Patents

Literature

137 results about "Tungsten borides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten borides are compounds of tungsten and boron. Their most remarkable property is high hardness. The Vickers hardness of WB or WB₂ crystals is ~20 GPa and that of WB₄ is ~30 GPa for loads exceeding 3 N.

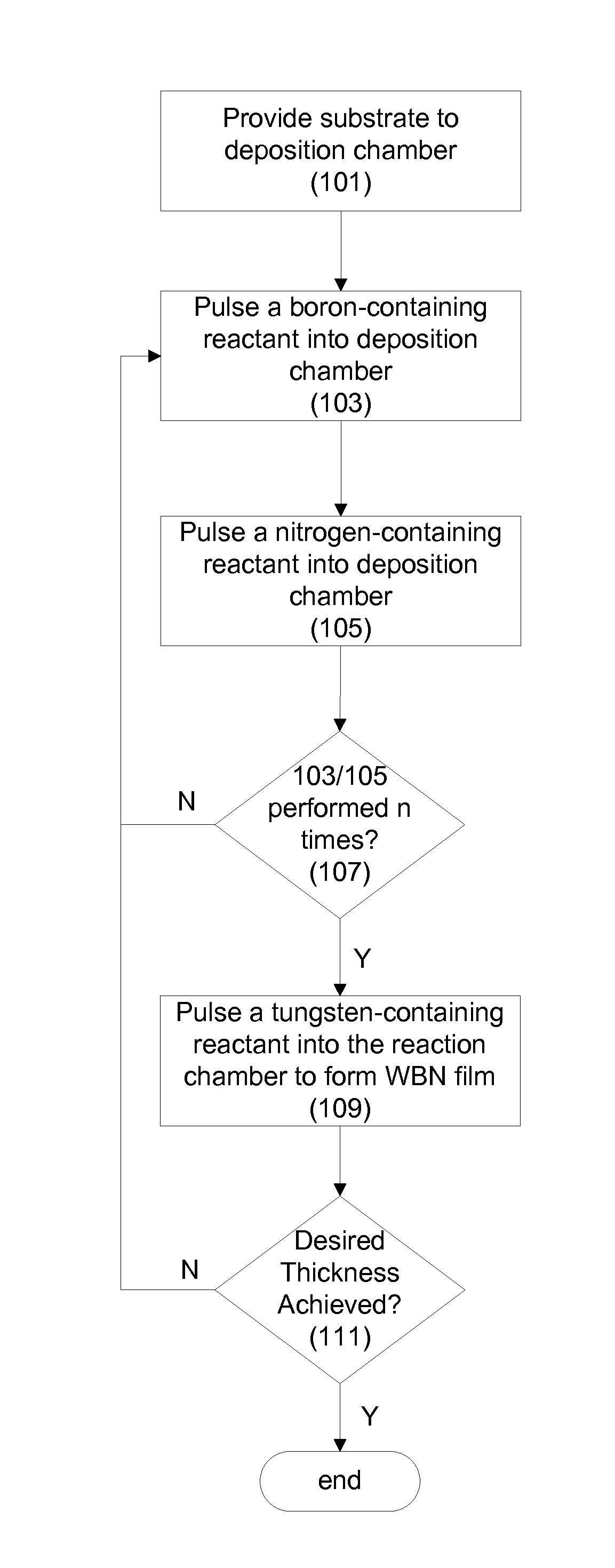

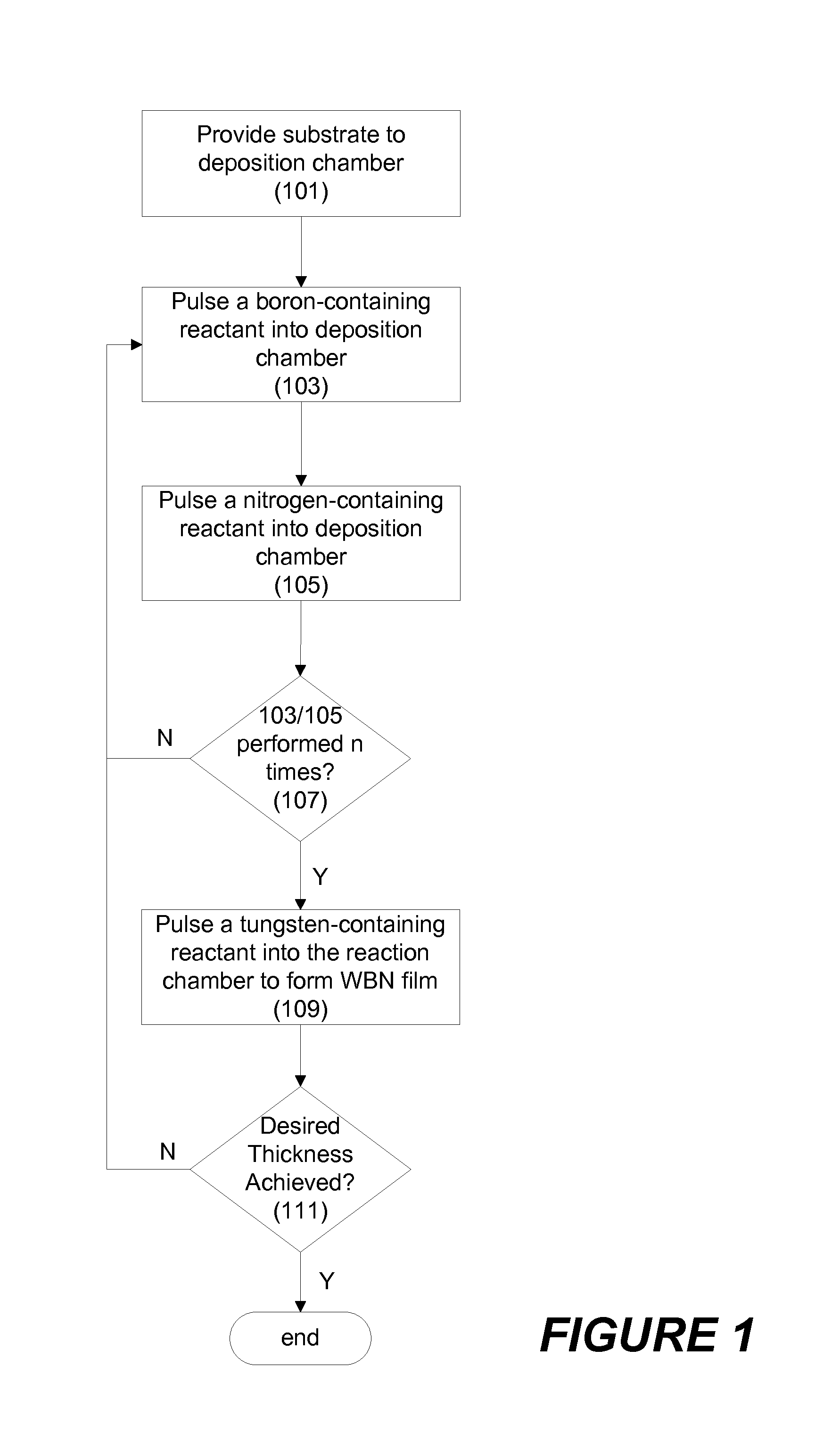

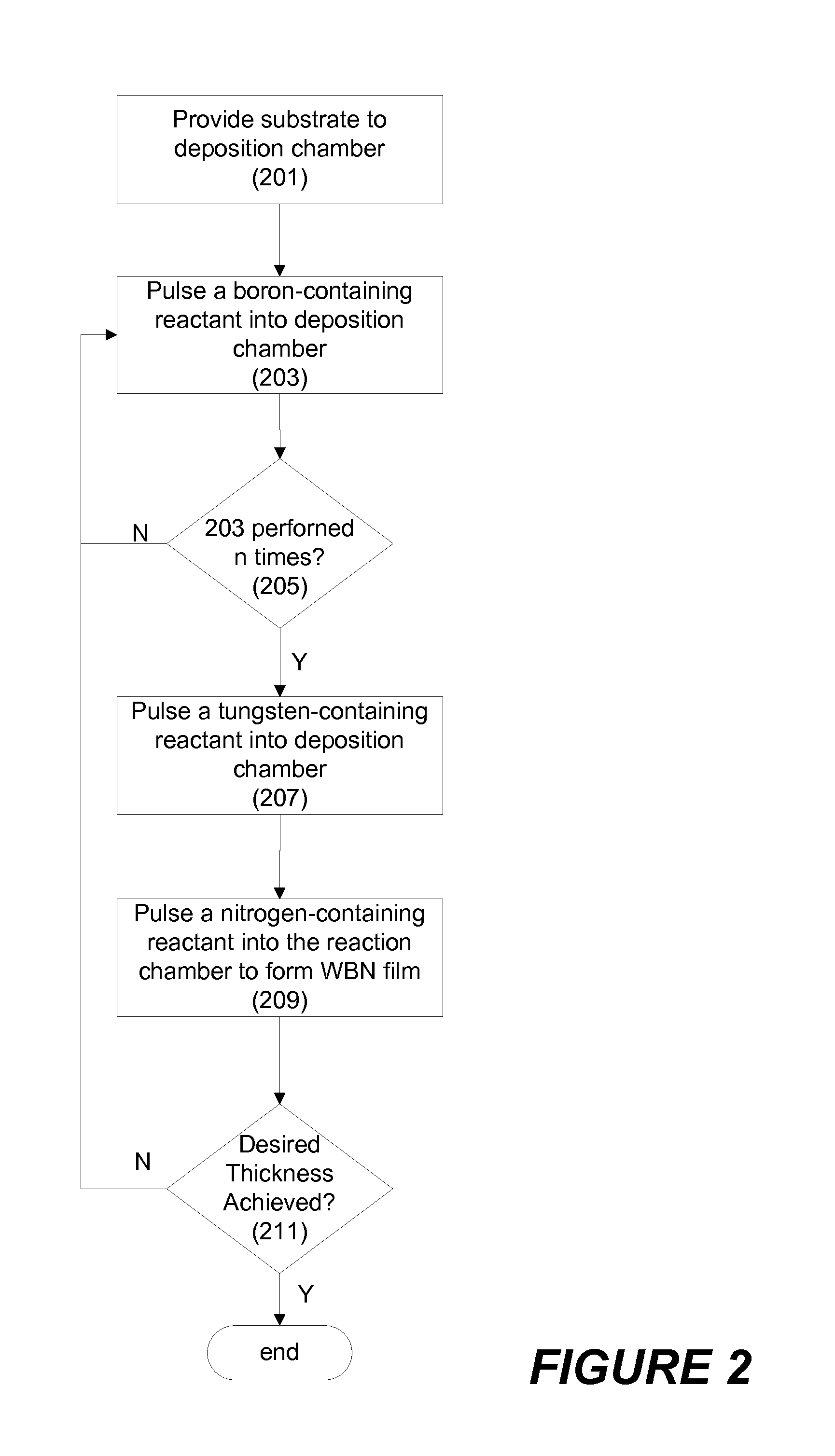

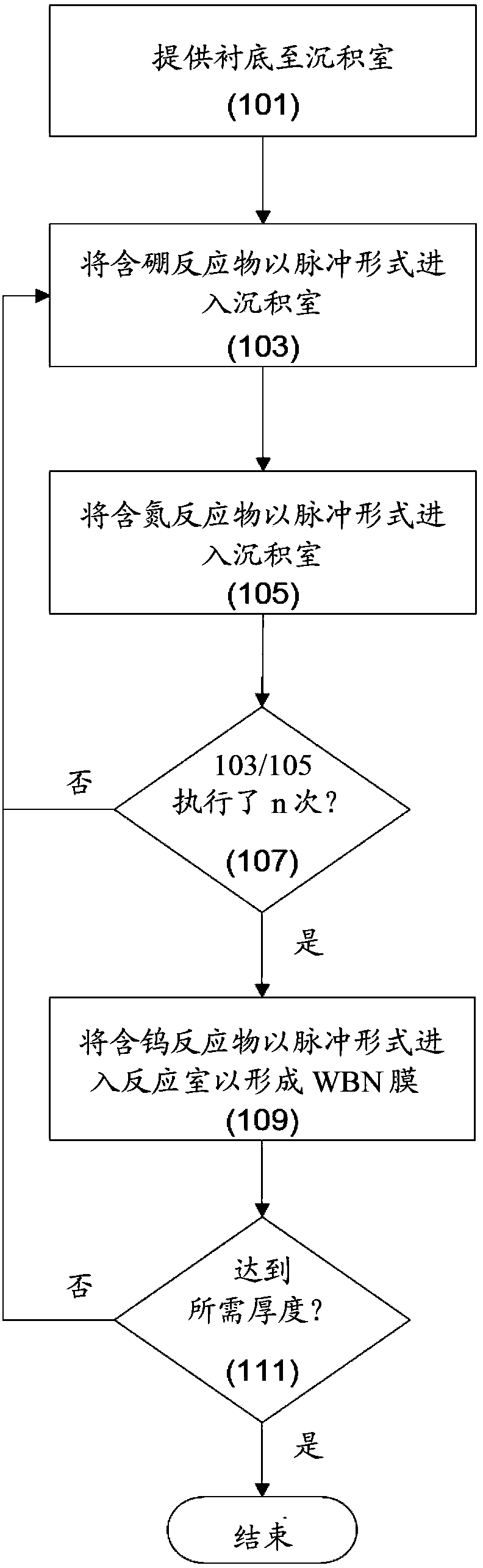

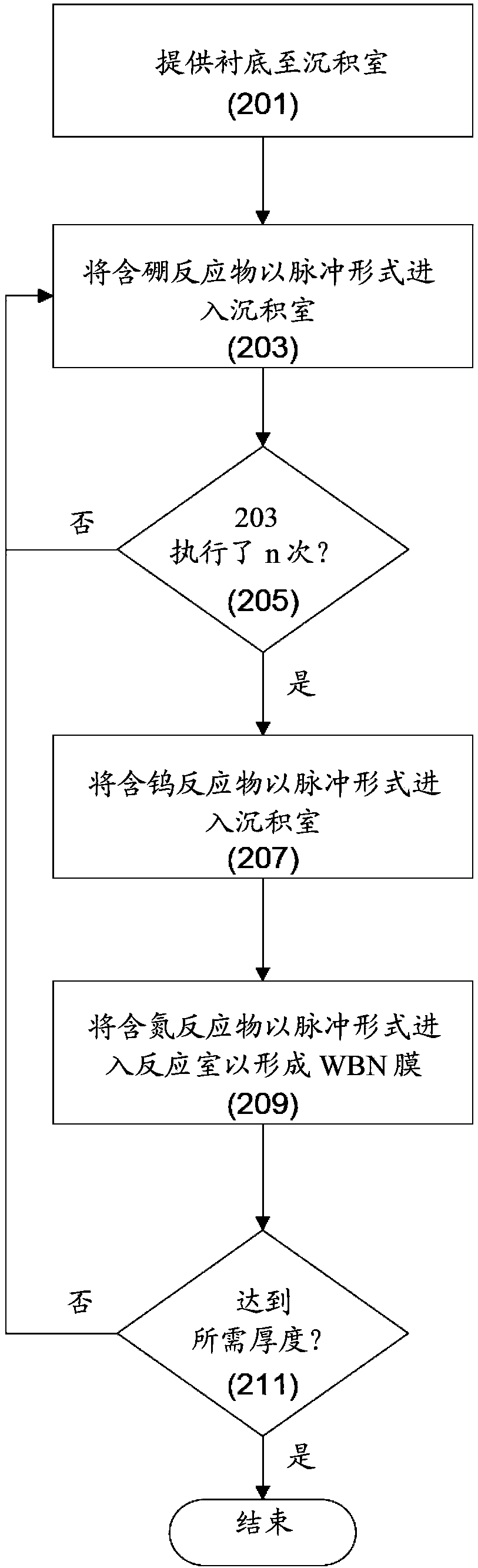

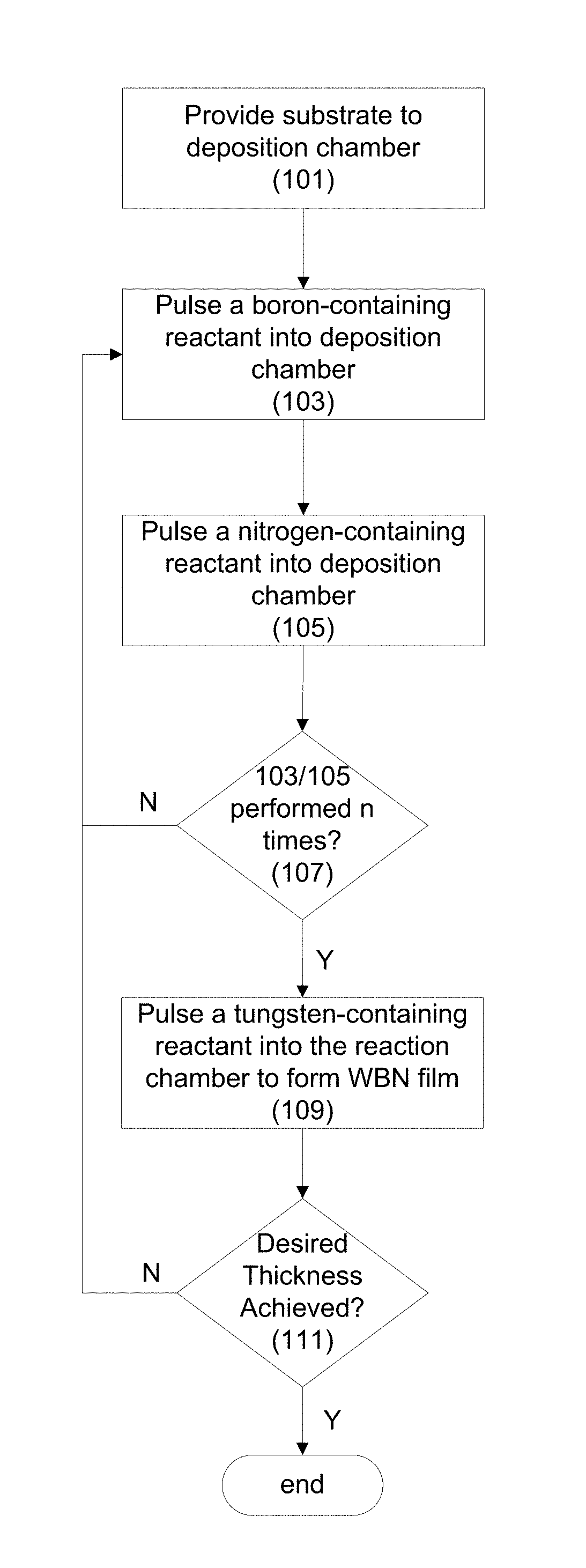

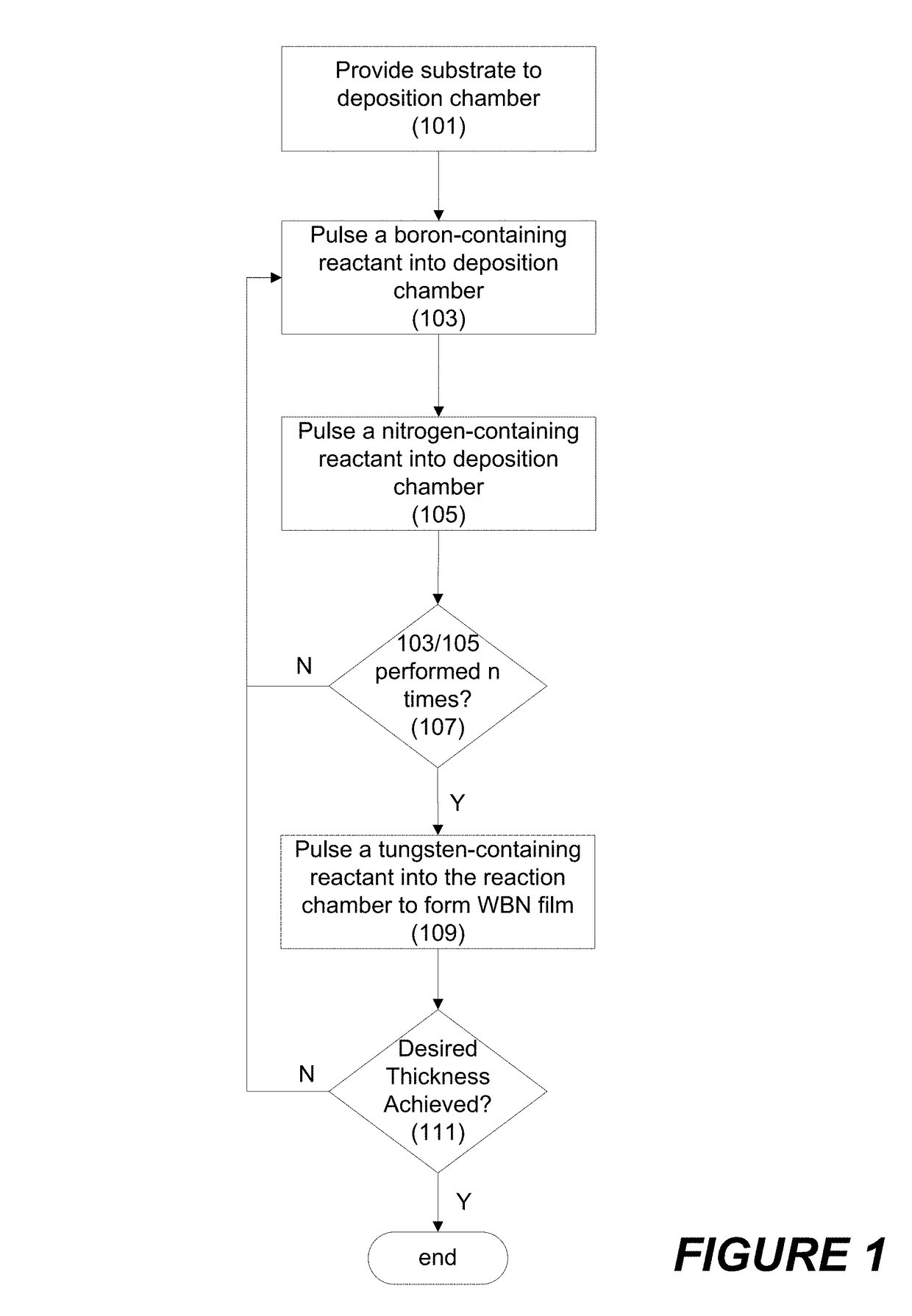

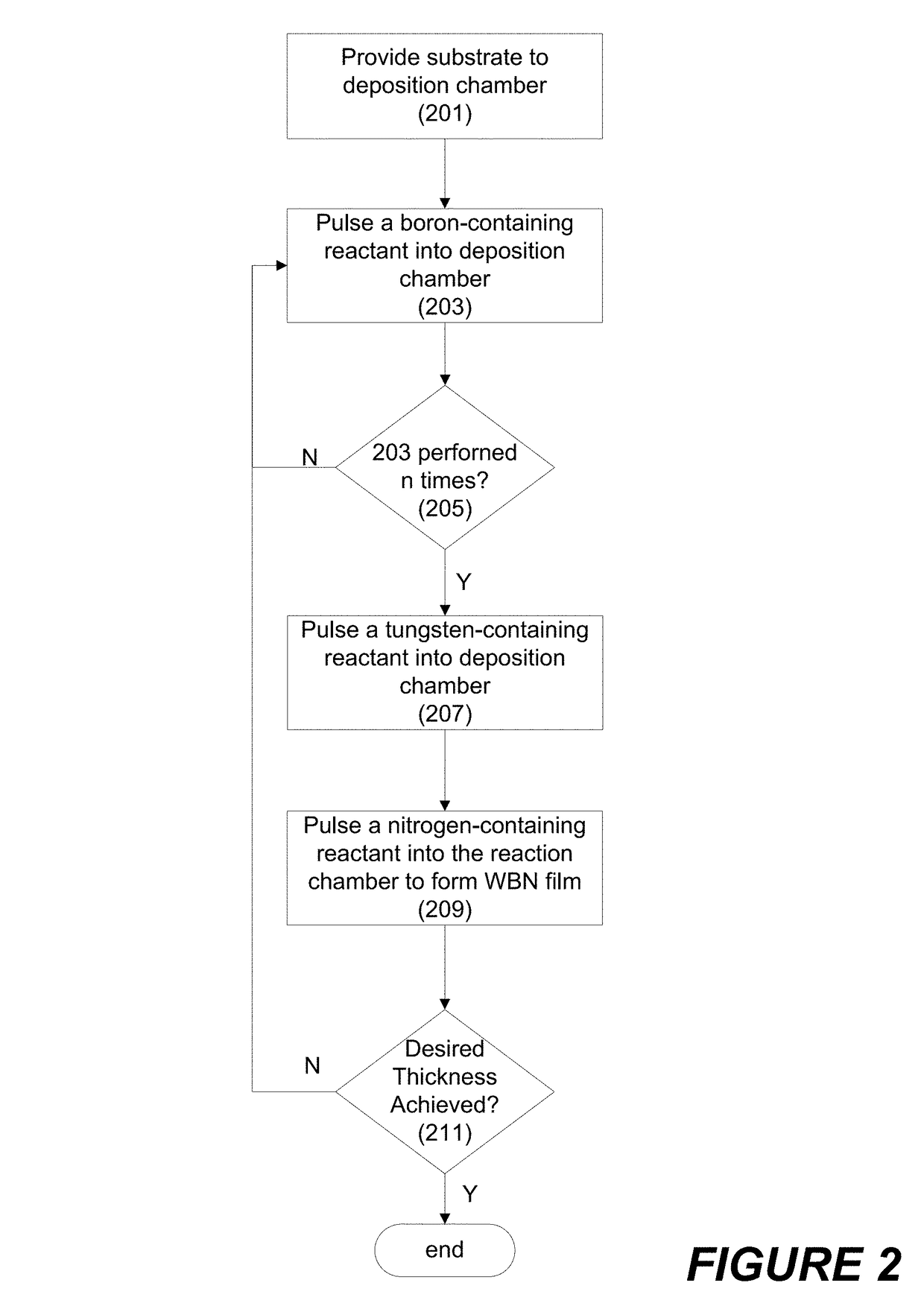

Ternary tungsten boride nitride films and methods for forming same

ActiveUS20140027664A1Improve thermal stabilityGood adhesion to oxidesLiquid surface applicatorsSemiconductor/solid-state device detailsBoron containingNitrogen

Ternary tungsten boride nitride (WBN) thin films and related methods of formation are provided. The films are have excellent thermal stability, tunable resistivity and good adhesion to oxides. Methods of forming the films can involve thermal atomic layer deposition (ALD) processes in which boron-containing, nitrogen-containing and tungsten-containing reactants are sequentially pulsed into a reaction chamber to deposit the WBN films. In some embodiments, the processes include multiple cycles of boron-containing, nitrogen-containing and tungsten-containing reactant pulses, with each cycle including multiple boron-containing pulses.

Owner:LAM RES CORP

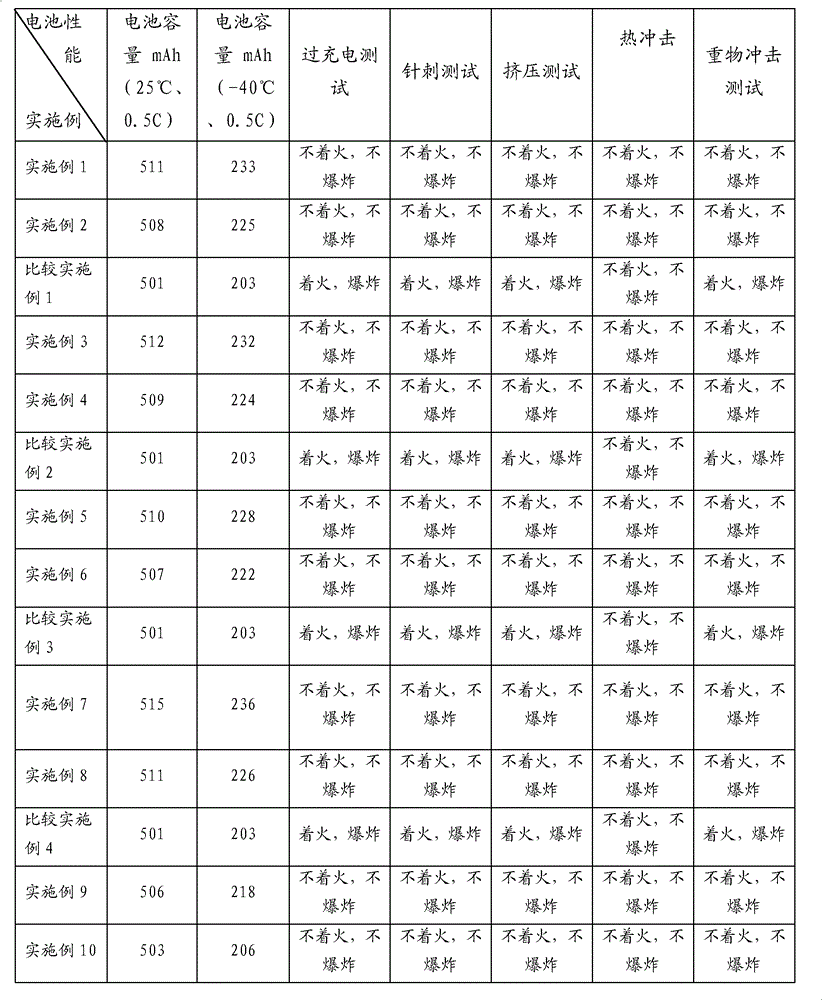

High capacity lithium ion battery containing metal conductive substances

ActiveCN102751530AImprove corrosion resistanceImprove antioxidant capacityCell electrodesSecondary cellsTitanium nitrideUranium carbide

The present invention discloses a high capacity lithium ion battery containing metal conductive substances. The battery comprises a positive electrode sheet, a negative electrode sheet, separation membranes, an electrolyte, a binder and a sealing material. A conductive substance of the positive electrode sheet comprises a metal carbide, a metal boride or a metal nitride. A conductive substance of the negative electrode sheet comprises a metal carbide, a metal boride or a metal nitride. The metal carbide is titanium carbonitride, tungsten carbide or titanium carbide, vanadium carbide, tantalum carbide, or a co-melting body of tungsten carbide and titanium carbide. The metal boride is a molybdenum boride, tungsten boride or vanadium boride. The metal nitride is titanium nitride, tungsten nitride or tantalum nitride. The conductive material of the positive electrode sheet further can contain powder metal, and the conductive material of the negative electrode sheet further can contain powdered metal, wherein the powdered metal is nickel powder, copper powder or chromium powder.

