Patents

Literature

242results about How to "Strong fire resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

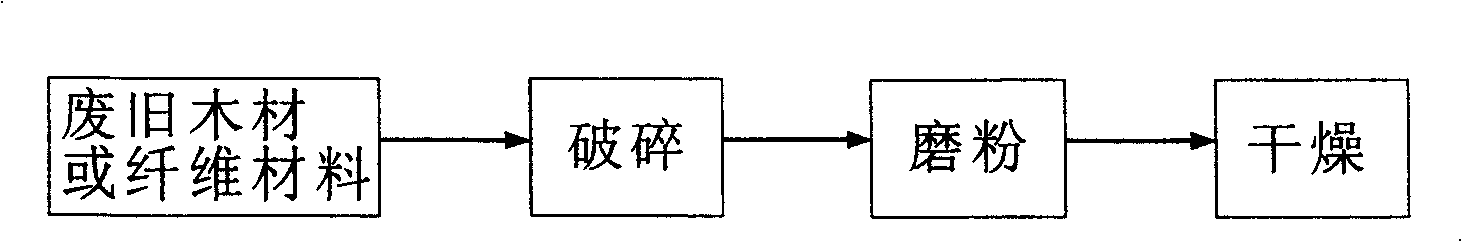

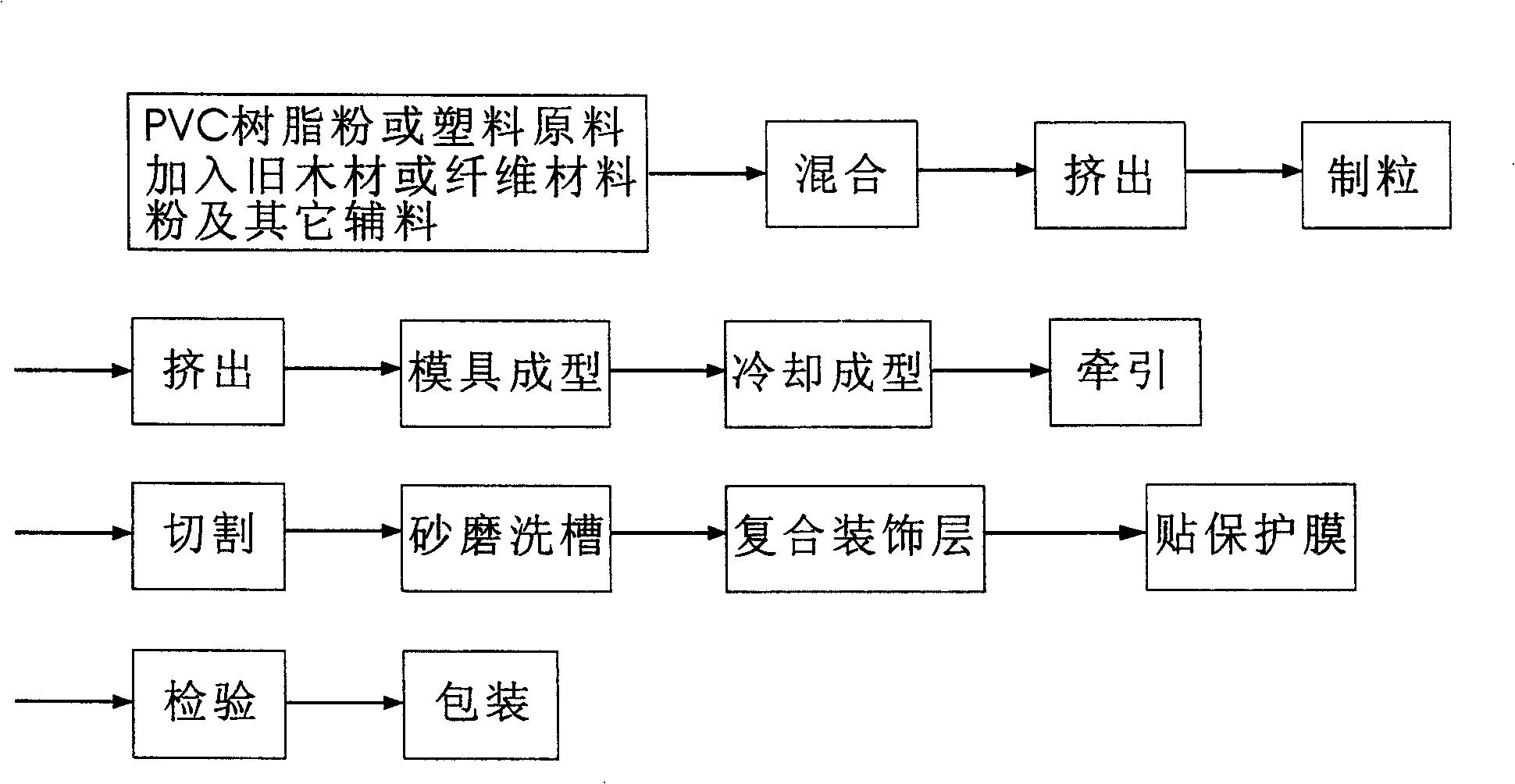

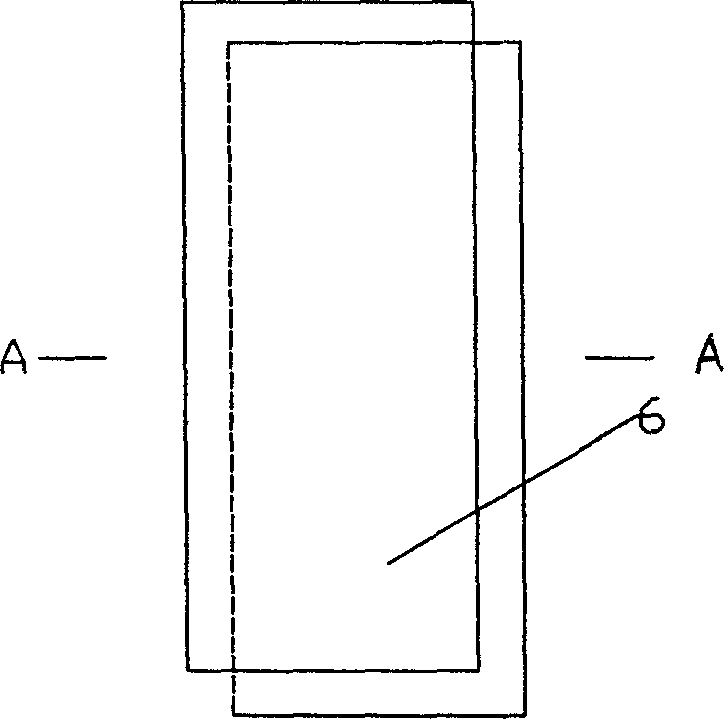

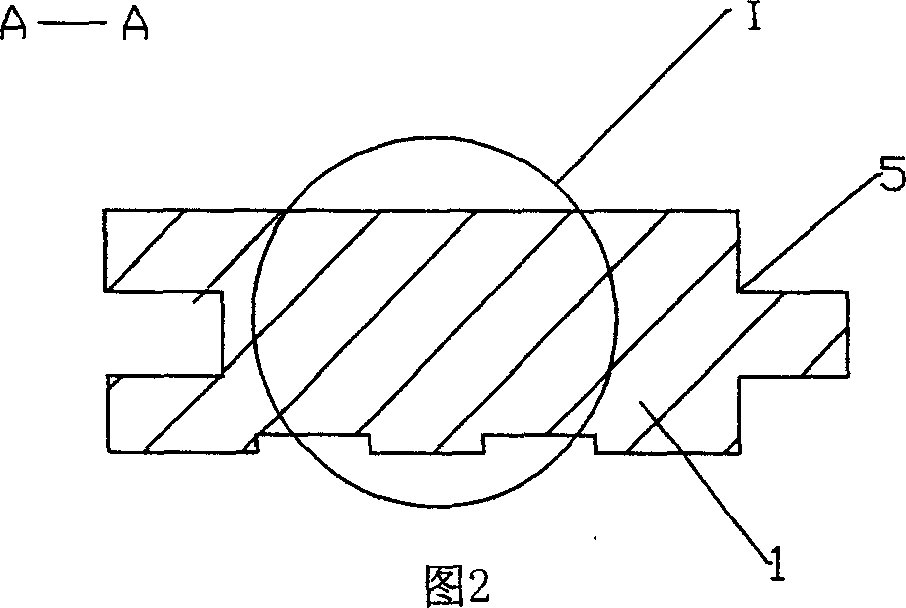

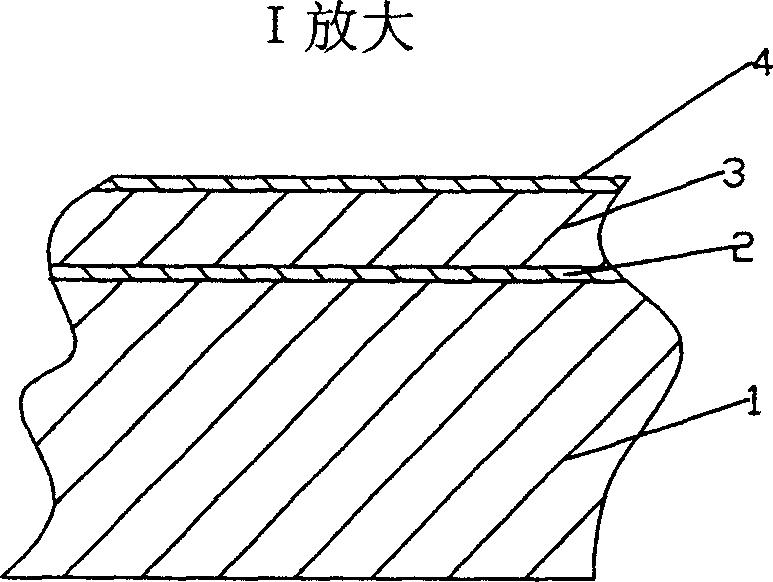

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

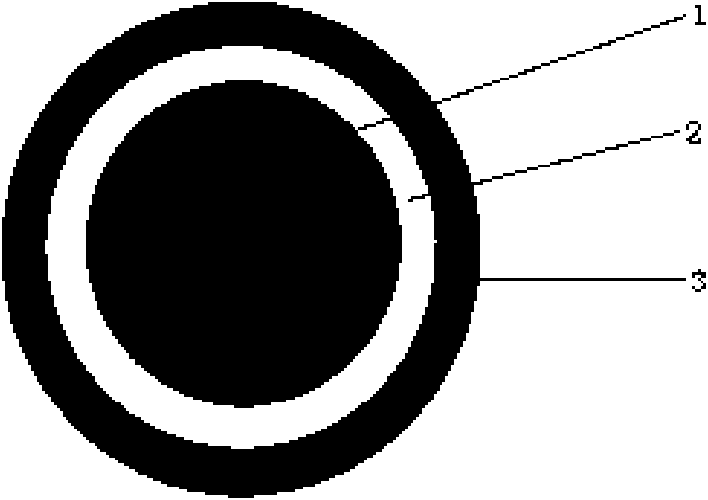

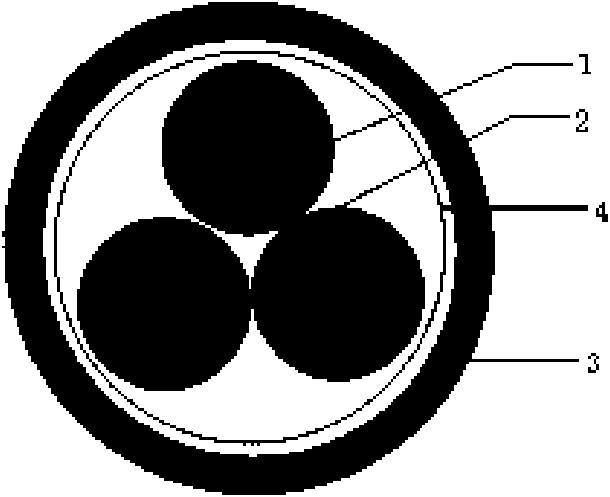

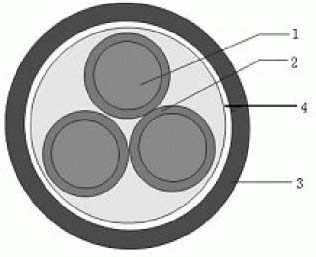

Fire-resistant silicon rubber and preparation method thereof and cable

ActiveCN101781463AStable fire resistanceImprove insulation performanceRubber insulatorsInsulated cablesMaterials sciencePlatinum Compound

The invention discloses a fire-resistant silicon rubber, which is prepared by the following raw materials by weight: 100 parts of silicon rubber, 0.1 to 3 parts of hydrogen-containing silicone oil, 2 to 15 parts of hydroxy silicone oil, 10 to 30 parts of pyrogenic silica, 10 to 30 parts of silicon epitaxy material, 20 to 50 parts of nanomontmorillonite, 10 to 30 parts of silicon carbide, 1 part of vulcanizing agent and less than 50 ppm of platinum compound calculating at the platinum quantity compared with the silicon rubber. The invention also provides a preparation method of the silicon rubber and a fire-resistant cable prepared with the silicon rubber. The fire-resistant silicon rubber has the performances such as stable fire resistance and good insulation performance, and has simple preparation method. The cable which is prepared with the fire-resistant silicon rubber has simple structure and convenient process. Particularly the reliability of the fire-resistant cable can be greatly improved.

