Silicon carbide/tungsten boride composite material and preparation method thereof

A technology of composite materials and silicon carbide, which is applied in the field of ceramic matrix composite materials, can solve the problems that the advantages of silicon carbide and tungsten boride cannot be fully utilized, the synthesis of single-phase tungsten boride is difficult, and the single-phase silicon carbide is difficult to densify. Achieve high strength, good conductivity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the silicon carbide / tungsten boride composite material adopts tungsten carbide WC powder, boron carbide B 4 C powder and silicon Si powder, or tungsten carbide WC powder, boron carbide B 4 C powder, silicon Si powder and silicon carbide SiC powder, tungsten diboron five W 2 B 5 One or two kinds of powder are raw materials, of which WC: B 4 C: The molar ratio of Si is 8:5:13; the raw material powder is mixed by physical and mechanical methods for 8-24 hours, put into graphite mold and cold-pressed, the applied pressure is 10-20MPa, and the time is 5-20 minutes; Sintering in a hot press furnace with an inert gas protective atmosphere, the heating rate is 1-20°C / min, the sintering temperature is 1600-2000°C, the sintering time is 0.5-3 hours, and the sintering pressure is 10-300MPa. The chemical reaction of raw material powder in situ hot pressing is as follows:

[0025] 8WC+5B 4 C+13Si→13SiC+4W 2 B 5 .

[0026] Among them, the particle si...

Embodiment 1

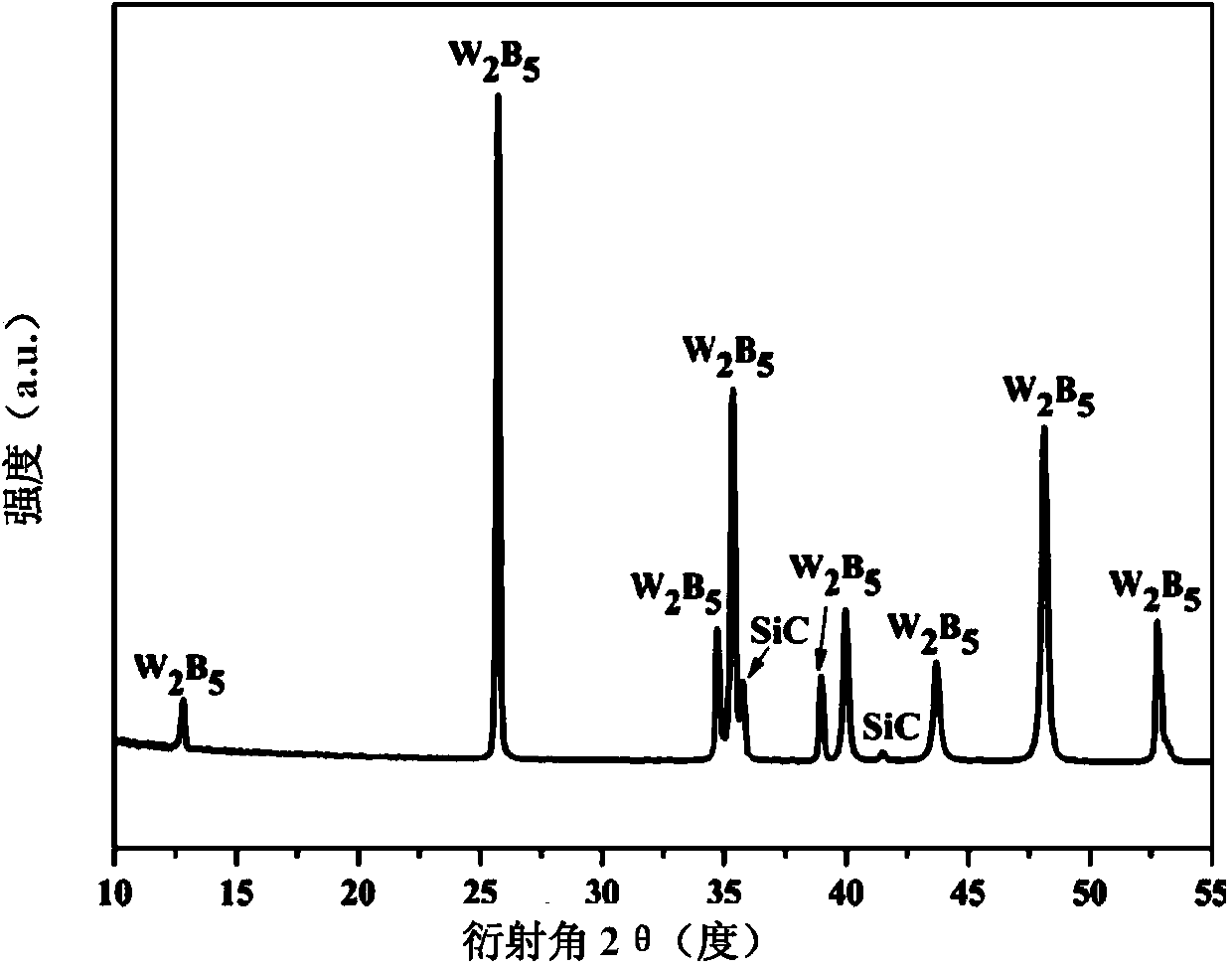

[0033] 35.5 grams of tungsten carbide powder with a particle size of 0.5 microns, 6.2 grams of boron carbide powder with a particle size of 0.5 microns, and 8.3 grams of silicon powder with a particle size of 200 mesh were ball-milled in a polyurethane ball mill tank for 24 hours, and then cold-pressed into a graphite mold for molding. The pressure is 20MPa; then, hot isostatic pressing is carried out at a heating rate of 20°C / min, heated to 1600°C and kept for 3 hours, while the pressure is gradually increased to 300MPa. The whole sintering process is carried out under the protection of argon. The obtained reaction product was subjected to XRD analysis, and it can be found that the prepared composite material is only composed of SiC and W 2 B 5 Composed of two phases, the molar ratio of silicon carbide to tungsten diboron five in the composite material is 13:4, and the grain size of silicon carbide is 1 micron. Lath-like W in the prepared composite 2 B 5 The grains are mo...

Embodiment 2

[0035] 35.5 grams of tungsten carbide powder with a particle size of 2 microns, 6.2 grams of boron carbide powder with a particle size of 5 microns, and 8.3 grams of silicon powder with a particle size of 300 mesh were ball milled in a polyurethane ball mill tank for 24 hours, and then cold-pressed into a graphite mold for molding. The pressure is 20MPa; then, put it into a hot-press furnace for hot-press sintering, the heating rate is 10°C / min, heat to 1900°C for 1 hour, and at the same time, gradually increase the pressure to 40MPa. The whole sintering process is carried out under the protection of argon (or helium). The obtained reaction product is carried out XRD analysis (see figure 1 ), it can be found that the prepared composite is only composed of SiC and W 2 B 5 Two-phase composition. The molar ratio of silicon carbide to tungsten diboron five in the composite material is 13:4, and the grain size of silicon carbide is 2 microns. Lath-like W in the prepared composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com