Owner:SHIHLIEN APEX HUAIAN TECH CO LTD

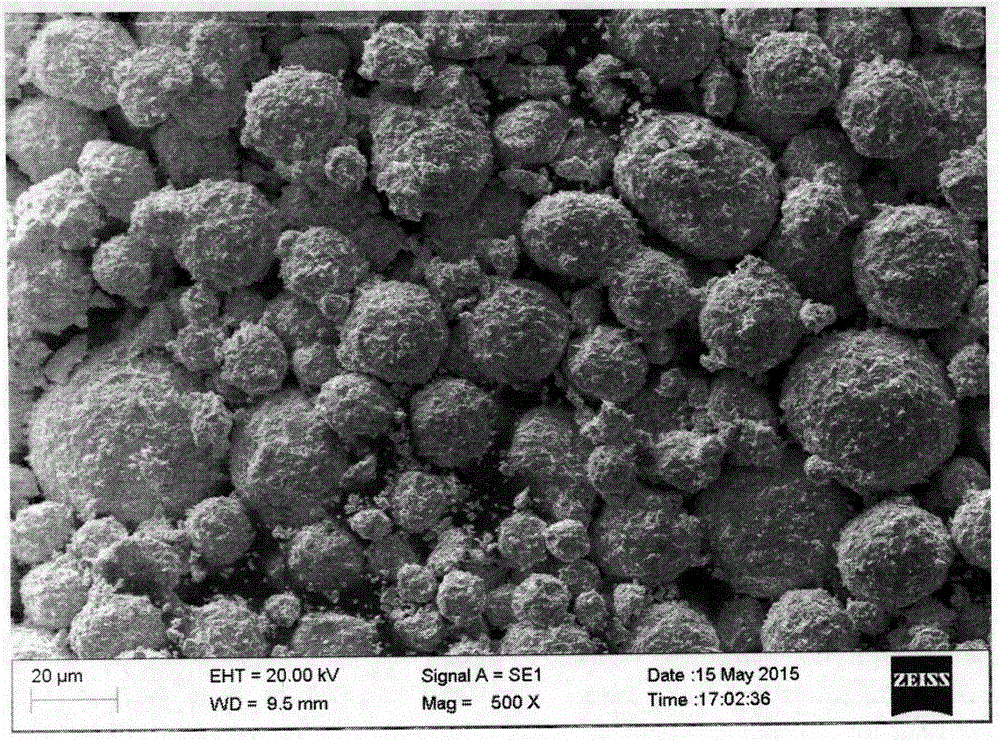

Large granular spherical metal ceramic nano composite spraying powder

The invention relates to macro aggregate ball shape metal ceramic nm compounding spray coating powder that contains titanium diboride 50-70wt%, cobalt 10-24wt%, chromium powder 6-13wt%, tungsten boride 5-11%, and the other is rare earth powder. Mixing the powder according to the ratio, wet method ball milling, centrifuging, pressure spraying graining, vacuum heat treatment technology and grain classifying process, the 20-45um and 45-75um granularity of powder would be gained. It has good abrasion resistant, high temperature resistant and corrosion resistance capability.

Owner:SHANGHAI JIAO TONG UNIV

High-efficiency antifouling antibacterial exterior wall coating and preparation method thereof

ActiveCN103351671AReduce lossesSimple processAntifouling/underwater paintsPaints with biocidesWater basedKetone

The invention provides an exterior wall coating which is composed of the following raw materials in parts by weight: 86-90 parts of water-based acrylic emulsion, 15-20 parts of styrene-acrylic emulsion, 30-40 parts of vermiculite powder, 10-15 parts of barite powder, 1-2 parts of 5-chloro-2-methyl-4-isothiazolin-3-ketone, 2-3 parts of butyl methacrylate, 2-3 parts of aluminium nitride, 1-2 parts of sodium alkylbenzene sulfonate, 0.3-1 part of coco fatty acid diethanol amide, 1-2 parts of diethylene triamine, 1-2 parts of tungsten boride, 0.7-1 part of anilmomethyl triethoxy silane, 0.1-0.2 part of polyoxyethylenepolyoxypropylene ether, 3-5 parts of coalescing agent and 10-30 parts of deionized water. The coating provided by the invention has the advantages of low raw material loss, low gel production, simple process, hard coating film, good glossiness, strong impact resistance, low cracking rate, soft texture, excellent decorative property, high weather resistance, good scrubbing resistance, high adhesion force and long service life; and the coating is free of special smell, and contains no heavy metals such as mercury and lead and also contains no formaldehyde volatile, and thus meets the technical requirements of an environment-friendly coating.