Owner:浙江元通线缆制造有限公司

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

Wear resistant type plastic floor and its production technology

ActiveCN1903926AGood mechanical propertiesExcellent weather and corrosion resistanceFlat articlesSpecific gravityWear resistant

The present invention relates to an abrasion-resistant plastic floor board and its production process. Said process includes the following steps: using waste and old plastic powder as main raw material, adding active calcium carbonate and plastic filling agent as auxiliary raw material, mixing them and extruding them to obtain plastic foamed granules, die-pressing and forming, cooling, setting, drawing and cutting so as to obtain the invented plastic base plate, then sticking plastic protection film on its surface, so that the invented plastic floor board finished product can be made up.

Owner:无锡市中德装饰新材料有限公司

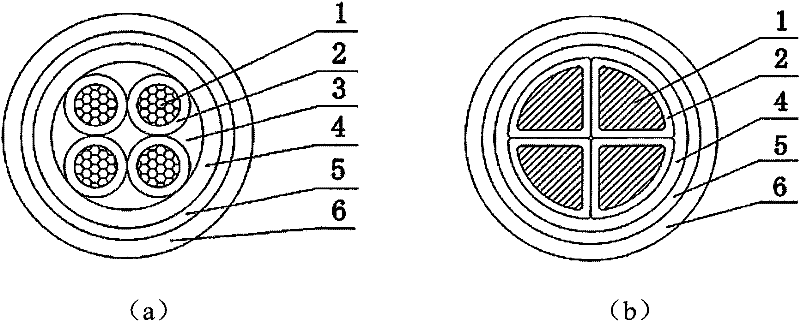

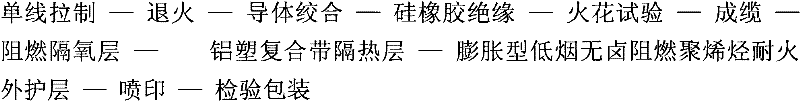

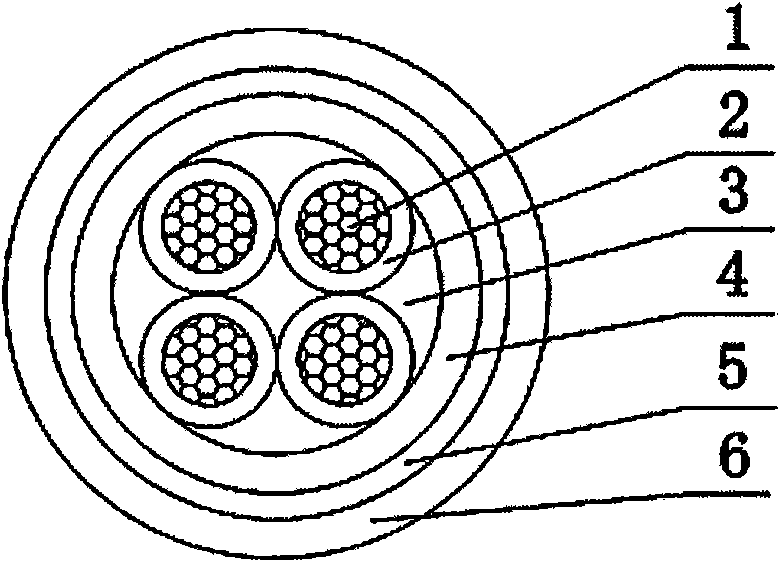

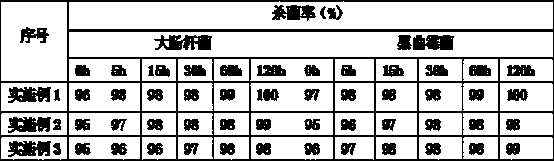

Expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and method thereof

InactiveCN102306513AEasy to processImprove mechanical propertiesFlexible cablesCable/conductor manufactureEnvironmental resistanceInsulation layer

The invention relates to an expansion type environment-friendly halogen-free high-flame retardant and fire-resistant cable and a method thereof. The cable is characterized in that: each core sequentially consists of conductors, a silicon rubber insulating layer, a filler, a flame retardant oxygen separation layer, an aluminum-plastic composite tape insulation layer and an expansion type fire-resistant outer protective layer made of low-smoke halogen-free flame retardant polyolefin from inside to outside, and adopts a fire-resistant cable structure formed by combining the expansion type fire-resistant outer protective layer made of the low-smoke halogen-free flame retardant polyolefin, the aluminum-plastic composite tape insulation layer and the silicon rubber insulating layer; and a flame retardant oxygen separation layer structure is formed by a halogen-free high-flame retardant material coated with metal hydrates. The preparation method comprises the following steps of: drawing single lines, performing annealing, twisting the conductors, insulating silicon rubber, cabling, and preparing the flame retardant oxygen separation layer, the aluminum-plastic composite tape insulation layer and the expansion type refractory outer protective layer made of the low-smoke halogen-free flame retardant polyolefin. The cable provided by the invention is easy to process, the external diameter of the cable is smaller than that of the traditional cable by 2 to 4 millimeters, and the structure can be obviously lightened.

Owner:南洋电缆集团有限公司

Tunnel fireproof paint

InactiveCN101747675AGood construction performanceConstruction stabilityFireproof paintsCalcium formateToxic material

The invention relates to fireproof paint, in particular to tunnel fireproof paint, which is prepared from the following ingredients: a major bonding agent (ordinary Portland cement), inorganic heat insulation filling materials (expanded perlite, expanded vermiculite, meerschaum, kaoline and wollastonite powder) and addition agents (calcium formate, starch ether, redispersible latex powder, methyl cellulose ether and polypropylene fiber). Through the unique addition agent combination and the prescription mixture ratio, the tunnel fireproof paint has the advantages that the construction performance is obviously improved, at the same time, the integral overall performance of the tunnel fireproof paint is greatly improved, and the tunnel fireproof paint has the characteristics of stable fireproof performance, high adhesion intensity and stable physicochemical performance. Simultaneously, the product per se generates no toxic substance in the construction and burning processes, has the effects of environment protection and high practicability, and can be widely used for the fireproof protection of buildings such as highways, railways, subway tunnels and the like.

Owner:江西三星气龙新材料有限公司

Water-based coating

ActiveCN104017445AImprove defoaming abilityWell mixedFireproof paintsAntifouling/underwater paintsExtensibilityWater based

The invention discloses a water-based coating which is characterized by comprising the following components by weight parts: 20-30 parts of water, 20-25 parts of an acrylic emulsion, 0.3-0.5 part of a wetting agent, 0.1-0.3 part of a de-foaming agent, 15-20 parts of titanium dioxide, 10-15 parts of talcum powder, 0.3-0.5 part of a fireproof agent and 0.2-0.4 part of an antibacterial agent. The coating disclosed by the invention is reasonable in composition, low in cost, good in compatibility among the components, environment-friendly, mildew-proof and flame-retardant, and has excellent application values; a natural antibacterial agent and an inorganic antibacterial agent are mixed for use, so that the problems of poor stability due to single use of the natural antibacterial agent or pollution caused by single use of an organic antibacterial agent and high cost due to single use of the inorganic antibacterial agent are solved; due to combined use, the mildew-proof effect is more lasting; the film-forming drying time is short, the hardness is good, and the extensibility and the heat resistance are good.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Gypsum board with air purification function and preparation method thereof

PendingCN105399395AStrong fire resistanceLong time fire stabilityCeramicwareEnvironmental resistanceActivated carbon

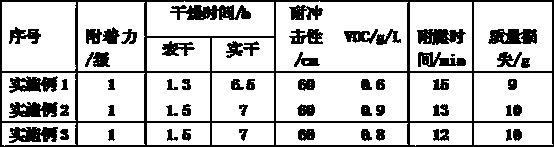

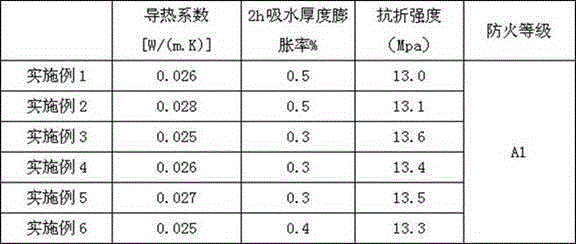

The invention provides a gypsum board with air purification function. The gypsum board is characterized by being prepared from the following components by weight: 50-80 parts of desulfurized gypsum, 20-30 parts of rock wool, 15-25 parts of diatomite, 10-20 parts of shell powder, 3-5 parts of activated carbon, 1-3 parts of a waterproof agent, 0.3-0.8 part of a foaming agent, 0.1-0.5 part of a binder, 0.1-0.5 part of a photocatalyst, and 30-55 parts of water. The gypsum board provided by the invention has very strong fire resistance, long time stability in case of fire, environmental protection and no pollution, can effectively remove harmful gas, has greatly improved heat conduction coefficient, 2h water absorption thickness swelling rate, bending strength and other performance parameters, and is completely superior to similar products on the market, thus having good market prospects. The preparation process involved in the invention is simple and feasible, and can realize large-scale industrial promotion.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Magnesium oxide board and preparation method thereof

The invention discloses a magnesium oxide board which is prepared by extruding a reinforced material and slurry into a sheet through forming equipment, wherein the reinforced material is composed of a non-woven fabric and a fiberglass mesh or other reinforced materials; the slurry comprises the following components in parts by mass: 100 parts of magnesium oxide with the magnesium content of at least 85% and the activity degree of at least 62%, 80-90 parts of anhydrous magnesium chloride water solution with the concentration of 10-40 baume degrees, 10-15 parts of lightweight filler A, 15-20 parts of lightweight filler B, 1-5 parts of silicon dioxide and 1-10 parts of foaming agent; the particle size of magnesium oxide is 250-400 meshes; preferably, the lightweight filler A is one or more selected from perlite, polyphenyl granules, gangue and vermiculite, and the lightweight filler B is one or more selected from wood flour, straw, rice husk and bamboo fiber; more preferably, the lightweight filler A is hole-closed perlite, and the lightweight filler B is straw sawdust of 80-100 meshes. The invention also discloses a preparation method of the magnesium oxide board. The magnesium oxide board prepared according to the invention is high in strength, not easy to get damp, strong in fire resistance and free of cracks after being fired at high temperature; in addition, the preparation method of the magnesium oxide board disclosed by the invention is short in time.

