Patents

Literature

121results about How to "Processing window width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

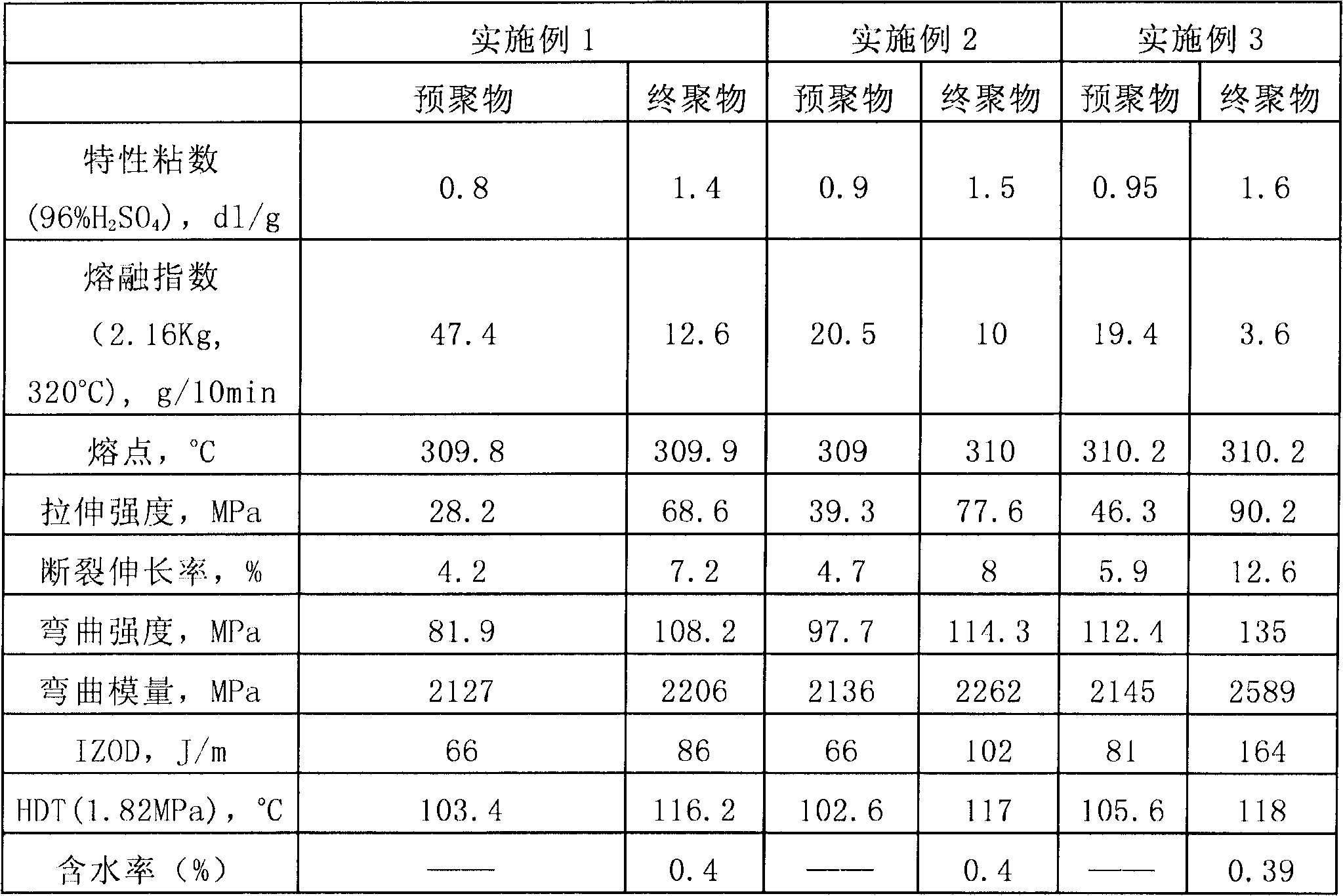

Homopolymer and copolymer of long-carbon-chain semi-aromatic high-temperature-resistant polyamide and synthesis method thereof

The invention provides a method for synthesizing a homopolymer and a copolymer of long-carbon-chain semi-aromatic high-temperature-resistant polyamide and polymerization products obtained by the method. The method comprises the following steps of: (a) prepolymerizing terephthalic acid and 1,10-decanediamine in a molar ratio of 1:(1.00-1.02) and optional copolymerization components to obtain a prepolymer that the intrinsic viscosity is controlled to be between 0.4 and 1.1dl / g; and (b) performing solid-phase polymerization on the prepolymer in step (a) to obtain the long-carbon-chain semi-aromatic high-temperature-resistant polyamide PA10T or the copolymer thereof, wherein the intrinsic viscosity is controlled to be between 1.2 and 2.6dl / g.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

