High inflaming retarding polyolefin cable insulating material and preparation method thereof

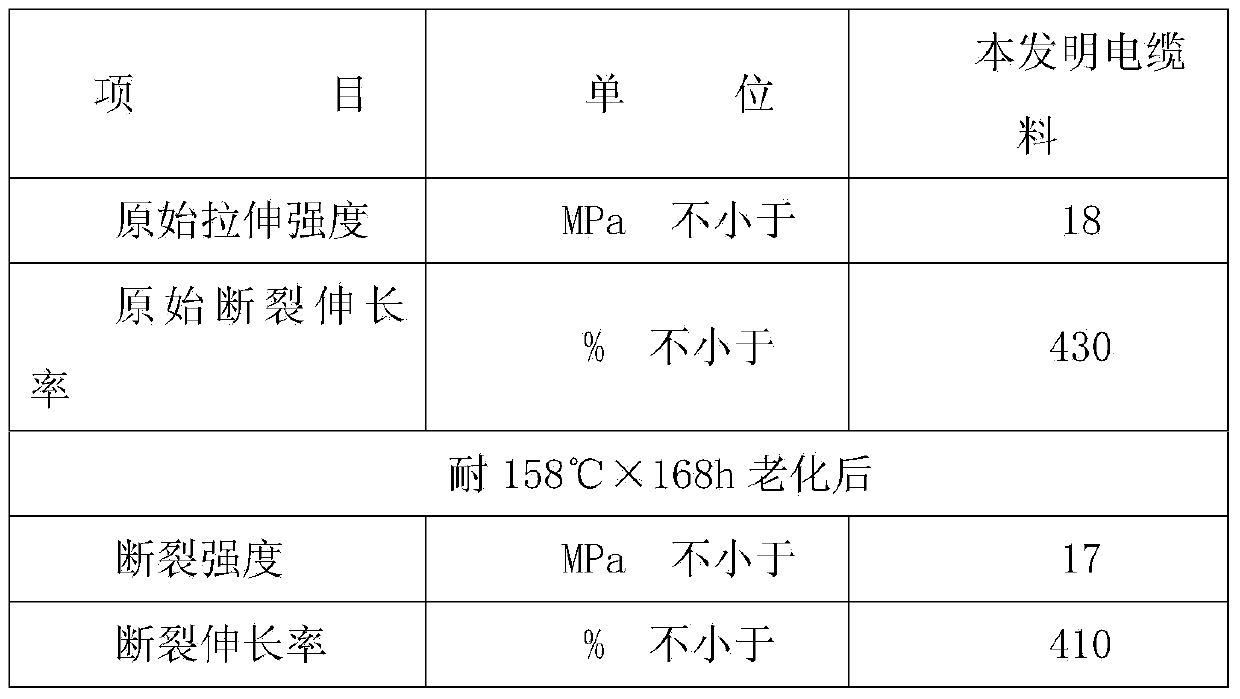

A technology of cable insulation and polyolefin, applied in the direction of insulated conductors, insulated cables, cables, etc., to achieve the effects of high tensile strength, good heat resistance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below through specific examples.

[0014] A high flame-retardant polyolefin cable insulation material, made of the following raw materials in parts by weight (kg): polyolefin elastomer resin 40, EVA14, polyethylene 12, aluminum hydroxide 10, silane coupling agent KH5502, crosslinking agent TAC1, polyvinyl acetate 4, dibutyltin dilaurate 2, vinyltriethoxysilane 2, isocyanate 1, ditungsten boride 1, ricinoleic acid 1, acetyl triethyl citrate 16, tributyl citrate Ester 5, Auxiliary 6;

[0015] The auxiliary agent is made of the following raw materials in parts by weight (kg): sepiolite powder 12, dimethylaminoethyl acrylate 4, urotropine 1, sodium tripolyphosphate 2, SnO21, silicon carbide powder 2, Joint agent TAC1, magnesium oxide 2, straw ash 1, aluminum stearate 1, tributyl citrate 1, wintergreen oil 0.1; the preparation method is to send sepiolite powder into a calciner and calcinate at 700-730°C for 3- After 4 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com