Owner:SHANGHAI HUIZHUO BUILDING DECORATIVE MATERIAL

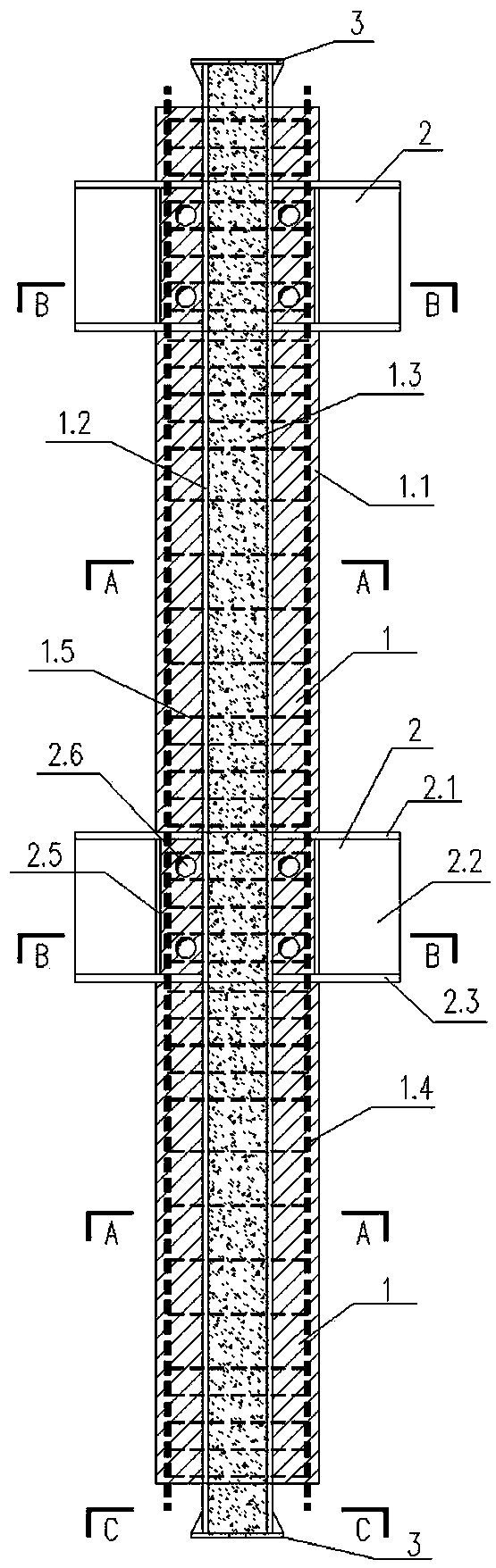

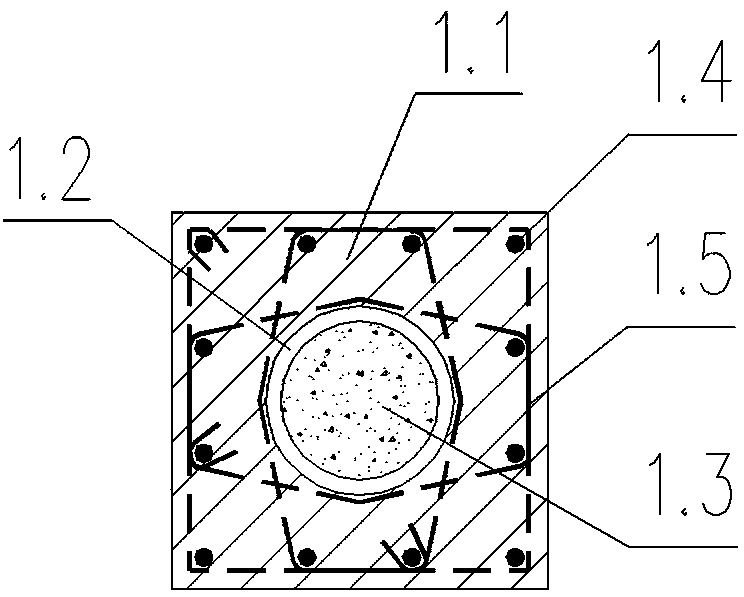

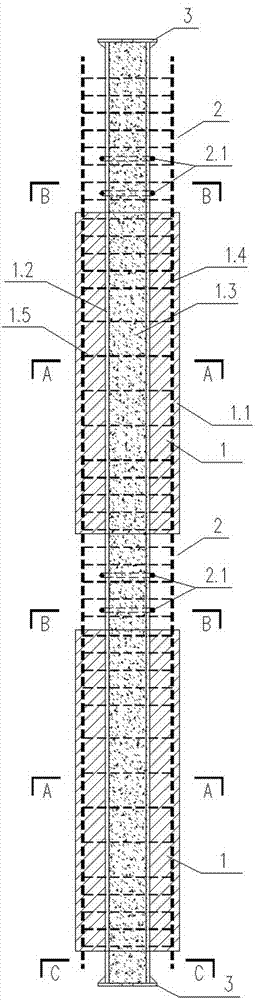

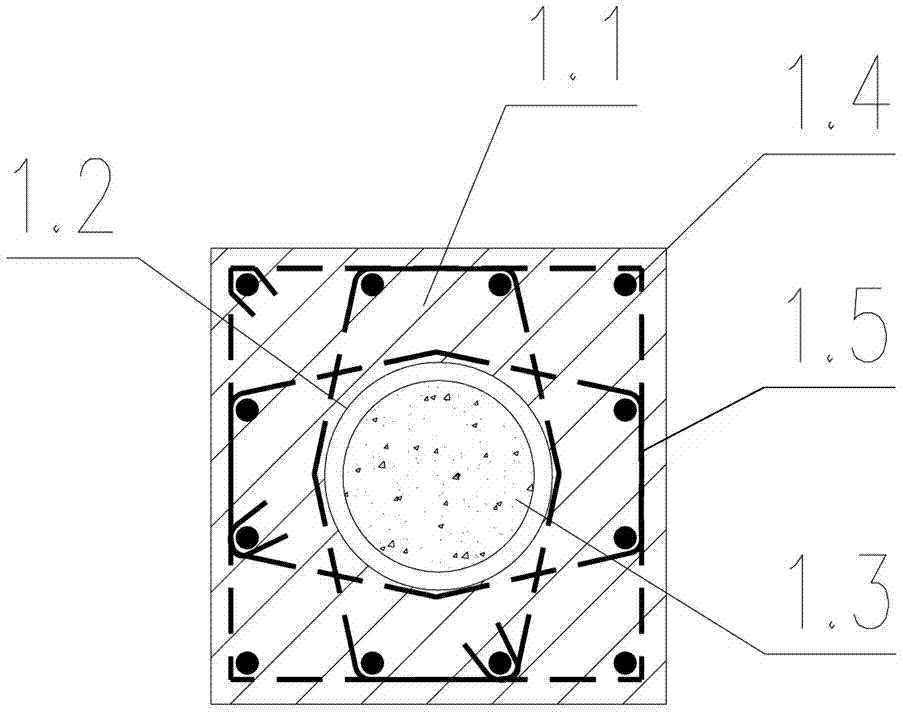

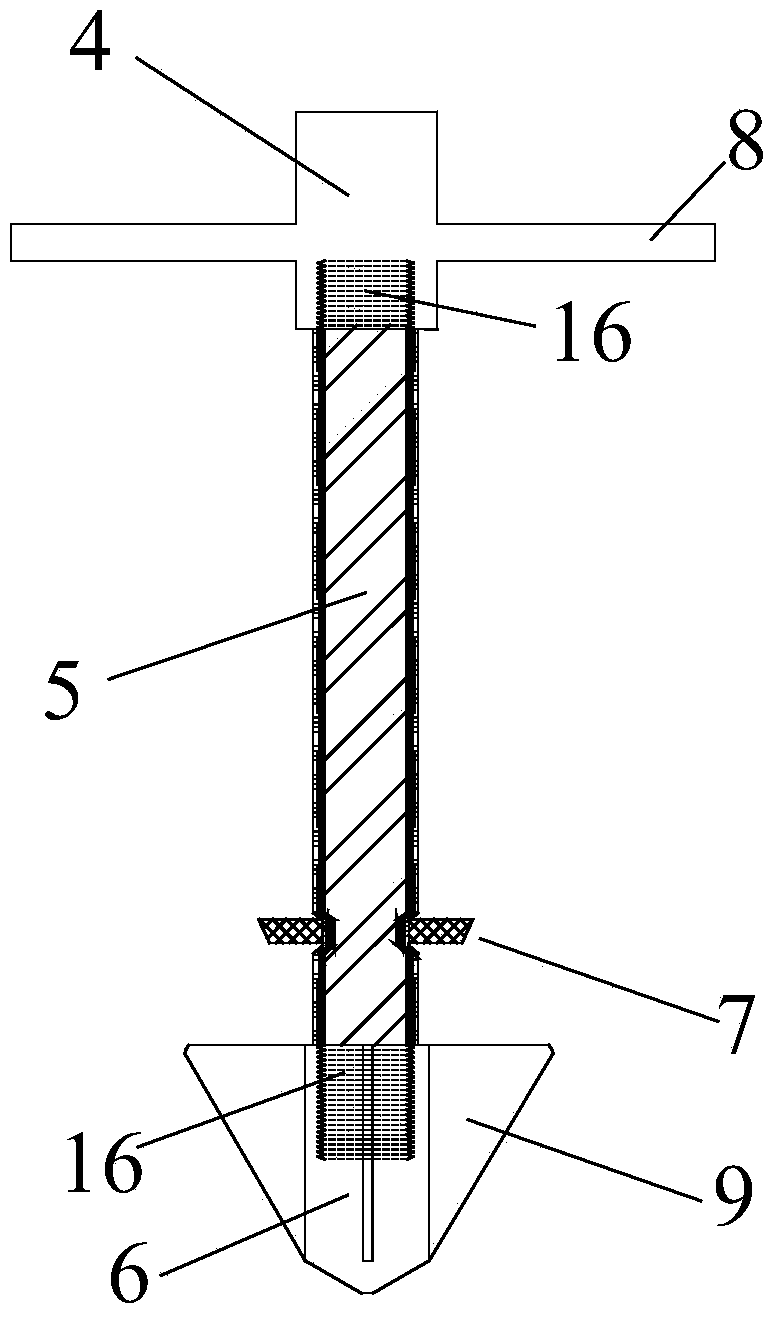

Fabricated frame strip steel bracket long column and construction method thereof

ActiveCN103556781AEasy to processEasy to installStrutsPillarsReinforced concrete columnEarthquake resistance

The invention discloses a fabricated frame strip steel bracket long column and a construction method of the fabricated frame strip steel bracket long column. The column body is a composite column consisting of three parts, namely steel pipe outer reinforced concrete, a steel pipe and steel pipe inner concrete; the steel pipe and the steel pipe inner concrete penetrate through the whole long column; the steel pipe inner concrete is subjected to primary prefabrication to form a steel pipe concrete column; concrete at a steel pipe outer joint or total concrete is poured in advance at the second time; a steel bracket is welded with the steel pipe. The long column has the advantages that 1, a multi-layer frame column is manufactured into a long column, the manufacture is simple, and the installation is convenient; 2, the column body is a composite column, the compression bearing capacity and shear capacity of the column are 2-4 times that of a reinforced concrete column with the same section, and the bearing capacity and anti-seismic property of the frame column are obviously improved; 3, the steel bracket is arranged and can be connected with a steel beam or a cast-in-place reinforcedconcrete beam, and the connection is convenient and reliable; and 4, high-strength concrete in the steel pipe is prefabricated in a factory, and the construction cost of the column is greatly reducedcompared with that of a conventional composite column. Therefore, the long column is suitable for various multi-story and high-rise prefabricated buildings and is wide in market prospects.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Refractory flame-retardant silicone rubber sheath material for cables and preparation method thereof