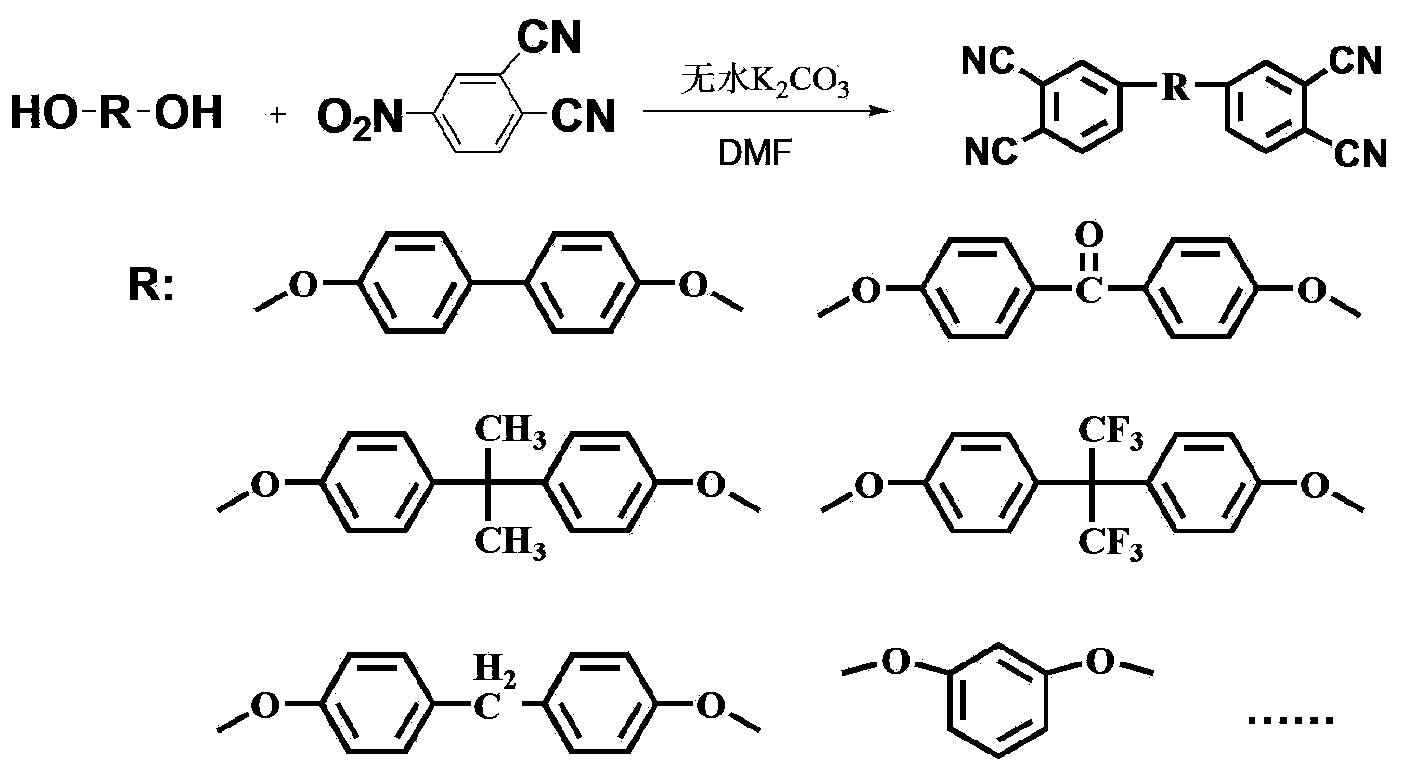

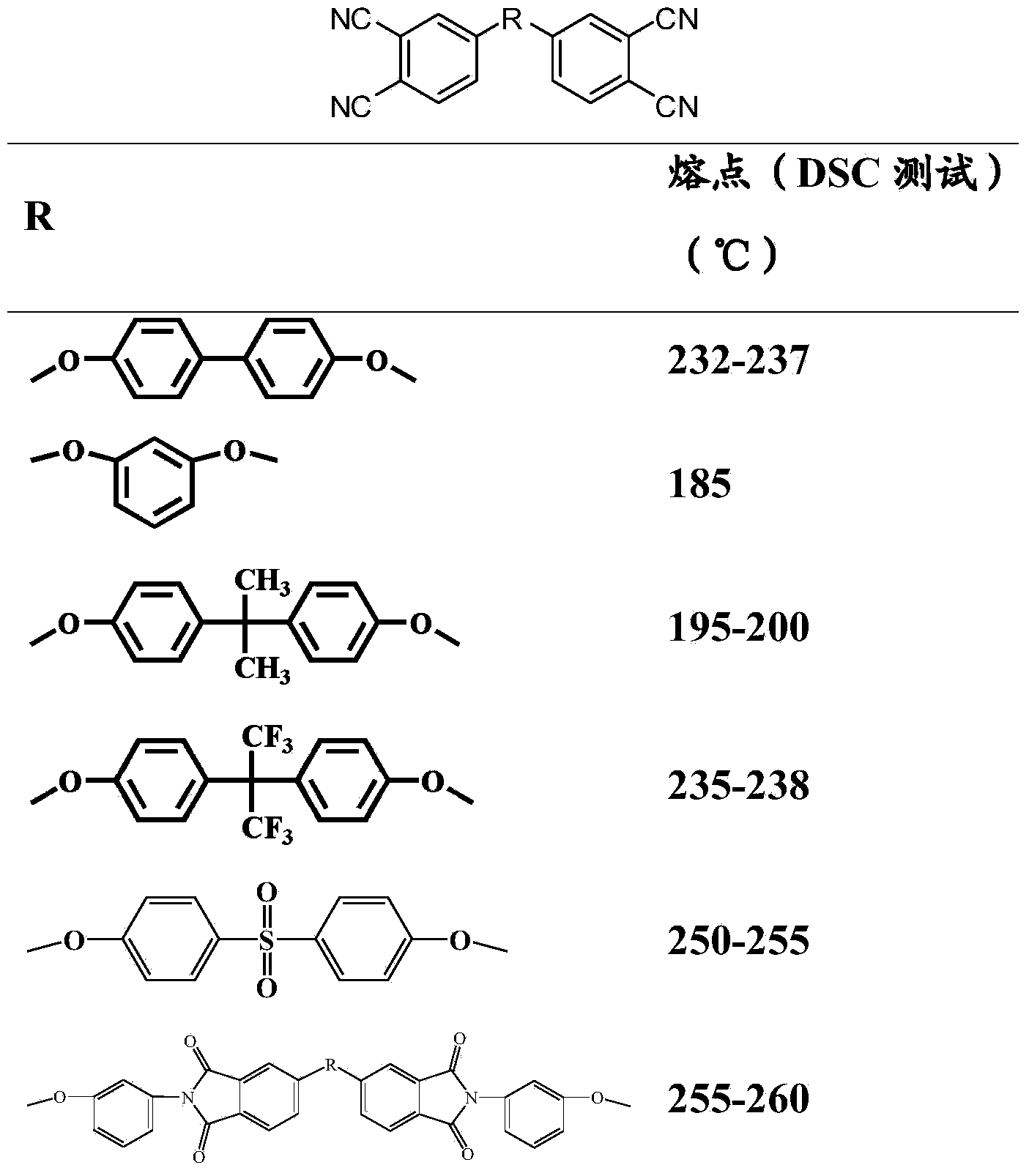

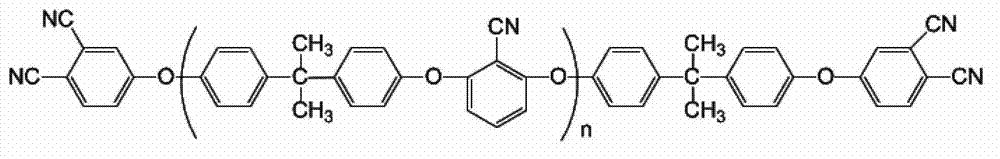

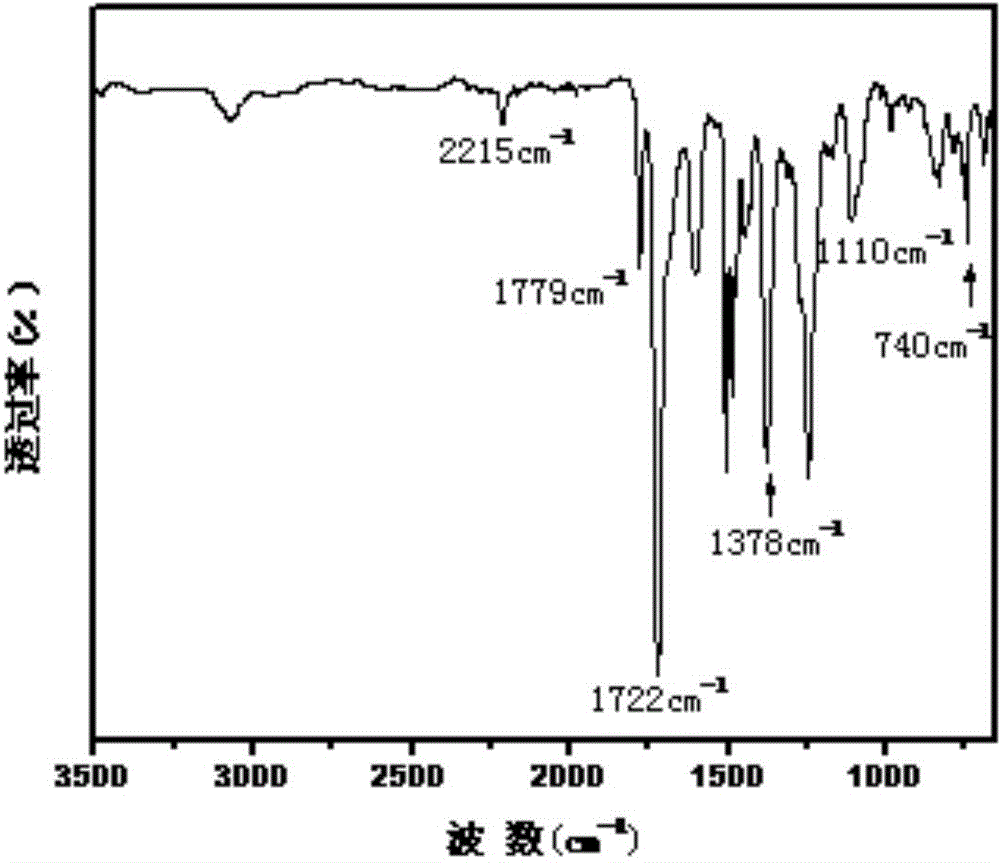

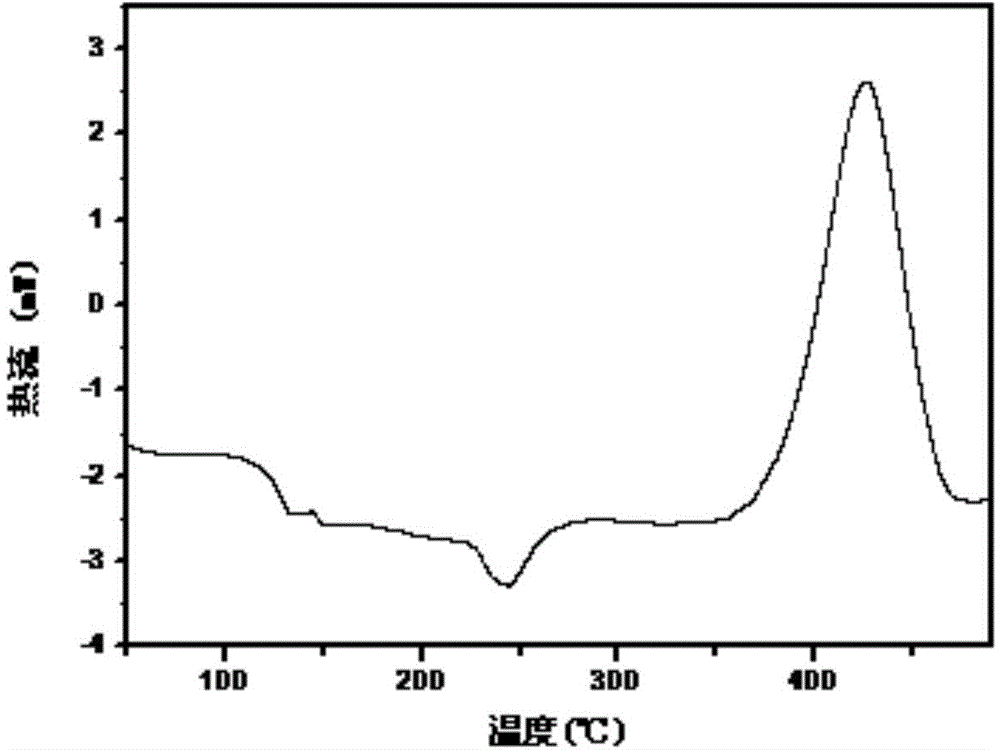

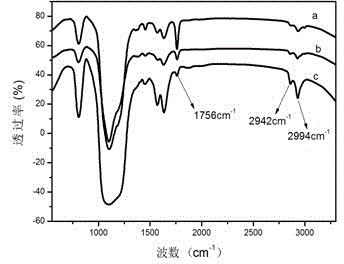

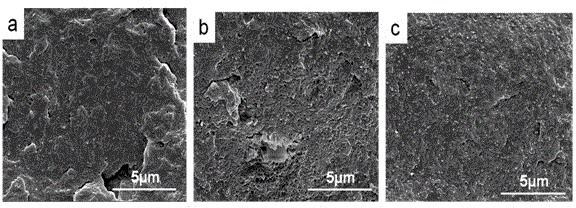

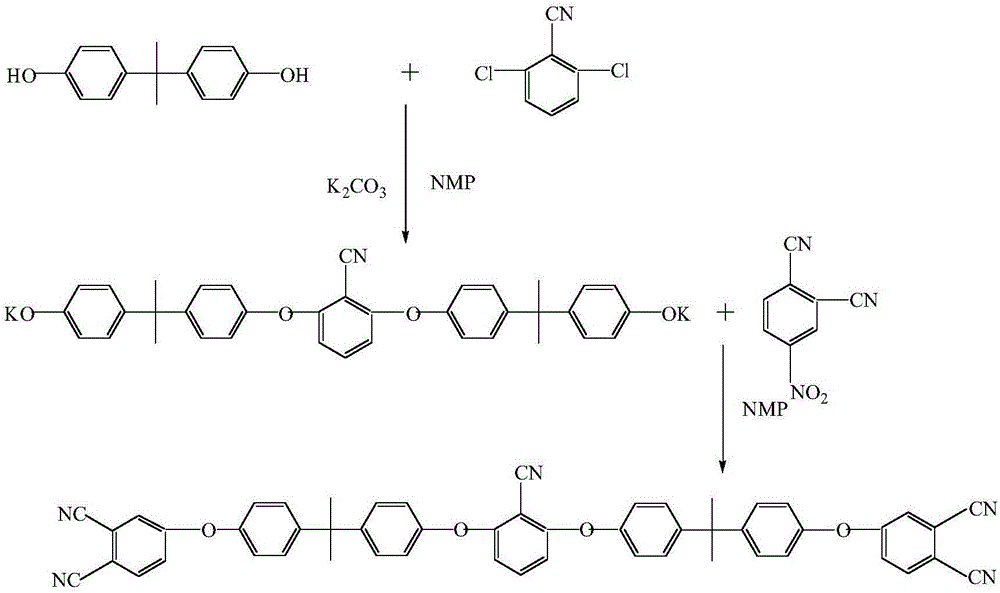

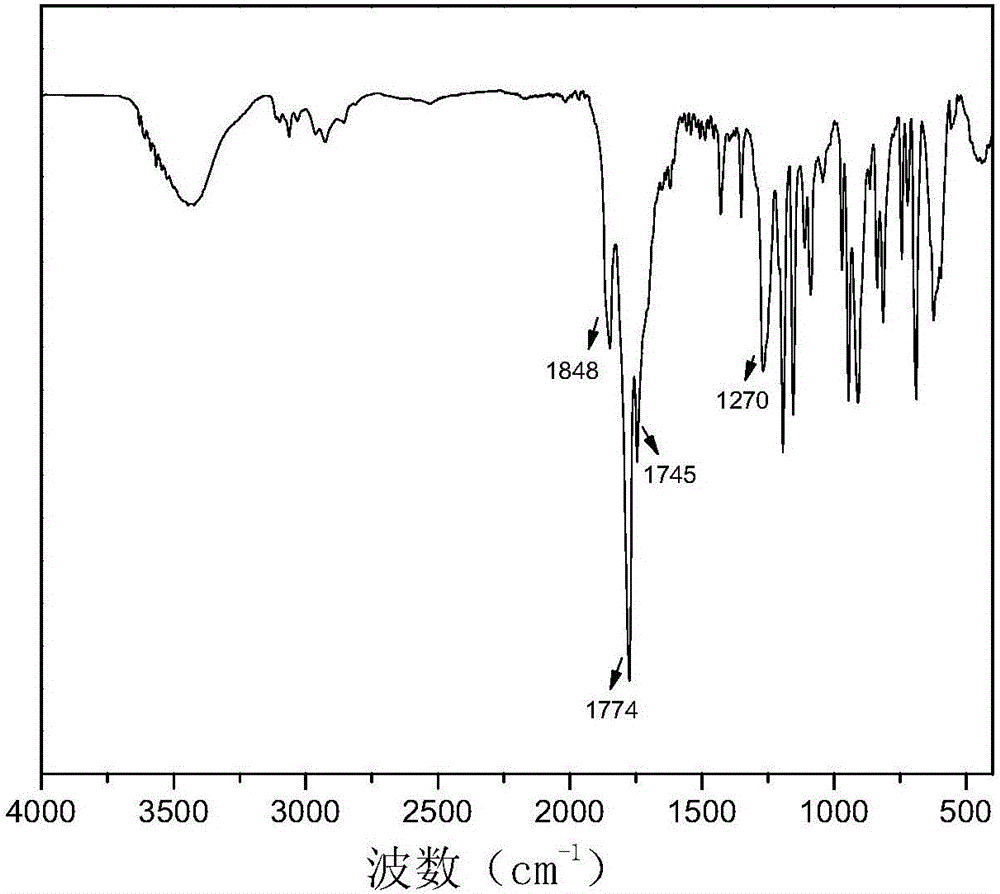

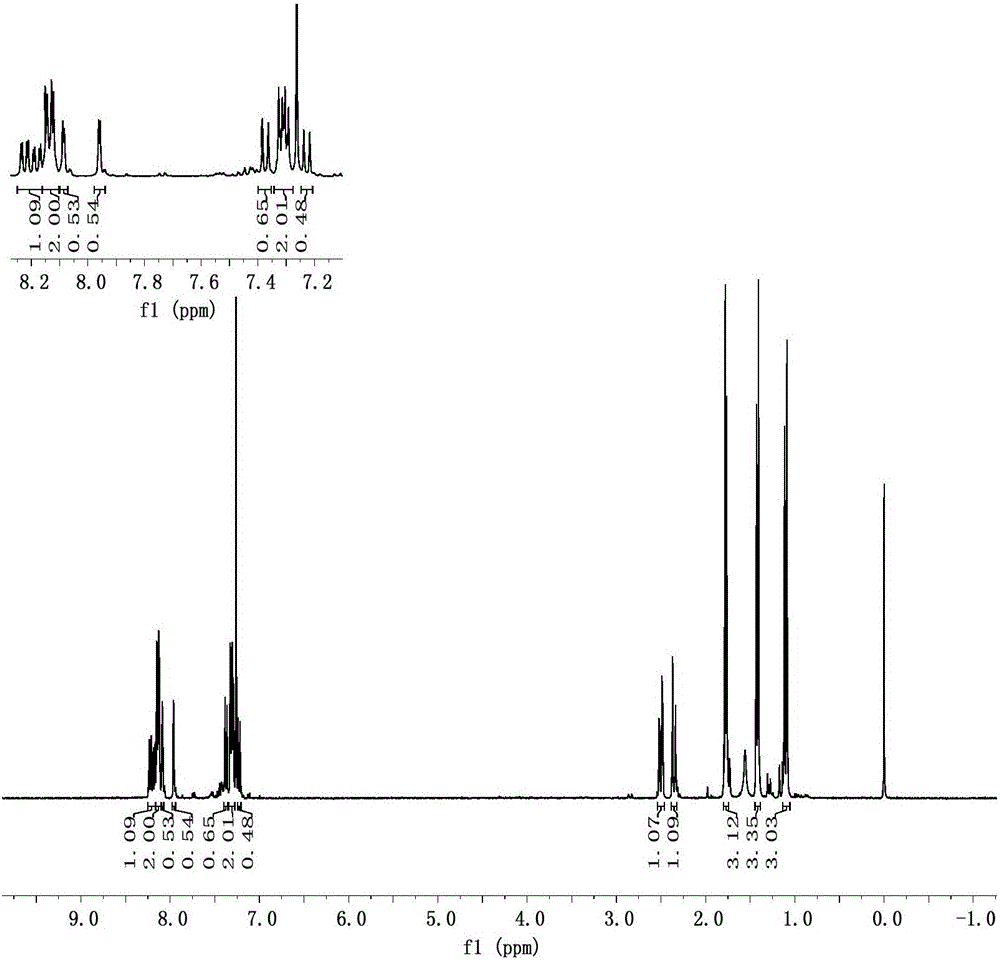

Novel phthalonitrile resin and preparation method thereof

ActiveCN103834008AIncrease asymmetryIncrease confusionSynthetic resin layered productsPhthalonitrileChemistry

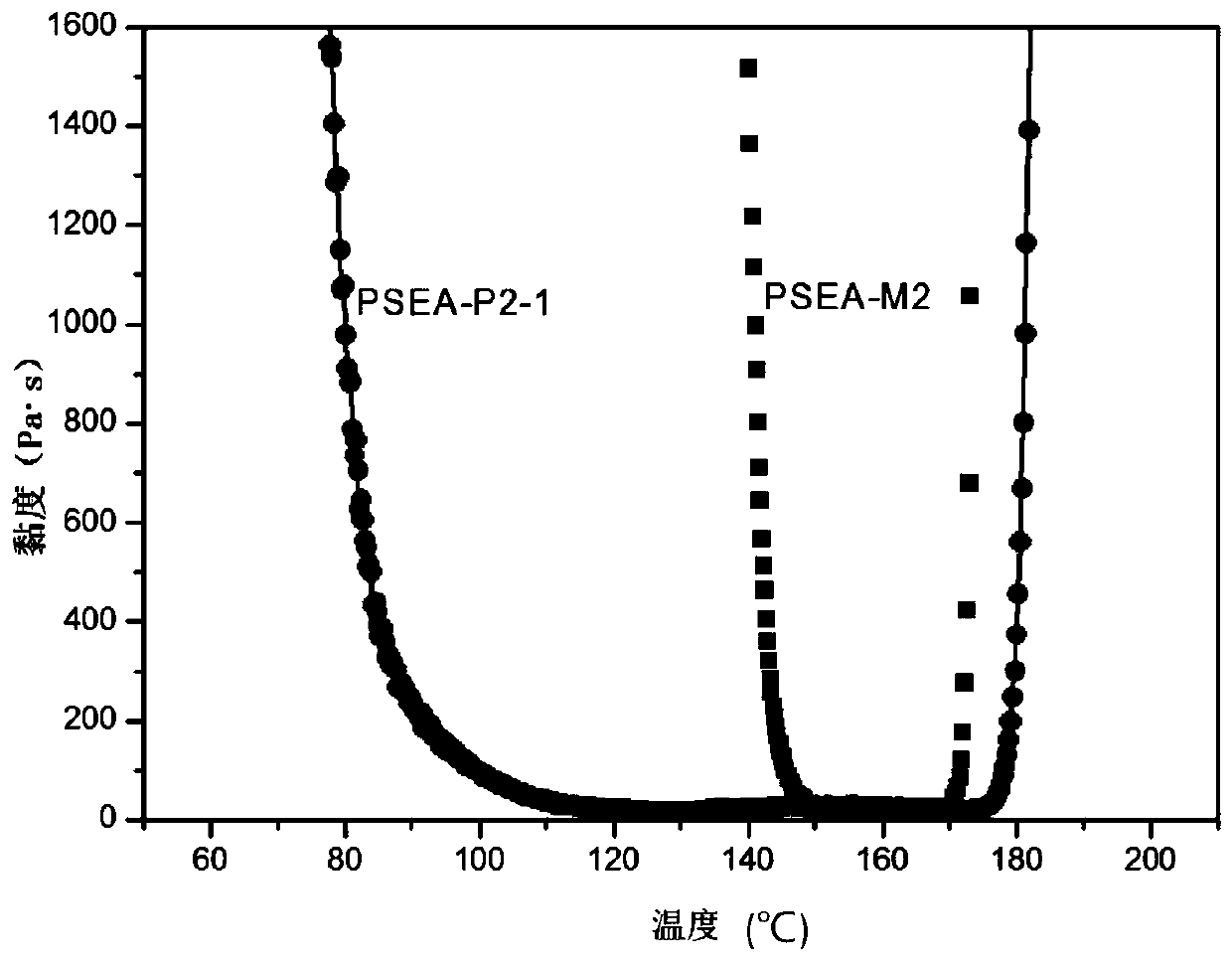

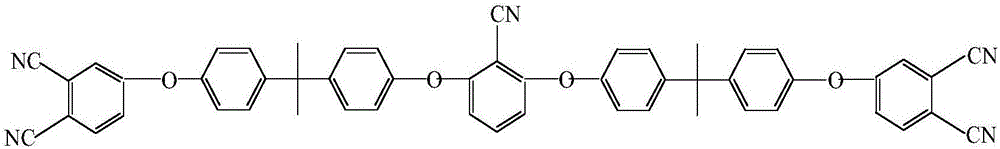

The invention discloses a novel phthalonitrile resin and a preparation method thereof. Compared with a conventional phthalonitrile resin (only 4-nitro phthalonitrile as an end-capping reagent, the novel phthalonitrile resin is introduced with 3-nitro novel phthalonitrile resin to cooperate end capping, and thus the asymmetry of a resin structure is increased and the turbidity of a resin component is increased (see a formula 1). Compared with the conventional phthalonitrile resin, the novel phthalonitrile resin disclosed by the invention has the characteristics of low melting temperature, good solubility, wide processing window, low curing temperature and the like; a prepared resin molded part and a resin-based composite material are low in porosity, excellent heat-resistant quality, and high in mechanical property, and can be applied to the fields of aerospace, a space technology, machine manufacturing, and the like as a light-weight and high-temperature resistant part. The formula is described in the specification.

