Ternary tungsten boride nitride films and methods for forming same

一种硼氮、成核层的技术,应用在三元钨硼氮薄膜及其形成领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

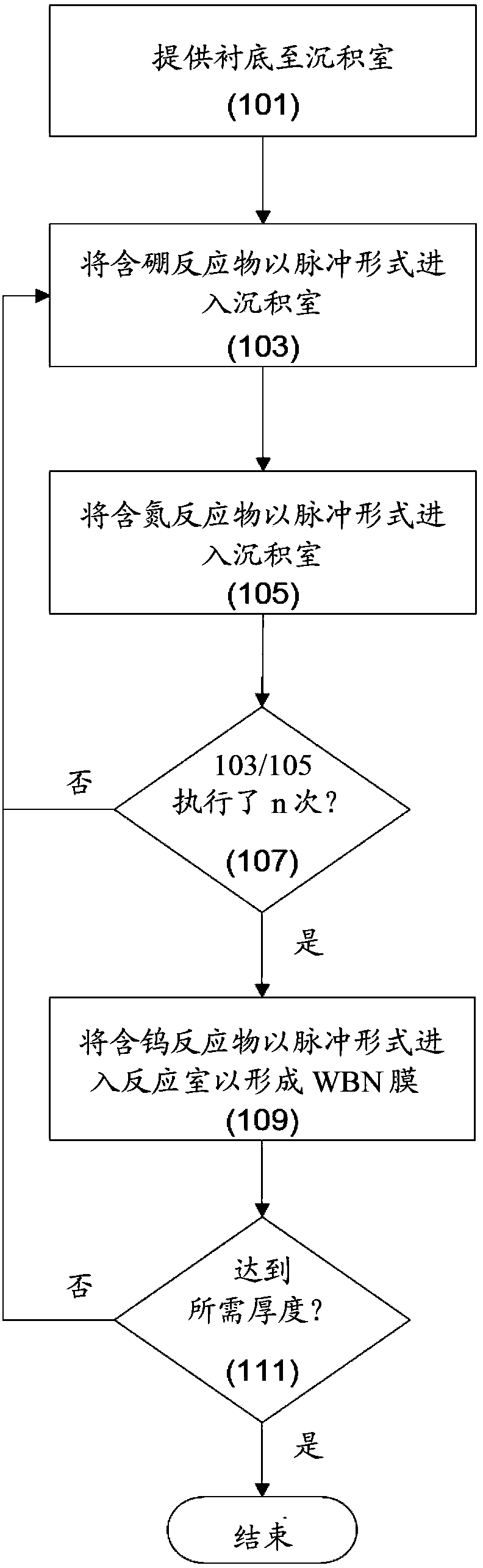

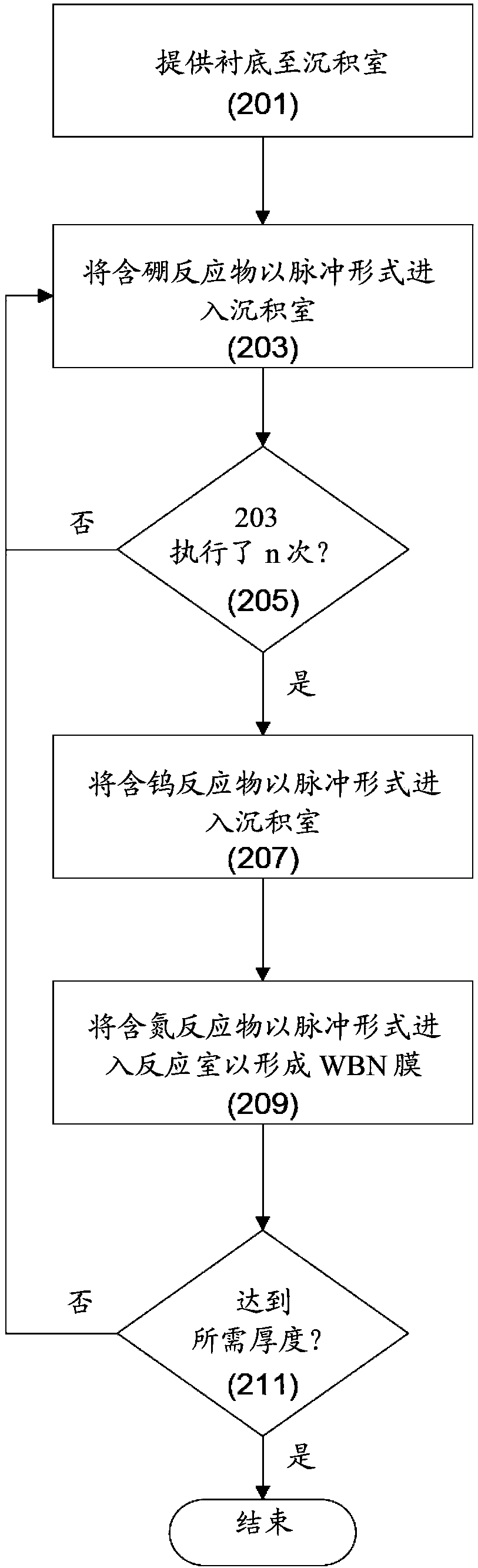

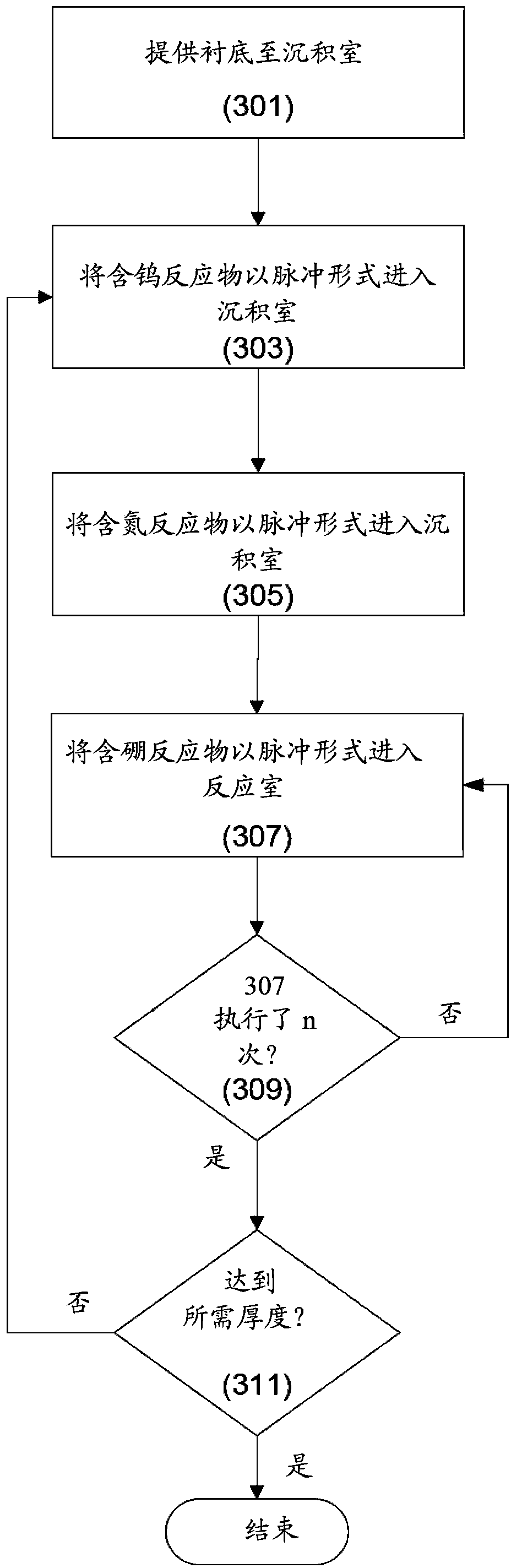

Method used

Image

Examples

Embodiment Construction

[0013] Introduction

[0014] In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention relating to tungsten boron nitride films and methods of forming them. Alterations, modifications or variations of the particular methods and structures shown of the invention will be apparent to those skilled in the art and are intended to be within the scope of the invention.

[0015] Resistivity is an intrinsic property of a material and is a measure of a material's resistance to the movement of electrical charges through the material. Materials with high or low resistivity are used for different applications. For example, low-resistivity metal layers in integrated circuits minimize power loss. The high-resistivity metal layer can be used as a heater element for phase-change memory or other applications.

[0016] In one example, the tungsten layer can be used for low-resistivity electrical connections in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com