InactiveCN103571210AStable fire resistanceImprove insulation performanceRubber insulatorsInsulated cablesMicrocrystalline waxGas phase

The invention discloses a refractory flame-retardant silicone rubber sheath material for cables and a preparation method thereof. The refractory flame-retardant silicone rubber sheath material for cables is prepared from the following raw materials in parts by weight: 70-90 parts of methylvinyl silicone rubber, 15-25 parts of epichlorohydrin rubber, 10-20 parts of bisphenol A polycarbonate, 2-3 parts of zinc oxide, 3-4 parts of 2-thiolbenzimidazole, 4-6 parts of microcrystalline wax, 1-2 parts of stearic acid, 3-5 parts of dimethyl silicone oil, 10-15 parts of nano silicon nitride, 20-30 parts of gas-phase silica white, 8-12 parts of calcined argil, 3-6 parts of fiberglass, 5-10 parts of alundum powder, 5-10 parts of epoxy soybean oil, 0.3-0.6 part of dicumyl peroxide, 1-2 parts of triallyl cyanurate and the like. The sheath material has the characteristics of stable fire resistance, favorable insulating property, high mechanical strength and the like, has excellent flame retardancy, oil resistance, freezing resistance, acid / alkali resistance, radiation aging resistance, wear resistance and other properties, and is completely reliable and durable.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