Owner:INST OF CHEM CHINESE ACAD OF SCI

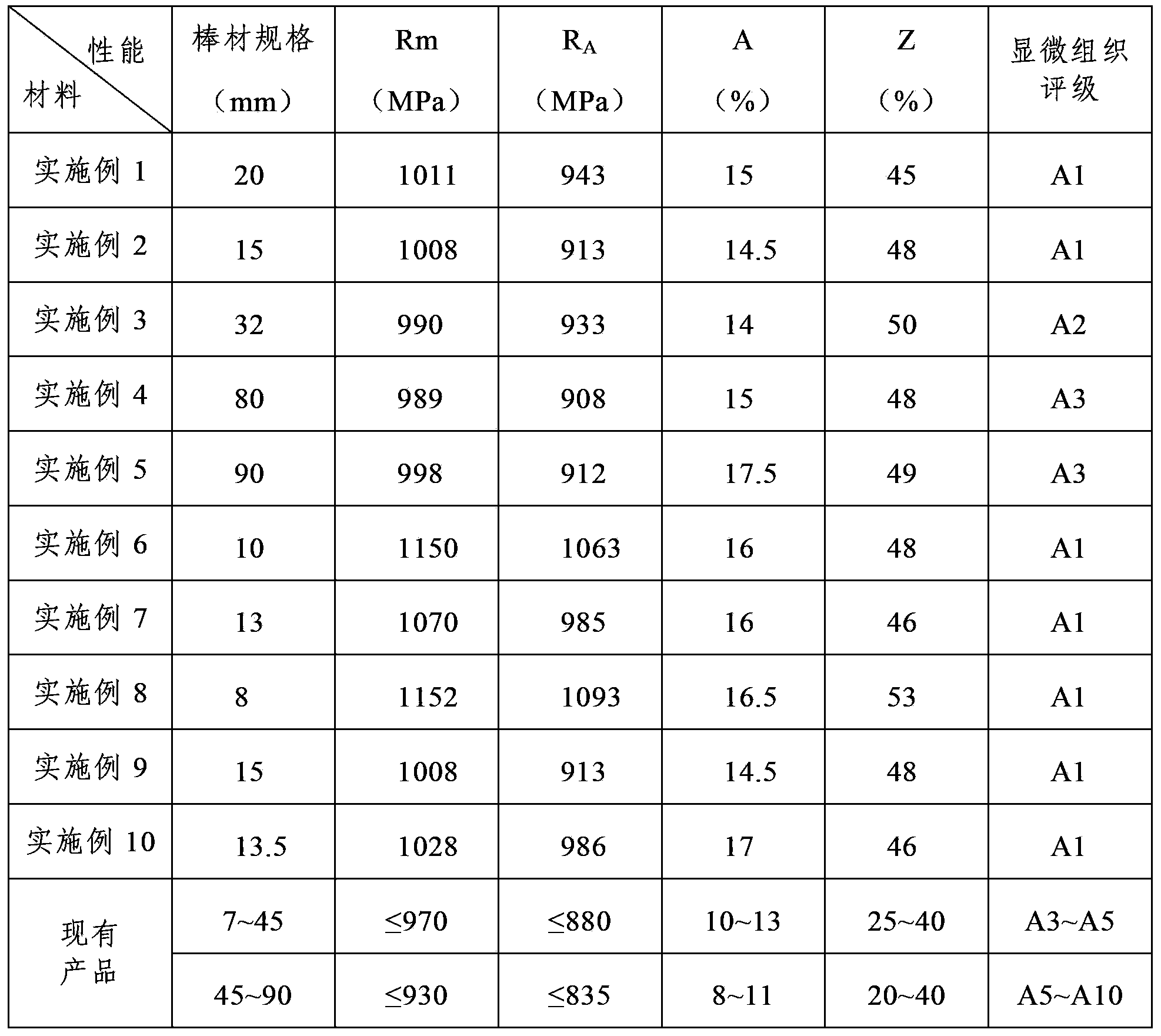

Preparation method of TC4ELI titanium alloy bar

The invention provides a preparation method of a TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 15mm-90mm. The invention also provides a preparation method of the TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) rolling; (5) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 8mm-15mm. The preparation method is simple in process, strong in repeatability and suitable for large-scale industrial production; the TC4ELI titanium alloy bar prepared by adopting the preparation method is uniform and fine in structure, high in microscopic structure level and excellent in mechanical property.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

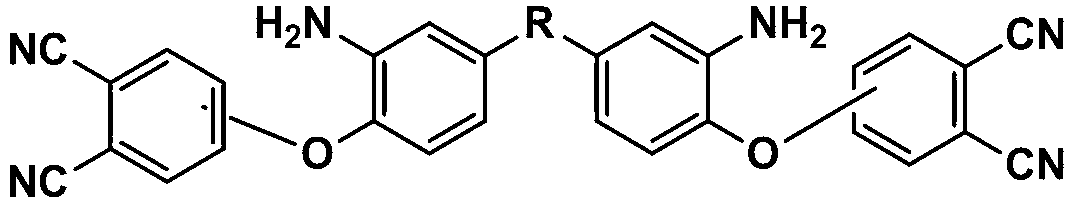

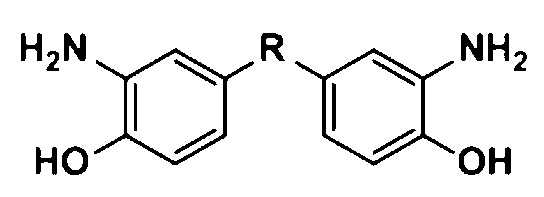

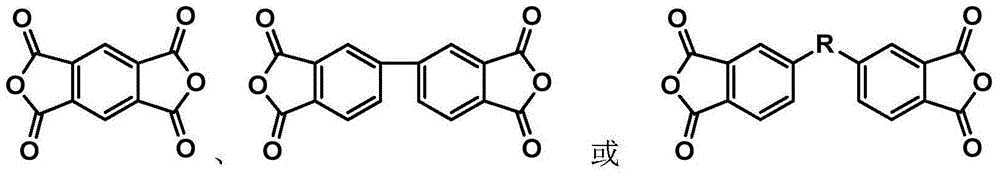

Aromatic diamine containing phthalonitrile side group and synthesis method and application thereof

InactiveCN102993070AIncrease typeBreak the rigid structureCarboxylic acid nitrile preparationOrganic compound preparationImidePolymer science

The invention discloses aromatic diamine containing phthalonitrile side group, which is characterized in that the structural formula is shown in the specification, wherein R is one of CF3CCF3, CH3CCH3, O, CO and S. A preparation method of the aromatic diamine containing phthalonitrile side group comprises the following steps of: adding 4-nitrophthalonitrile or 3-nitrophthalonitrile, a compound 1, potassium carbonate and a high-boiling point solvent into a reaction container; conducting reaction for 10-24 hours at room temperature under protection of nitrogen; and then precipitating, filtering and drying. The aromatic diamine containing phthalonitrile side group can be applied to the preparation of polyimide, polyamide and polyamide-imide.

Owner:SICHUAN UNIV

Laser welding tractable polycarbonate composition and preparation method thereof

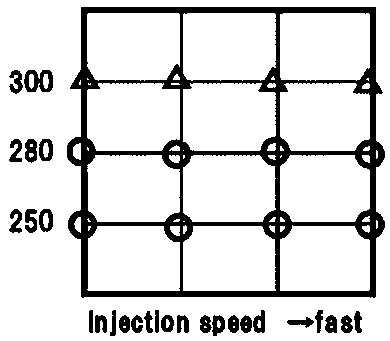

The invention relates to a laser welding tractable polycarbonate composition and a preparation method thereof. The composition comprises the following components in parts by weight: 50-80 parts of polycarbonate (PC) resin, 15-40 parts of ABS resin, 5-10 parts of amelt reinforcing agent, 0.1-1 part of a near infrared laser absorbent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The preparation method of the alloy comprises the following steps: (a) mixing the PC resin, the ABS resin, the melt reinforcing agent, the near infrared laser absorbent, the antioxidant and the lubricant in a mixing agitator; and (b) performing blending granulation on the mixture obtained in the step (a) by virtue of a twin-screw extruder to obtain a product. Compared with the prior art, the polycarbonate composition provided by the invention is higher in melt strength after the melt reinforcing agent is added, so that the surface of a product after welding has no bulges orbreakdowns, welding can be performed under a higher laser intensity, the obtained product is higher in welding strength at the same time, a processing window of a laser welding process of the polycarbonate composition is broadened, and the laser welding tractable polycarbonate composition is obtained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

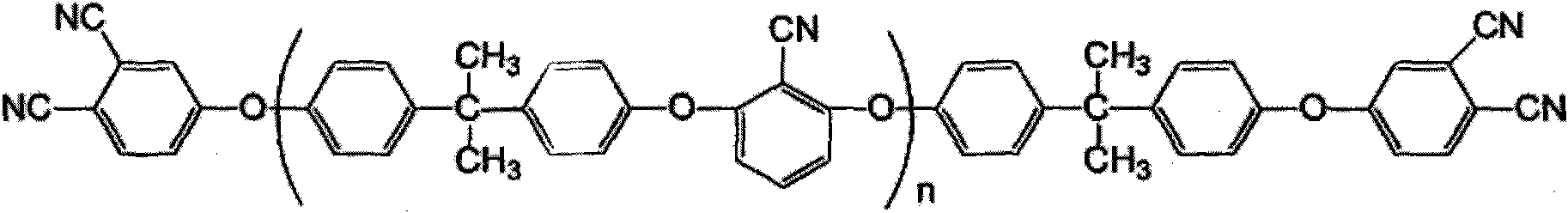

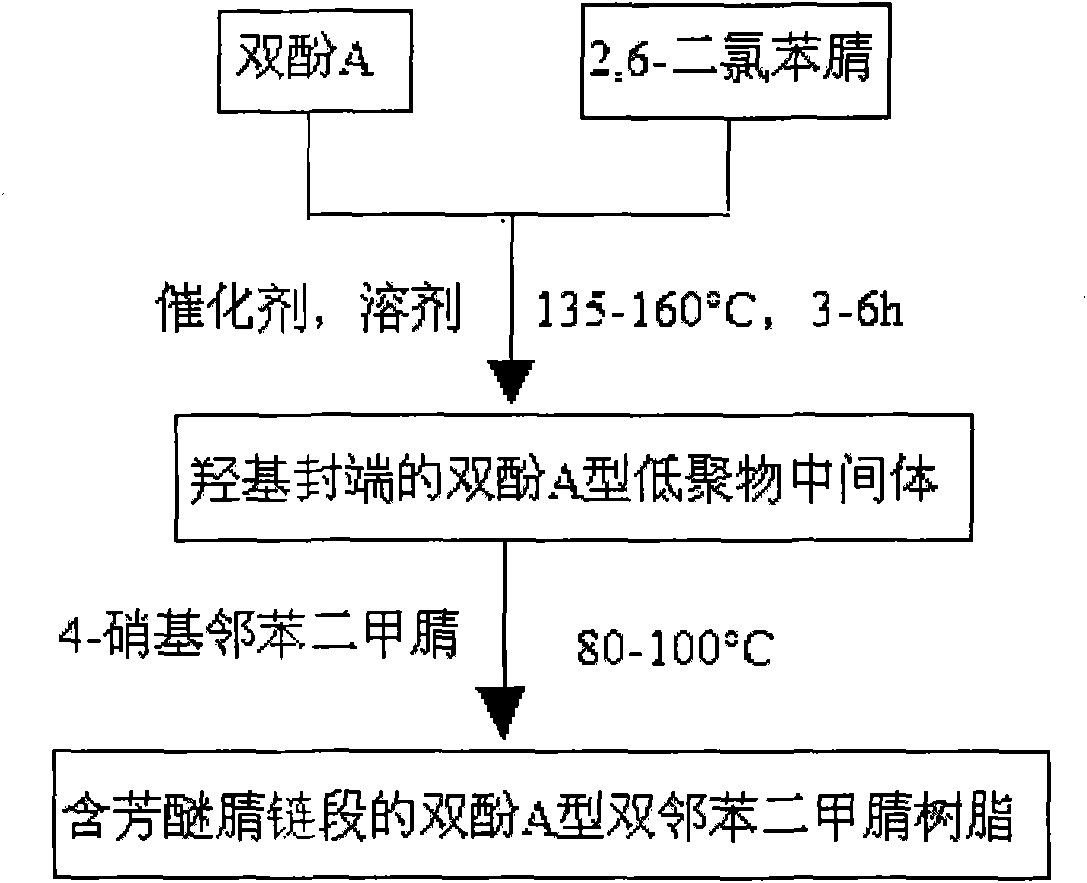

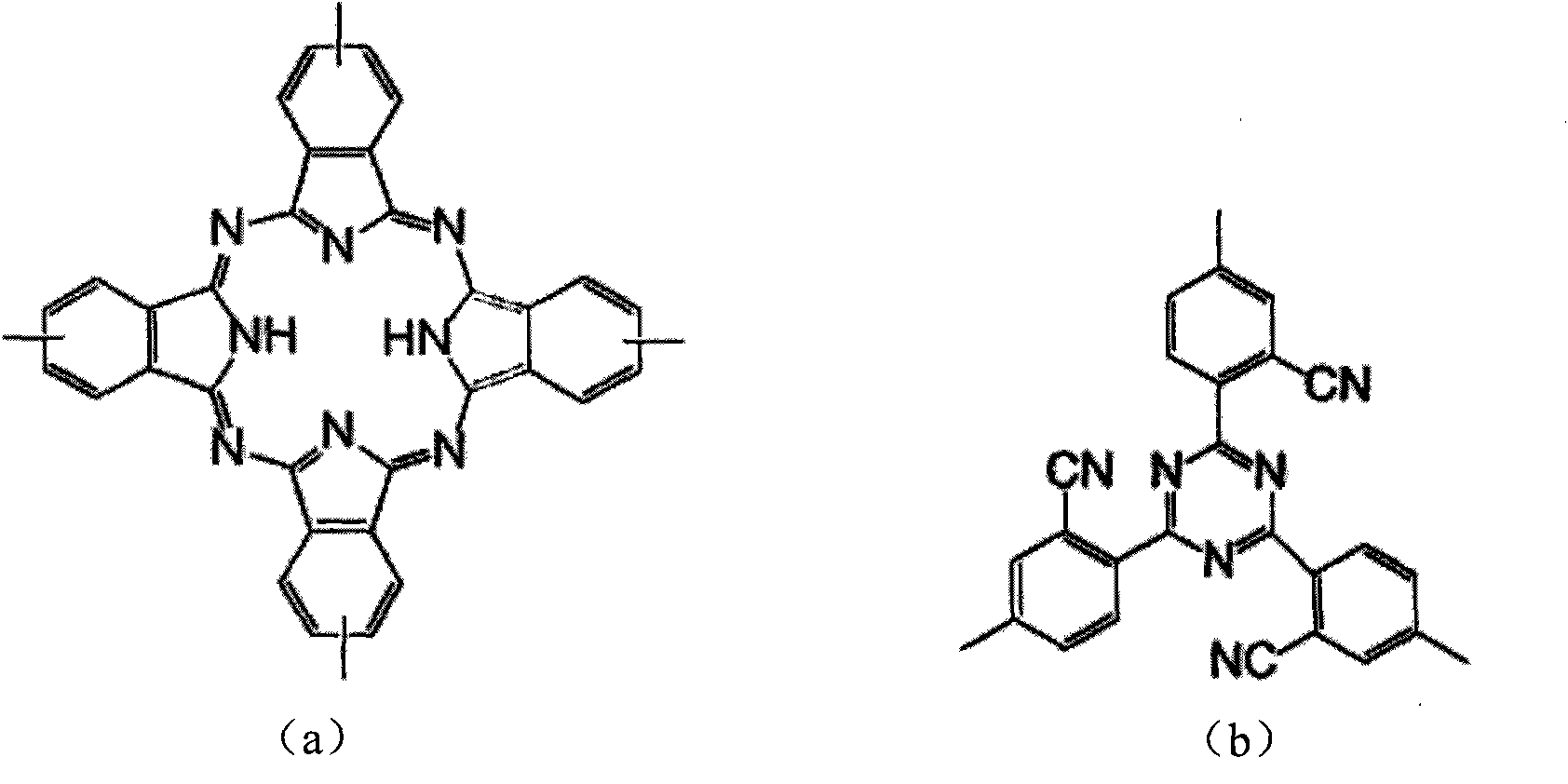

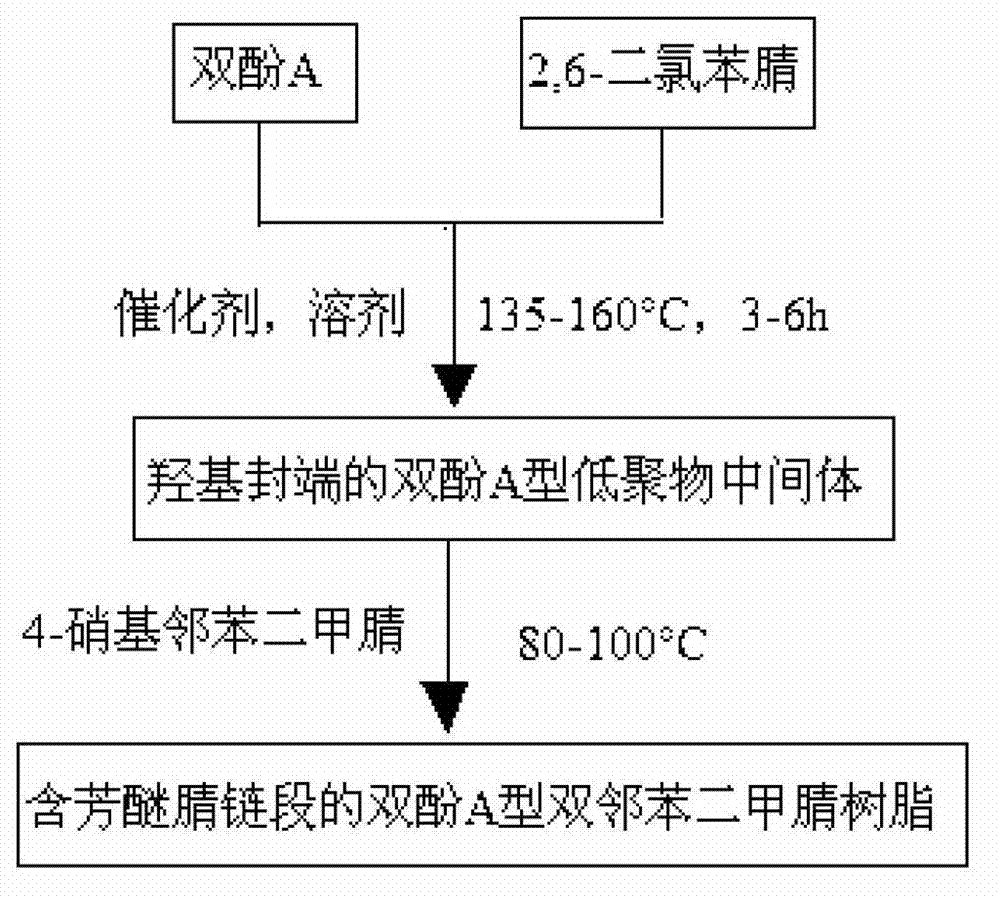

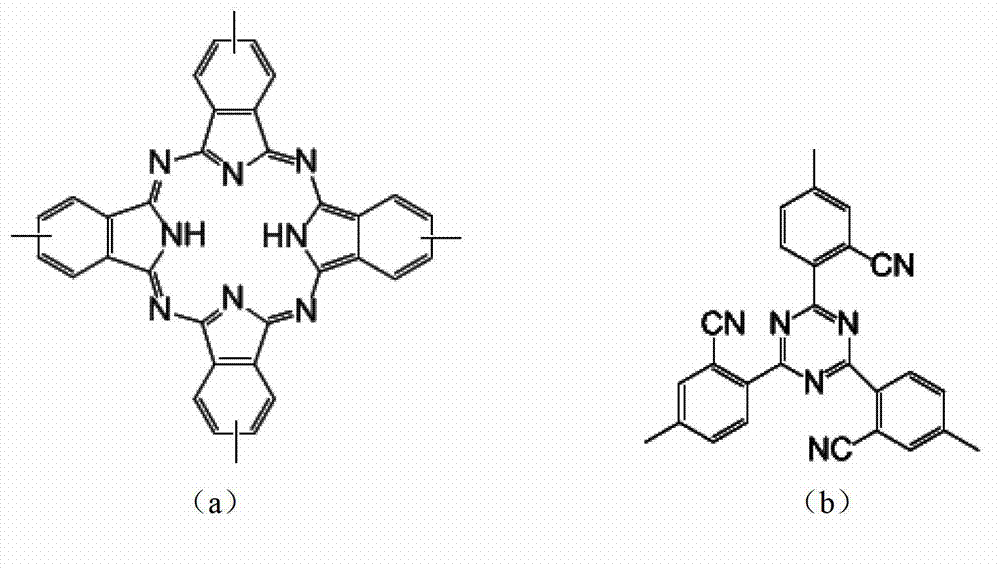

Bisphenol A type bis-phthalonitrile resin with aryl ether nitrile segments, cured product and preparation method thereof