Owner:CHUZHOU MAISITE NEW BUILDING MATERIAL

High capacity lithium ion battery containing metallic conducting materials

InactiveUS20140113175A1High capacity densityEasy dischargeElectrode carriers/collectorsOrganic electrolyte cellsAdhesiveElectrical battery

A lithium ion battery containing conducting materials comprises a positive electrode, a negative electrode, a separator, an electrolyte, adhesives and sealing materials. The conducting materials in the positive electrode comprise metal carbides, metal borides or metal nitrides. The conducting materials in the negative electrode comprise metal carbides, metal borides or metal nitrides. The metal carbide is titanium carbonitride, tungsten carbide or titanium carbide, vanadium carbide, tantalum carbide, and eutectic of tungsten carbide and titanium carbide. The metal boride is molybdenum boride, tungsten boride or vanadium boride. The metal nitride is titanium nitride, tungsten nitride or tantalum nitride. The conducting materials in the positive electrode may also comprise powdered metals. The conducting materials in the negative electrode comprise powdered metals. The powdered metal is nickel powder, copper powder or chromium powder.

Owner:ZHANG PANYI

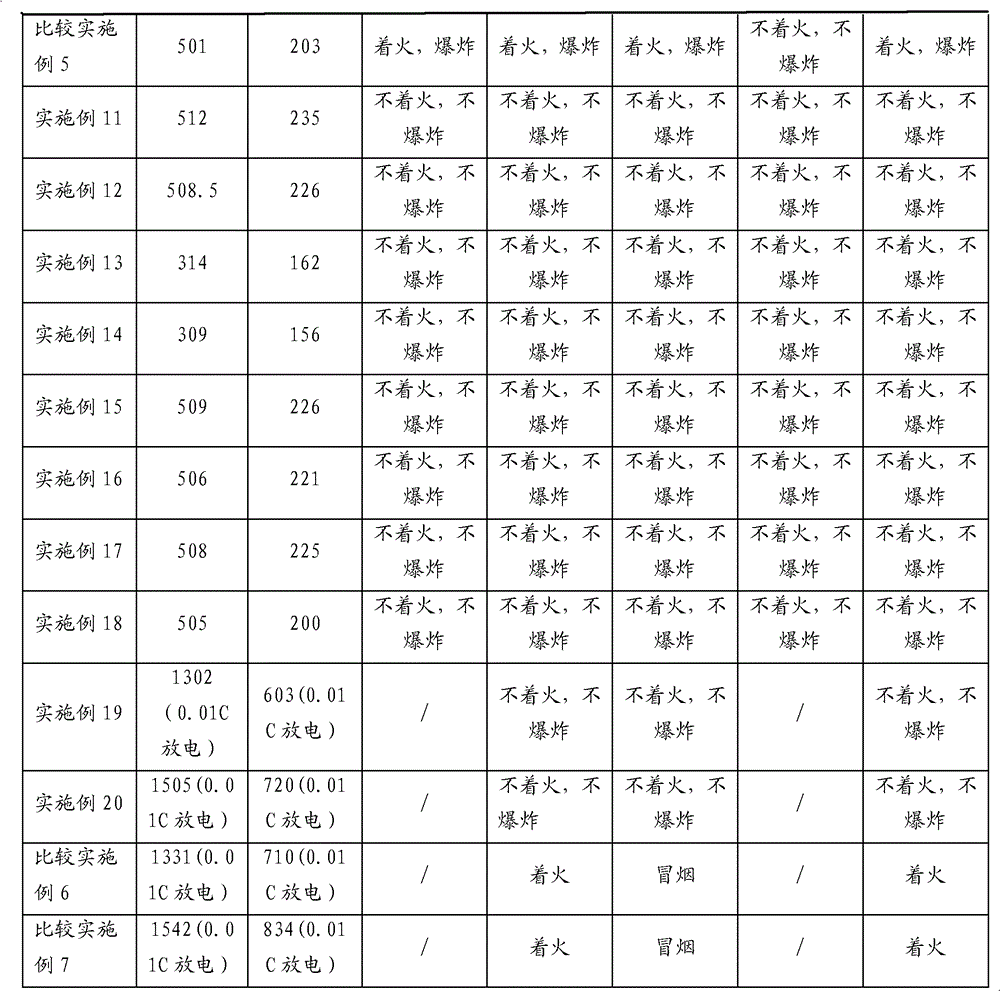

Nano-composite metal ceramic powder for molten metal resistant erosion and method for manufacturing same

InactiveCN101244937AImprove toughnessGood resistance to high temperature oxidationTemperature resistanceCobalt

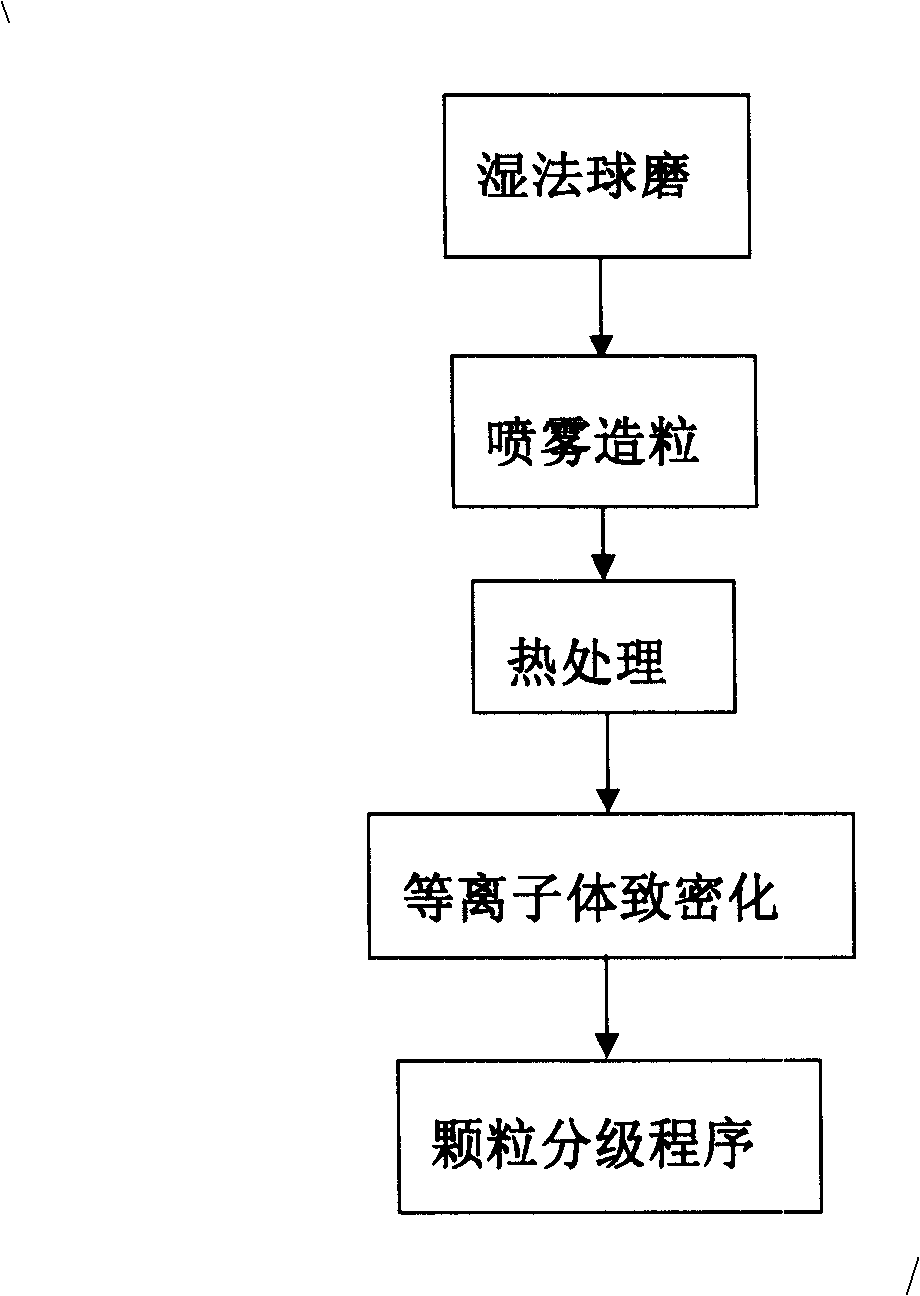

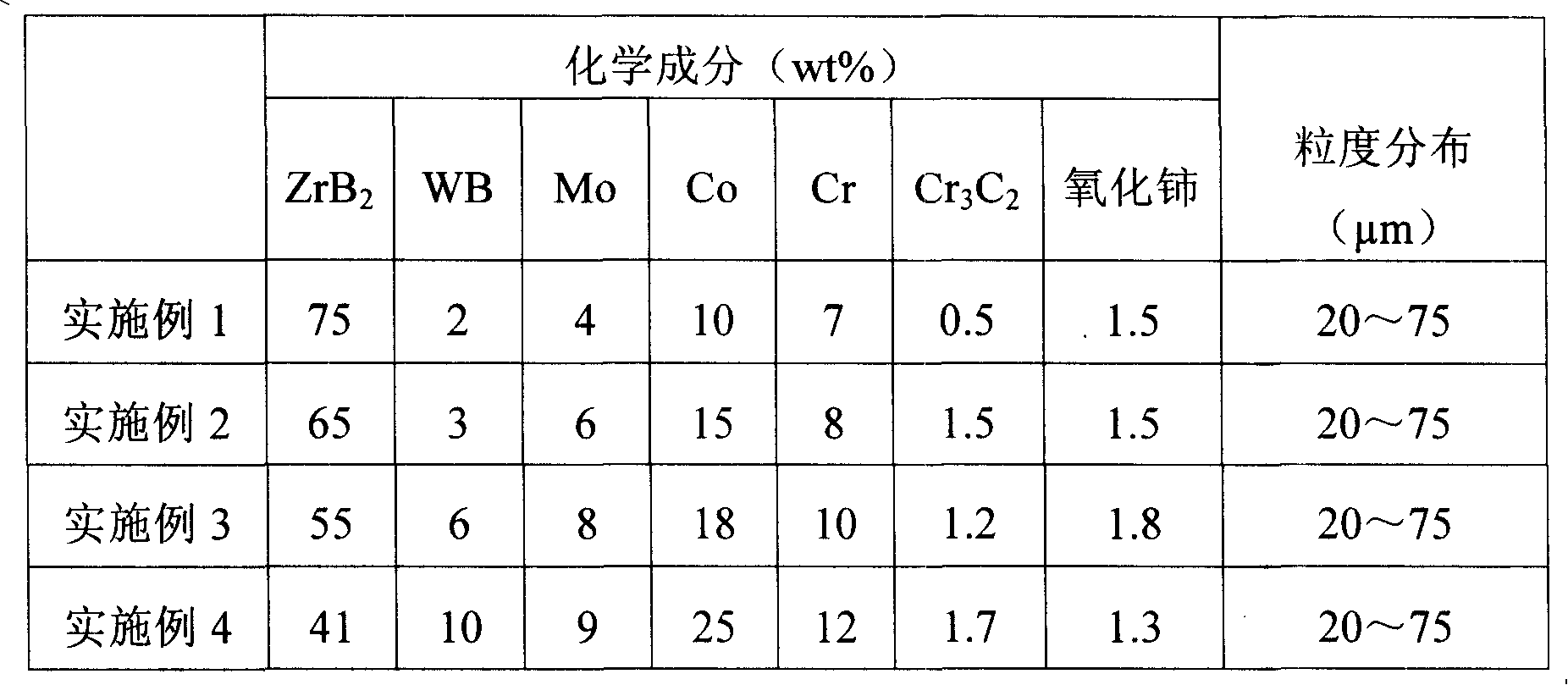

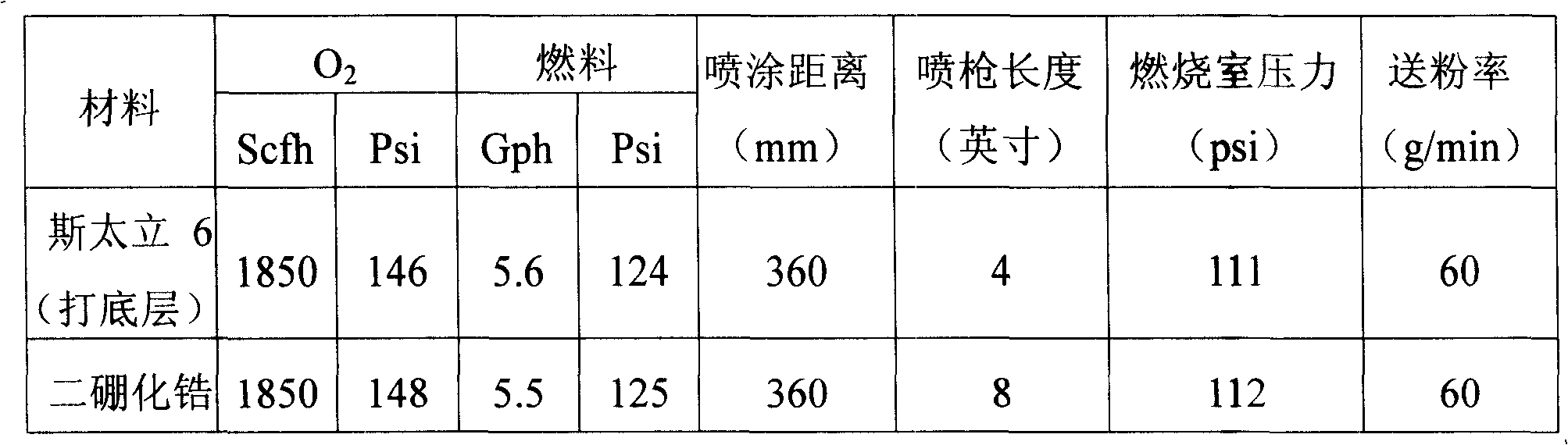

The invention provides a nano complex metal ceramic powder used for the erosion of melting-resistant metals, the components and weight percentages of which are as following: 41 to 75 percent of zirconium diboride, 10 to 25 percent of cobalt, 7 to 12 percent of chromium powder, 2 to 10 percent of tungsten boride, 4 to 9 percent of molybdenum, and 0.5 to 1.7 percent of chromium carbide, the rest is cerium oxide, wherein the particle sizes of cobalt, chromium, tungsten boride, molybdenum, chromium carbide and cerium oxide are all between 0.5 Mum and 1 Mum, the particle size of zirconium diboride is less than 100nm, the powder can be produced by the processes of wet-ball grinding, spray granulation, heat treatment, plasma densification and particle classification, sink rolls and stable rolls after being sprayed by the powders has the advantages of high temperature resistance, corrosion resistance and abrasion resistance, the average time for being used on sink rolls of continuous hot-dipped al-zn group is 20 to 31 days, the times and time of changing sink rolls are reduced so as to save the cost, improve the economic benefit and improve the quality of aluminum plating zinc strip steels.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Production method of high-purity tungsten boride

The invention relates to a production method of high-purity tungsten boride, comprising the following steps: 50 to 55 parts by weight of boron carbide, 35 to 45 parts by weight of metal tungsten and 0 to 30 parts by weight of additive containing carbon are mixed, and then the mixture is electrically melted and smelted for 4 to 5 hours at the temperature 2000 DEG C to 2400 DEG C in a vacuum resistance furnace, thus obtaining the high-purity tungsten boride, wherein the additive containing carbon is one or any combination of charcoal, graphite, and petroleum coke. The production method has the advantages of low production cost and environment protection, and the high-purity tungsten boride produced by adopting the method has the advantages of stable quality, and less possibility of volatilization and oxidation.

