the fixing bolt 131 The position of the motor 10 is fixed to ensure the stability of the motor 10 during operation;

[0051] The motor 10 drives the worm 7 to move up and down through the meshing of the worm wheel 11 and the worm 7, and the worm 7 pulls the plug body 3 to reciprocate in the housing 1, and the inner wall of the housing 1 and the plug body 3 are closely fitted. Form a negative pressure area in the housing 1, which can pump the liquid inside the water inlet pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com