HIPS composite material with high flammability

A composite material, high flame retardant technology, applied in the field of engineering plastics, to achieve balanced strength and notched impact properties, high flame retardant grade, and good appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~6

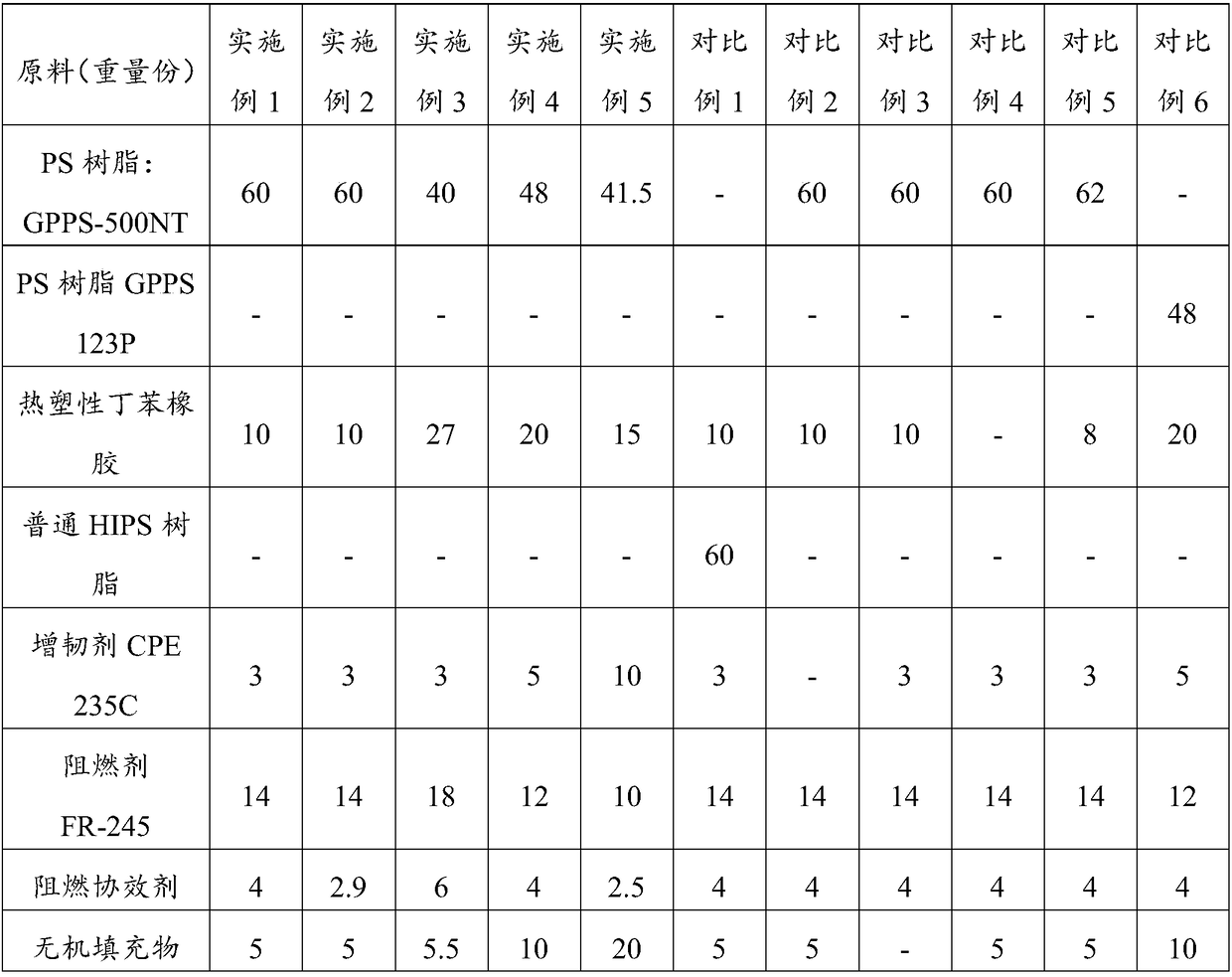

[0027] The formulations of the HIPS composite materials of Examples 1-5 and Comparative Examples 1-6 are shown in Table 1.

[0028] The HIPS composite material formula of table 1 embodiment 1~5 and comparative examples 1~6

[0029]

[0030]

[0031] "-" means do not add.

Embodiment 6~9

[0033] The HIPS composite material formulations of Examples 6-9 differ from Example 4 only in the ratio of the toughening agent to the inorganic filler. The HIPS composite material formulations of Examples 6-9 are shown in Table 2.

[0034] The HIPS composite material formula of table 2 embodiment 6~9

[0035] Raw materials (parts by weight)

Embodiment 10~12

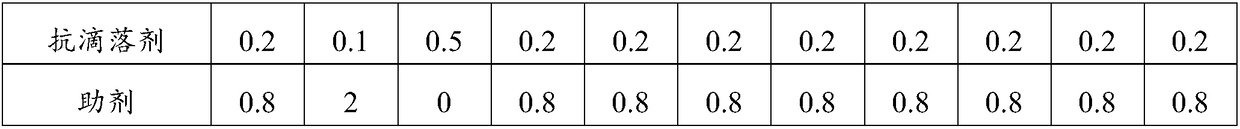

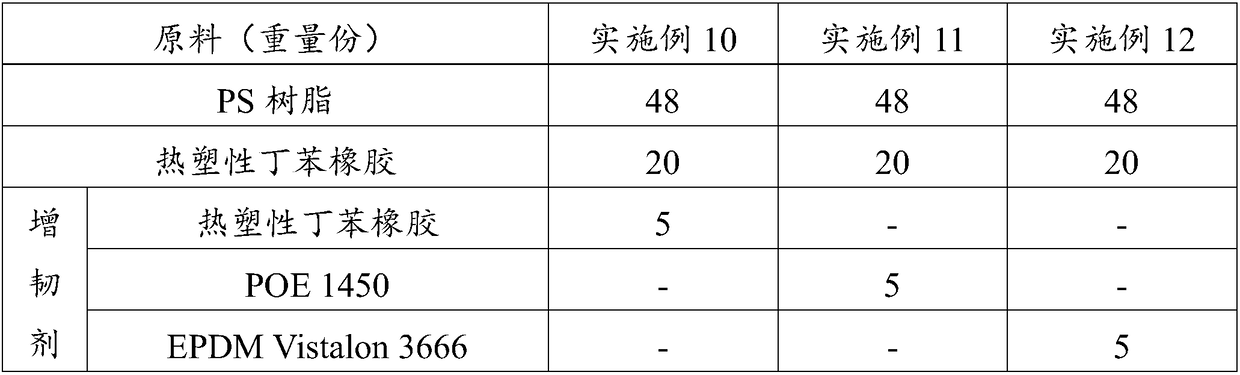

[0037] The only difference between the ABS composite material formulations of Examples 10-12 and Example 4 is the type of toughening agent. The ABS composite material formulations of Examples 10-12 are shown in Table 3.

[0038] The HIPS composite material formula of table 3 embodiment 10~12

[0039]

[0040]

[0041] "-" means do not add.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com