Owner:鲍迎全

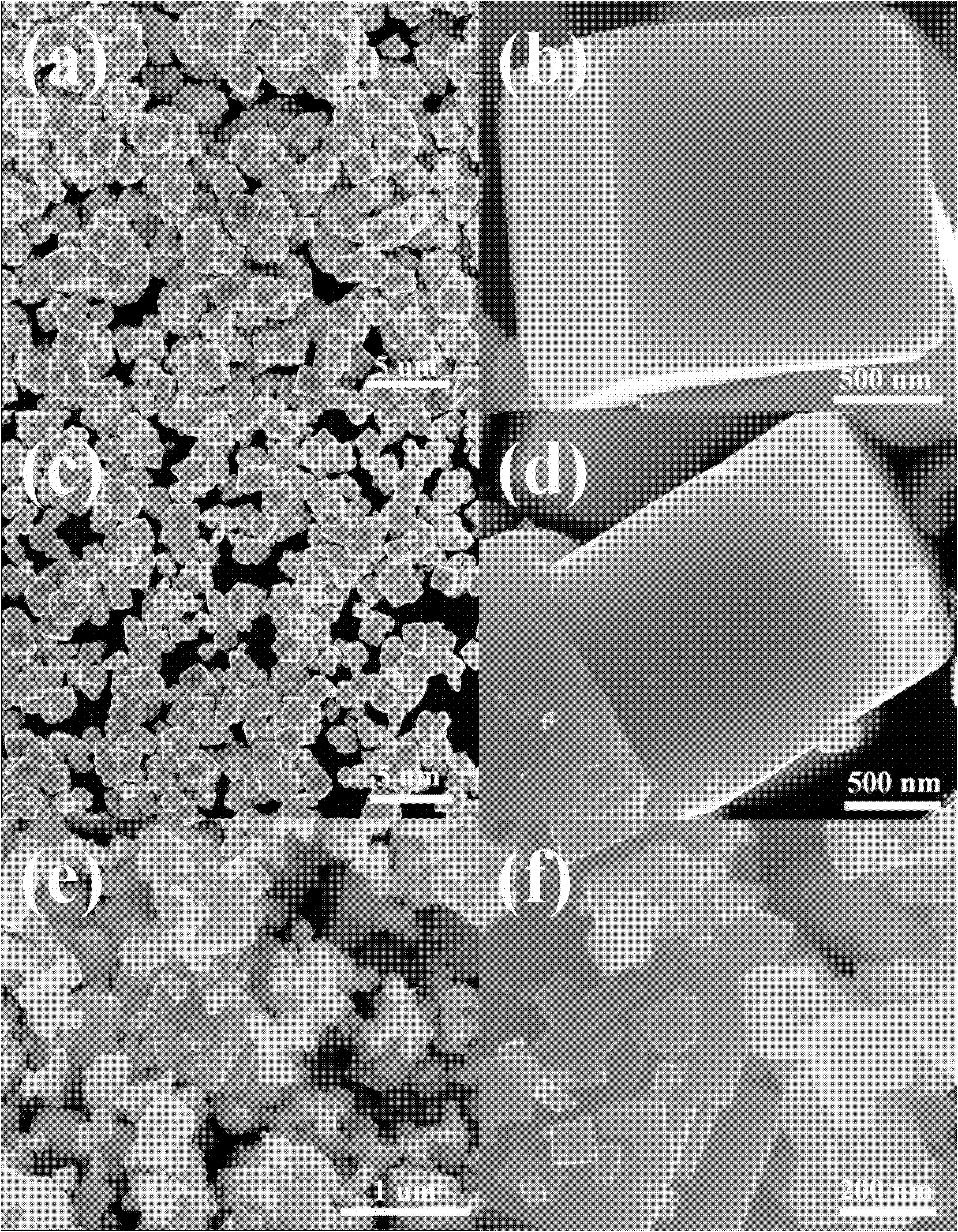

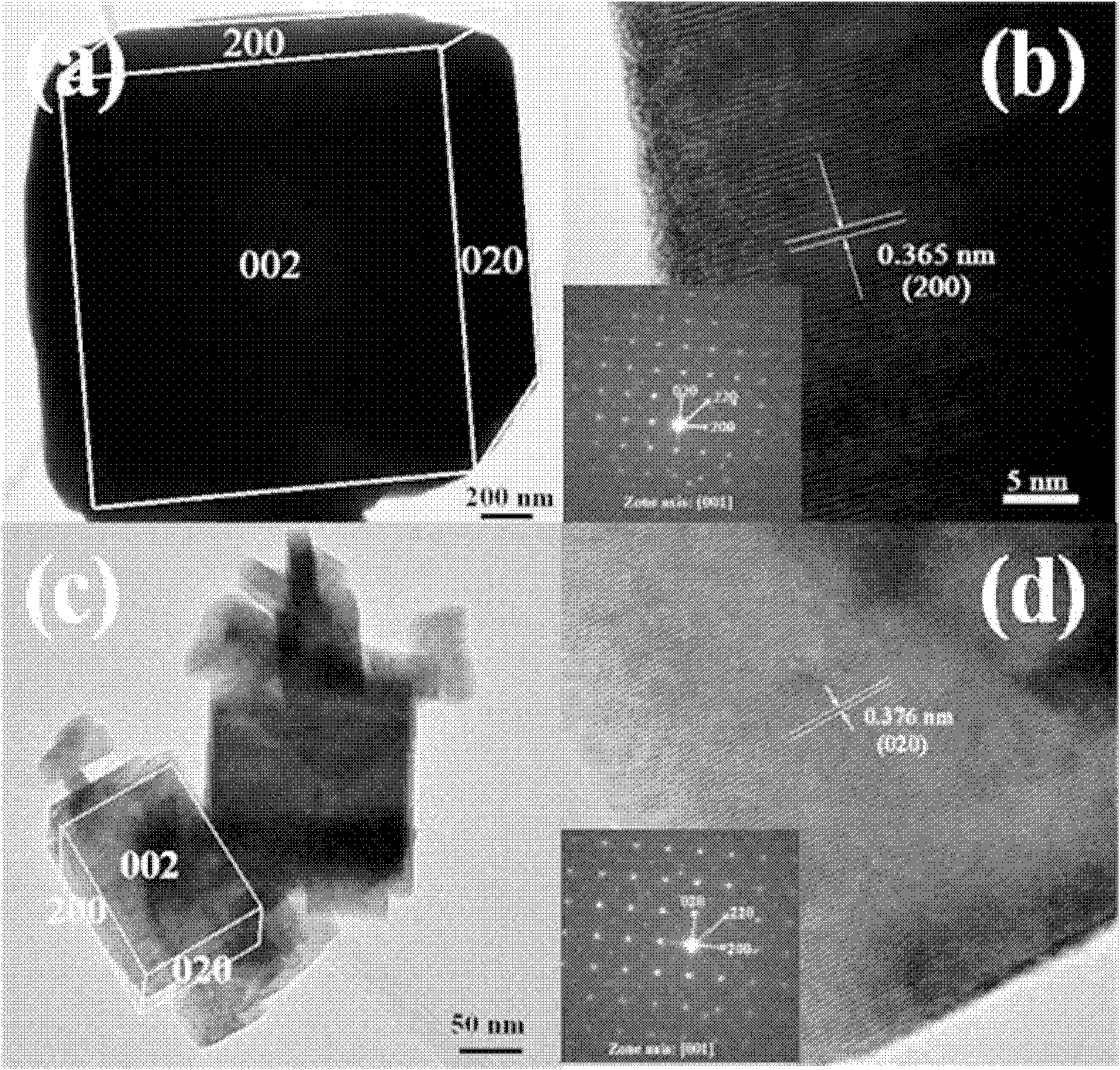

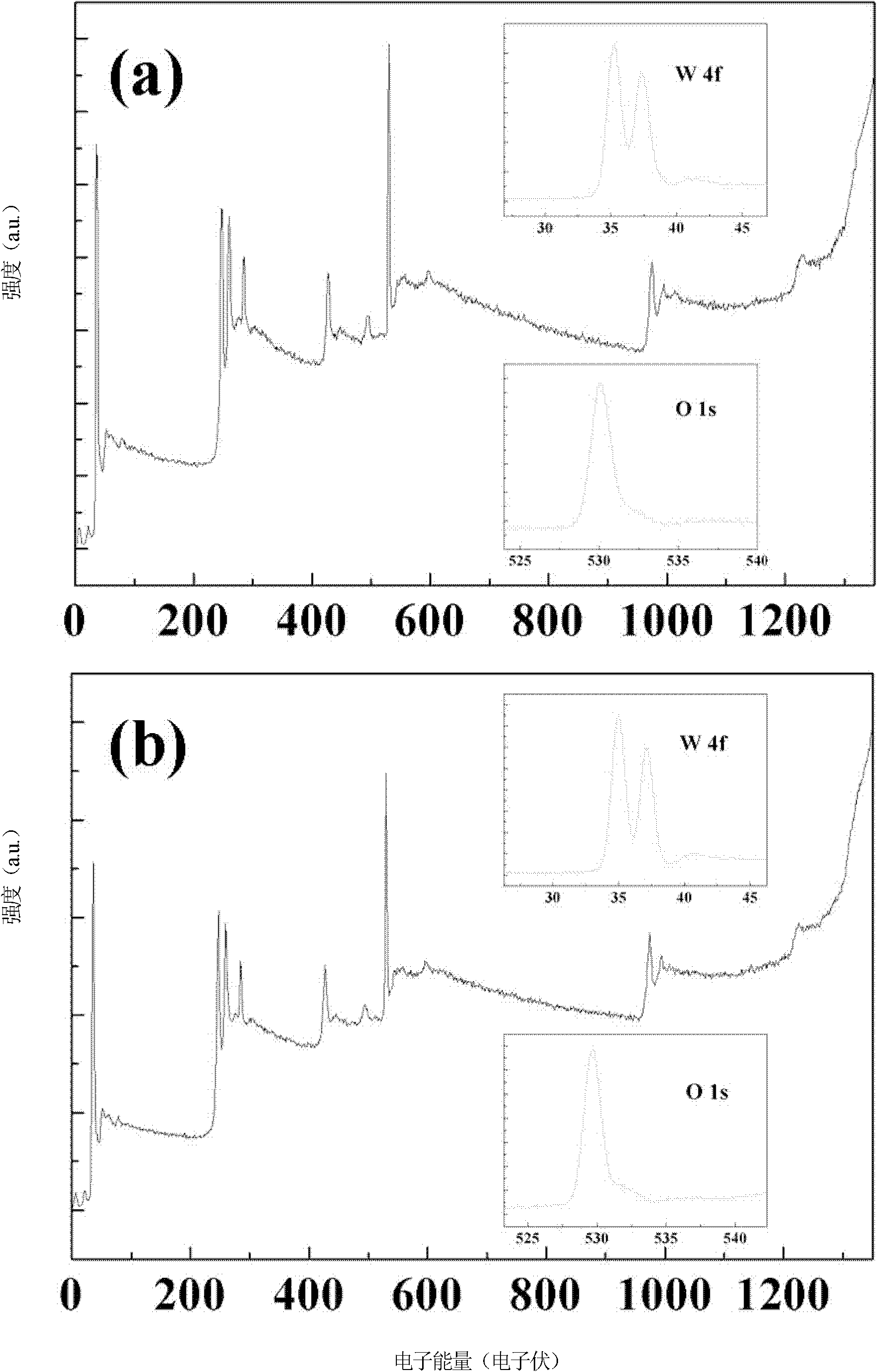

Method for preparing tungsten trioxide crystals with controllable growth of crystal surfaces

ActiveCN102719891AExcellent crystal surfaceUniform shapePolycrystalline material growthFrom normal temperature solutionsOxygenTungsten borides

The invention, relating to the field of tungsten trioxide crystals, concretely discloses a method for preparing tungsten trioxide crystals with controllable growth of the crystal surfaces. The method is characterized by using tungsten boride as a precursor by wet chemical process and carrying out hydrothermal growth of the crystal surfaces to expose tungsten trioxide crystals with different proportions, so that the problem of providing tungsten trioxide catalysts with different redox abilities for different reaction systems can be solved; putting the precursor in a reaction vessel filled with an aqueous nitric acid solution, and carrying out heat treatment to obtain crystal surface-dominated tungsten trioxide crystals {002}; putting the precursor in a reaction vessel filled with a hydrofluoric acid solution or a hydrofluoric acid ethanol solution or a mixed solution of aqueous hydrofluoric acid and ethanol, carrying out heat treatment to obtain cubic hydrogen tungsten bronze crystals, and heating the hydrogen tungsten bronze crystals in air to obtain tungsten trioxide crystals with identical crystal surface proportion {002}, {200}, {020}. According to the invention, tungsten trioxide crystals with regular morphology, different crystal surface proportions, and good ability of oxygen production by water splitting can be prepared.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Environment-friendly exterior wall paint and preparation method thereof

The invention discloses an exterior wall paint prepared from the following raw materials in parts by weight: 86-90 parts of waterborne acrylic emulsion, 17-20 parts of styrene-acrylic emulsion, 20-50 parts of wollastonite powder, 2-3 parts of iso-octyl acrylate, 1-2 parts of potassium borate, 0.4-1 part of ethylene glycol dimethacrylate, 3-4 parts of tungsten boride, 1-2 parts of sodium dodecyl sulfate, 0.6-1 part of dibenzoyl peroxide, 3-4 parts of absolute ethyl alcohol, 0.8-1 part of gamma-aminopropyltriethoxysilane, 0.1-0.2 part of polyoxyethylene polyoxypropylene ether, 3-5 parts of coalescing agent and 10-20 parts of deionized water. The paint produced by the invention is low in raw material loss, less in gel generation, simple in process, firm in paint film, good in glossiness, strong in impact force resistance, not easy to crack, soft in texture, strong in decoration, high in weather and scrubbing resistance, strong in adhesive force, long in service life, free of special smell, heavy metals such as mercury, lead and the like and formaldehyde volatiles, and capable of meeting the technical requirement of an environment-friendly paint; and the added coalescing agent has very high stability, efficient adhesiveness and film forming property, so that the density of the paint film is increased, the film forming quality is improved, and a film layer has the advantages of strong adhesive force, no hole and rift, densification, uniformity and the like.

Owner:CHUZHOU MAISITE NEW BUILDING MATERIAL

Process for preparing large particle spherical metal ceramic nano composite spraying powder

The invention relates to a macro aggregate spheroid metal ceramic nm compounding powder manufacture method. The primary powder constituents and the weight ratio is 50-70% titanium diboride, 10-24% cobalt, 6-13% chromium powder, 5-11% tungsten boride, and the other is rare earth powder. The process includes the following steps: making nm cobalt and chromium water solution, making metal ceramic nm compounding gel, spraying, taking grain powder stage treatment. The invention is low cost, simple method.

Owner:SHANGHAI JIAO TONG UNIV

Aluminum-based composite material for shielding high-dose gamma-rays and thermal neutrons and preparation method thereof

The invention discloses an aluminum-based composite material for shielding high-dose gamma-rays and thermal neutrons and a preparation method thereof, and belongs to the technical field of composite shielding materials. The aluminum-based composite material comprises, by mass percentage, 75%-90% of tungsten element, 0.5%-3% of boron element and the balance aluminum or aluminum alloy. Raw materialsof the tungsten element are selected from one or more of tungsten, tungsten carbide, tungsten oxide and tungsten boride. Raw materials of the boron element are selected from one or more of boron carbide and / or tungsten boride. The method specifically includes mixing the raw material powder under the protection of inert gas, and then conducting cold isostatic pressing and hot isostatic pressing molding processing to obtain the aluminum-based composite material. The aluminum-based composite material has the density of more than 99%, has good shielding performance, mechanical property, heat resistance and processing property, is applied to shielding of high-dose gamma-rays and thermal neutrons in a nuclear reactor, and is especially suitable for shielding the high-dose gamma-ray leakage areain the nuclear reactor.