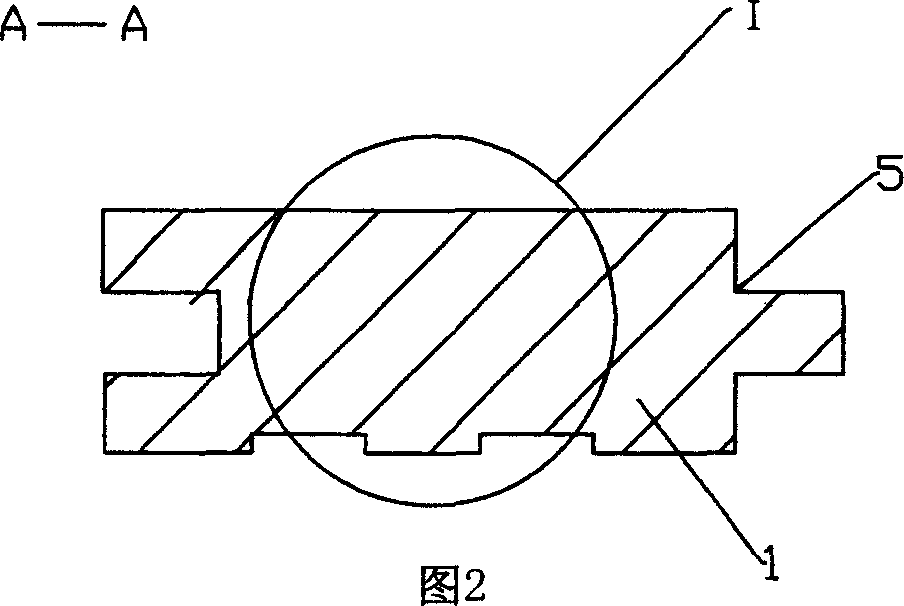

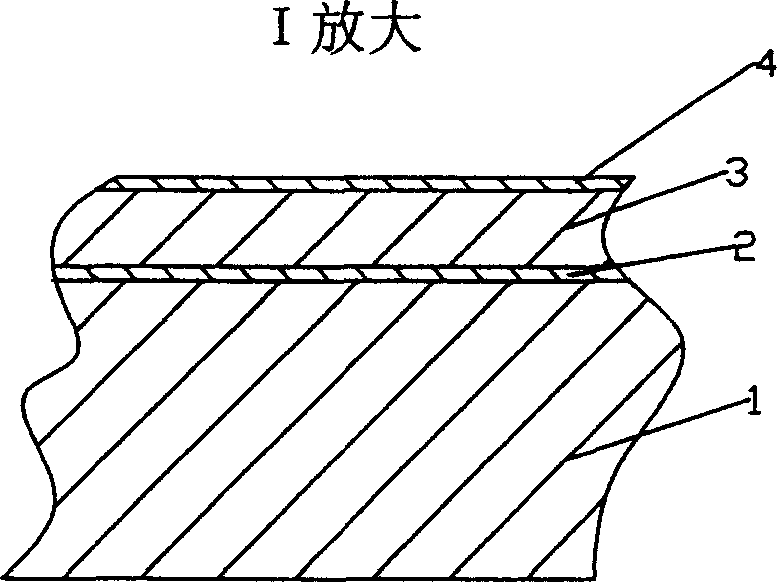

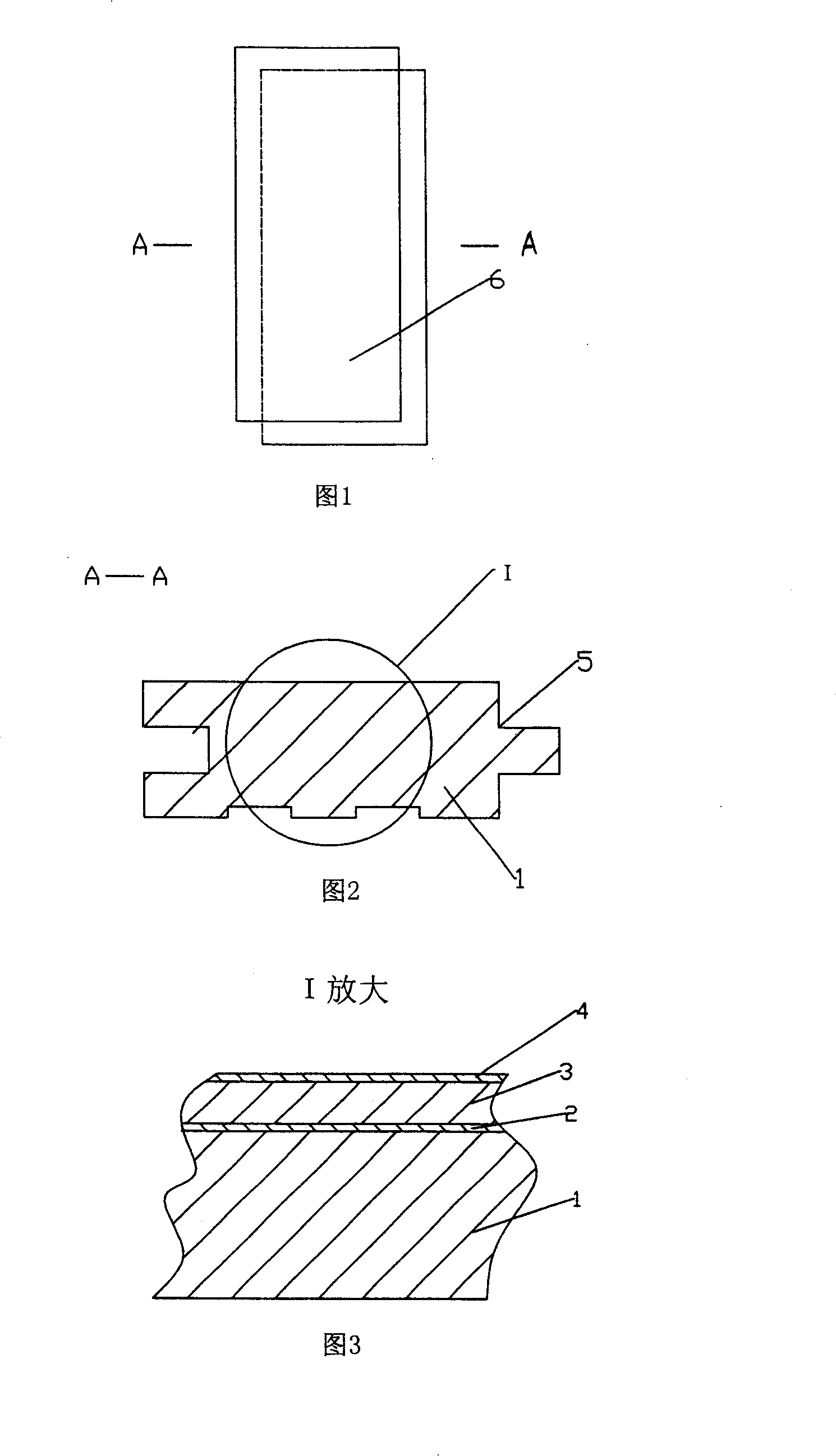

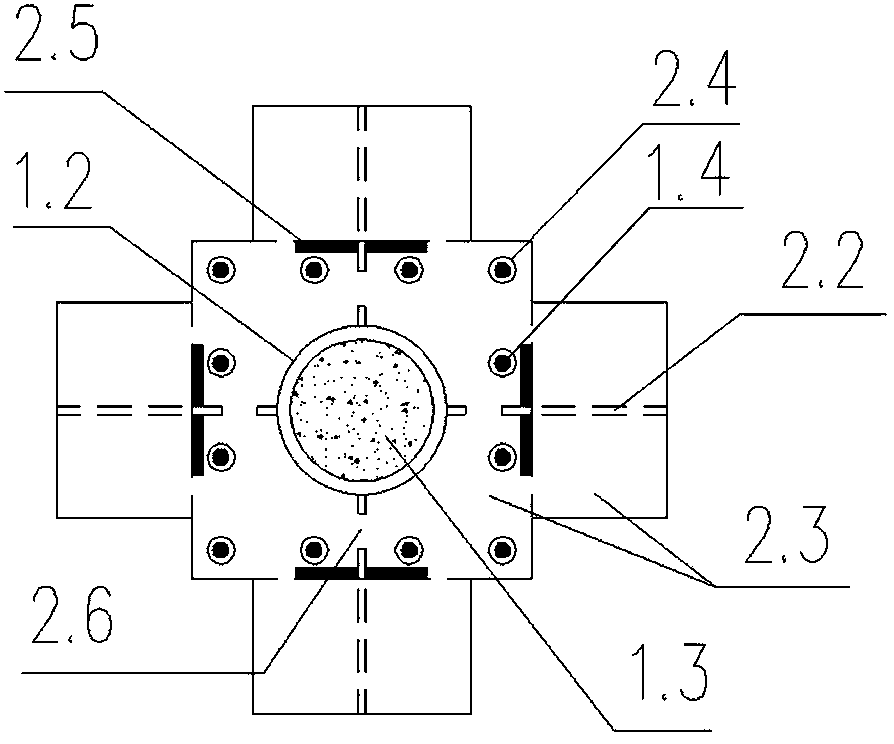

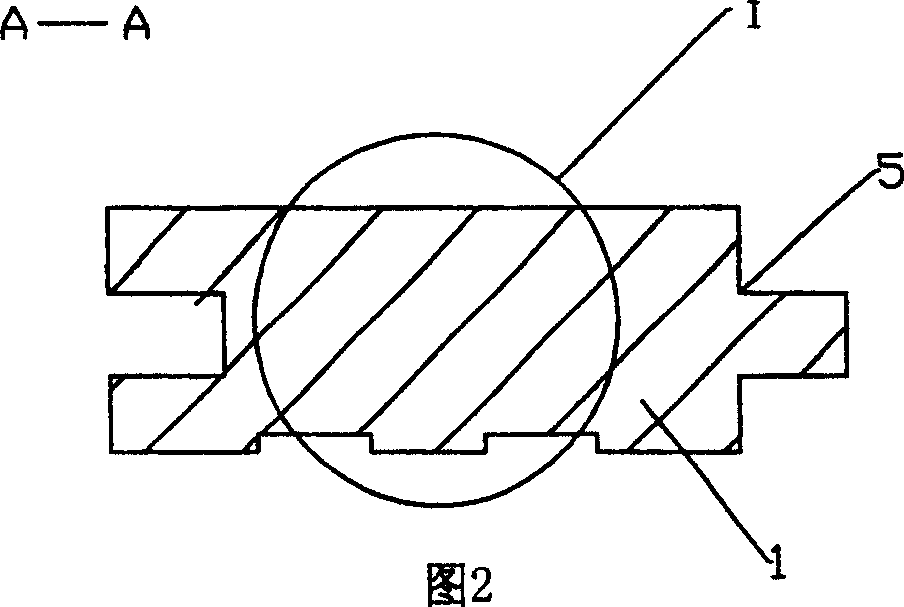

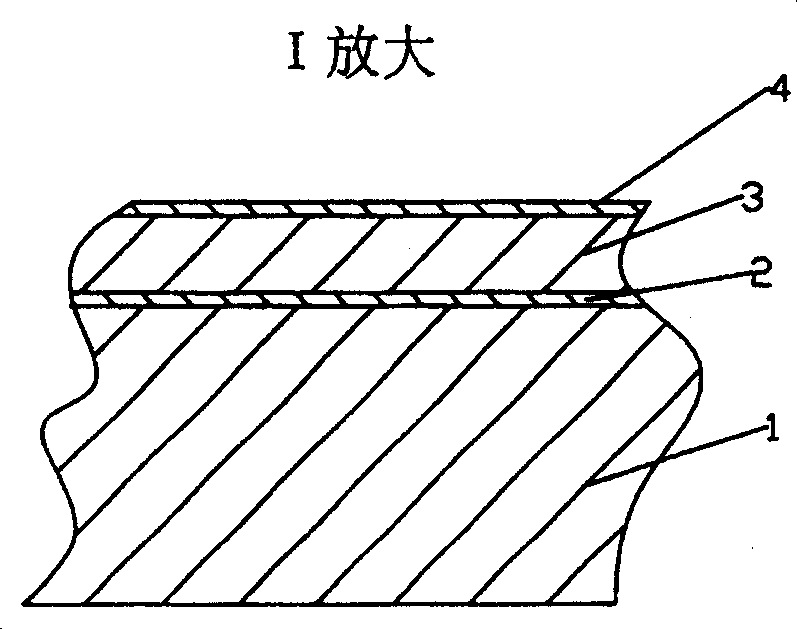

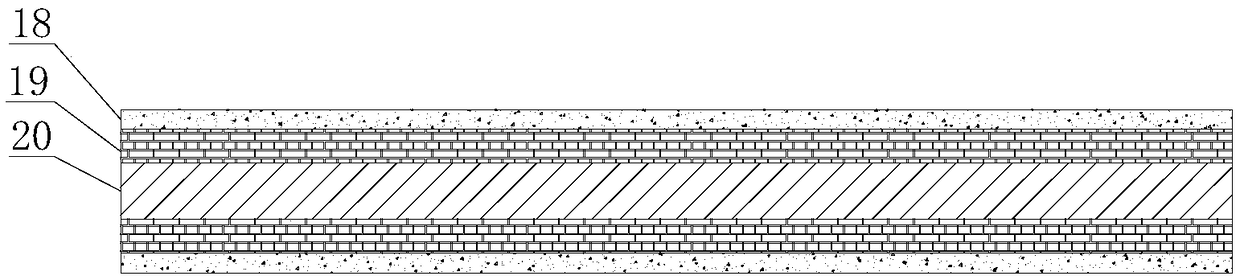

Processing method of fire resistant mica tape and structure

ActiveCN101417885AImprove fire resistance and insulation performanceGood adhesionMicaFireproofingEngineering

The invention relates to a processing method of fire resistant mica tapes, which is characterized in that a diluted peptizing agent is uniformly immersed into the front and reverse faces of fiber cloth, then mica paper is flatly spread on the surface of a mucilage layer on the upper side of fiber cloth, thus forming a mica layer which is again put in an adhesive groove so as to cause the peptizing agent to uniformly immerse into the surface of the mica layer, then the fiber cloth is flatly spread on the surface of the mucilage layer formed on the upper side of the mica layer, thereby obtaining mica tapes without composite forming; and then cut and drum are carried out on the mica tapes after drying and then the preparation is completed. The structure of the mica tapes prepared by using the method is characterized by at least three fiber layers, at least two mica layers and at least one mica layer arranged between the two fiber layers. The preparation method can effectively increase the viscosity between the fiber layer and mica layer which are not separated, and the method not only improves the whole fireproofing and insulating property leading to more stable fireproofing property but also has the advantages of impact resistance, water durability and the like.