InactiveCN101914038ALow water absorptionImprove curing effectCarboxylic acid nitrile preparationOrganic compound preparationPhthalonitrileSolvent

The invention discloses a bisphenol A type bis-phthalonitrile resin with aryl ether nitrile segments, a cured product and a preparation method thereof and belongs to the field of polymer materials. Raw materials of bisphenol A and 2,6-dichlorobenzonitrile are subjected to nucleophilic substitution reaction, anhydrous potassium carbonate and anhydrous sodium carbonate are used as a catalyst, a hydroxyl-terminated bisphenol A type oligomer intermediate is formed in mixed liquor of a strong polar solvent and toluene, and then hydroxyl groups are substituted by 4-nitrophthalonitrile, thus obtaining the resin. A cure-crosslinking agent, the mass of which is equal to 5 percent of the resin, is added into the resin, and then after pre-curing at 220-240DEG C and heat treatment at 375DEG C at least, the cured product of the resin can be obtained. The bis-phthalonitrile resin provided by the invention has different chain lengths and the aryl ether nitrile segments as well as a low melting point and wider curing process temperature, and the cured product is of a net structure which comprises a phthalocyanine ring and a triazine ring and has excellent heat stability. The manufacturing methods of the resin and the cured product are simple and controllable and are suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

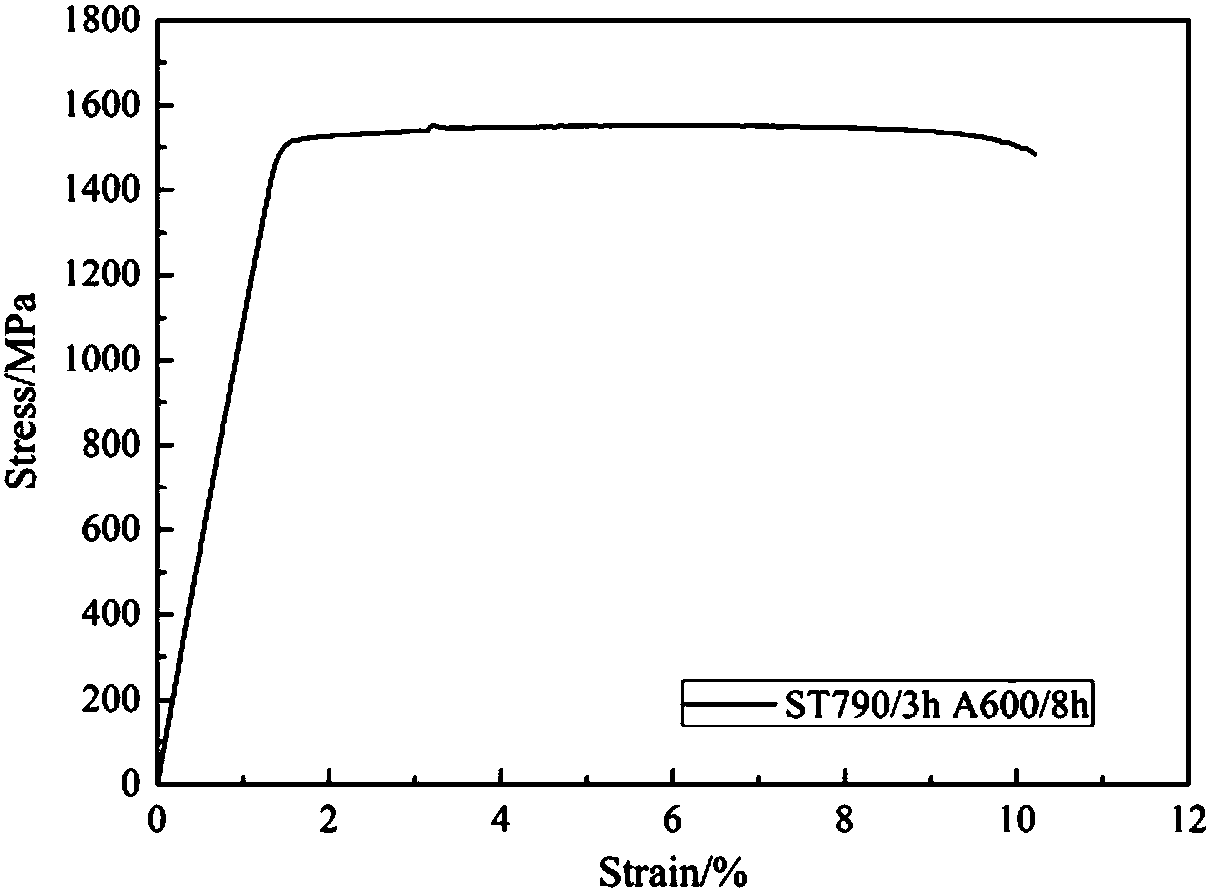

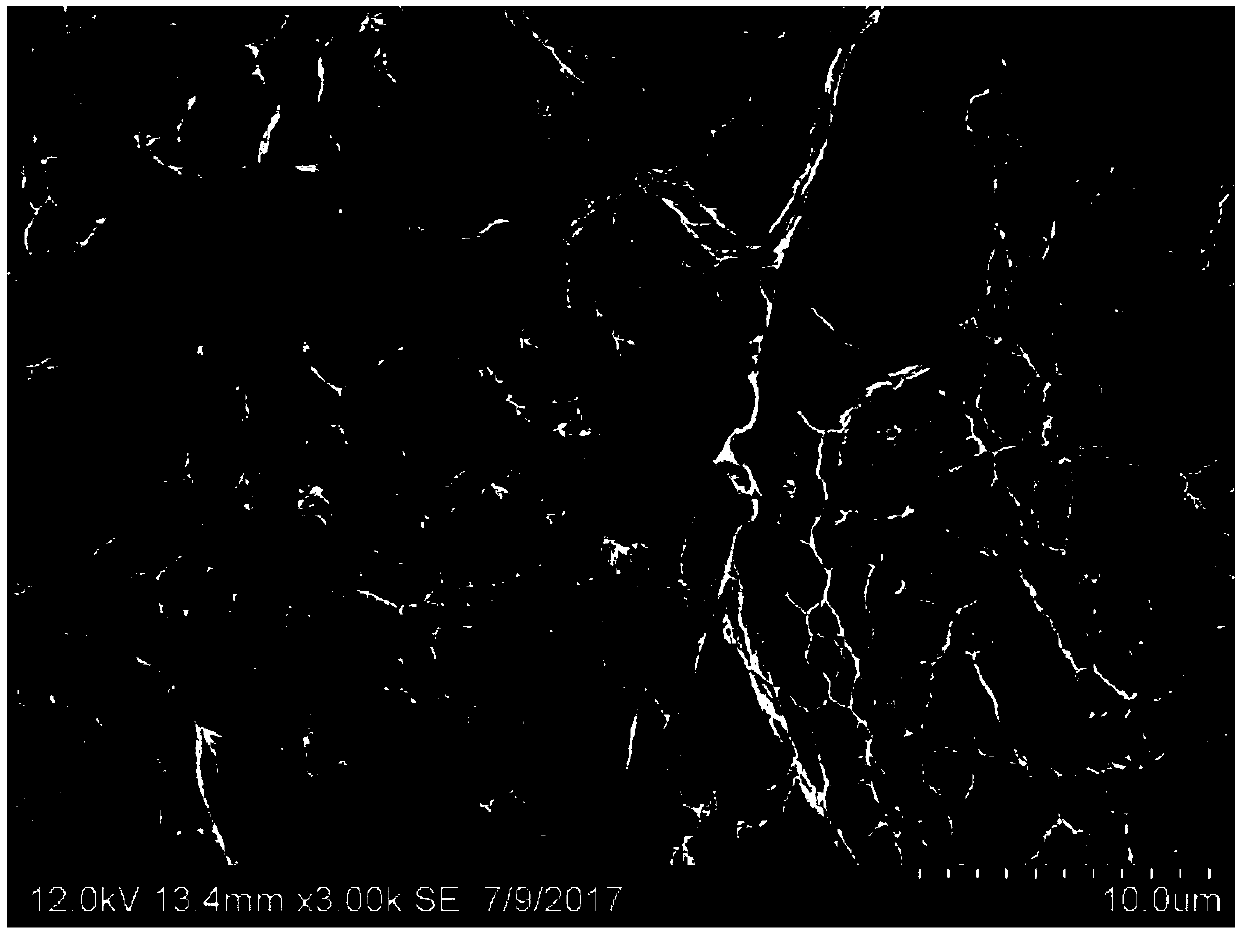

Ultrahigh-strength Ti-Al-Zr-Mo-Cr-series beta titanium alloy and thermal treatment process thereof

Ultrahigh-strength Ti-Al-Zr-Mo-Cr-series beta titanium alloy and a thermal treatment process thereof. The thermal treatment includes steps of performing solution treatment to Ti-Al-Zr-Mo-Cr-series beta titanium alloy and then performing aging treatment. The Ti-Al-Zr-Mo-Cr-series beta titanium alloy includes, by weight, 4.5-5.5% of Al, 3.5-4.5% of Zr, 9.5-10.5% of Mo, and 2.5-3.5% of Cr, the balanced being Ti. The alloy, after smelting, forging and toughening thermal treatment, has ultrahigh strength and plasticity. The alloy includes aluminum and also a certain amount of a neutral element, zirconium, so that alpha-phase is further reinforced; by adding the molybdenum at high mass percentage, a beta-matrix is reinforced; in addition, due to the low diffusion rate of molybdenum, temperaturesensitivity of the alloy in a two-phase zone during forging is reduced, thus enlarging processing window of the alloy.

Owner:XI AN JIAOTONG UNIV

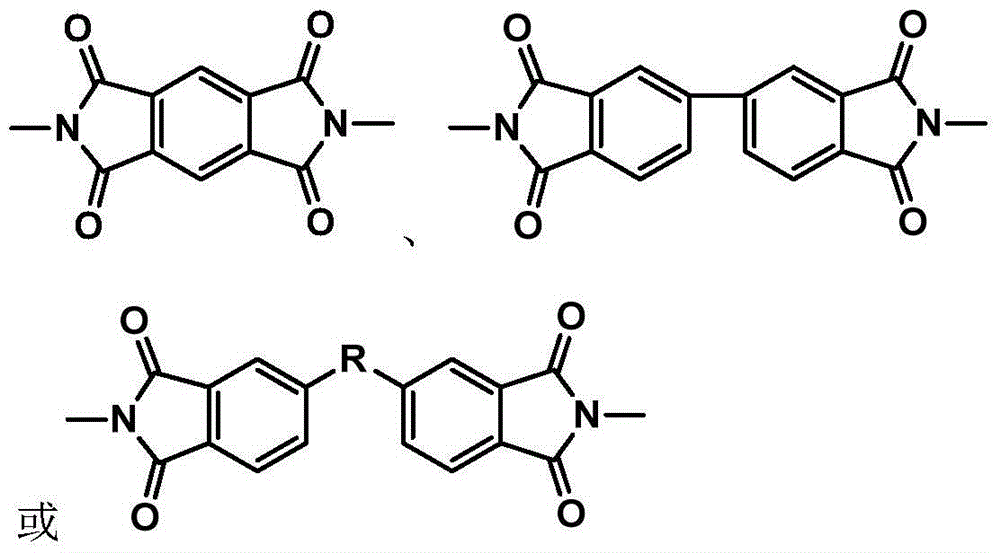

Synthesis method of phthalonitrile and arylacetylene-terminated aromatic imide

ActiveCN104130177AImprove the disadvantages of difficult processingEasy to processOrganic chemistryAcetic anhydrideSynthesis methods

The invention discloses a synthesis method of phthalonitrile and arylacetylene-terminated aromatic imide. The method comprises the following steps: I, synthesis of a single-component system: reacting tetracid dianhydride serving as a raw material with a raw material containing amine phthalonitrile in a polar solvent to obtain an intermediate 1, adding acetic anhydride to obtain an intermediate 2, and reacting the intermediate 2 with a raw material containing amine arylacetylene to obtain a target product; and II, synthesis of a multi-component system: reacting the tetracid dianhydride serving as the raw material with the raw material containing the amine phthalonitrile to obtain a first monomer; reacting the raw material containing the amine arylacetylene with the tetracid dianhydride serving as the raw material to obtain a second monomer; and performing melt blending or solution blending on the first monomer and the second monomer to obtain a target product. By adopting the synthesis method, the aromatic polyimide, a polyphthalonitrile resin and a polyarylacetylene resin are introduced into the same curing system through physical blending or chemical modification, so that the processing performance of the product can be improved effectively, and the processing cost is lowered.