Owner:GRIMAT ENG INST CO LTD

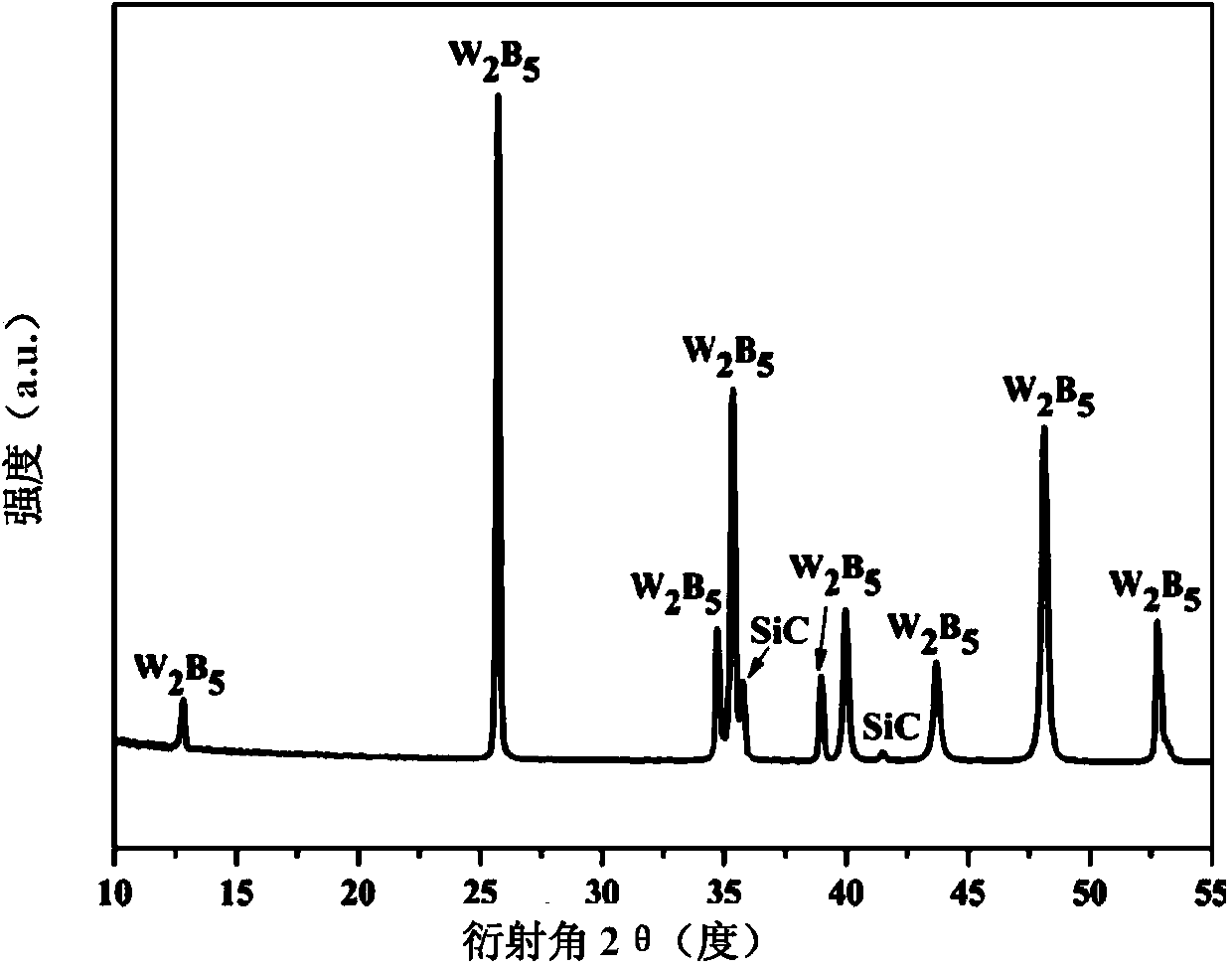

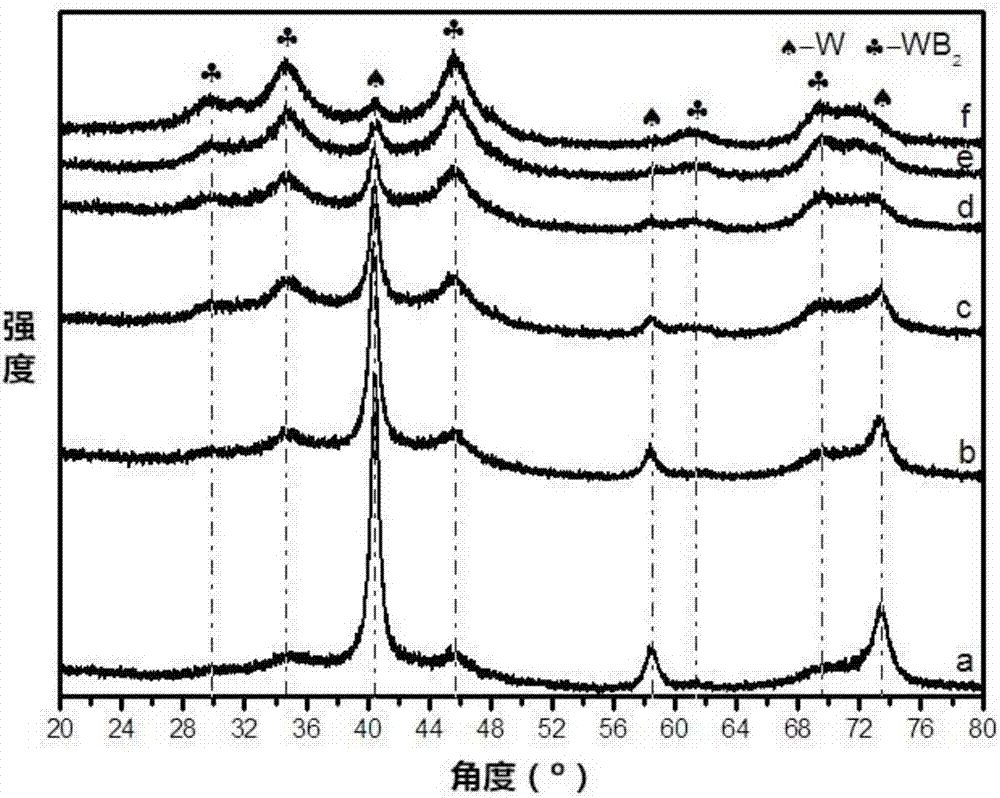

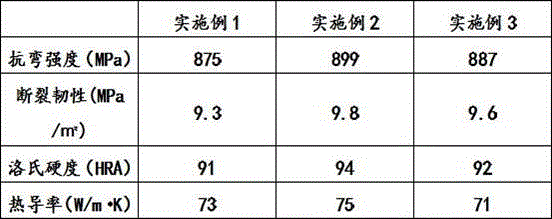

Silicon carbide/tungsten boride composite material and preparation method thereof

The invention relates to the field of ceramic matrix composite materials and specifically relates to a silicon carbide / tungsten boride composite material and a preparation method thereof. The composite material is composed of a ditungsten pentaboride reinforced phase and a silicon carbide matrix, wherein the ditungsten pentaboride reinforced phase is evenly dispersed in the silicon carbide matrix. The preparation method comprises the steps: with tungsten carbide powder, boron carbide powder and silicon powder, or tungsten carbide powder, boron carbide powder, silicon powder, and one or two of silicon carbide powder and ditungsten pentaboride powder as raw materials, mixing by a physical mechanical method for 8-24 hours, and putting the mixture in a graphite mold for cold press molding with the applied pressure ranging from 10MPa to 20MPa, and sintering in a hot-pressing furnace with the protective atmosphere of an inert gas at a temperature rise rate of 1-20 DEG C / minute and at 1600-2000 DEG C for 0.5-3 hours under the sintering pressure ranging of 10-300MPa. The method is capable of preparing the silicon carbide / tungsten boride composite material through in-situ synthesis, and the synthesized silicon carbide / tungsten boride composite material has the optimal properties of hardness of 30GPa, bending strength of 900MPa, breaking tenacity of 6.1MPA.m<1 / 2>, and electrical conductivity of 6*10<5> ohm<-1>m<-1>.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

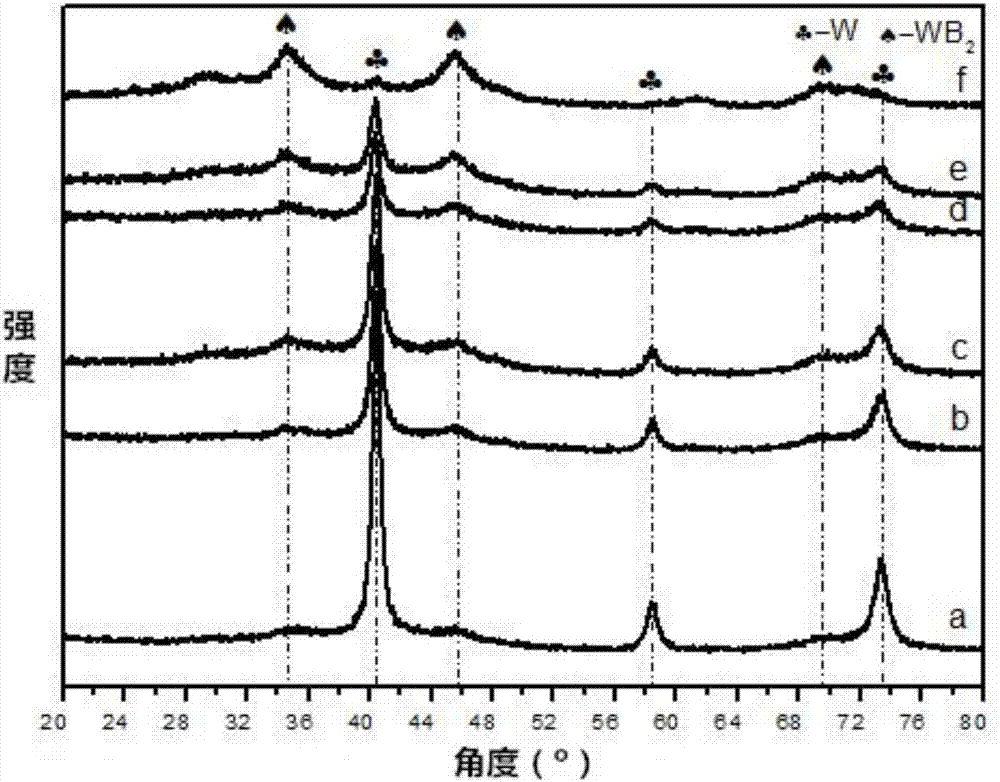

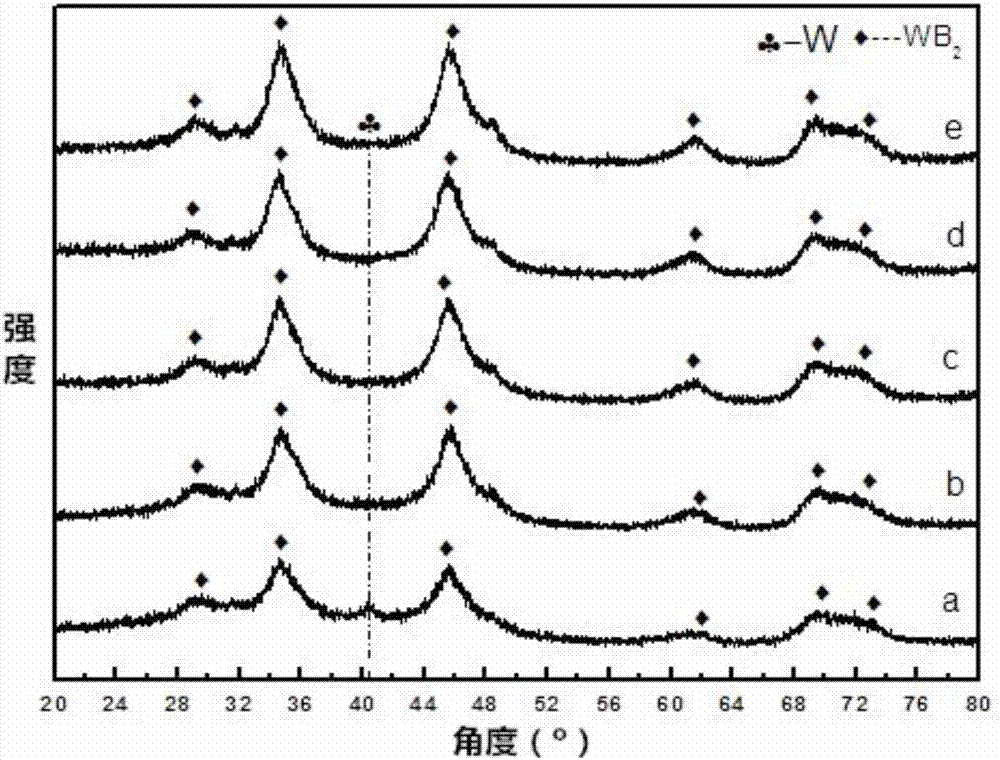

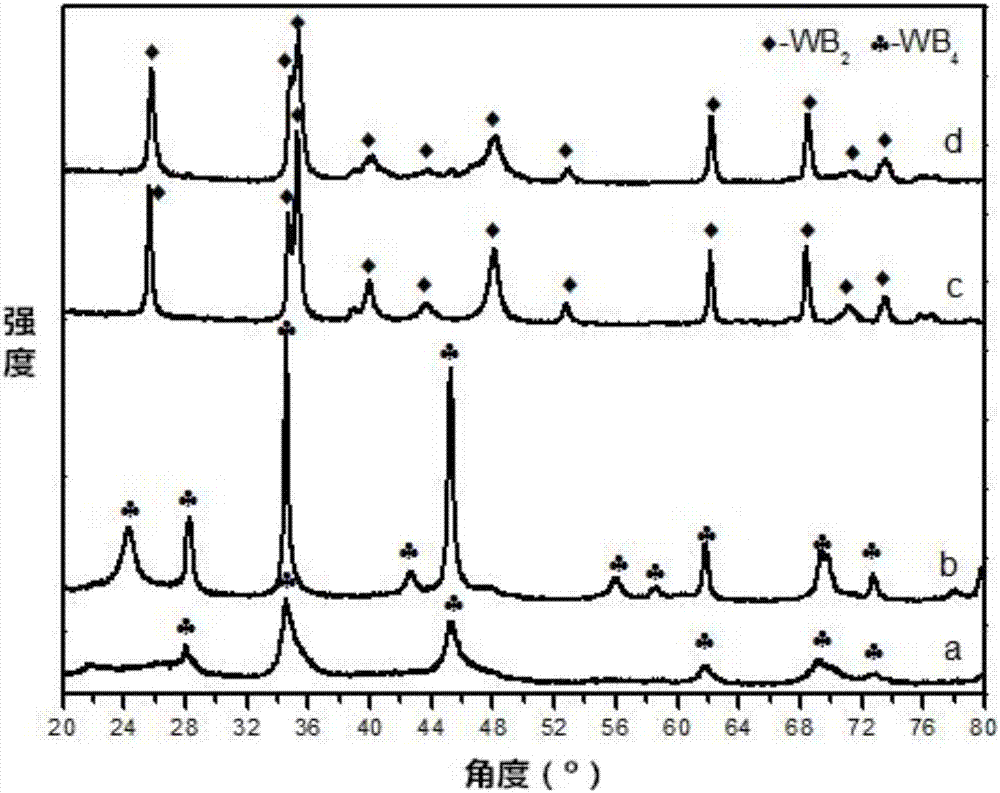

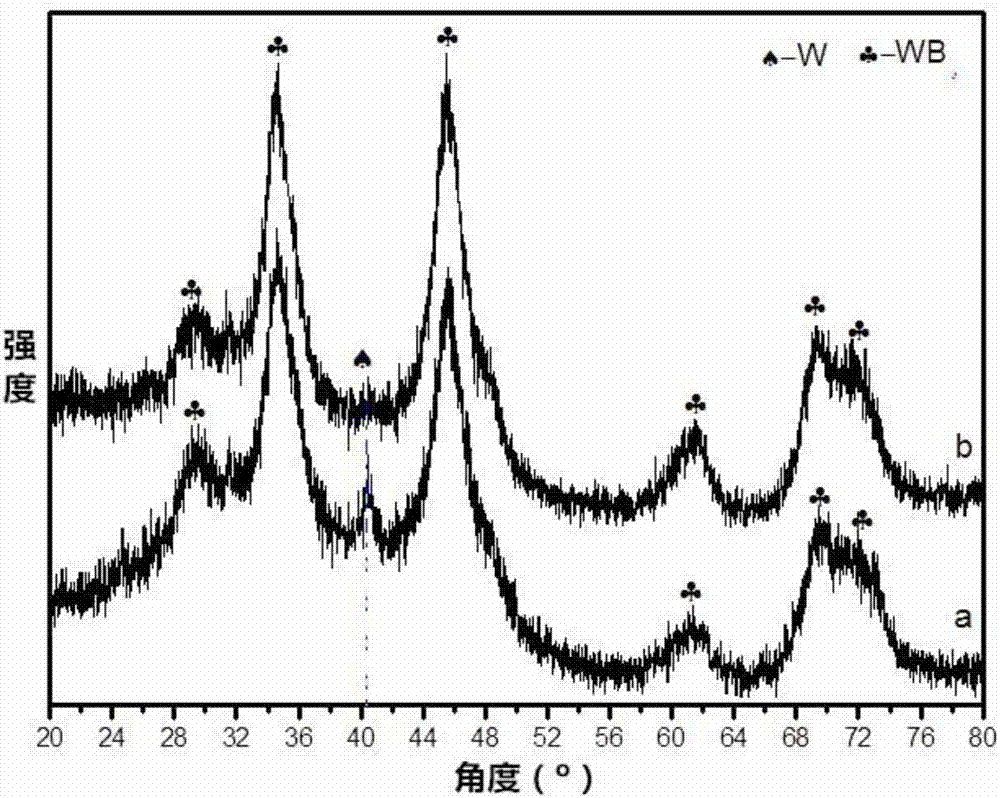

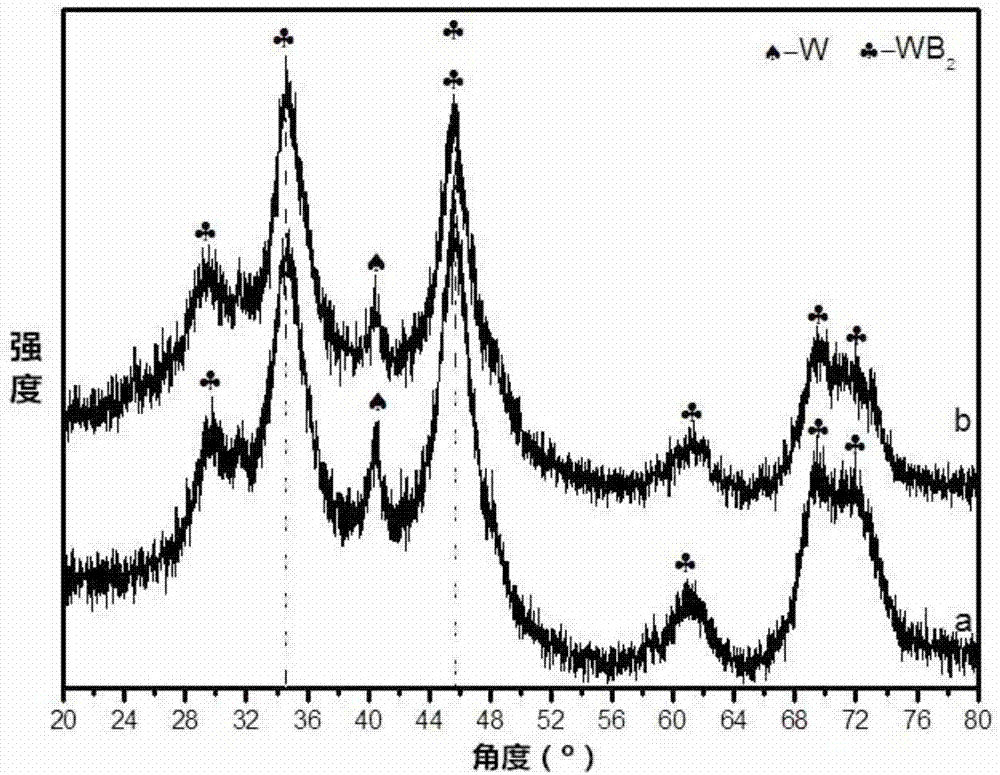

Preparation method of binary tungsten boride superhard material

ActiveCN107473237ASolve the problem that the target product cannot be generatedEasy to manufactureMetal boridesSuperhard materialHigh energy

The invention discloses a preparation method of a binary tungsten boride superhard material, which comprises: by adopting a mechanical alloy method and utilizing high-energy ball milling, in the argon shield atmosphere, using high purity tungsten powder and boron powder as raw materials to directly synthesize tungsten diboride powder in a powder state under room temperature, and then carrying out thermal processing on the synthetic powder to prepare a tungsten tetraboride material. The preparation method disclosed by the invention is simple and convenient in preparation process and high in controllability, adopts atmosphere sintering in the sintering stage, has no other special requirements for equipment, and is high in universality.