Owner:北京倚天凌云科技股份有限公司

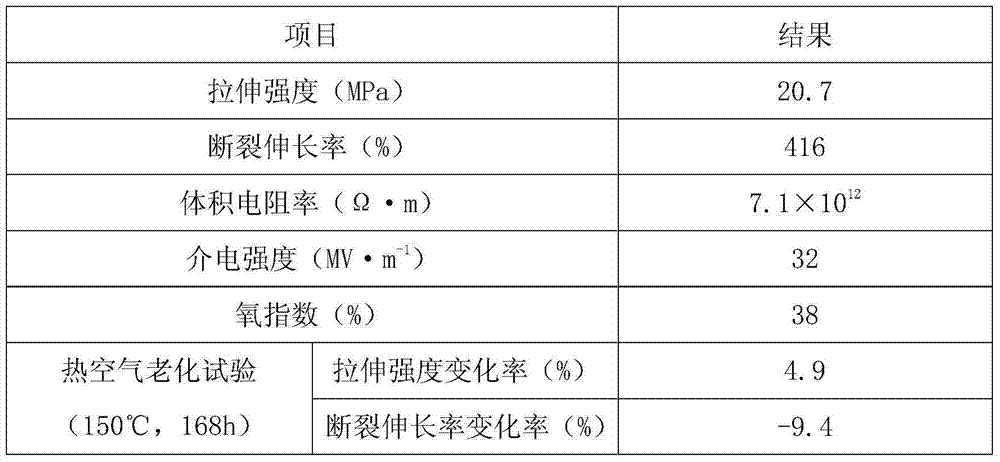

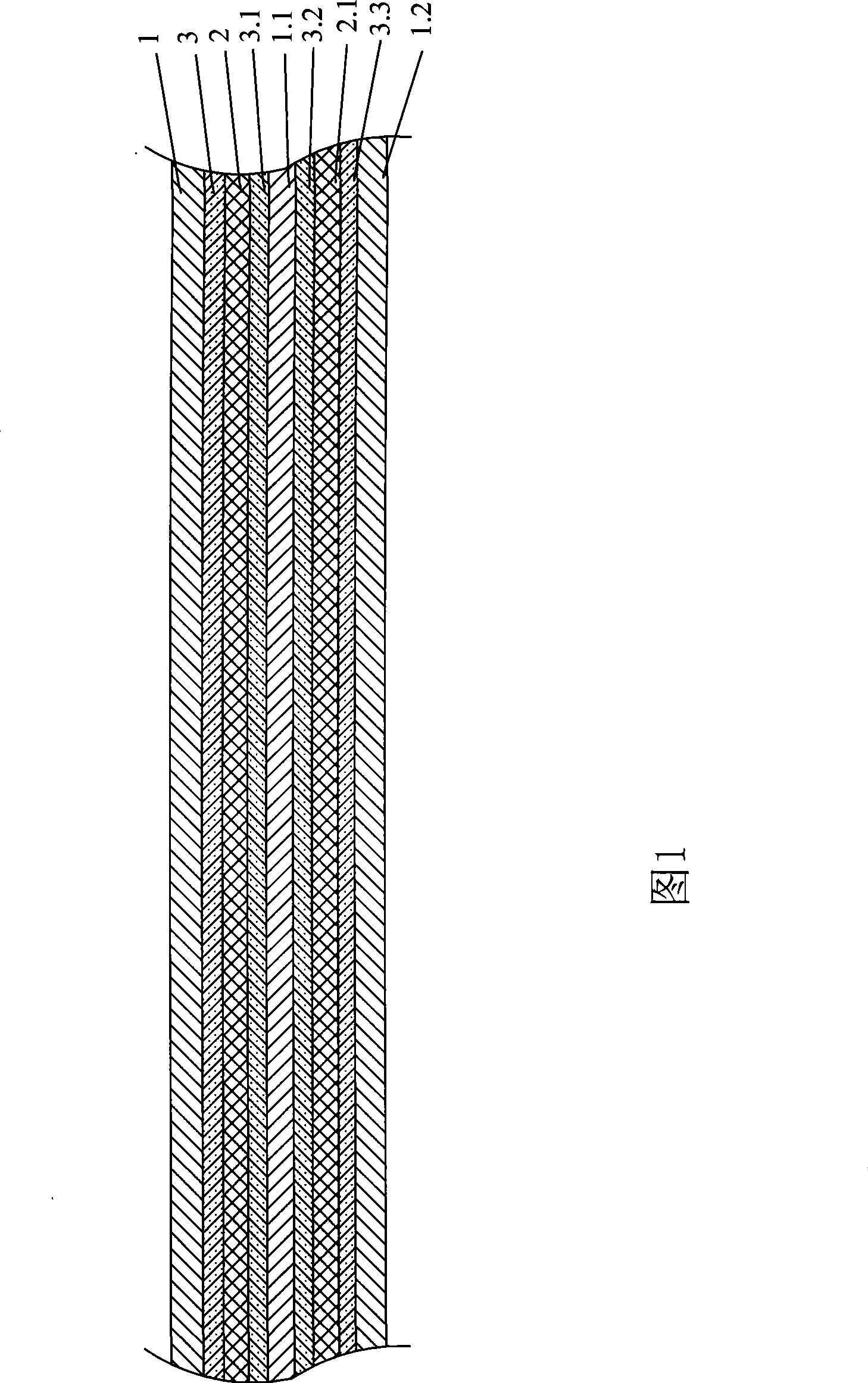

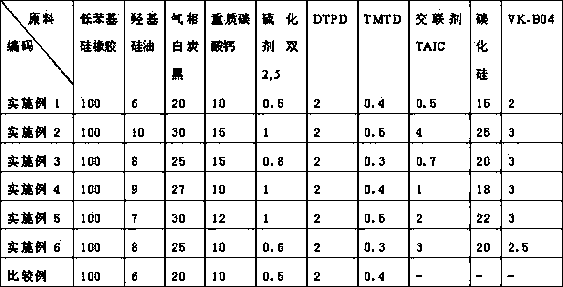

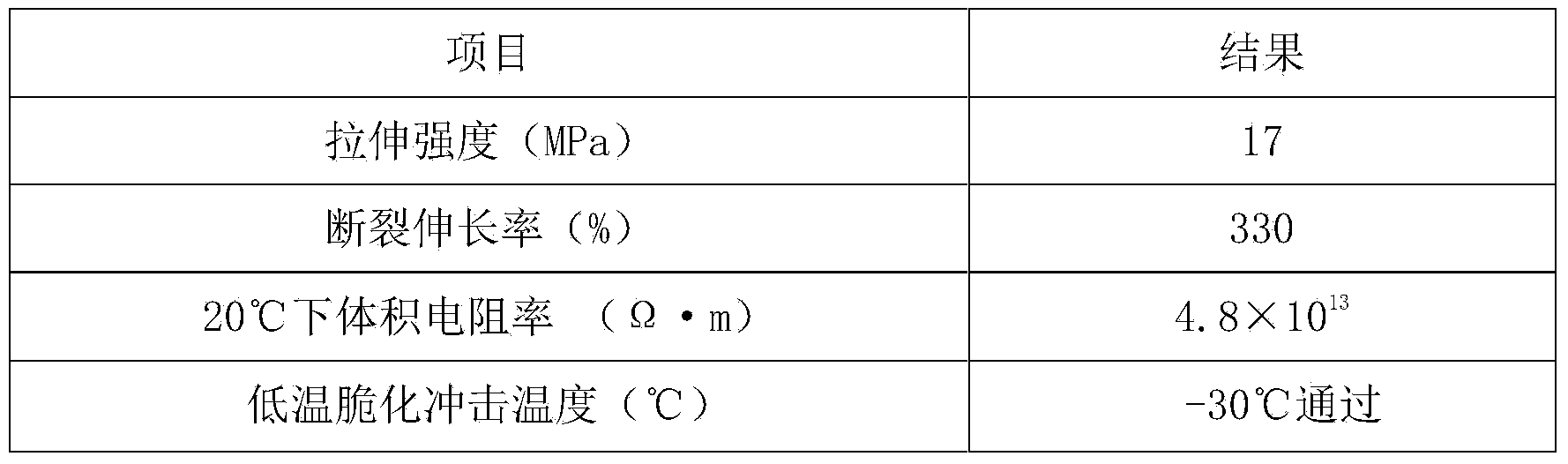

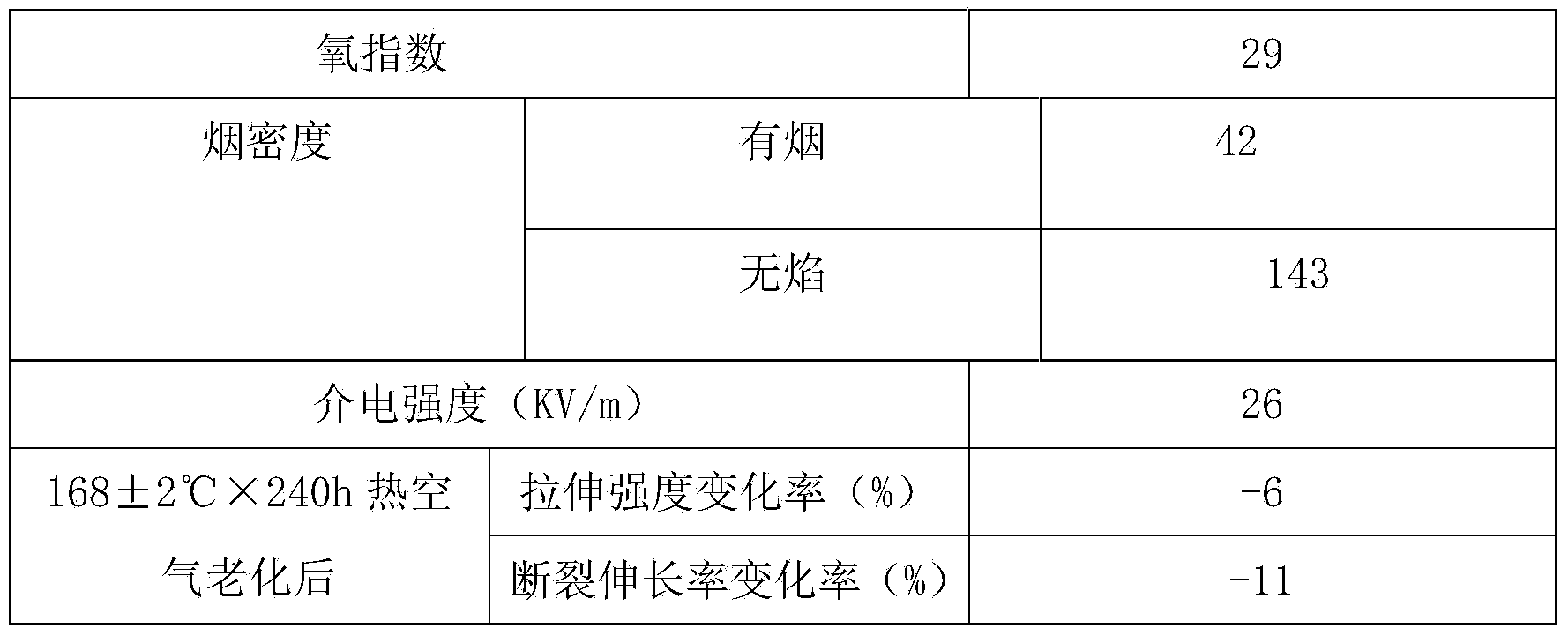

Fire-resistant silicone rubber cable material and preparation method thereof

InactiveCN103665881AStrong fire resistanceImprove insulation performanceInsulated cablesInsulated conductorsPolymer scienceFire retardant

The invention belongs to the field of fire-resistant materials, and particularly relates to a fire-resistant silicone rubber cable material. The fire-resistant silicone rubber cable material is mainly prepared from the following raw materials in parts by weight: 100 parts of phenyl silicone rubber, 6-10 parts of hydroxyl silicone oil, 20-30 parts of white carbon black, 10-15 parts of heavy calcium carbonate, 0.5-1 part of a vulcanizing agent, 2 parts of an anti-ageing agent, 0.3-0.5 part of an accelerant, 0.5-4 parts of a co-curing agent, 15-25 parts of a flame retardant and 2-3 parts of a heat stabilizer. The fire-resistant silicone rubber cable material disclosed by the invention has the advantages of stable fire resistance, high insulating performance and high mechanical performance.

Owner:苏州德亮材料科技有限公司

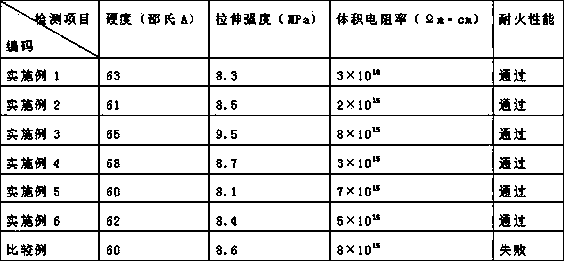

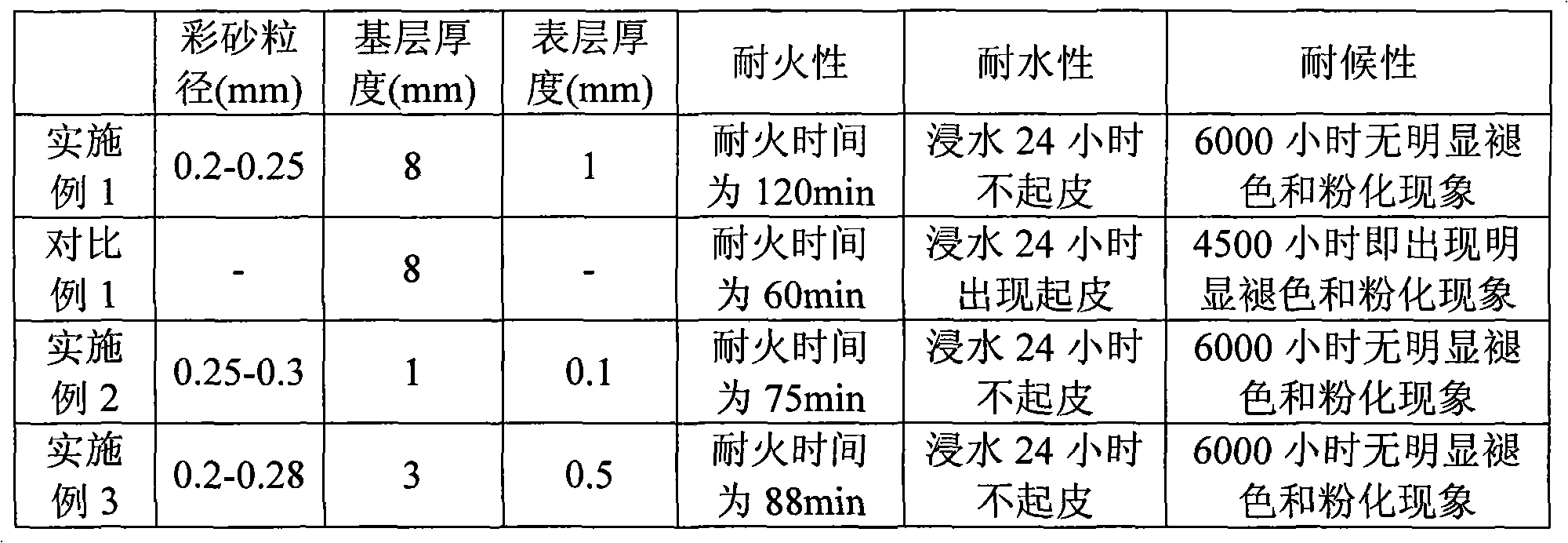

Fireproof coating composition and fireproof steel material

ActiveCN102485684AImprove fire resistanceImprove water resistanceFireproof paintsEpoxy resin coatingsSurface layerMetallurgy

The invention provides a fireproof coating composition. The coating composition comprises colored sand and a binder which are respectively and independently preserved. The invention also provides a fireproof steel material. The fireproof steel material comprises a steel material main body, a fireproof base layer coated on the steel material main body, and a fireproof surface layer coated on the fireproof base layer, wherein the fireproof surface layer is formed by curing the binder in the fireproof coating composition provided in the invention. The fireproof steel material prepared according to the invention has the advantages of fine surface, and good fire proofness, water proofness and weatherability.

Owner:北京仁创合力化工科技有限公司

Fireproof plaster board and production method thereof

InactiveCN103541531AStrong fire resistanceLong time fire stabilityMonocarboxylic acid ester polymer adhesivesCovering/liningsEnvironmental resistanceBuilt environment

The invention belongs to the field of build environment-friendly materials and discloses a fireproof plaster board. The fireproof plaster board is formed by a plaster base body and protective paper; the plaster base body is arranged in the middle; the protective paper is arranged on the upper side and the lower side; binding materials are bound between the plaster base body and the protective paper. The produced fireproof plaster board has the advantages of being good in fire resistance, environmentally friendly and free of pollution, greatly improving the mechanical performance such as the compressive and bending strength and being good in market prospect.

Owner:海门市创豪工业设计有限公司

Prefabricated frame bracket-free long column and construction method thereof

ActiveCN103526882AEasy to processLow costStrutsBuilding material handlingReinforced concrete columnConcrete beams

The invention provides a prefabricated frame bracket-free long column and a construction method thereof. A column body comprises more than two layers of interlayer columns and more than two beam column nodes, and the long column penetrates through steel tubes of each interlayer column and the beam column nodes, steel tube internal concrete undergoing primary pouring in advance and column longitudinal steel ribs bound on the outer sides of the steel tubes. Steel tube external concrete is poured for the second time in advance in the range of each interlayer column of the long column. The column and the method have the advantages that a plurality of frame columns are manufactured into one long column, manufacturing is simple and installation is convenient to achieve; a column body is a stacked column, compression strength and shear strength are twice to four times those of a steel rib concrete column with the same section area, and bearing force and anti-shock performance of the frame columns are remarkably improved; gaps are reserved between outer tube steel tube concrete and the beam column nodes, and connection between the outer tube steel tube concrete and steel rib concrete beams is convenient to achieve; inner high-strength steel tube concrete is prefabricated in a factory, and manufacturing cost is greatly reduced. The prefabricated frame bracket-free long column and the construction method are suitable for various high-rise prefabricated buildings, and are wide in market prospect.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Insulating fireproof composite board for wall body

InactiveCN103556720AStrong fire resistanceImprove insulation effectSpecial paperPaper/cardboardFire resistanceUpper floor

The invention belongs to the field of fire-proof heat insulating materials for buildings, and discloses an insulating fireproof composite board for a wall body. The insulating fireproof composite board comprises a gypsum board on the lower layer and surface cover paper on the upper layer, wherein the gypsum board and the surface cover paper are bonded through a binding material. The insulating fireproof composite board has better fire resistance and heat preservation, has wide raw material sources, is simple in preparation method, and has brighter market prospect.

