Preparation method of binary tungsten boride superhard material

A technology of superhard materials and borides, applied in the direction of boron/borides, metal borides, etc., can solve problems such as difficult to obtain, vacuum degree and cooling speed affect product quality, boron volatilization, etc., to achieve simple control and preparation process Simple, Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

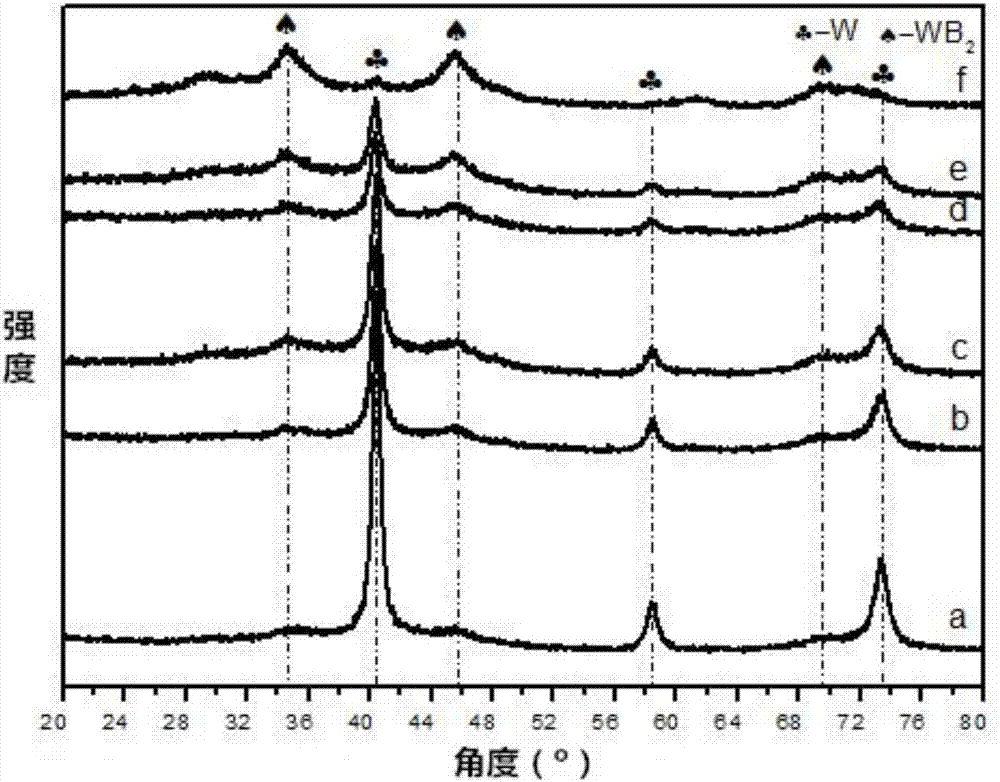

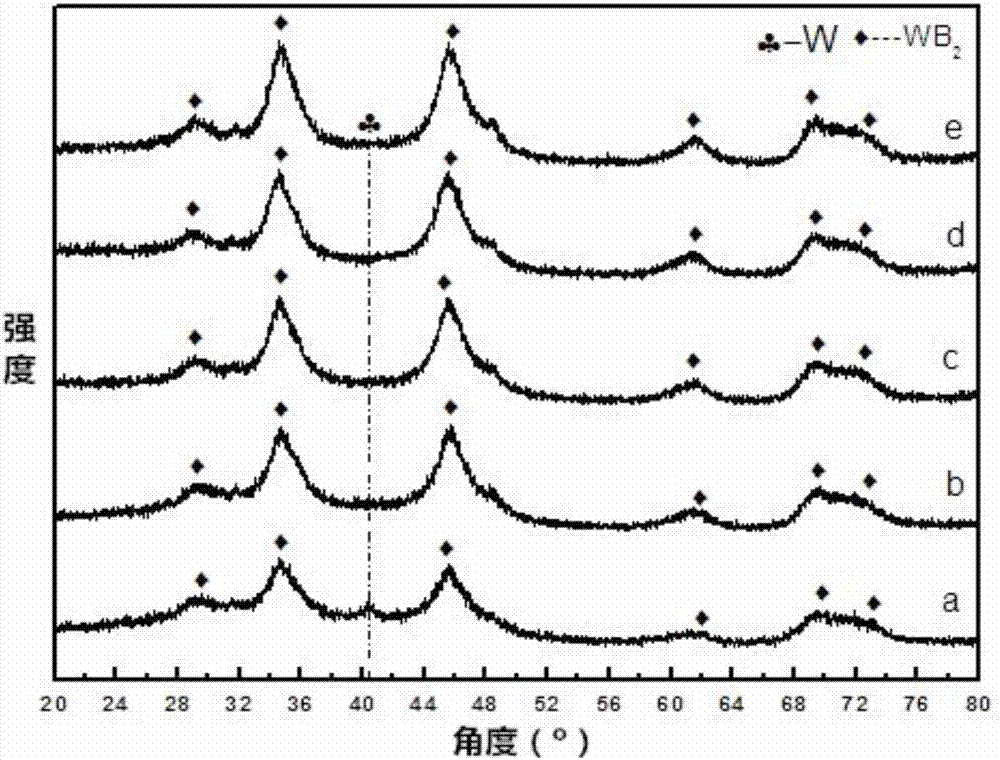

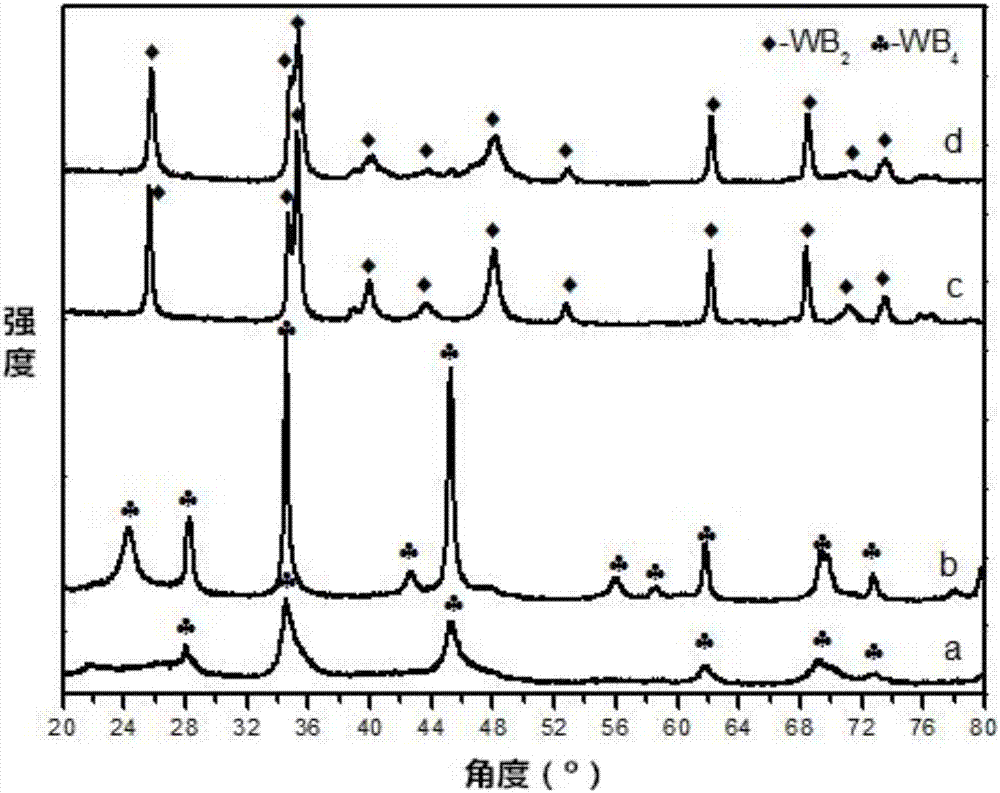

Embodiment 1

[0035] (1) Use a high-energy ball mill for ball milling. In a glove box filled with argon, mix high-purity tungsten powder (W) and boron powder (B) at a stoichiometric ratio of 1:5, and add six tungsten carbide balls. , the size is 11.20mm, the mass ratio of the ball to the mixed powder is 4:1.

[0036] (2) Fix the tungsten carbide ball mill tank with powder and balls on the high energy ball mill. Stop the ball mill for 20 minutes every 1 hour (to prevent the engine from overheating), and obtain tungsten diboride powder.

[0037] (3) The ball milling time is 20h.

Embodiment 2

[0039] The difference from Example 1 is that the ball milling time is 24h, and the others are the same as Example 1.

Embodiment 3

[0041] The difference from Example 1 is that the ball milling time is 28h, and the others are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com