Owner:SICHUAN UNIV

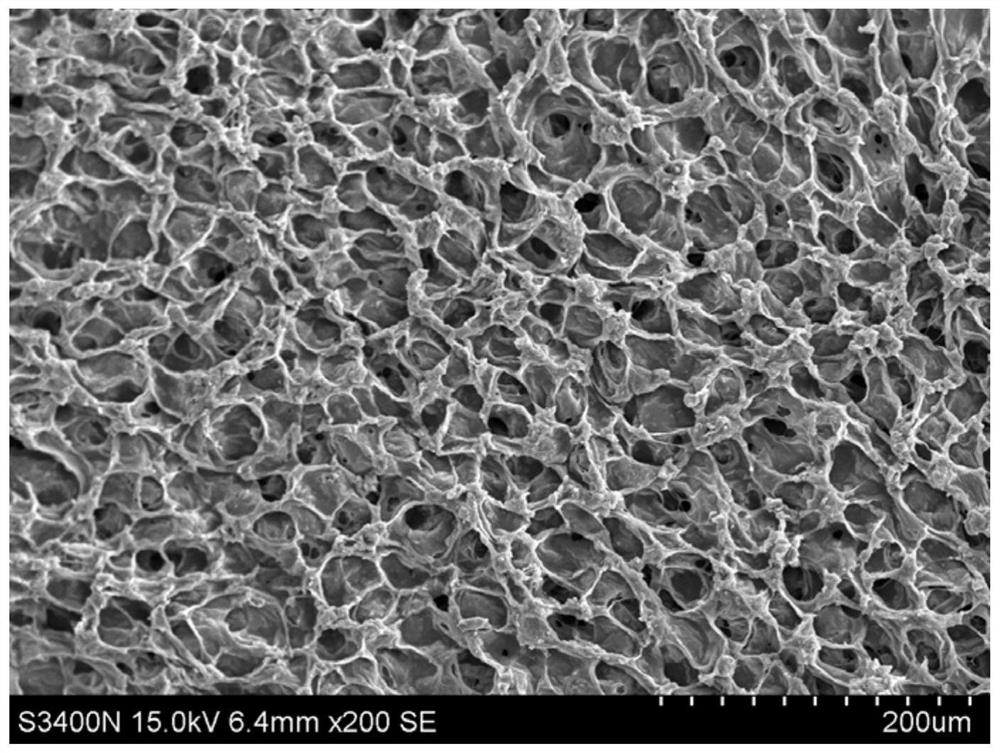

Totally degradable foam buffer packaging material and its manufacturing method

The invention provides a complete biodegradable foam cushioning packing material and method for preparation, characterized in that starch over 80% content is used as base-material, ultra-fine polyvinyl alcohol is used as film forming intensifier, water is used as foaming agent, and core forming agent and flow modifier are added, wherein the mixture is amalgamated through blending homogeneous machine and fed into reverse-flighted screw extrusion machine for one-shot extrusion forming. The product can be used to substitute polystyrene foam for filling with no requirement on shapes.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

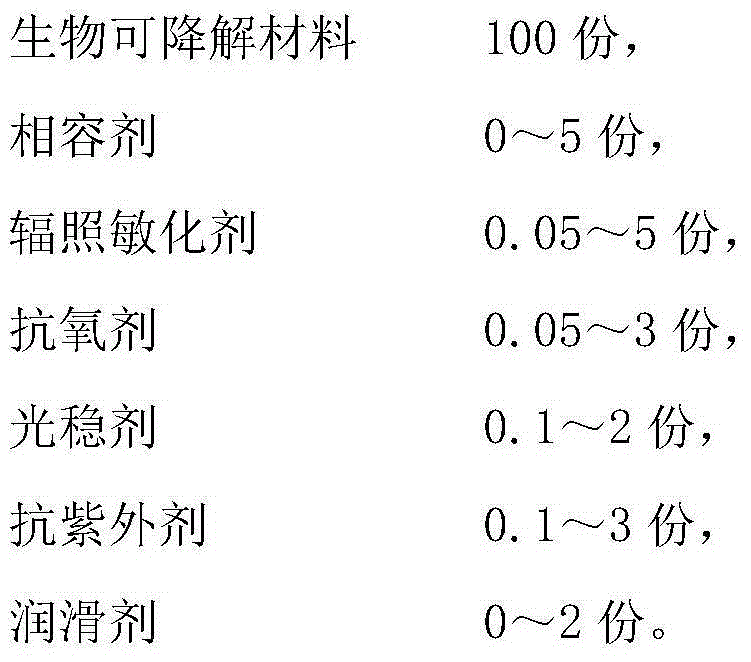

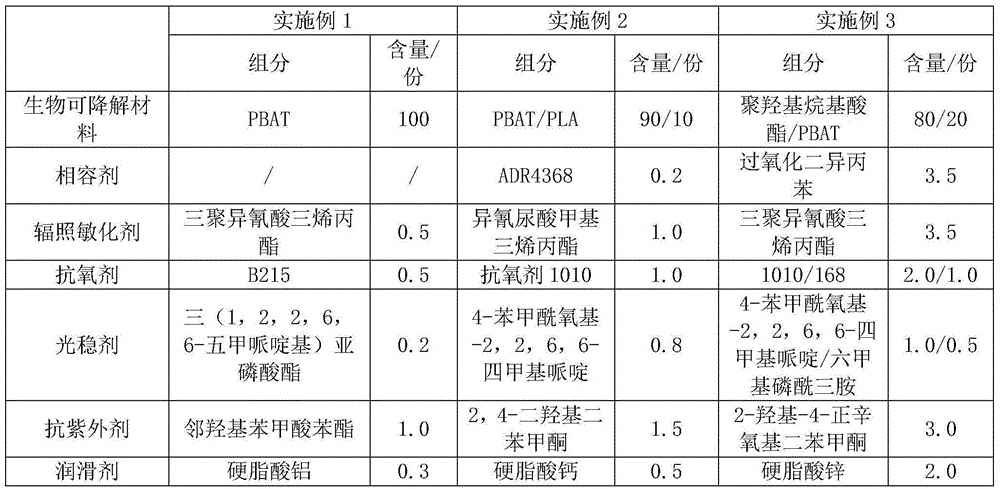

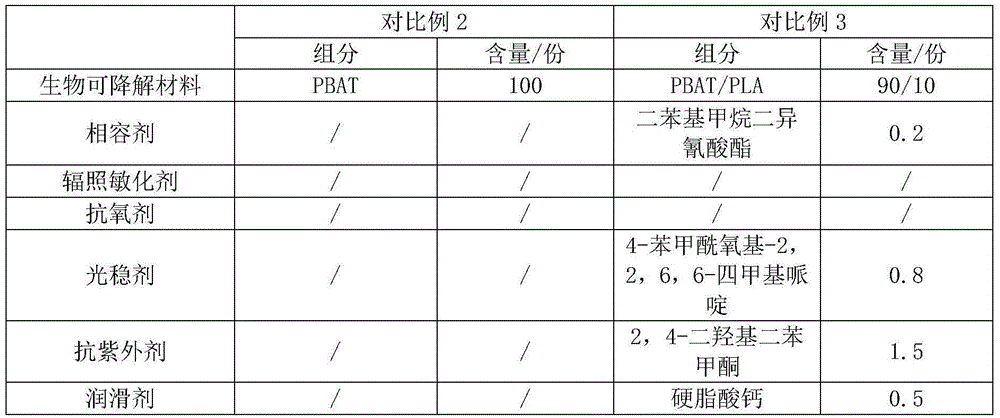

Biodegradable film based on irradiation modification and preparing method thereof

The invention discloses a biodegradable film based on irradiation modification and a preparing method thereof. The degradable film is composed of, by weight, 100 parts of biodegradable materials, 0-5 parts of compatilizer, 0.05-5 parts of irradiation sensitizing agents, 0.05-3 parts of antioxidants, 0.1-2 parts of light stabilizer, 0.1-3 parts of anti-ultraviolet agents and 0-2 parts of lubricating agents in a mixed mode. Compared with the prior art, the biodegradable film has the following advantages of having excellent mechanical strength, barrier performance, ageing resistance and the like, and being innovative, and application of the biodegradable film is expanded; the composite film keeps complete biodegradable performance, and has high application potentiality in medical science and environmental science, the composite film can replace petroleum-base general films to be used greatly, and environmental pressure is relieved. The preparing method is simple and easy to implement, the addition quantity of all the auxiliaries is small, cost is low, and the production process is controllable.

Owner:SHANGHAI HONGRUI CHEM PROD CO LTD

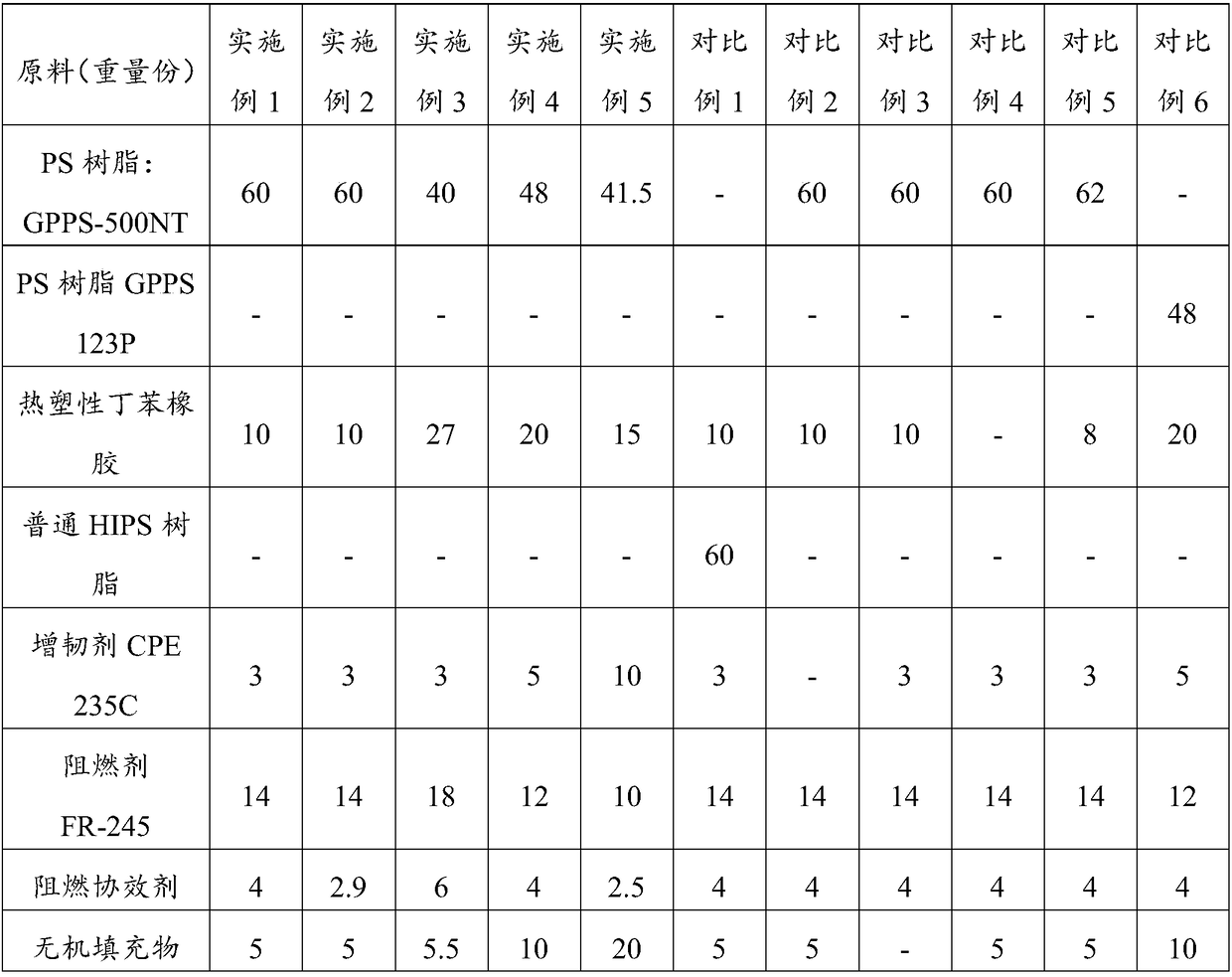

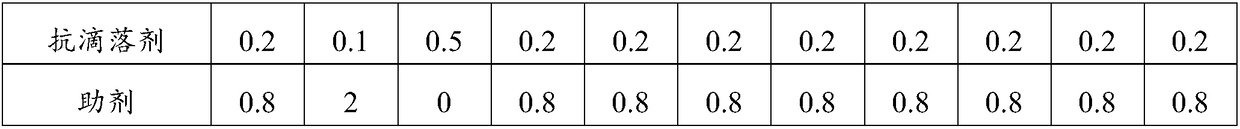

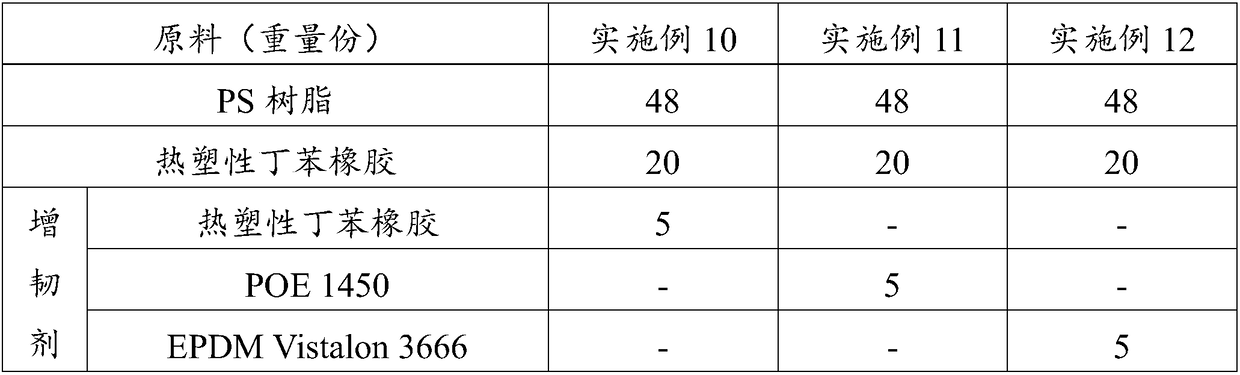

HIPS composite material with high flammability

ActiveCN109503970AHigh flame retardant gradeImprove performanceUltimate tensile strengthFire retardant

The invention discloses a HIPS composite material with high flammability. The HIPS composite material comprises the following components in parts by weight: 40-60 parts of PS resin, 10-27 parts of thermoplastic butadiene styrene rubber, 3-10 parts of flexibilizer, 10-18 parts of fire retardant, 2.5-6 parts of flame retardant synergist, 5-20 parts of inorganic filler, 0.1-0.5 part of anti-drippingagent and 0-2 parts of auxiliaries; weight-average molecular weight of PS resin is more than or equal to 15*104g / mol; melt flow rate MFR is 3-6g / 10min. The HIPS composite material with high flammability disclosed by the invention has the following advantages: 1) high flame retardant level (maximal level can reach up to 2.0mm 5VA level); 2) excellent overall performance and balanced strength and notch impact property; 3) low cost and capability of substituting high-flammability ABS in some situations; 4) good appearance and wide processing window.

Owner:江苏金发再生资源有限公司

Method for preparing supercritical fluid reinforced fluorine-containing polymer product

The invention relates to a method for preparing a supercritical fluid reinforced fluorine-containing polymer product, which comprises: preheating a region 1 and a region 2 in a double screw extruder, feeding the fluorine-containing polymer into the region 1, and injecting supercritical carbon dioxide at 31.1 to 70 DEG C and under 7.4 to 25MPa into a cylinder from a region 3; regulating the rotating speed of a screw melt pump to 1 to 10r / min, melting and blending the carbon dioxide and the fluorine-containing polymer in regions 4, 5, 6, and 7, releasing carbon dioxide, and reducing pressure ina cylinder in a region 9 to normal temperature; and extruding from a die head to form the fluorine-containing polymer product. According to the method disclosed by the invention, the pressure in the double screw cylinder is controlled by regulating the rotating speed of the melt pump to allow the carbon dioxide fluid to uniformly and stably plasticize and melt the polymer; and thus, the processing temperature is reduced to 5 to 20 DEG C, the fluorine-containing polymer is protected from decomposition, and processing window is enlarged. The method disclosed by the invention is environment-friendly, avoids solvent pollution and can ensure continuous production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Bisphenol A bisphthalonitrile resin containing arylethernitrile chain segment, cured resin and preparation method thereof

InactiveCN102887999AWide processing temperature windowEasy to solidify and processPolymer sciencePhthalocyanine

The invention relates to a bisphenol A bisphthalonitrile resin containing an arylethernitrile chain segment, a cured resin and a preparation method thereof, belonging to the field of high polymer materials. The preparation method comprises the following steps: performing nucleophilic substitution reaction on bisphenol A and 2,6-dichlorobenzonitrile used as raw materials in a strongly polar solvent / methylbenzene mixed solution in the presence of anhydrous potassium carbonate or anhydrous sodium carbonate used as a catalyst, thus forming a hydroxyl-terminated bisphenol A low polymer intermediate; then, substituting hydroxyl therein with 4-nitrophthalonitrile, thus obtaining the target resin; and adding curing crosslinking agent of which the mass is equivalent to 5% of that of the resin into the resin, precuring at 220-240 DEG C, and performing heat treatment at a temperature not lower than 375 DEG C to obtain the cured resin. The bisphthalonitrile resin provided by the invention has different chain lengths, contains an arylethernitrile chain segment, and has a low melting point and a wide curing processing temperature; the cured resin is in a network structure comprising phthalocyanine rings and triazine rings, and has excellent heat stability; and the provided preparation method of the resin and the cured resin is simple and controllable, and is suitable for industrial production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Copolymer composition containing ethylene and vinyl alcohol structure unit, and preparation method thereof

The present invention discloses a copolymer composition containing an ethylene and vinyl alcohol structure unit, and a preparation method thereof. The composition comprises components A, B, C and D, wherein the component A is a copolymer containing an ethylene and vinyl alcohol structure unit, the component B is an acid, the component C is a phenol or amine organic compound, the component D is an alkali metal or an alkaline earth metal salt, and by adopting the mass of the component A as 100%, the mass contents of the components B and D are 0.1-4.0%, and the mass content of the component C is 0.01-1.8%. The preparation method specifically comprises: (1) preparation of the solution of a copolymer containing an ethylene and vinyl alcohol structure unit; (2) preparation of the solution of a copolymer composition containing an ethylene and vinyl alcohol structure unit; and (3) sold molding of the copolymer composition containing the ethylene and vinyl alcohol structure unit. According to the present invention, the composition has characteristics of uniform component dispersion, high thermal stability, and product quality improving.