Owner:海门市创豪工业设计有限公司

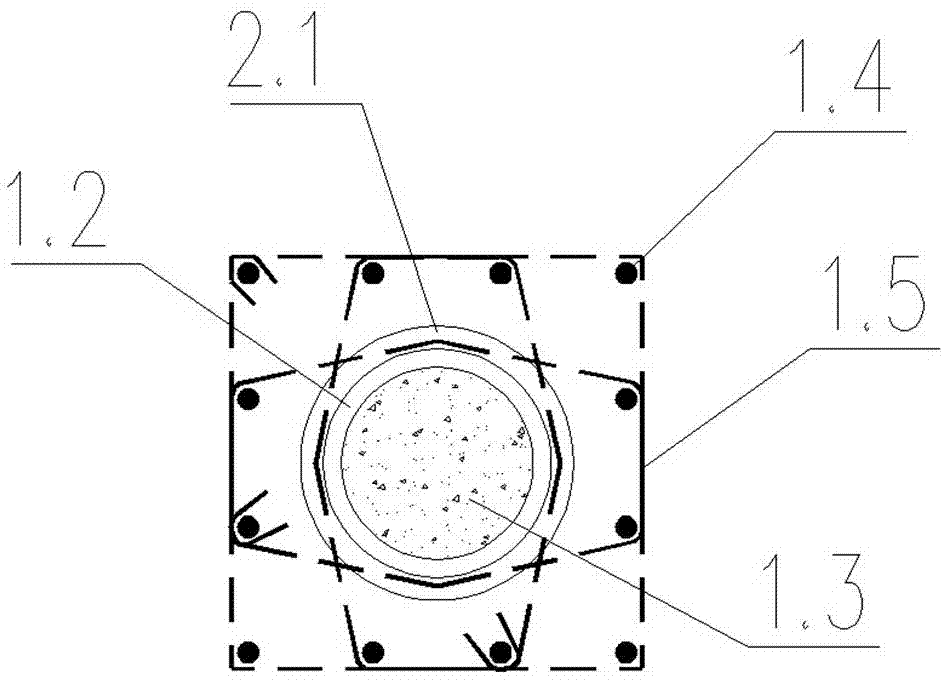

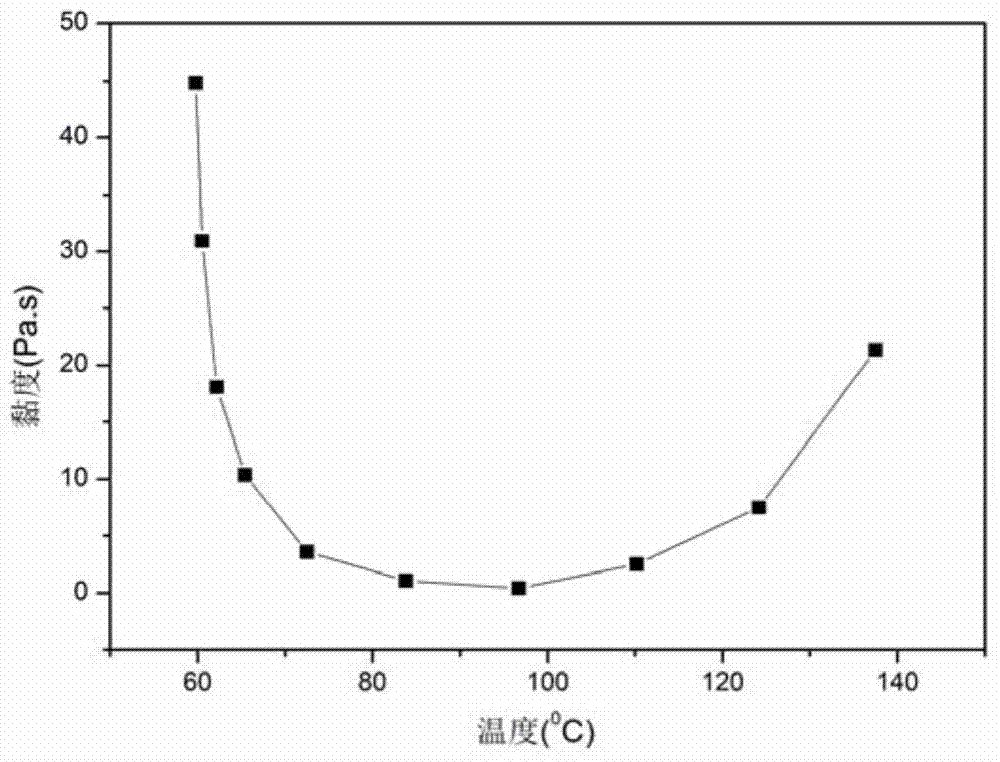

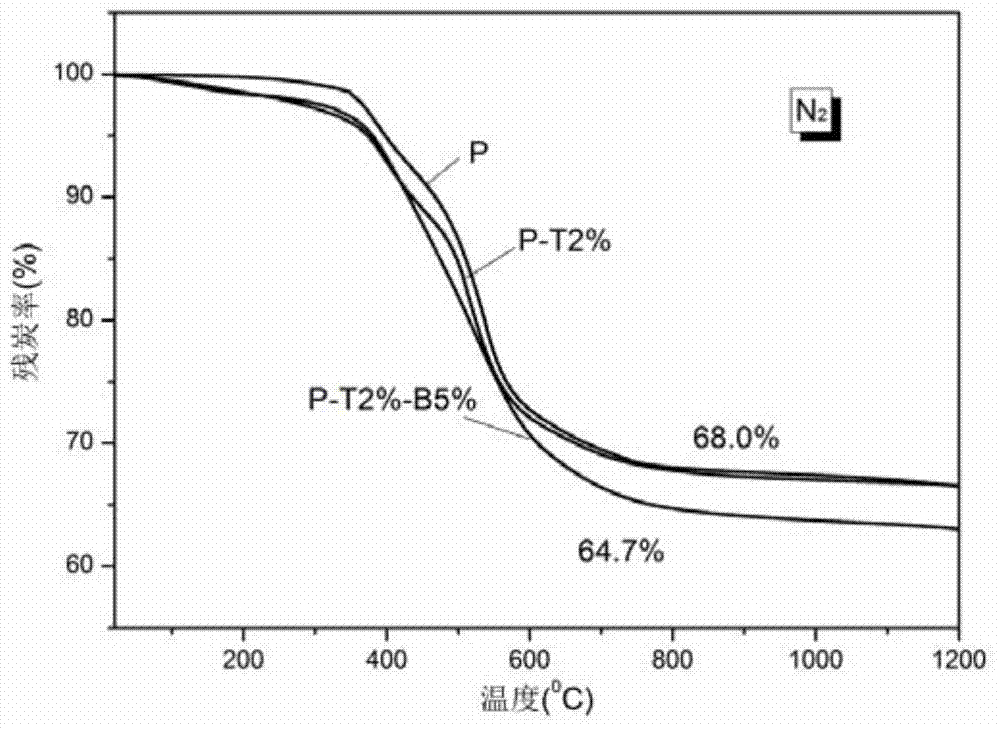

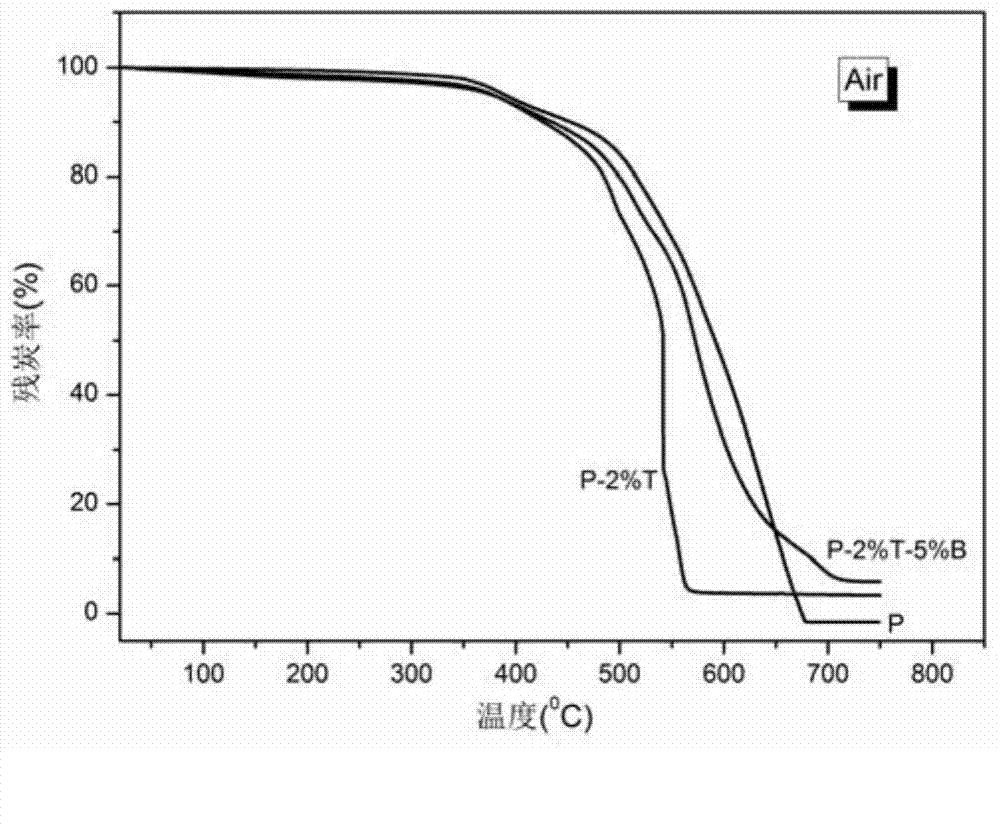

Ablation-resistance resin for resin film infusion process and preparation method thereof

ActiveCN104774424AMeet the requirements of the infiltration processStrong fire resistanceHeat resistanceThermoplastic polyurethane

The invention discloses ablation-resistance resin for a resin film infusion process and a preparation method thereof, for solving such defects of the existing thermosetting resin substrate as poor processing property, high cost, poor heat resistance (low carbon yield) when used in ablating material in the resin film infusion process. According to the invention, thermoplastic polyurethane and boron phenolic resin take a synergic effect to improve the processing property and heat resistance and a preparation method of a resin film (sheet) having resistance to ablation heat and meeting requirements of the resin film infusion process is further obtained. A composite material made by using the film sheet has ablation resistance and oxidation resistance and also has the advantages of low cost, excellent heat resistance, and excellent processing property, can be widely applied to preparation of protective material, carbon material and anti-wear material having ablation heat resistance and can be used in the most advanced fields such as aerospace and electronics technology.

Owner:XI AN JIAOTONG UNIV

Method for producing wear resistant type plastic floor

ActiveCN100462398CImprove wear resistanceStrong fire resistanceFlat articlesTectorial membraneAdhesive

The present invention relates to an abrasion-resistant plastic floor board and its production process. Said process includes the following steps: using waste and old plastic powder as main raw material, adding active calcium carbonate and plastic filling agent as auxiliary raw material, mixing them and extruding them to obtain plastic foamed granules, die-pressing and forming, cooling, setting, drawing and cutting so as to obtain the invented plastic base plate, then sticking plastic protection film on its surface, so that the invented plastic floor board finished product can be made up.