Owner:GUANGDONG UNIV OF TECH

Ternary tungsten boride nitride films and methods for forming same

ActiveCN103579184ASemiconductor/solid-state device detailsSolid-state devicesBoron containingNitrogen

Ternary tungsten boride nitride (WBN) thin films and related methods of formation are provided. The films are have excellent thermal stability, tunable resistivity and good adhesion to oxides. Methods of forming the films can involve thermal atomic layer deposition (ALD) processes in which boron-containing, nitrogen-containing and tungsten-containing reactants are sequentially pulsed into a reaction chamber to deposit the WBN films. In some embodiments, the processes include multiple cycles of boron-containing, nitrogen-containing and tungsten-containing reactant pulses, with each cycle including multiple boron-containing pulses.

Owner:LAM RES CORP

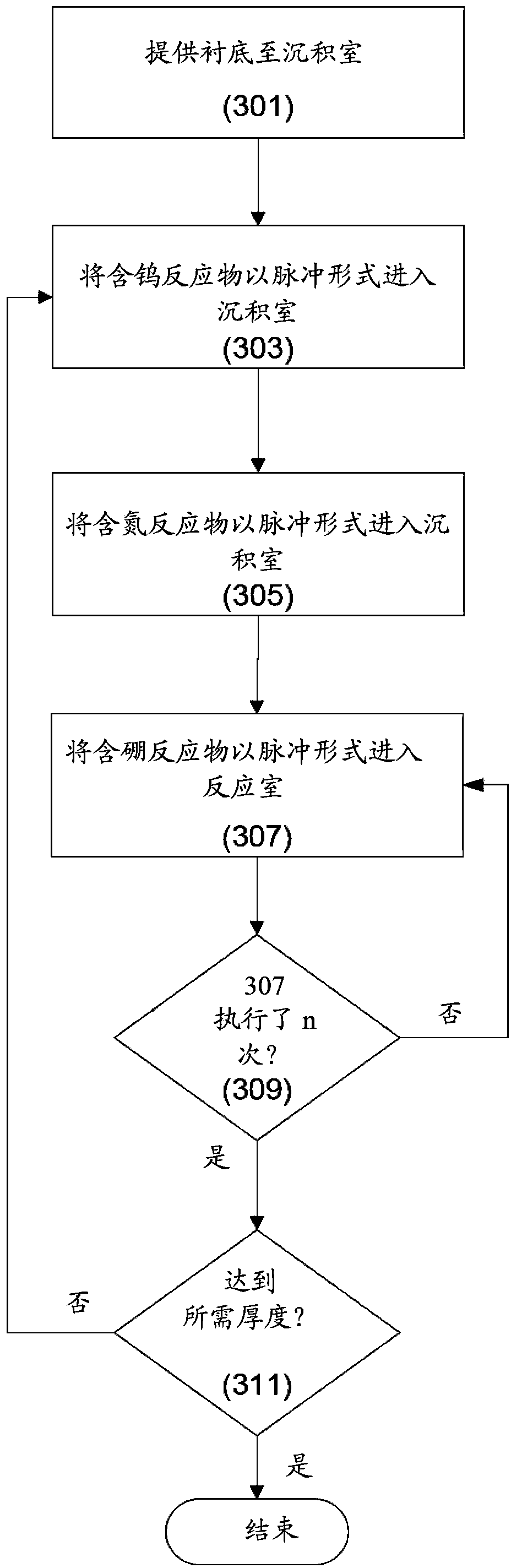

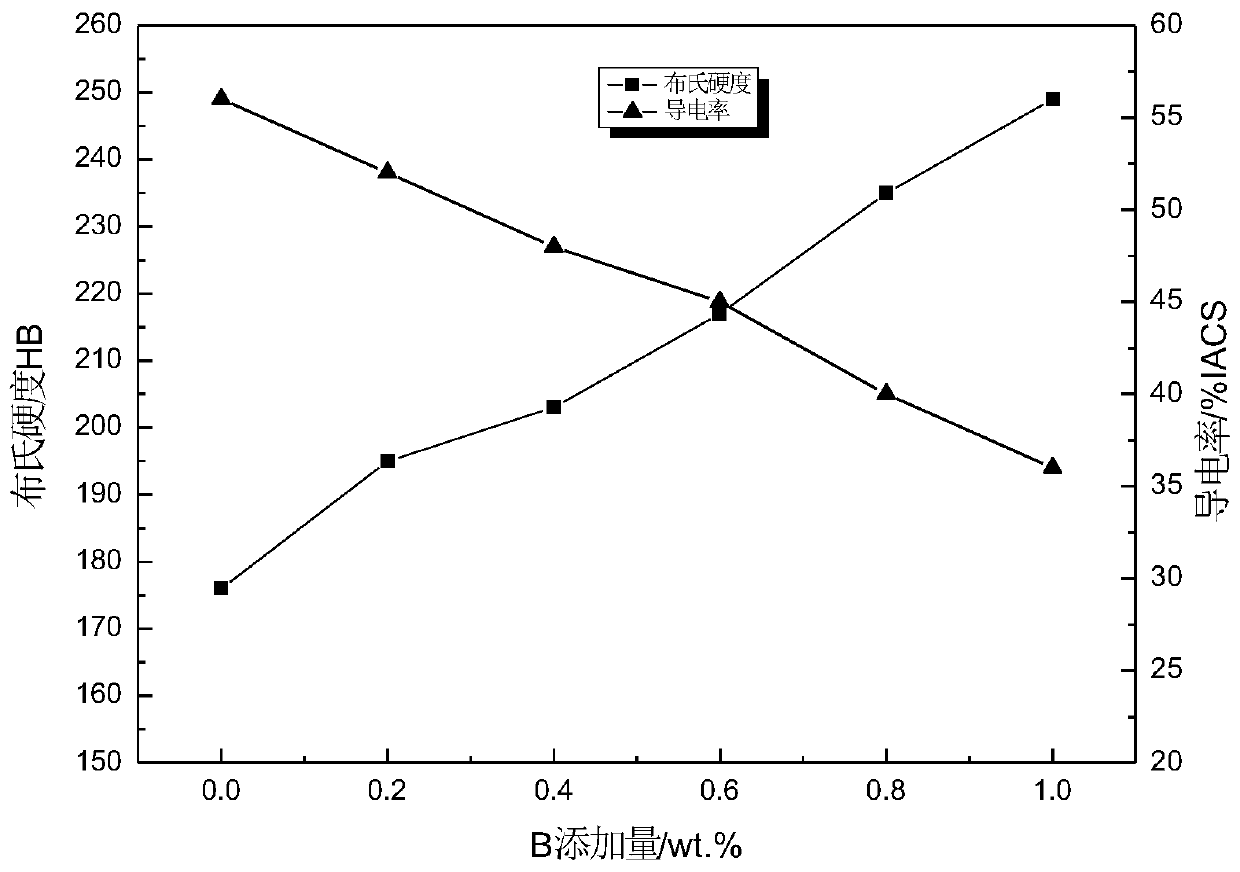

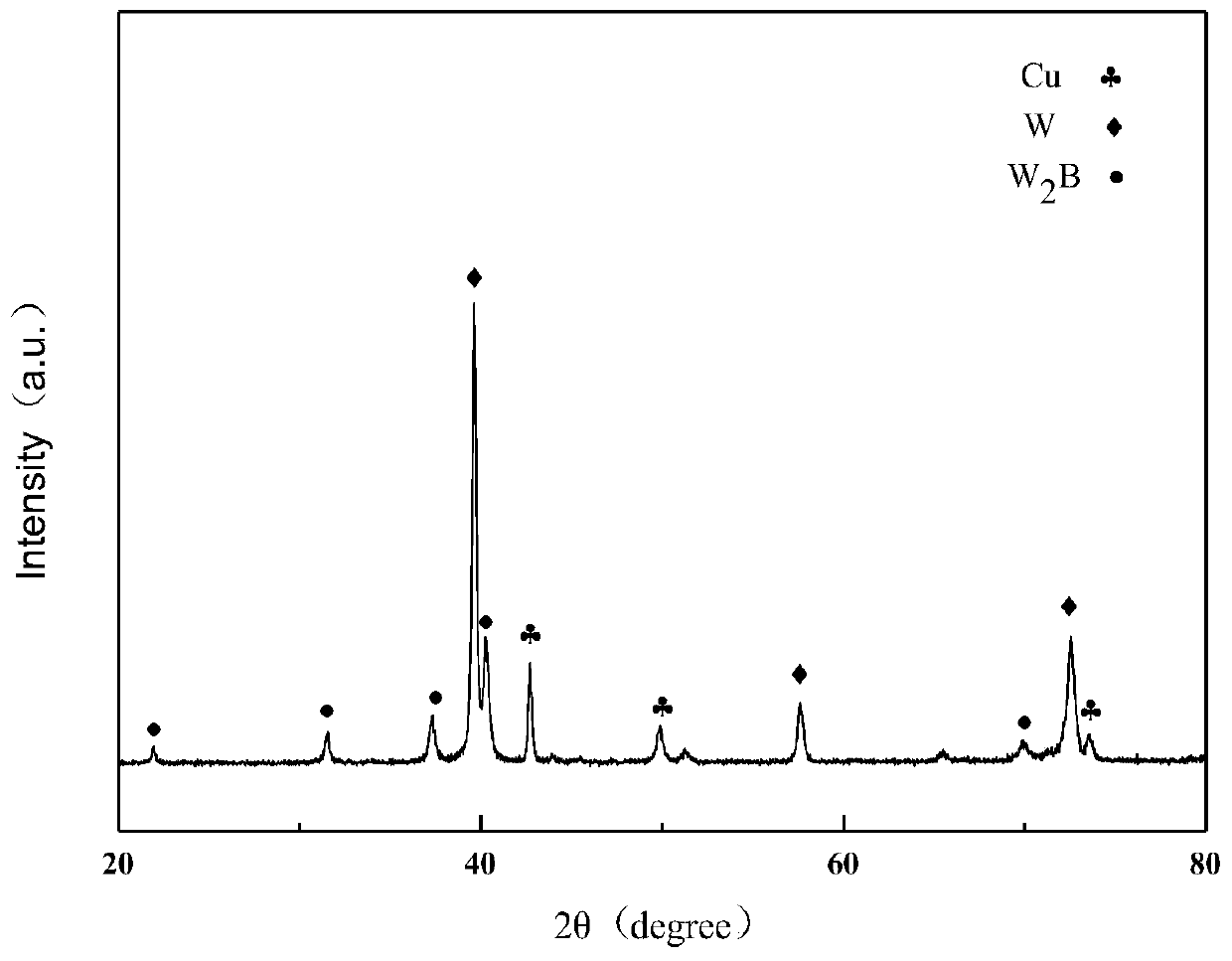

Method for in-situ self-reproducing tungsten boride reinforced CuW alloy

The invention discloses a method for in-situ self-reproducing a tungsten boride reinforced CuW alloy. The method for in-situ self-reproducing the tungsten boride reinforced CuW alloy comprises the steps of uniformly mixing W powder, B powder and induced copper powder, and carrying out compression moulding to obtain a tungsten compression blank; placing the tungsten compression blank into an atmosphere sintering furnace for sintering, and obtaining a tungsten skeleton; and placing a pure copper block above the tungsten skeleton, placing into a graphite crucible paved with graphite paper, carrying out infiltration in the sintering furnace, and obtaining the in-situ self-reproduced tungsten boride reinforced CuW alloy. According to the method for in-situ self-reproducing the tungsten boride reinforced CuW alloy provided by the invention, through adopting a sintering-infiltrating method, a ceramic phase W2B is in-situ generated in a CuW material, and an electric arc is effectively dispersed due to the existence of the low-escape ceramic phase, so that the arc ablation resistance of the CuW contact material is improved; and meanwhile, by adopting the in-situ produced tungsten boride reinforced CuW material, the particular surface pollution of a reinforced phase is avoided.

Owner:XIAN UNIV OF TECH

Ternary tungsten boride nitride films and methods for forming same

ActiveUS9969622B2Improve thermal stabilityGood adhesion to oxidesSemiconductor/solid-state device detailsSolid-state devicesNitrogenBoron containing

Ternary tungsten boride nitride (WBN) thin films and related methods of formation are provided. The films are have excellent thermal stability, tunable resistivity and good adhesion to oxides. Methods of forming the films can involve thermal atomic layer deposition (ALD) processes in which boron-containing, nitrogen-containing and tungsten-containing reactants are sequentially pulsed into a reaction chamber to deposit the WBN films. In some embodiments, the processes include multiple cycles of boron-containing, nitrogen-containing and tungsten-containing reactant pulses, with each cycle including multiple boron-containing pulses.

Owner:LAM RES CORP

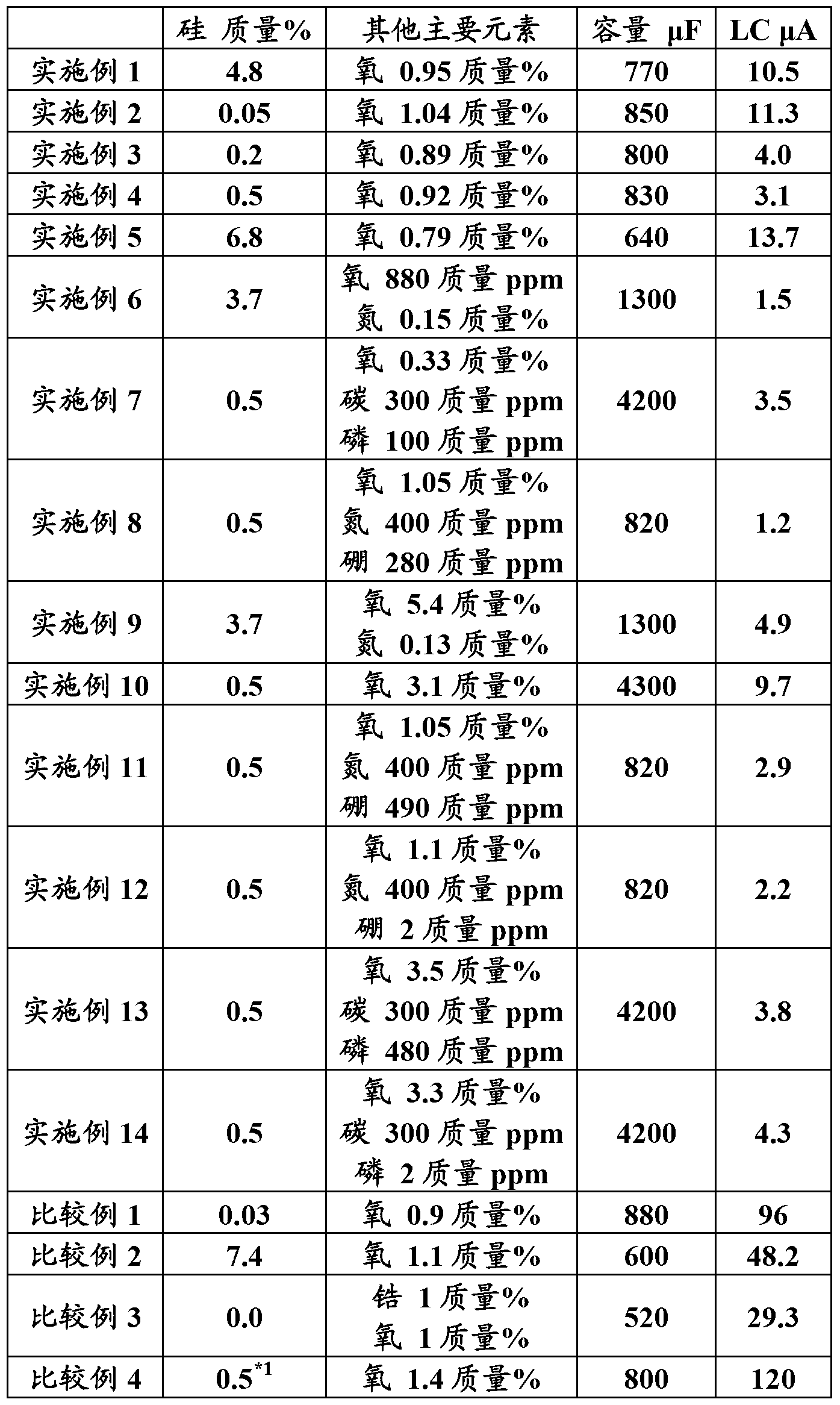

Tungsten powder, positive electrode body for capacitors, and electrolytic capacitor

InactiveCN103269815ALC characteristics are goodElectrolytic capacitorsTransportation and packagingElectrolysisTungsten nitride

The present invention relates to: a tungsten powder which has tungsten silicide (such as W5Si3) on the surfaces of particles and has a silicon content of 0.05-7% by mass; a positive electrode body for capacitors; an electrolytic capacitor; a method for producing a tungsten powder; and a method for producing a positive electrode body for capacitors. The tungsten powder has an average primary particle diameter of 0.1-1 [mu]m, and tungsten silicide is localized within 50 nm from the surface of each particle. The tungsten powder contains at least one of tungsten nitride, tungsten carbide and tungsten boride in a part of the surface of each particle. It is preferable for the tungsten powder that the content of phosphorus element is 1-500 ppm by mass, the oxygen content is 0.05-8% by mass, and the content of elements other than tungsten, silicon, nitrogen, carbon, boron, oxygen and phosphorus is 0.1% by mass or less. It is also preferable that the tungsten granulated powder has an average particle diameter of 50-200 [mu]m and a specific surface area of 0.2-20 m2 / g. According to the present invention, a tungsten capacitor which has good leakage current (LC) performance can be provided.

