Homopolymer and copolymer of long-carbon-chain semi-aromatic high-temperature-resistant polyamide and synthesis method thereof

A technology of high temperature resistance and polyamide, which is applied in the field of long carbon chain semi-aromatic high temperature resistance polyamide PA10T and its synthesis, and can solve the problems of color tone, high production cost, unfavorable environmental protection and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for synthesizing long-chain semi-aromatic polyamide and its copolymer. The polyamide is mainly made of terephthalic acid and 1,10-decanediamine, and may also contain aromatic, alicyclic or aliphatic other diacids, lactams, amino acids and nylon salts. Or several. The melting point of the semi-aromatic polyamide obtained by the two-step polymerization method is between 270-320°C, which belongs to the category of high-temperature nylon. One of the characteristics of the semi-aromatic polyamide is that it has both the excellent physical and mechanical properties, thermal deformation of the fully aromatic polyamide and the good processing performance and impact resistance of the aliphatic polyamide; the second feature is its molecular structure The excellent low water absorption determined by the low amide group content in the polyamide is very important for maintaining the performance and dimensional stability of the product during use; the...

Embodiment 1

[0064] Embodiment 1 PA10T homopolymer

[0065] Mix 2500g of terephthalic acid, 2600g of 1,10-decanediamine, 5g of sodium hypophosphite, 40g of benzoic acid and 3000g of deionized water in a 25L closed polymerization kettle, replace the air in the kettle with nitrogen twice, and stir The speed is 20r / min, the temperature is raised to 130°C for salt-forming reaction, the reaction time is 3h, then the temperature is raised and the system pressure is raised to 2.5-2.7MPa within 2h, the constant pressure reaction is carried out and the pressure is released when the temperature is rapidly raised to 300°C, 30min Discharge to normal pressure, react at normal pressure for 15 minutes, fill with nitrogen and pressurize the material, the prepolymer is extruded through the die head of the discharge port to granulate, and the surface of the material is cooled by air to maintain the good color of the material.

[0066] Dry the prepolymer at 80°C for 24 hours and put it into the vacuum drum. ...

Embodiment 2

[0067] Embodiment 2 PA10T homopolymer

[0068] The previous steps are the same as in Example 1. After 15 minutes of reaction at normal pressure, vacuum devolatilization for 10 minutes is carried out, and the material is discharged under pressure with nitrogen filling. Good color. The properties of the prepolymer are shown in Table 1.

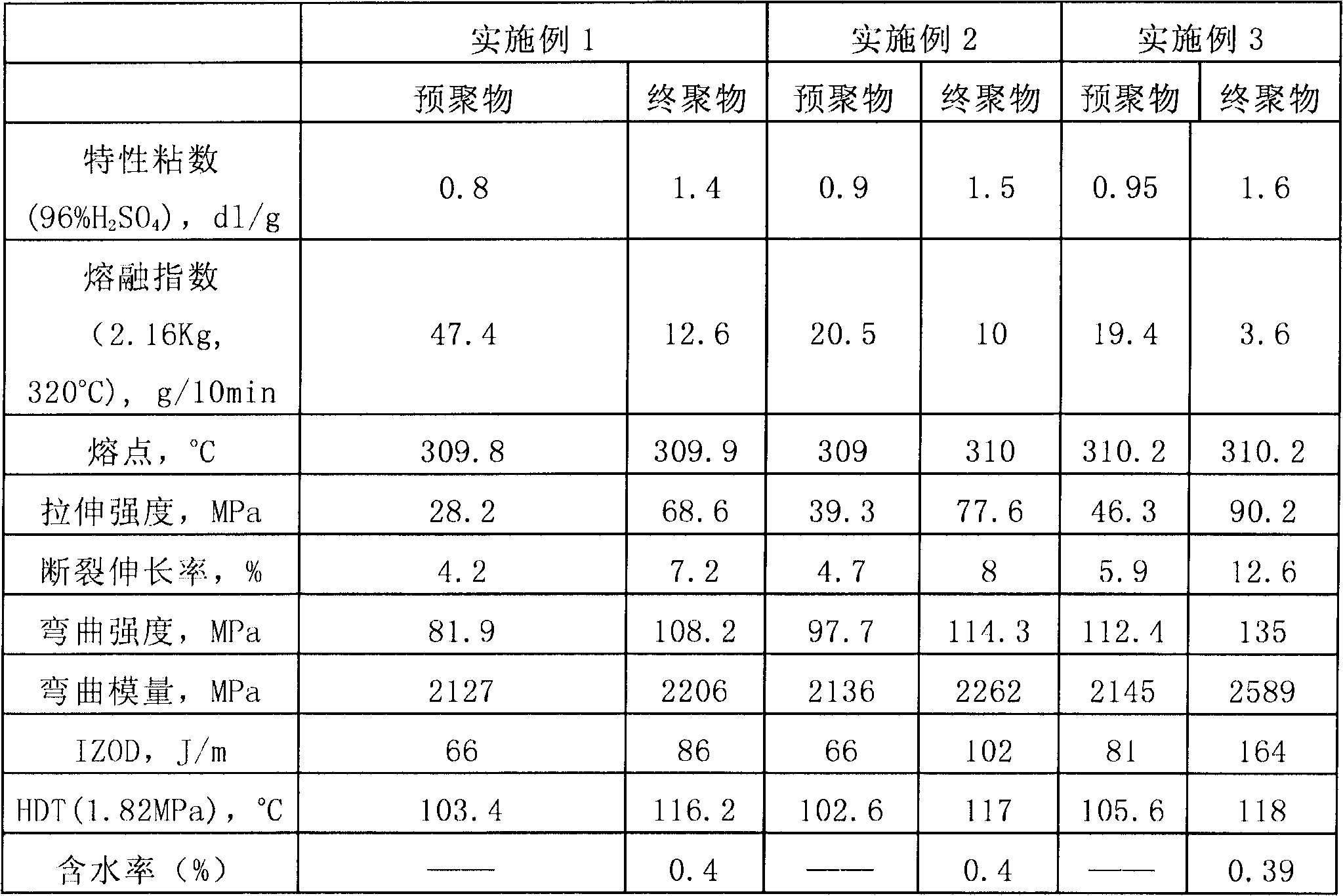

[0069] The solid-phase polymerization conditions are the same as in Example 1, and the performance comparison between the prepolymer and the final polymer is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com