Owner:CHINA PETROLEUM & CHEM CORP +1

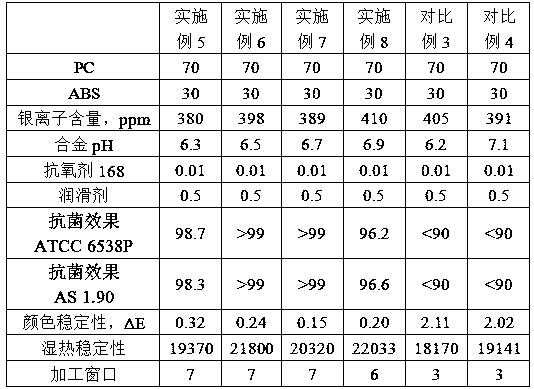

Polycarbonate alloy and preparation method thereof

The invention discloses polycarbonate alloy. The polycarbonate alloy is characterized by being prepared from, by weight, 70 parts of polycarbonate and 1-60 parts of ABS resin; a pH value of the polycarbonate alloy is 6.3-6.9 and regulated through liquid acid. By regulation of the pH value of the polycarbonate alloy, high hydrothermal stability, wide process window and the like of the polycarbonatealloy are guaranteed.

Owner:KINGFA SCI & TECH CO LTD

High-strength titanium alloy plate and manufacturing method thereof

Owner:南通波斯佳织造科技有限公司

Preparing method for titanium alloy panel

InactiveCN105349808ATake full advantage of performanceHigh strengthIngot castingNon-metallic inclusions

The invention relates to a preparing method for a titanium alloy panel. An alloy comprises, by mass percentage, 4%-5% of Al, 1%-2% of Ni, 0.7%-0.8% of Cu, 0.5%-0.7% of V, 0.1%-0.2% of Bi, 0.1%-0.2% of Si, 0.07%-0.09% of In, 0.05%-0.06% of Ni, 0.03%-0.04% of Pd, 0.03%-0.04% of Pr, 0.01%-0.02% of Y and the balance titanium and titanium non-metallic inclusion; and the titanium alloy panel is obtained through ingot casting, annealing treatment, forging, hot rolling, cold rolling, quenching treatment and heat preservation. The intensity of the titanium alloy panel reaches more than 1200 MPa.

Owner:WUXI QINGYANG MACHINERY MFG

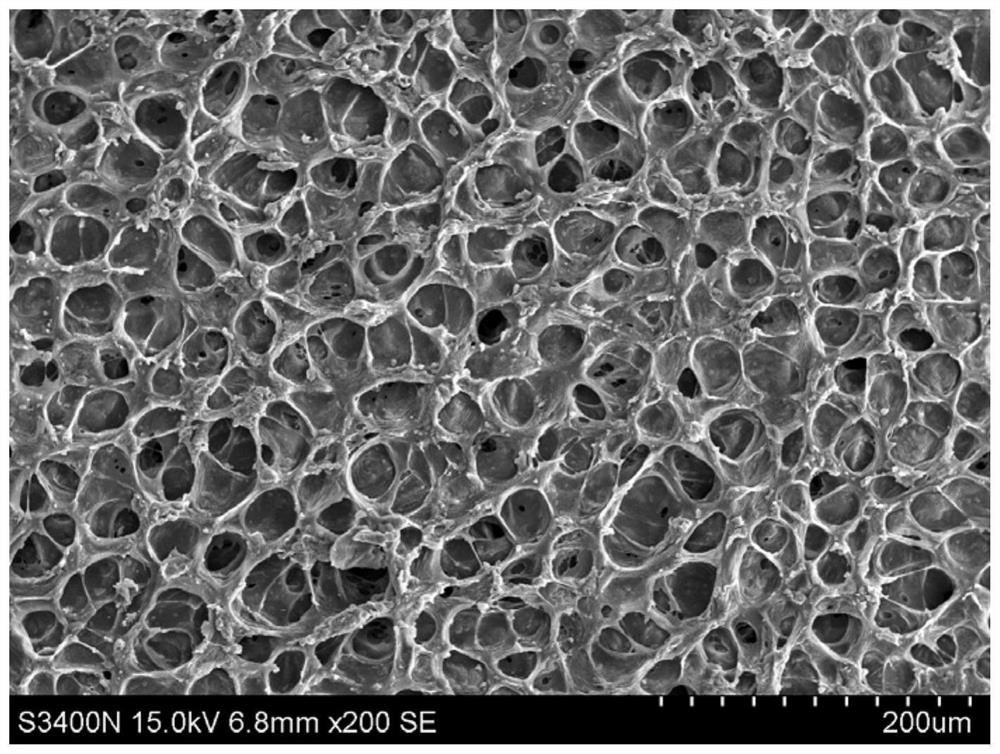

Polylactic acid foaming composite material as well as preparation method and application thereof

The invention belongs to the technical field of biodegradable foaming materials, and discloses a polylactic acid foaming composite material as well as a preparation method and application thereof. The polylactic acid foaming composite material comprises the following components in parts by weight: 100 parts of polylactic acid resin, 5-15 parts of other biodegradable materials, 0.5-3 parts of a bio-based nucleating agent, 0.5-4 parts of a chain extender and 0.1-1 part of a lubricant. The preparation method comprises the steps of mixing, extruding, drawing and pelletizing the components to prepare a polylactic acid foaming master batch; and putting the polylactic acid foaming master batch into a high-pressure reaction kettle, introducing a fluid serving as a foaming agent into the high-pressure reaction kettle, controlling the temperature of the high-pressure reaction kettle to be 40-200 DEG C and the pressure of the high-pressure reaction kettle to be 8-20 MPa, keeping the temperature and the pressure for 30-120 minutes, releasing gas in the reaction kettle, reducing the pressure to normal pressure, and taking out polylactic acid foaming particles from the reaction kettle, so as to obtain the particles, namely, the polylactic acid foaming composite material.

Owner:GUANGDONG UNIV OF TECH

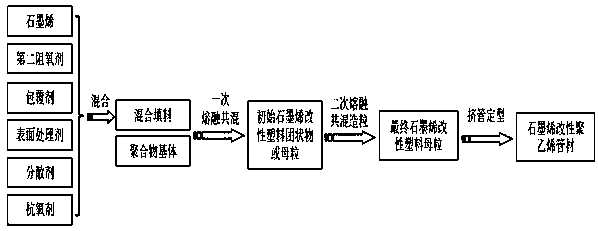

Graphene modified oxygen-resistant polyethylene master batch and preparation method and application thereof

InactiveCN111117041AEvenly dispersedGood oxygen barrierBulk chemical productionPolymer chemistryChemistry

The invention relates to the technical field of functionalization and high performance of plastic pipes, in particular to a graphene modified oxygen-resistant polyethylene master batch and a preparation method and application thereof. The modified plastic master batch is composed of the following components: a polyethylene matrix, graphene, a second oxygen inhibitor, a coating agent, a surface treating agent, a dispersing agent and an antioxidant. According to the three-step production process, the mixing, dispersing and stripping effects of graphene in a polyethylene matrix are improved, thefilling proportion of graphene in the composite material is increased through organic combination of a new material, a new technology and a new method, and formation of a perfect network structure inthe composite material matrix is promoted. The oxygen barrier property of the composite material can be remarkably improved through good construction of a network, so that the application potential ofgraphene in the oxygen barrier pipe is brought into full play, and the pipe filled with the high-barrier graphene nanosheet layer structure is obtained.

Owner:江苏新奥碳纳米材料应用技术研究院有限公司 +1

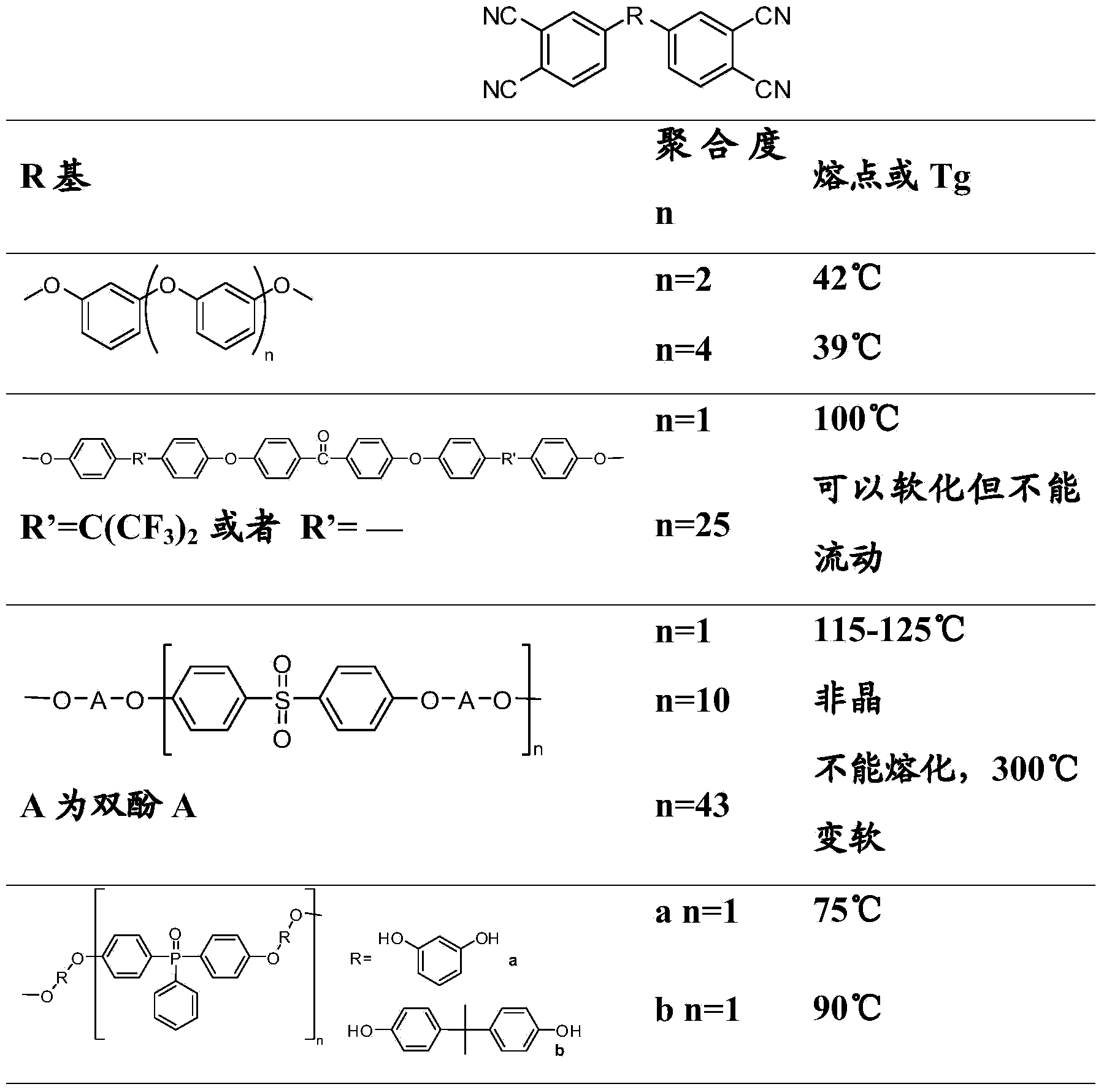

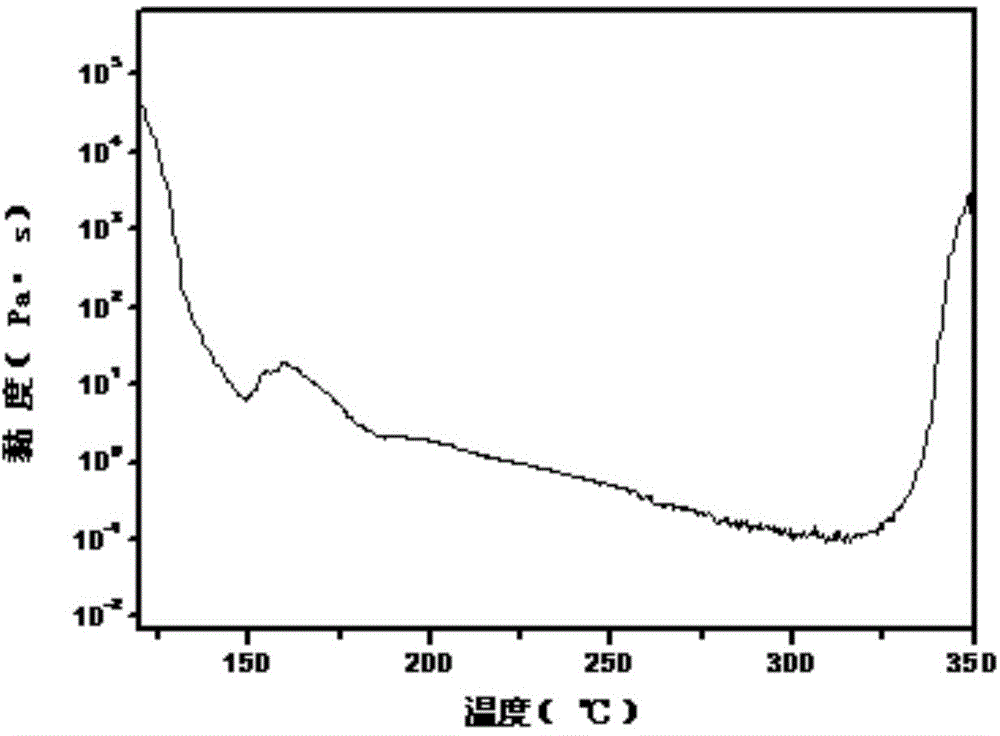

High-fluidity wide-processing-widow polyimide pre-polymer and preparation method thereof

ActiveCN104530429ALower glass transition temperatureProcessing window widthOrganic chemistryDiaminodiphenyl etherAdhesive

The invention relates to a high-fluidity wide-processing-widow polyimide pre-polymer and a preparation method thereof. A structural formula is shown in the description, wherein n is 1-20 and is an integer. The preparation method comprises the steps of dissolving 3,4'-diaminodiphenyl ether 3,4'-ODA in an organic solvent under the nitrogen protection condition, adding 2,3,3',4'-tetracarboxydiphthalic ether dianhydride a-ODPA after complete dissolution, meanwhile adding the organic solvent to enable the solid content of a solution to be 10%-40%, adding an end-capping reagent during reaction at the room temperature to continue to perform reaction, dropwise adding a dehydrating agent to perform reaction, washing, drying and smashing. The pre-polymer can be formed through compression molding, is well applicable to a resin transfer forming process and has potential application value on the aspect of preparation of high-performance composite materials, high-temperature-resisting adhesives and the like.

Owner:DONGHUA UNIV

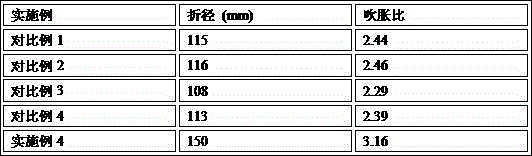

Polylactic acid film blowing processing aid and preparation method and application thereof

InactiveCN103602048AImprove blown film processabilitySimple production processSilicon dioxideSurface modification

The invention discloses a preparation method of a polylactic acid film blowing processing aid, which comprises the following steps of (1) performing surface modification on nano silicon dioxide by use of a silane coupling agent, adding 0.01-6 weight parts of isocyanate substrate, and reacting at over 25 DEG C for more than 4 hours for secondary modification on the silicon dioxide; (2) taking the silicon dioxide after the secondary modification and a polylactic acid prepolymer as raw materials, preferably adding 50-200 parts of polylactic acid prepolymer into each part of silicon dioxide, introducing nitrogen into the reaction kettle, adding a metal lithium or tin catalyst, magnetically stirring at 25-140 DEG C, and heating and reacting for 1-24 hours to finally obtain solid powder; drying in a vacuum oven for 24 hours to obtain the polylactic acid film blowing processing aid. The invention also discloses an application of the polylactic acid film blowing processing aid. In the method disclosed by the invention, polylactic acid is directly grafted to the surface of the silicon dioxide to obtain polylactic acid-grafted silicon dioxide modified particles which are used as a polylactic acid processing aid, and the film blowing processability of polylactic acid is effectively improved.