Owner:SHOWA DENKO KK

Tungsten diboride hard material, preparation method and application thereof

ActiveCN107285329AImprove controllabilityHigh purityTurning toolsMetal boridesDiborideRoom temperature

The invention belongs to an inorganic nonmetal hard material and discloses a preparation method for a tungsten diboride hard material. The method comprises the following steps: adopting a mechanical chemical method for compounding the raw materials including high-purity tungsten (W) powder and boron (B) powder into tungsten diboride powder under room temperature, adopting high-temperature sintering for compacting the compounded powder under the argon shield atmosphere, thereby acquiring a tungsten diboride block material. According to the method, the compact tungsten diboride block material can be acquired in the manner of sintering under the conditions of normal temperature and normal pressure. The tungsten diboride block material prepared according to the invention has a series of excellent properties, such as, certain hardness, high stability and excellent absorbing effect for neutrons. The tungsten diboride material prepared according to the invention has wide application in the fields of corrosion-resisting materials, cutting tools, novel shielding materials, and the like.

Owner:GUANGDONG UNIV OF TECH

Micropore nano-silver active filter core and preparation method thereof

ActiveCN103381318AEfficientHigh temperature resistanceFiltration separationTemperature resistanceSodium sulfate

The invention discloses a micropore nano-silver active filter core and a preparation method thereof, and is characterized in that the micropore nano-silver active filter core is prepared from the following raw materials, in parts by weight: 18-21 parts of polyvinylidene fluoride, 12-14 parts of ethylene-methyl acrylate copolymer (EMA1214AC), 4-6 parts of rosin-polythylene oxide ester, 4-6 parts of ammonium hydrogen carbonate, 1-2 parts of silver nitrate, 20-23 parts of a sepiolite powder, 10-12 parts of a bamboo charcoal powder, 5-8 parts of an ultrafine powder of ABS, 6-8 parts of soybean oil, 3-4 parts of an alum powder, 1-2 parts of tungsten boride, 1-2 parts of sodium sulfate, and 25-35 parts of modified bentonite. The micropore nano-silver active filter core has the functions of sterilization and adsorption, can be recycled, has the outstanding advantages of acid resistance, alkali resistance, salt spray resistance, high purification efficiency, high temperature resistance, low pressure loss, corrosion resistance, and long service life, and can also remove micro-dust in air.

Owner:ANHUI PHOENIX INT CO LTD

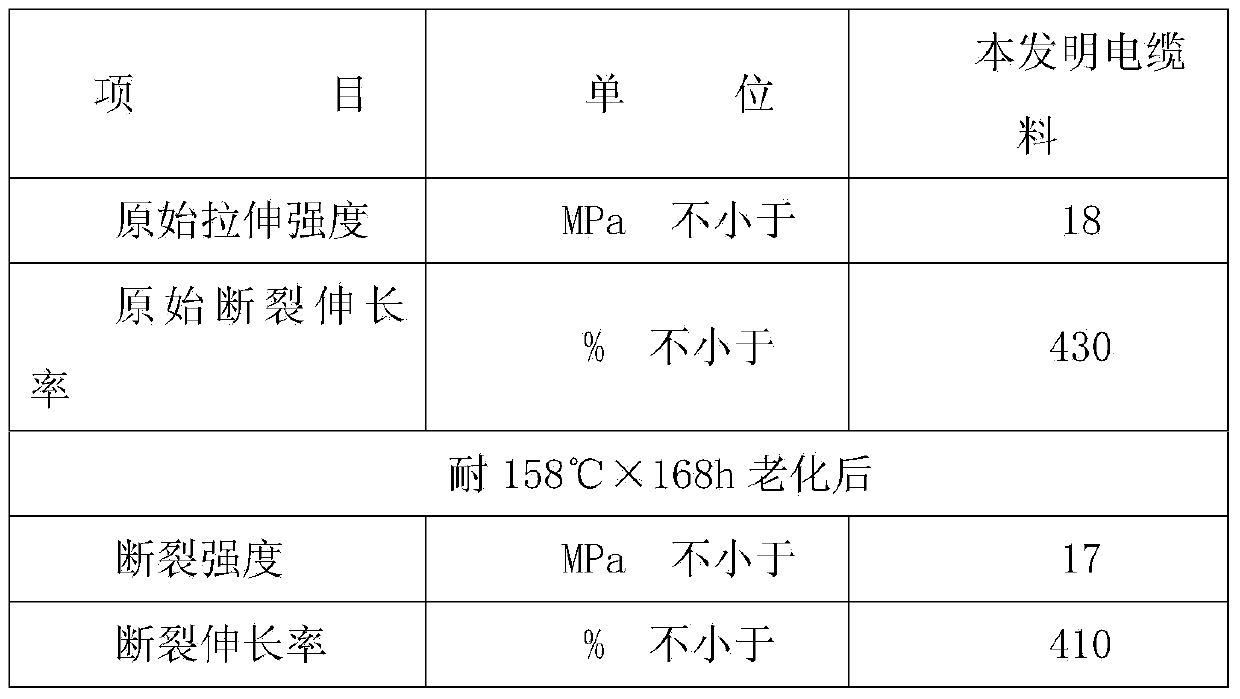

High inflaming retarding polyolefin cable insulating material and preparation method thereof

InactiveCN103724748AHigh tensile strengthImprove heat resistanceInsulated cablesInsulatorsElastomerCross-link

The invention discloses a high inflaming retarding polyolefin cable insulating material which is characterized by comprising the following raw materials in parts by weight: 40-45 parts of polyolefin elastomer resin, 14-18 parts of EVA, 12-15 parts of polyethylene, 10-12 parts of aluminium hydroxide, 2-3 parts of a silane coupling agent KH550, 1-2 parts of a cross-linking agent TAC, 4-6 parts of polyvinyl acetate, 2-3 parts of dibutyltin dilaurate, 2-3 parts of triethoxyvinylsilane, 1-2 parts of isocyanate, 1-2 parts of tungsten boride, 1-2 parts of ricinoleic acid, 16-18 parts of triethyl O-acetylcitrate, 5-8 parts of tributyl citrate and 6-8 parts of an addition agent. The high inflaming retarding polyolefin cable insulating material provided by the invention is high in tensile strength, has better heat resistance and processability, and improves the flame retardant rating. The preparation method of the high inflaming retarding polyolefin cable insulating material is reasonable in design and simple and convenient to operate.

Owner:WUHU JIACHENG ELECTRONICS TECH

Preparation method of tungsten boride powder

The invention provides a preparation method of tungsten boride powder. The method comprises the following steps: dosing, mixing, curing, milling, briquetting, firing and milling. The method is characterized in that tungsten oxide powder, boron carbide powder and B2O3 powder are mixed with phenolic resin, the mixture is cured at 40-100 DEG C to mill, the obtained powder is briquetted and then fired in 1350-2000 DEG C of argon or hydrogen atmosphere for 6-8 hours to prepare tungsten boride blocks, and the blocks are decarbonized and milled to prepare the tungsten boride powder. The method has the characteristics of simple process, high tungsten boride powder purity, good sintering performance of tungsten boride powder and low cost.

Owner:SHANDONG UNIV OF TECH

Modified flexible ozone-resistant polyethylene cable sheath material

InactiveCN103540003AImprove performanceImprove mechanical propertiesInsulated cablesInsulatorsLow-density polyethylenePolyester

The invention relates to a cable material, and in particular relates to a modified flexible ozone-resistant polyethylene cable sheath material. The cable sheath material is prepared from the following raw materials in parts by weight: 28 to 32 parts of low-density polyethylene, 18 to 23 parts of ethylene-vinyl acetate copolymer (EVA), 3 to 5 parts of ACR (Acrylate) impact modifier, 2 to 3 parts of tungsten boride, 4 to 6 parts of aluminum nitride, 1 to 2 parts of ricinoleic acid, 12 to 15 parts of talcum powder, 8 to 12 parts of bentonite powder, 15 to 17 parts of diisononyl phthalate, 15 to 18 parts of propanediol sebacate polyester, 10 to 12 parts of sodium fluosilicate, 4 to 6 parts of barium sulfate, 1 to 2 parts of phenol and 14 to 16 parts of auxiliary agent. The prepared cable sheath material is firm and flexible, and has the performance of aging resistance, ozone resistance, tearing resistance and chemical solvent resistance by combining the advantages of the low-density polyethylene, the ethylene-vinyl acetate copolymer (EVA) and the other raw materials. Thus, the prepared cable sheath material is safe and reliable to use. Therefore, the cable sheath material can be widely used for preparing various cable sheath insulating materials. The cable sheath material provided by the invention has broad market demand prospect.

