Preparing method and application of tungsten boride thermal spraying coating material

A coating material and thermal spraying technology, applied in the field of materials, can solve problems such as undiscovered composite thermal spraying materials, achieve the effects of increasing hardness, safe and reliable application, and improving bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Attached Figure 1~2 , The preparation method of a tungsten boride series thermal spray coating material according to the present invention, the preparation method specifically includes the following steps:

[0027] The first step ingredients:

[0028] The adding ratio of WC powder is 30%~80%, WB n The addition ratio of powder is 10%-45%, and the addition ratio of metal powder M is 5%-30%;

[0029] The amount of binder added is WC powder, WB n 0.5 to 6.0% of the total mass of powder and metal powder M, and the solid-to-liquid ratio (the ratio of the mass of solid raw materials to the mass of liquid deionized water or alcohol) is controlled between 2.75 and 3.25;

[0030] The second step wet grinding and spraying:

[0031] Following the previous step, place the prepared materials in a ball milling tank, use deionized water or alcohol as the ball milling medium, control the ball-to-material ratio in the range of 2:1-8:1, and control the milling time between 12h and 72h , After th...

example 1

[0039] (1) Ingredients: the addition rate of WC powder is 60%, the addition rate of WB powder is 30%, and the addition rate of metal powder Co is 10%;

[0040] (2) Wet milling and spraying: Place the prepared materials in a ball milling tank, use deionized water as the ball milling medium, and after a certain period of ball milling time, the slurry is granulated by spray drying tower;

[0041] (3) Sintering: place the spray-dried powder in a graphite crucible, sinter it at an appropriate sintering temperature, and take it out after keeping it warm for a period of time;

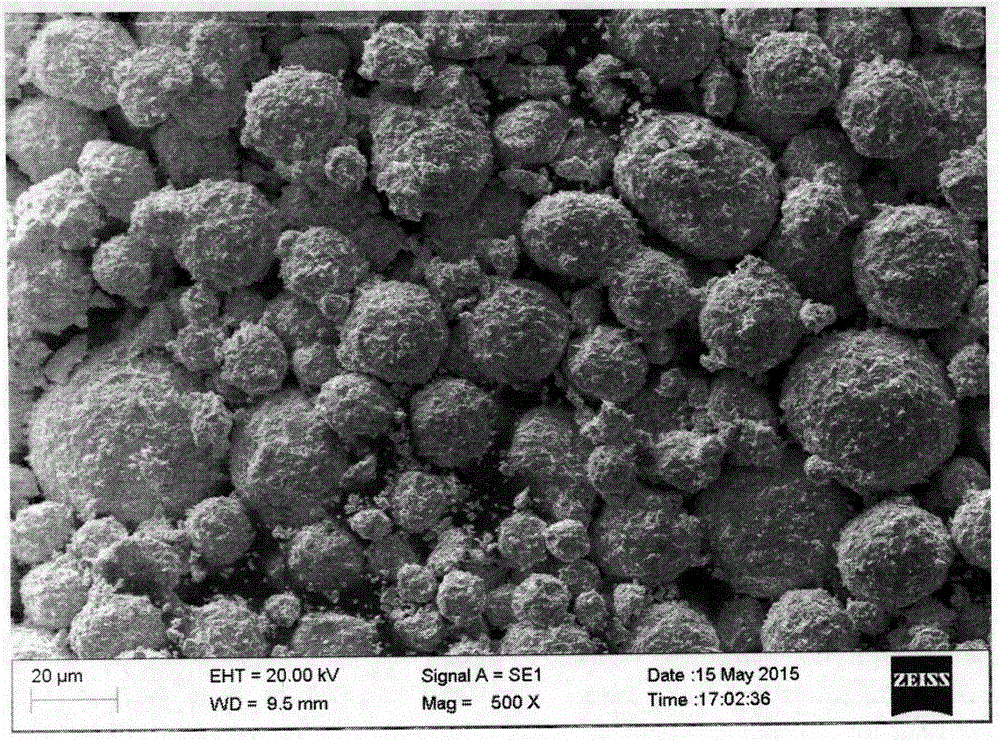

[0042] (4) Crushing and sieving: the sintered powder is crushed and then sieved. The SEM morphology of the powder after screening is shown figure 1 .

example 2

[0044] (1) Ingredients: 70% of WC powder, 20% of WB powder, and 10% of metal powder Co;

[0045] (2) Wet milling and spraying: Place the prepared materials in a ball milling tank, use deionized water as the ball milling medium, and after a certain period of ball milling time, the slurry is granulated by spray drying tower;

[0046] (3) Sintering: place the spray-dried powder in a graphite crucible, sinter it at an appropriate sintering temperature, and take it out after keeping it warm for a period of time;

[0047] (4) Crushing and screening: the sintered powder is crushed and then sieved;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com