Owner:SICHUAN UNIV

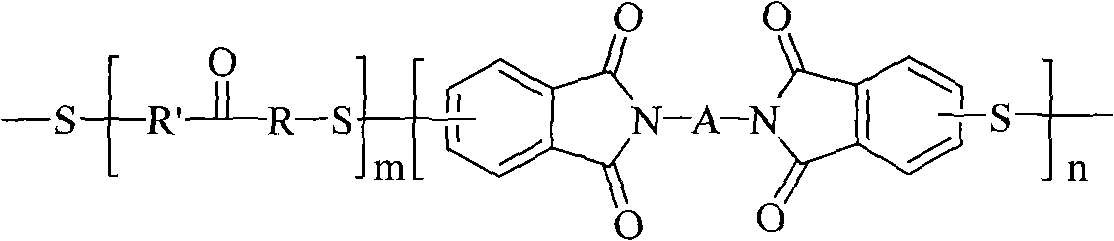

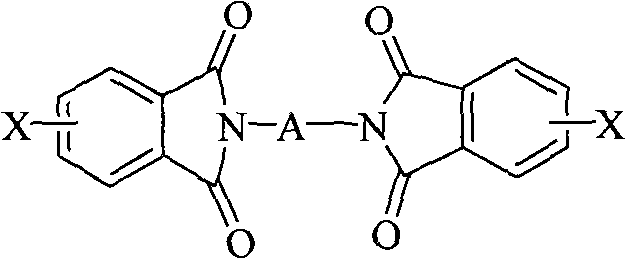

Polythioether ketone imide terpolymer and preparation method thereof

The invention discloses polythioether ketone imide terpolymer and a preparation method thereof. The polythioether ketone imide terpolymer is characterized by being prepared by the following steps of: adding sulfur, disubstituted phthalimide, disubstituted ketone, a reducing agent and a reaction assistant into a reactor into which a solvent is filled; heating to react for a certain period of time;pouring reaction solution into a precipitator; and stirring, purifying and drying. Compared with the prior art, the invention has the advantages that: the disubstituted phthalimide and the disubstituted ketone are used as raw materials and the sulfur is used as a coupling agent for preparation; and an obtained product is hypocrystalline and has high dissolubility, mechanical performance and heat resistance, low melting viscosity, wider processing window and high processing performance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

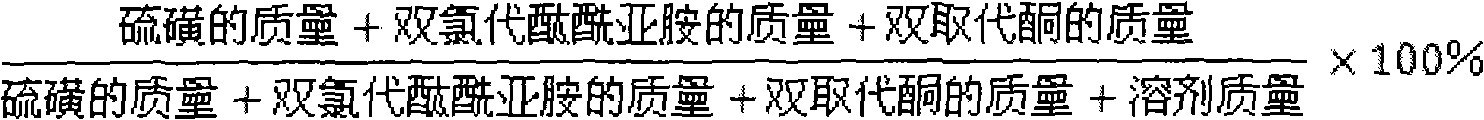

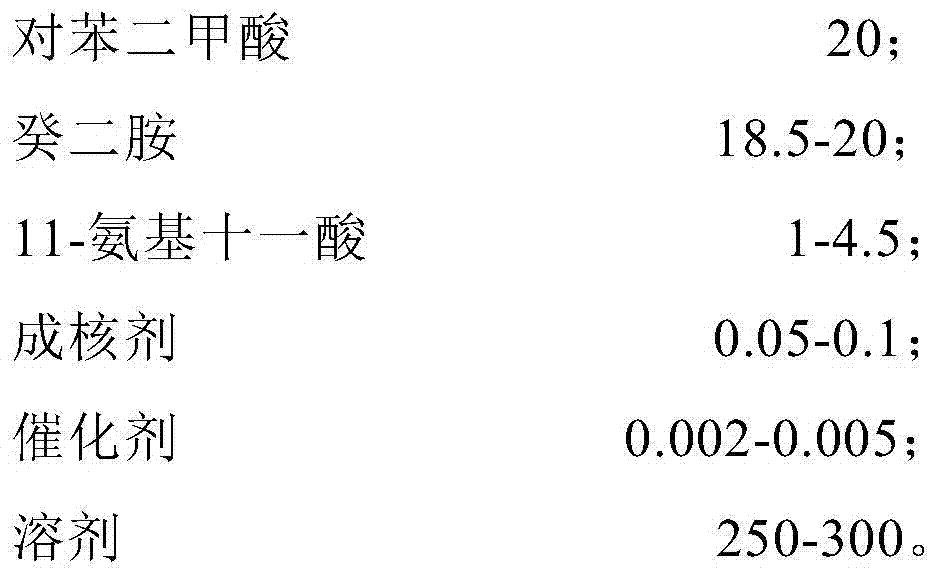

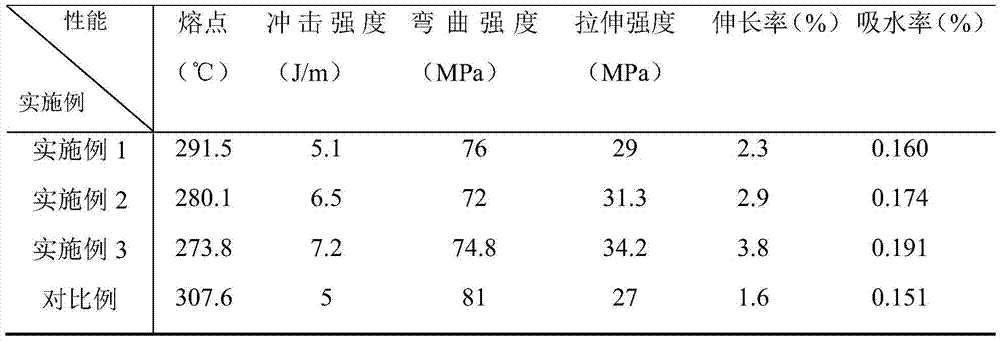

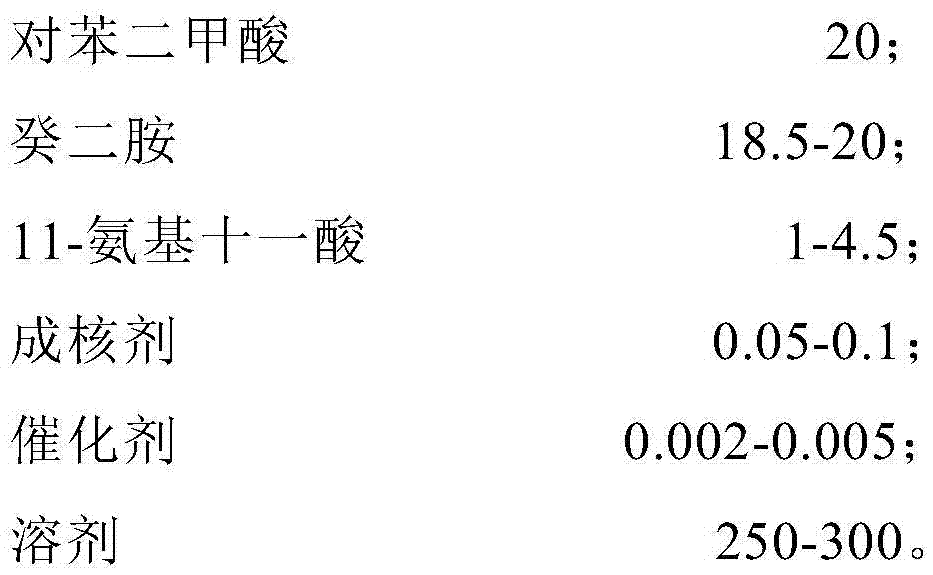

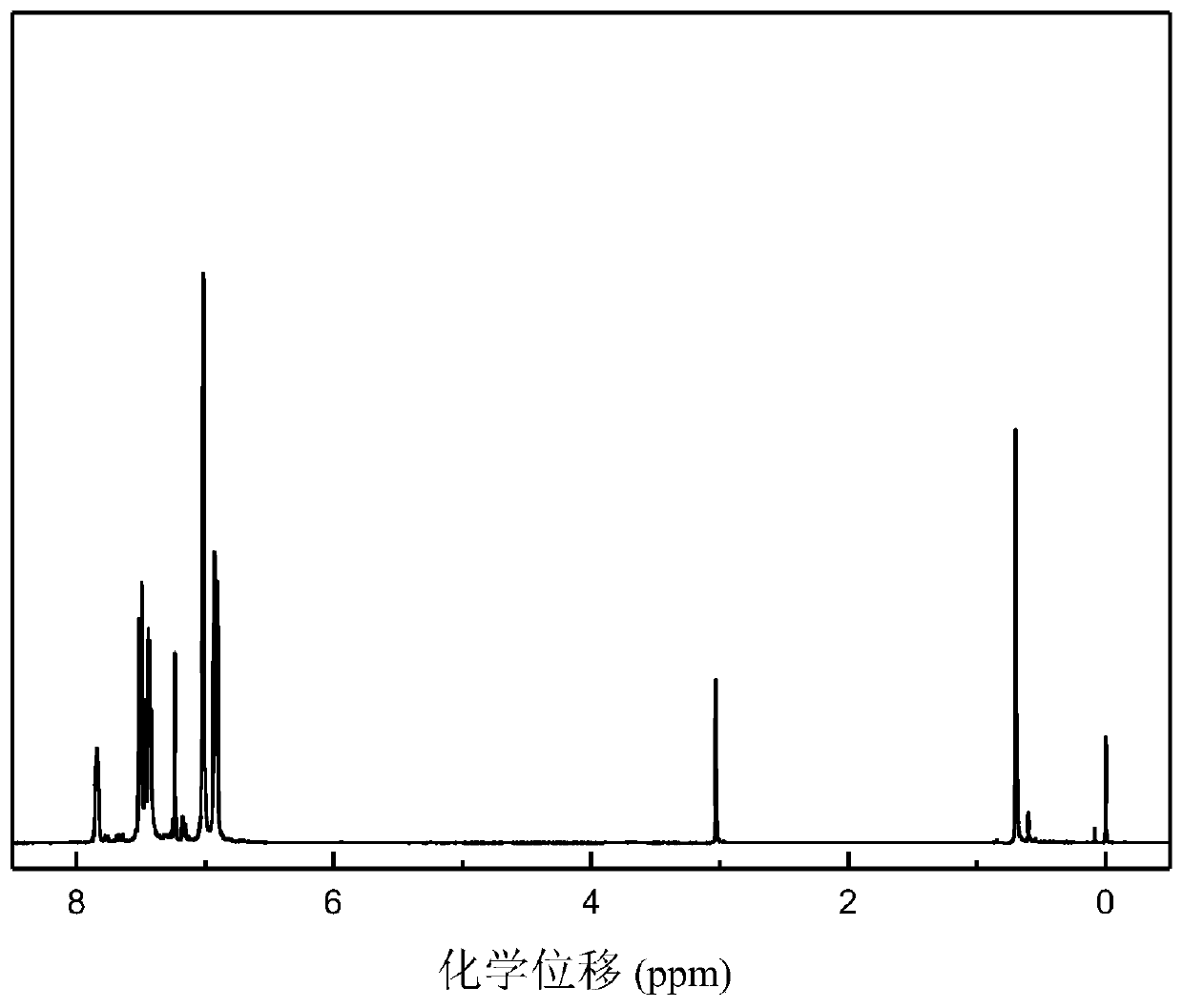

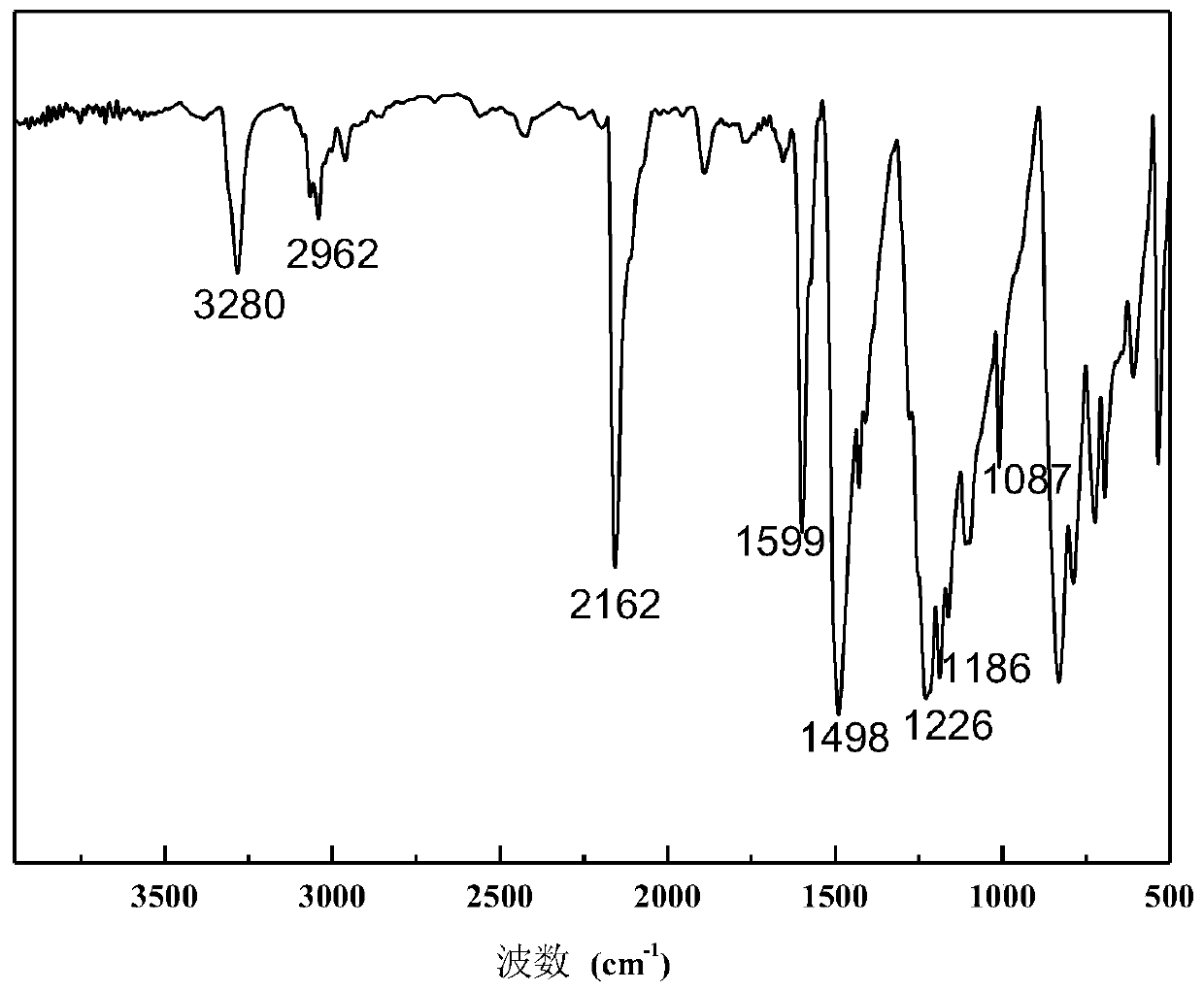

Environmental-protection bio-based semi-aromatic PA10T/11 copolymerization material and preparation method thereof

The present invention relates to an environmental-protection bio-based semi-aromatic PA10T / 11 copolymerization material and a preparation method thereof, wherein the environmental-protection bio-based semi-aromatic PA10T / 11 copolymerization material is prepared from the following components by mole: 20 parts of terephthalic acid, 18.5-20 parts of diaminodecane, 1-4.5 parts of 11-aminoundecanoic acid, 0.05-0.1 part of a nucleating agent, 0.002-0.005 part of a catalyst, and 250-300 parts of a solvent. Compared to the material in the prior art, the material of the present invention has the following characteristics that the monomer 11-aminoundecanoic acid in the PA10T / 11 provides the flexible chain segment to the main chain molecule, such that the flexibility of the main chain molecule is increased, the toughness is improved, the obtained product has the wide processing window, and the molding processing difficulty is lower than the molding processing difficulty of PA10T; and the synthesis material has characteristics of low water absorption and good material stability. According to the present invention, the PA10T / 11 is prepared by using the one-step melt condensation polymerization method so as to continuously perform the whole polymerization process, wherein the one-step melt condensation polymerization method has advantages of less process step, short polymerization period, high production efficiency, low production cost and the like, and creates the conditions for the future continuous industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Methylphenyl silicon aryl ether aryne resin and composite material and preparation method thereof

The invention discloses methylphenyl silicon aryl ether aryne resin and a composite material and preparation method thereof. The resin has a structural formula defined in the description, wherein m =0-4, n = 1-6, and m and n are integers. The methylphenylsilyl silicon aryl ether aryne resin is yellow solid, has stability and easy storage at normal temperature, and polymerized crosslinking curingcan be performed at 180-260 DEG C; a wide processing range is achieved, the cured product of the resin has excellent processability, mechanical properties and heat resistance, and the cast body curedproduct of the resin has excellent mechanical properties; and the composite material prepared from the resin has high bending strength, high flexural modulus and high shear strength, for example, thebending strength of the carbon fiber-reinforced composite material can reach 766.1 MPa, and a wide application prospect is achieved in aerospace and other high-tech fields.