Owner:LVBAO CABLE GROUP

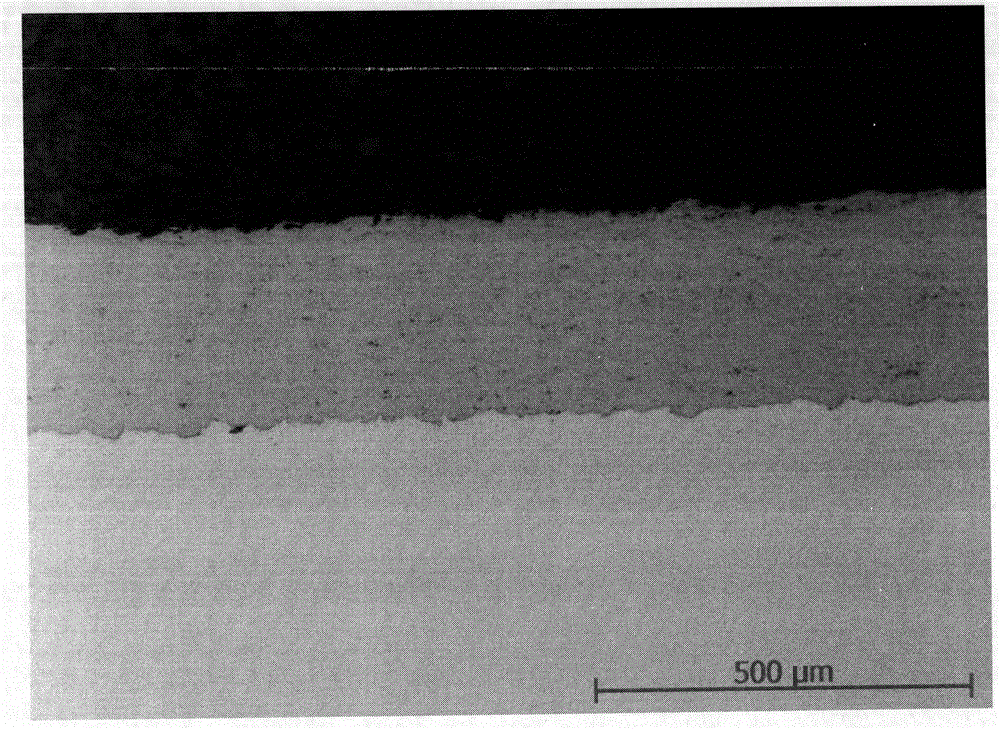

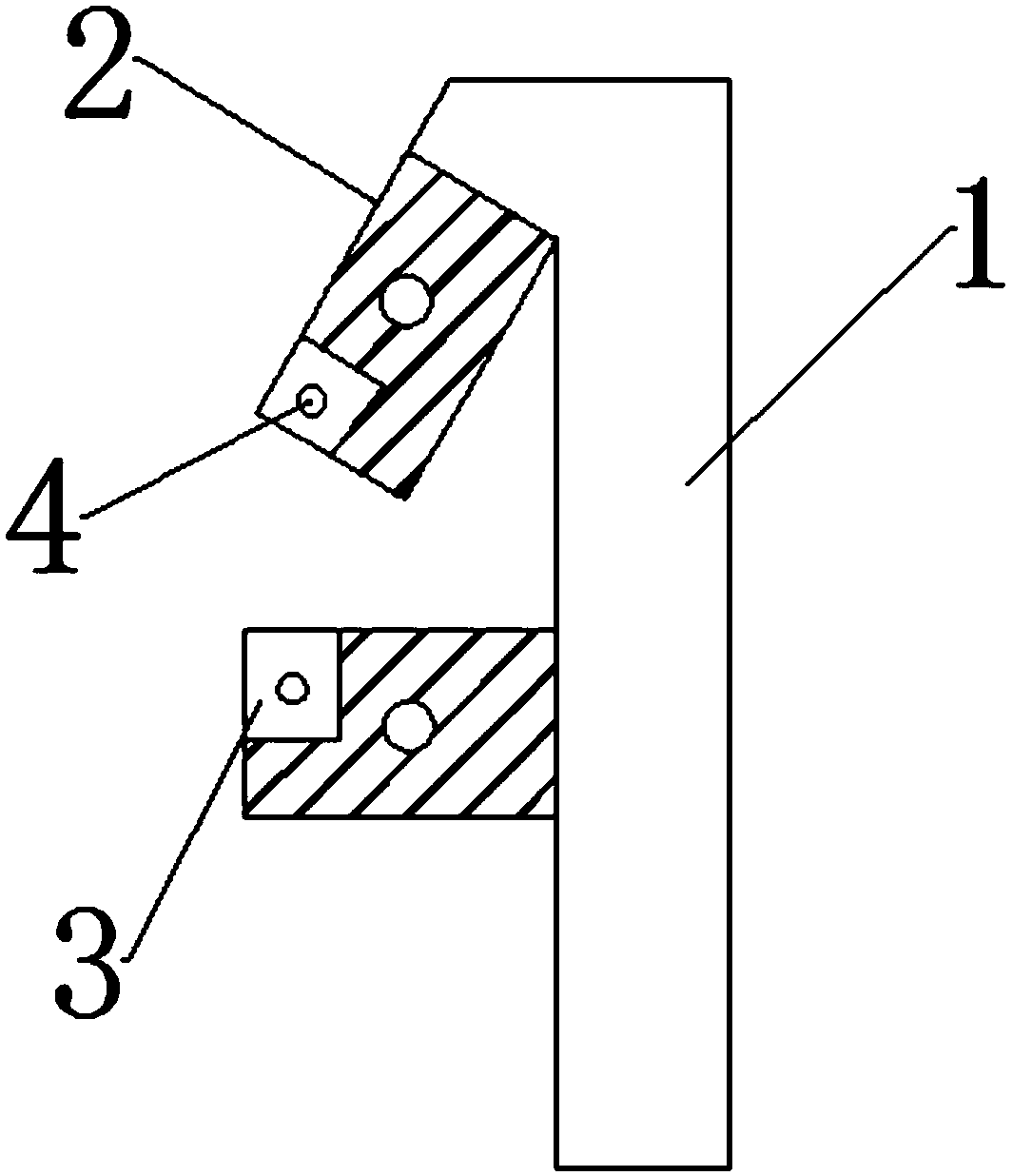

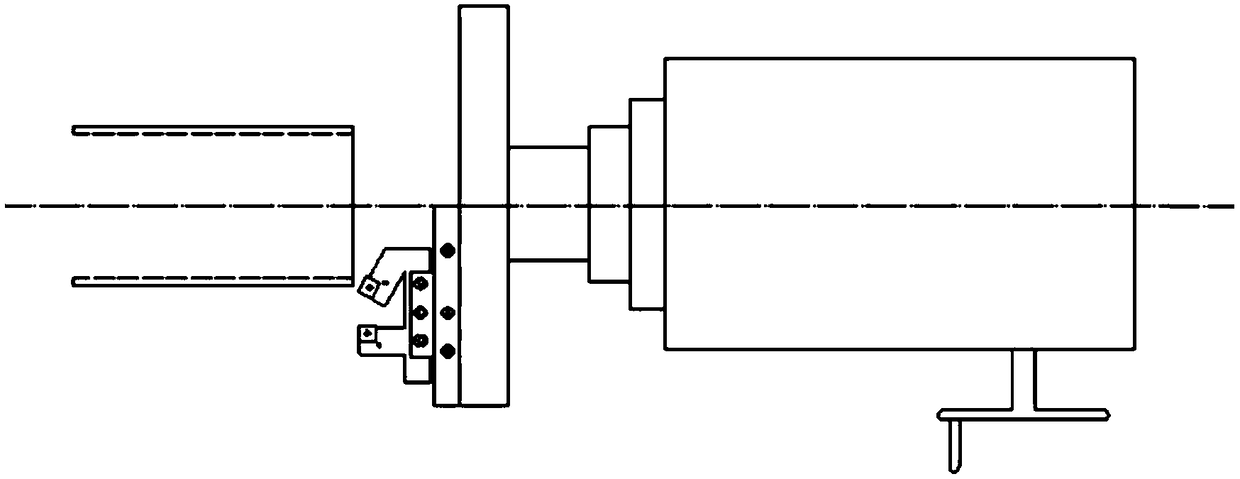

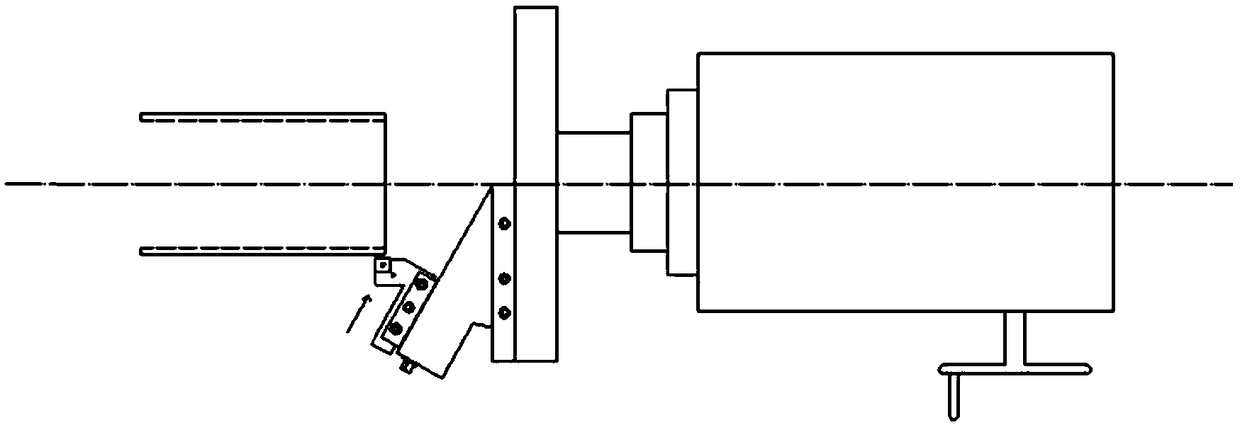

Preparing method and application of tungsten boride thermal spraying coating material

InactiveCN105463283AWide range of usesHigh hardnessMolten spray coatingApparent densityThermal spraying

The invention discloses a preparing method and application of a tungsten boride thermal spraying coating material, and relates to the technical field of materials. According to the preparing method and application, due to the adding manner of tungsten boride, the mobility and the apparent density of thermal spraying powder are improved, and the hardness, the abrasive resistance, the corrosion resistance and the basal-body bonding strength of a coating are greatly improved; HV0.3 is larger than or equal to 1,350; and compared with a conventional thermal spraying material, the overall performance is obviously improved, and the produced tungsten boride thermal spraying coating material has the wider application range and the higher market competitiveness. The preparing method and application are safe and reliable in application and particularly suitable for various coating materials.

Owner:LUOYANG GOLDEN EGRET GEOTOOLS

Chinese herbal medicine modified isotatic polypropylene non-woven fabric and preparation method thereof

InactiveCN103753875AHeat resistantImprove adhesionSynthetic resin layered productsNon-woven fabricsBitter gourdEngineering

A Chinese herbal medicine modified isotatic polypropylene non-woven fabric comprises a top surface layer, a back surface layer and a cellucotton fiber layer clamped between the top surface layer and the back surface layer, the top surface layer and the back surface layer use a non-woven fabric material, the non-woven fabric is made from the following raw materials in part by weight by a melt-blowing method: 100 parts of isotactic polypropylene, 2-3 parts of tungsten boride, 1-2 parts of sodium fluosilicate, 0.5-1 part of uvioresistant agent UV-531, 1-2 parts of crosslinking agent TAIC, 12-15 parts of dioctyl terephthalate, 2-3parts of antioxidant 1035, 12-15 parts of coconut shell, 4-5 parts of montmorillonite powder, 1-2 parts of uncaria rhynchophylla, 2-3 parts of bitter gourd vine, 2-3 parts of mother chrysanthemum, 1-2parts of prunella vulgaris, and 4-5 parts of an auxiliary. The non-woven fabric has the characteristic of being heat resistant, corrosion resistant, non-toxic and odorless, is high in tensile strength, good in bonding, and free of dust and debris production, has a fragrant odor and antibacterial effect, can absorb harmful gases and peculiar smell, and has uvioresistant as well as antioxidant effects.

Owner:芜湖跃飞新型吸音材料股份有限公司

Hard alloy material for preparing bevelling machine special cutter and preparation method thereof

InactiveCN109321797AHigh hardnessImprove wear resistanceChemical vapor deposition coatingManganeseTitanium carbonitride

The invention discloses a hard alloy material for preparing a bevelling machine special cutter. The hard alloy material is composed of a hard alloy matrix and a coating; the hard alloy matrix is composed of, by mass, 80%-85% of a hard phase, 5%-10% of a bonding phase, 3%-5% of an inhibiting phase and 2%-5% of a hardening phase; the hard phase is composed of, by mass, 65%-71% of tungsten carbide, 22%-28% of titanium carbide and 3%-7% of tungsten boride; the bonding phase is composed of, by mass, 62%-71% of cobalt, 15%-21% of hydroxy nickel powder, 10%-13% of manganese, 3%-5% of hydroxy iron powder and 1%-2% of tungsten powder; the inhibiting phase is composed of, by mass, 80%-87% of vinylene carbonate, 5%-8% of titanium dioxide, 3%-6% of niobium carbide, 3%-6% of tantalum carbide, 1%-3% ofchromium carbide and 0.5%-2% of vanadium carbide; and the hardening phase is composed of, by mass, 51%-60% of zirconium carbide, 25%-42% of green silicon carbide, 4%-9% of yttrium oxide and 3%-7% of zirconium dioxide; and the coating is a titanium nitride-titanium carbonitride-aluminum oxide composite coating.

Owner:CHENGXI SHIPYARD

Corrosion-resistant milling cutter

The invention discloses a corrosion-resistant milling cutter. The corrosion-resistant milling cutter is characterized by being made of a steel bond hard alloy, wherein the steel bond hard alloy powder comprises a hard phase and a steel-based binder. According to the milling cutter disclosed by the invention, the hard phase consists of tungsten boride, silicon carbide, nickel oxide, cerium oxide and Cr, so that the mechanical property of the material is improved; and the components of the steel-based binder have relatively high strength, so that the strength of the steel bond hard alloy is further improved under the action of the hard phase.

Owner:刘辉

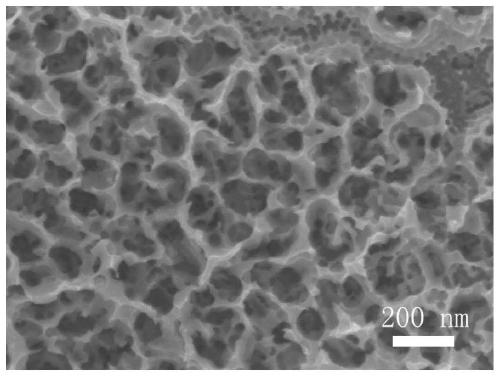

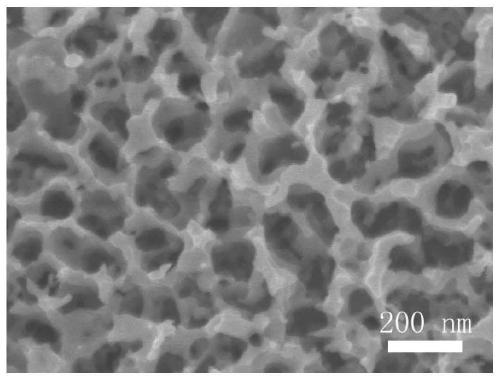

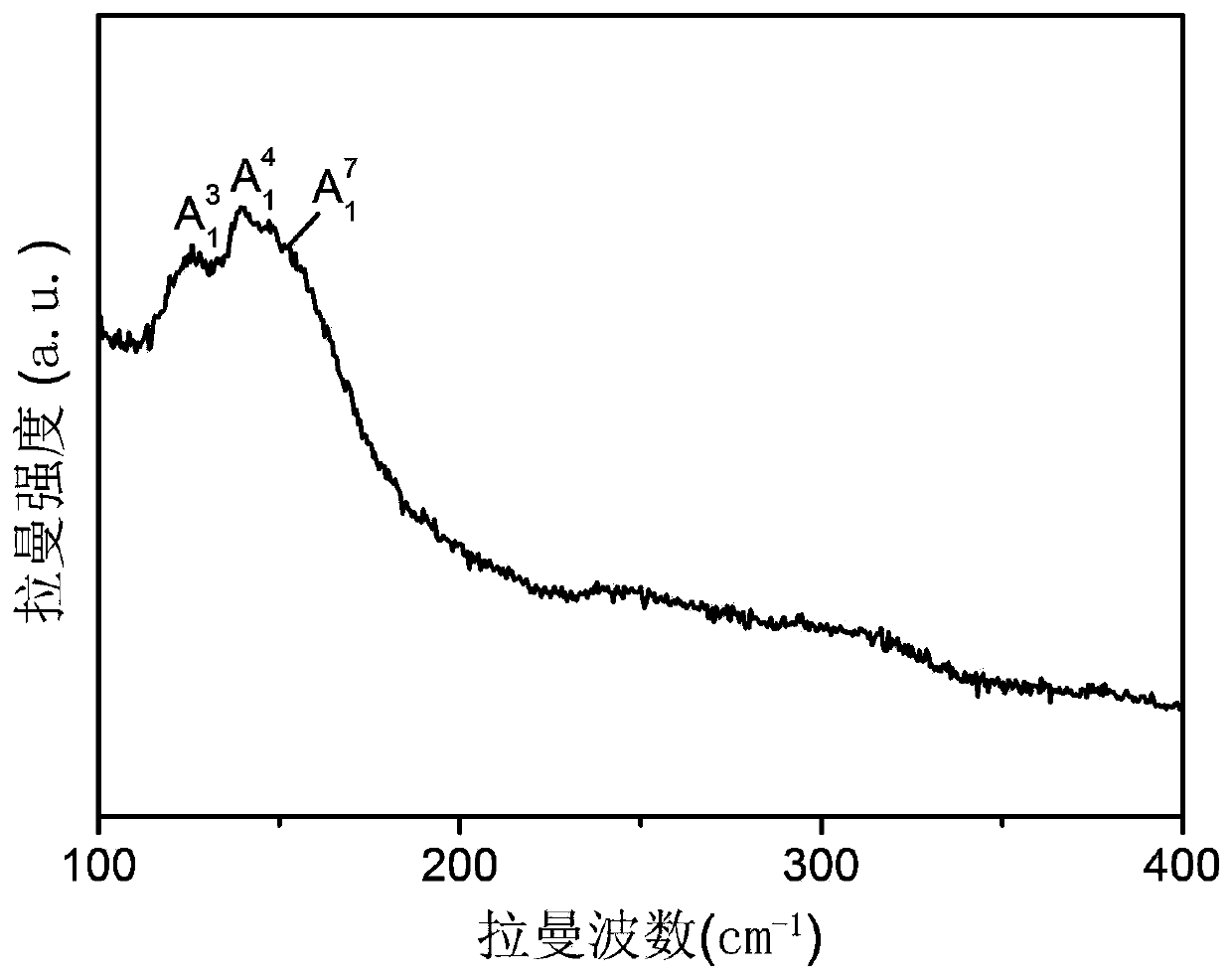

Tungsten telluride-tungsten boride heterojunction electrocatalyst and preparation method and application thereof

ActiveCN111437841AUniversalThe synthesis process is simplePhysical/chemical process catalystsElectrodesHeterojunctionPtru catalyst

The invention relates to a tungsten telluride-tungsten boride heterojunction electrocatalyst and a preparation method and application thereof, and aims to provide a porous tungsten telluride and tungsten boride heterojunction porous thin film material as a novel electrocatalyst so as to obtain stronger moisture desorption hydrogen electrocatalytic performance. The technical scheme is as follows: the method comprises the following steps that: the tungsten telluride-tungsten boride heterojunction electrocatalyst is a tungsten telluride and tungsten boride two-phase heterojunction nano-porous film which is prepared by taking an anodized tungsten foil as a template and a tungsten source, tellurium powder is taken as a tellurium source and boron-oxygen mixture powder is taken as a solid boron source through adoption a two-step chemical vapor deposition method in sequence. The tungsten telluride-tungsten boride heterojunction electrocatalyst has the excellent hydrogen evolution electrochemical reduction performance, electrons in tungsten telluride are transferred to tungsten boride through the heterostructure, the local electronic structure of the tungsten telluride and tungsten boride interface is optimized, the hydrogen adsorption energy of the tungsten telluride-tungsten boride heterojunction electrocatalyst is improved, the catalytic activity of the tungsten telluride-tungsten boride heterojunction electrocatalyst is enhanced, and the hydrogen evolution performance is highly stable.

Owner:SHANXI UNIV

High-bending-strength porous silicon carbide ceramic and preparation method thereof

The invention discloses a high-bending-strength porous silicon carbide ceramic which is prepared from the following raw materials in parts by weight: 45-52 parts of silicon carbide fine powder with the particle size of 80-120 mu m, 36-40 parts of silicon carbide medium powder with the particle size of 120-160 mu m, 15-18 parts of silicon carbide coarse powder with the particle size of 160-200 mu m, 12-16 parts of tantalum nitride powder, 8-14 parts of tungsten boride powder, 9-12 parts of activated carbon powder, 5-8 parts of epoxy resin and 4-6 parts of tungsten powder. The invention also discloses a preparation method of the high-bending-strength porous silicon carbide ceramic. On the premise of ensuring the porosity of 47.3% or above, the bending strength of the high-bending-strength porous silicon carbide ceramic reaches 92.8-108.6 MPa, thereby greatly enhancing the bending strength of the porous silicon carbide ceramic. Various devices prepared from the high-bending-strength porous silicon carbide ceramic have the advantages of high durability and long service life, thereby lowering the use cost.

Owner:梁小利

Flame-retardant fire-resistant power cable material and preparation method thereof

InactiveCN105754352AStrong fire resistanceHigh strengthRubber insulatorsInsulated cablesGlycerolFire resistance

The invention discloses a flame-retardant fire-resistant power cable material which is prepared from the following raw materials in parts by weight: 65-73 parts of methyl vinyl rubber, 38-44 parts of a maleic anhydride grafted ethylene-acetic ether copolymer, 26-30 parts of chloroprene rubber, 10-15 parts of fumed silica, 12-16 parts of mica powder, 28-33 parts of glass fiber, 15-19 parts of kaolin, 1-4 parts of ferrocene, 23-26 parts of melamine, 3-6 parts of an anti-aging agent ODA, 10-25 parts of an antioxidant 1010, 4-7 parts of 1-stearoyl-rac-glycerol, 0.2-0.5 part of chloroplatinic acid, 3-6 parts of calcium stearate, 2-4 parts of tetra-n-butyl titanate, 3-6 parts of tantalum oxide, 5-8 parts of tungsten boride and 5-9 parts of zinc borate. The invention further provides a preparation method of the flame-retardant fire-resistant power cable material. The flame-retardant fire-resistant power cable material disclosed by the invention is high in strength and very good in fire resistance, and increasingly improved requirements of the market on properties of fire-resistant power cables can be met.

Owner:王维娜

High wear resistant ceramic tool material and preparation method thereof

The invention discloses a high abrasion resistant ceramic tool material and a preparation method thereof, and the high abrasion resistant ceramic tool material is mainly prepared from silicon oxide, waste glass scraps, serpentine tailings, blast furnace slag, copper oxide, steel slag micro powder, tungsten boride, nano diamond, aluminum oxide, yttrium oxide, potassium magnesium titanate lamellas, glycerol, phenolic resin emulsion, polyvinyl alcohol, propylene glycol alginate (PGA), titanium dioxide, baddeleyite, garnet, bauxite, iron sulfide and other raw materials. By calcinations of the bauxite, serpentine tailings and other raw materials, high strength, high hardness, room temperature and high temperature friction increasing effects are fully played, by mutual cooperation of the baddeleyite, the garnet, the potassium magnesium titanate lamellas and other raw materials, friction coefficient stabilization is facilitated, wear resistance of the material is enhanced, abrasion is reduced, the titanium dioxide plays the role of increasing toughness and enhancing anti shearing ability, and the high abrasion resistant ceramic tool material has good overall abrasion resistance, high strength and long service life.

Owner:佛山市东方智柏纳米材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com