Owner:EAST CHINA UNIV OF SCI & TECH

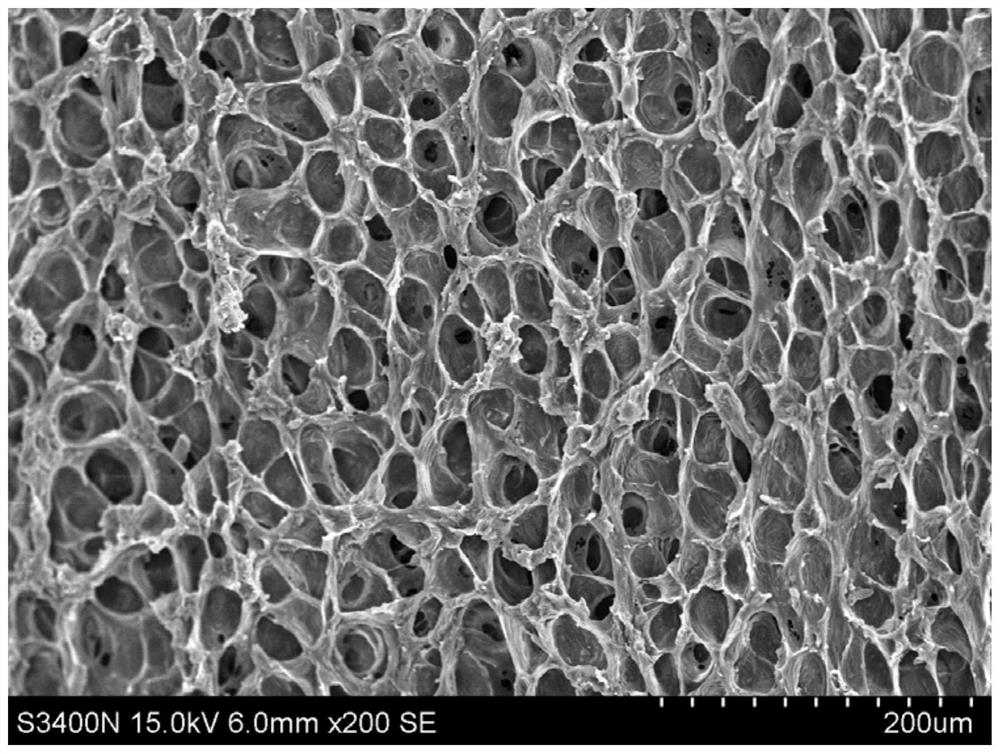

High-fiber volume content polylactic acid homopolymer composite material and preparation method thereof

ActiveCN106671545AImprove mechanical propertiesRenewable resourcesSynthetic resin layered productsPolymer scienceEthylene Homopolymers

The invention discloses a high-fiber volume content polylactic acid (PLA) homopolymer composite material and a preparation method thereof. A reinforced phase is a PLA fiber of which the content of a dextrolactic acid structure unit (D-LA) is 0-10mol% and a matrix is PLA of which the content of the dextrolactic acid structure unit (D-LA) is 10-50mol%, or the reinforced phase is an isotactic composite polylactic acid (sc-PLA) fiber, wherein sc-PLA is a mixture of poly L-lactic acid (PLLA) and poly D-lactic acid (PDLA), the weight ratio of the PLLA to the PDLA is 1:1 and the matrix is PLA of which the D-LA content is 0-100mol%; and the volume content of the strengthened phase is 5-90mol%. The preparation method of the corresponding composite material comprises the steps of (1) processing the PLA fiber of a skin-core structure into fiber assemblies; (2) overlaying 1-1,000 layers of PLA fiber assemblies of the skin-core structure; and (3) forming a PLA homopolymer composite material through hot pressing of the PLA fiber assemblies of the skin-core structure on a hot press under the conditions that the pressure is 1-20MPa and the temperature is 100-210 DEG C. The obtained PLA homopolymer composite material can be applied to the fields of packaging, automobiles and the like.

Owner:JIANGNAN UNIV

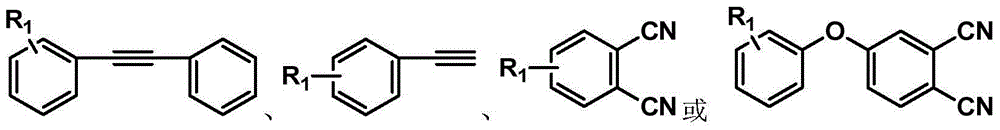

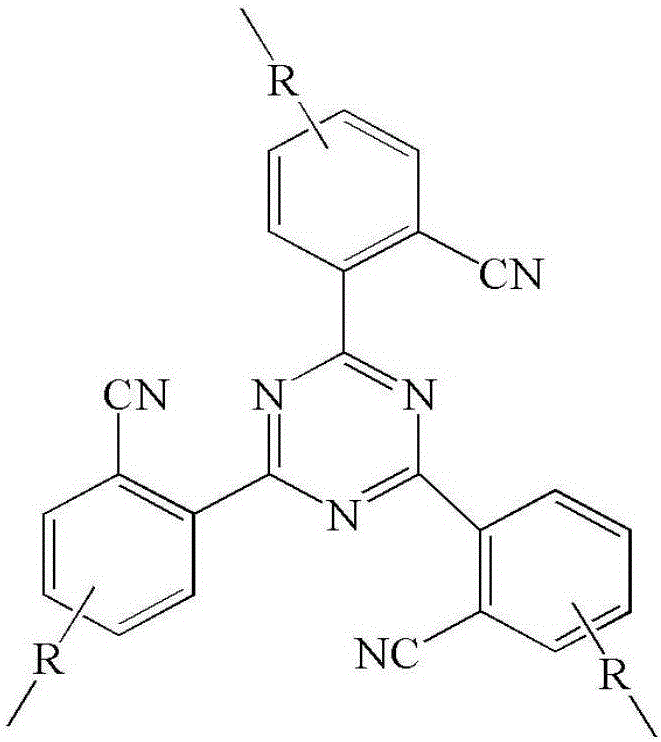

Low-melting-point aromatic-nitrile-group resin monomer and preparation thereof and aromatic-nitrile-group polymer and preparation method thereof

InactiveCN105061262AImprove heat resistanceIncrease cross-linking pointCarboxylic acid nitrile preparationOrganic compound preparationEtherThermal stability

The invention discloses a low-melting-pint aromatic-nitrile-group resin monomer and a preparation method thereof and an aromatic-nitrile-group polymer and a preparation method thereof. Under the condition of ensuring that thermal stability of resin is not affected greatly, the purposes of reducing a resin melting point, widening a resin processing window, lowering resin curing temperature and lowering the resin cost are achieved through changing the structure of the resin monomer. The aromatic-nitrile-group resin monomer is a bisphenol A type aromatic-nitrile-group resin monomer containing aromatic ether nitrile chain segments, has the advantages of a low melting point, a wide processing window, a low curing temperature and others, has better processing performance and keeps the good thermal stability, mechanical performance and flame resistance of aromatic-nitrile-group resin; meanwhile, side nitrile groups are introduced to increase the number of crosslinking points in the process of resin curing, finally, the effect of increasing crosslinking density is achieved, and the thermal stability of the resin is further improved.

Owner:GUANGDONG SHUNDE GAONAITE NEW MATERIAL +1

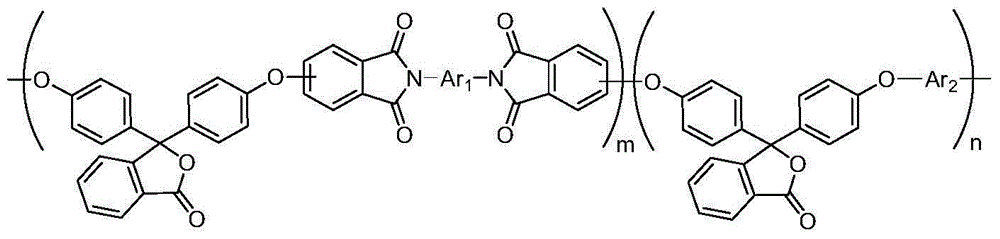

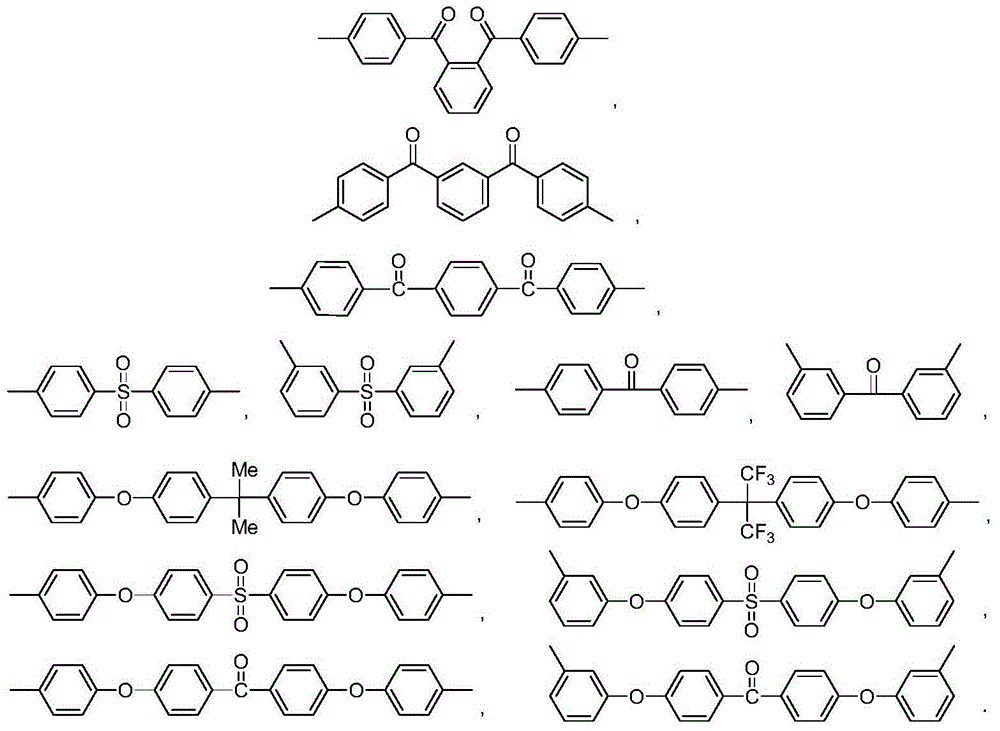

Phenolphthalein type copolyimide and preparation method thereof

The invention provides phenolphthalein type copolyimide. According to the phenolphthalein type copolyimide, a side-hanging phenolphthalein constructional unit and a side-hanging ether bond flexible unit are introduced into a rigid main chain of polyimide, and the phenolphthalein type copolyimide has the characteristics of good solubility, good processibility, good mechanical property, good heat resistance and the like, is suitable for injection molding, extrusion, mold pressing and solution spinning processing, and has a good application prospect in related fields of high-temperature-resistant engineering plastics, films, fibers, adhesives, coatings, advanced composite materials and the like. Besides, the phenolphthalein type copolyimide is prepared from raw materials including phenolphthalein monomer I, double-X-replaced polyimide monomer II and double-Y-replaced monomer III, and the phenolphthalein type copolyimide is prepared by virtue of an aromatic nucleophilic substitution reaction; the preparation method is low in cost, the polymer is excellent in performance and can be adjusted and controlled by virtue of a copolymerization unit, the defect that a dianhydride and diamine method adopted to prepare polyimide has a complex synthetic route is overcome, and the production cost of polyimide can be greatly reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of laser welding easy-processing polycarbonate composition and preparation method thereof

The invention relates to a laser welding tractable polycarbonate composition and a preparation method thereof. The composition comprises the following components in parts by weight: 50-80 parts of polycarbonate (PC) resin, 15-40 parts of ABS resin, 5-10 parts of amelt reinforcing agent, 0.1-1 part of a near infrared laser absorbent, 0.1-1 part of an antioxidant and 0.1-1 part of a lubricant. The preparation method of the alloy comprises the following steps: (a) mixing the PC resin, the ABS resin, the melt reinforcing agent, the near infrared laser absorbent, the antioxidant and the lubricant in a mixing agitator; and (b) performing blending granulation on the mixture obtained in the step (a) by virtue of a twin-screw extruder to obtain a product. Compared with the prior art, the polycarbonate composition provided by the invention is higher in melt strength after the melt reinforcing agent is added, so that the surface of a product after welding has no bulges orbreakdowns, welding can be performed under a higher laser intensity, the obtained product is higher in welding strength at the same time, a processing window of a laser welding process of the polycarbonate composition is broadened, and the laser welding tractable polycarbonate composition is obtained.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

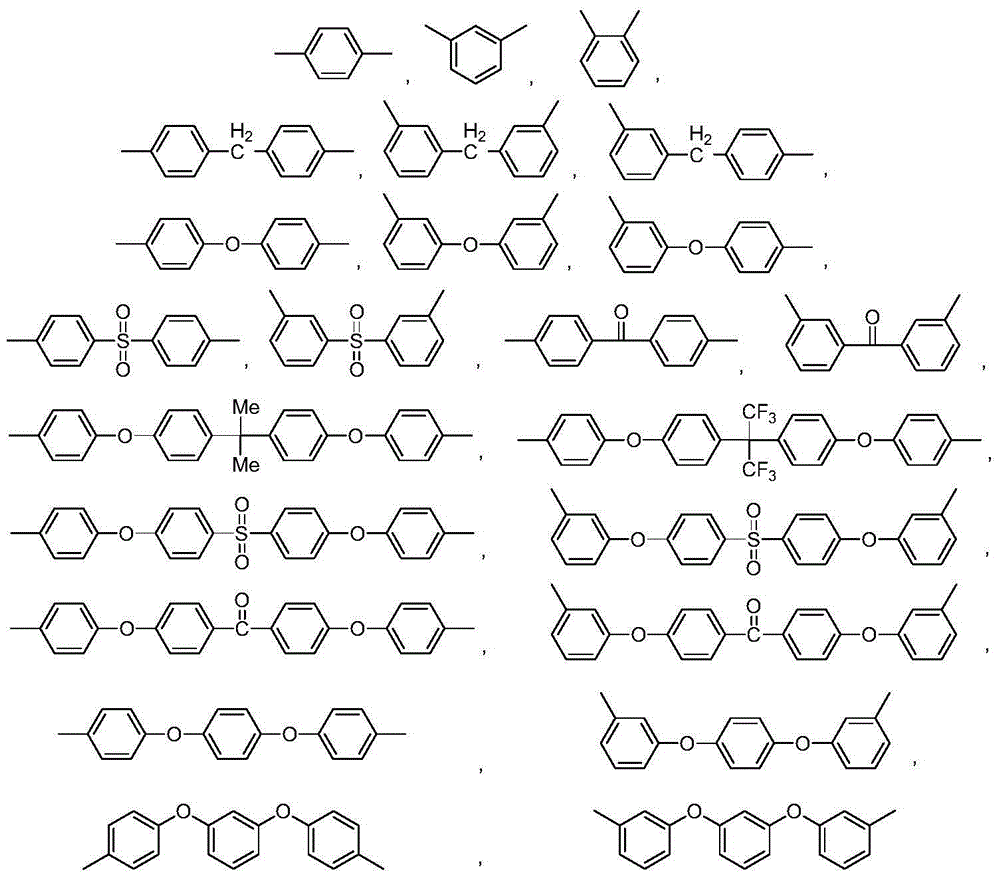

Polyamide-imide with indan structure and preparation method of polyamide-imide

ActiveCN106748963AReduce bulk densityReduce interactionOrganic chemistryPolyamide-imideHeat resistance

The invention provides polyamide-imide with an indan structure. The polyamide-imide has a structural formula as shown in the specification, and in the formula, n is from 1 to 8. The invention further discloses a material which is prepared after the polyamide-imide with the indan structure is cured at 220-380 DEG C, and a preparation method of the polyamide-imide with the indan structure. The invention studies the synthesis and the properties of polyamide-imide, thermal-curing polyamide-imide of different polymerization degrees is prepared from 5(6)-amino-1-(4-amino phenyl)-1,3,3-trimethyl indan as monomers, then the stacking density and the interaction of molecular chains can be reduced, the flexibility of the molecular chains can be improved, and finally polyamide-imide resin which is excellent in solubleness and excellent in thermal resistance can be synthesized.

Owner:BEIHANG UNIV

Preparation method of polyphenylene sulfide resin for melt blowing

PendingCN107722274AImprove Tangling EffectLower melt blown temperatureMonocomponent synthetic polymer artificial filamentBenzeneDecomposition

The invention discloses a preparation method of polyphenylene sulfide resin for melt blowing. The preparation method is characterized by comprising the following steps: reacting p-dihalogenated benzene, an S<-2>-containing compound, an amide organic compound with alkali salt at a temperature 180-250 DEG C and a pressure of 0.1MPa-5.0MPa for 1-24 hours, so as to obtain a linear PPS prepolymer; andreacting the linear PPS prepolymer with dihalogenated hydrocarbon at a temperature of 230-280 DEG C and a reaction pressure of 0.1MPa-5.0MPa for 1-24 hours, so as to obtain PPS resin for melt blowing,wherein dihalogenated hydrocarbon is m-dihalogenated aromatic hydrocarbon or p-dihalogenated hydrocarbon. When being added, m-dihalogenated aromatic hydrocarbon is taken as a structural regulator, and the high-entanglement helical-structure or spring-structure PPS resin for melt blowing is obtained; and when being added, p-dihalogenated hydrocarbon is taken as a chain extender, and high-linearityand relatively-low-viscosity PPS resin for melt blowing is obtained. The preparation method is relatively low in processing temperature, so that the decomposition and carbonization of PPS can be inhibited, and the oxidation and crosslinking of PPS can be prevented.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com