Owner:无锡市中德装饰新材料有限公司

Ceramic composite sheet material and production process thereof

InactiveCN110423096AHigh bonding strengthImprove stabilityCeramic materials productionCeramicwareCeramic compositeInsulation layer

The invention relates to the field of ceramic composite sheet material production processes, and discloses a ceramic composite sheet material and a production process thereof. The ceramic composite sheet material includes an insulation layer and a decorative layer, the insulation layer and the decorative layer both include base materials, the insulation layer further includes a foaming agent, thedecorative layer further includes zirconium silicate, and the base materials are prepared from the components in parts by mass: 20-30 parts of kaoline, 10-15 parts of kieselguhr, 5-8 parts of talcum powder, 3-5 parts of clay, 5-8 parts of a lead-zinc tailing, 8-12 parts of a fluxing agent, 2-4 parts of the foaming agent and 1-3 parts of the zirconium silicate. The service life of the composite sheet material can be prolonged.

Owner:湖北壁玉新材料科技有限公司

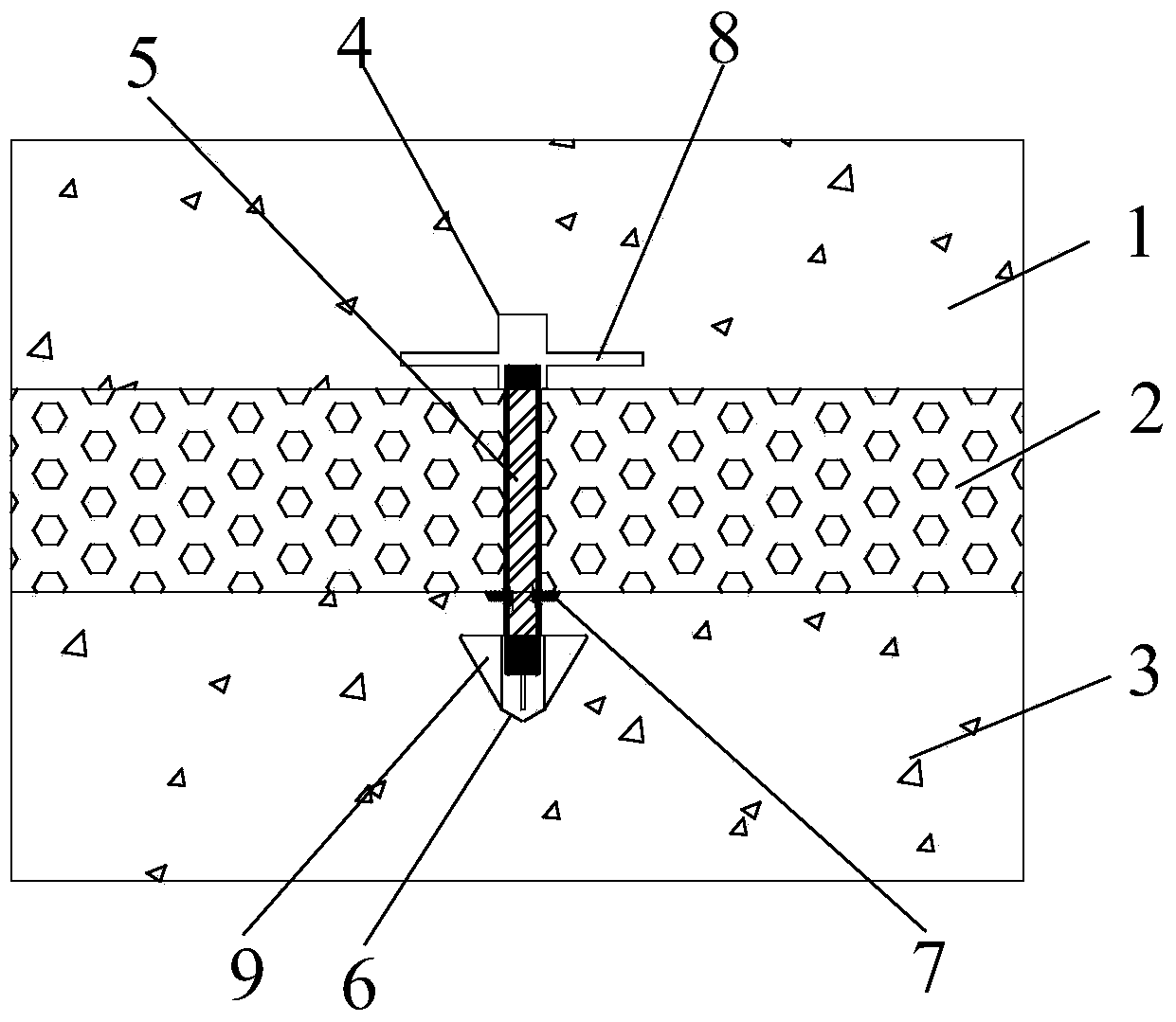

Steel-fiber plastic combined connector, prefabricated sandwich thermal insulation wall and manufacturing method

ActiveCN103967162AStrong bending resistanceStrong shear resistanceWallsBuilding material handlingFiberThermal insulation

The invention discloses a steel-fiber plastic combined connector, a prefabricated sandwich thermal insulation wall and a manufacturing method. The connector comprises a columnar connecting body, a connecting base and a connecting cap, and the connecting base and the connecting ca are fixedly connected to the two ends of the columnar connecting body respectively. The columnar connecting body comprises a metal column, fiber cloth wrapping the outer side of the metal column and a fiber bunch axially wound on the fiber cloth along the metal column. The connecting base comprises a metal base body and a plurality of metal rib angles, and the metal rib angles are distributed on the lateral surface of the metal base body at intervals. The connecting cap comprises a metal cap body, metal inserting ribs and a plastic cap sleeve. The metal inserting ribs transversely penetrate through the metal cap body, and the plastic cap sleeve wraps the exposed part of the metal cap body and the exposed parts of the metal inserting ribs. The connector has the advantages of being high in anti-shear strength, low in processing cost, high in fire resistance, low in heat conduction coefficient, convenient and fast to install and the like. The prefabricated sandwich thermal insulation wall has the advantages of being high in anti-bending performance and anti-shear performance, good in thermal insulation effect, low in manufacturing cost, long in service life and the like.

Owner:SHANGHAI CONSTRUCTION GROUP

Quickly-vitrified fire resisting cable material

The invention provides a quickly-vitrified fire resisting cable material. The fire resisting cable material is prepared from the following raw materials in parts by weight: 40-50 parts of ethylene-vinyl acetate copolymer, 30-40 parts of polyethylene, 20-35 parts of natural rubber, 30-40 parts of butadiene styrene rubber, 4-6 parts of a compatilizer, 1-2 parts of zinc oxide, 20-30 parts of argil, 10-15 parts of kaolin, 5-6 parts of medical stone, 6-7 parts of garnet, 1-2 parts of 3-aminopropyl trimethoxy silane, 3-4 parts of rapeseed oil, 1-2 parts of pentaerythritol, 1-2 parts of melamine cyanurate, 1-2 parts of molybdenum trioxide, 4-6 parts of ammonium molybdate, 1-2 parts of copper oxide, 1-2 parts of polytetrafluoroethylene micropowder, 10-12 parts of DIBP (diisobutyl phthalate), 6-8 parts of tributyl acetocitrate, 2-4 parts of epoxyoctyl stearate, 1-2 parts of a crosslinking agent TAIC (triallyl isocyanurate), 1-2 parts of ferrocene, and 12-15 parts of a modified filler. The fire resisting cable material is high in fire resistance. At high temperature, the fire resisting cable material can be quickly vitrified to protect the normal use of a cable. Meanhwile, the fire resisting cable material is environment-friendly and high in weather resistance.

Owner:北京福斯机械有限公司

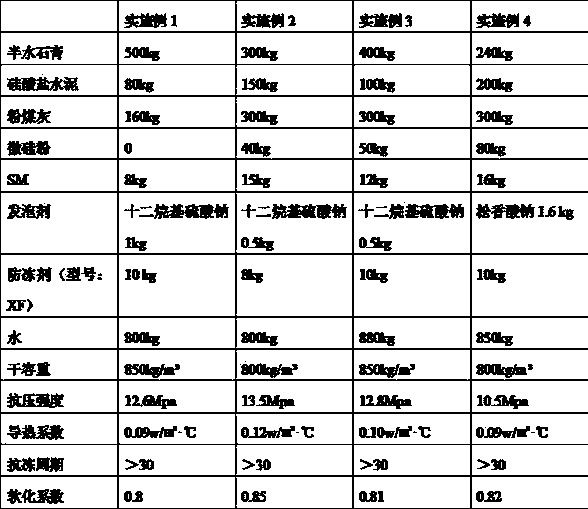

Composite-based self-heat-insulation building block and preparation method thereof

InactiveCN103553532AReduce intensityHigh strengthSolid waste managementCeramicwareFoaming agentCompressive strength

The invention relates to a composite-based self-heat-insulation building block. The composite-based self-heat-insulation building block comprises the following components in parts by weight: 240 to 500 parts of semi-hydrated gypsum, 80 to 200 parts of silicate cement, 160 to 300 parts of coal ash, 8 to 16 parts of a high-efficiency water reducing agent SM, and 0.5 to 1.6 parts of foaming agent. The composite-base self-heat-insulation building block is prepared by adding the high-efficiency water reducing agent SM and the foaming agent into 800 to 880 parts of water to obtain a mixture; adding the semi-hydrated gypsum, the silicate cement and the coal ash into the mixture; stirring the mixture, casting and molding to harden the mixture; drying or naturally curing to obtain the composite-based self-heat-insulation building block. The prepared composite-based self-heat-insulation building block has light weight, high compressive strength, a good heat insulation effect, high water resistance and a high softening coefficient, and is an excellent material for an energy-saving wall body of a building.

Owner:CHANGSHA YUKANG BUILDING MATERIAL TECH

Dry-type floor heat conduction caulking material

InactiveCN101628803AImprove performanceExtended inflation timeSolid waste managementGraphiteThermal expansion

The invention discloses a dry-type floor thermal heat conduction material which comprises the following components by weight percent: 9 to 10 percent of thermal expansion agent, 38 to 40 percent of graphite powder, 38 to 40 percent of white cement, 1.5 to 2 percent of natural gypsum, 1.5 to 2 percent of anhydrite, 2.8 to 3 percent of lime, 5.2 to 5.5 percent of calcium aluminate cement, 0.2 to 0.5 percent of fly ash and 0.2 to 0.5 percent of ground granulated blast furnace slag. The dry-type floor thermal caulking material can be caulked between floor heating tanks and floor heating pipes to play the heat-conduction role well.

Owner:蔡春

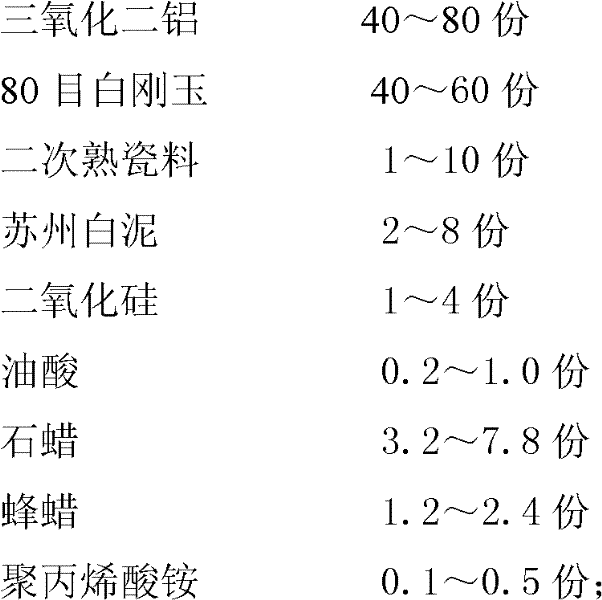

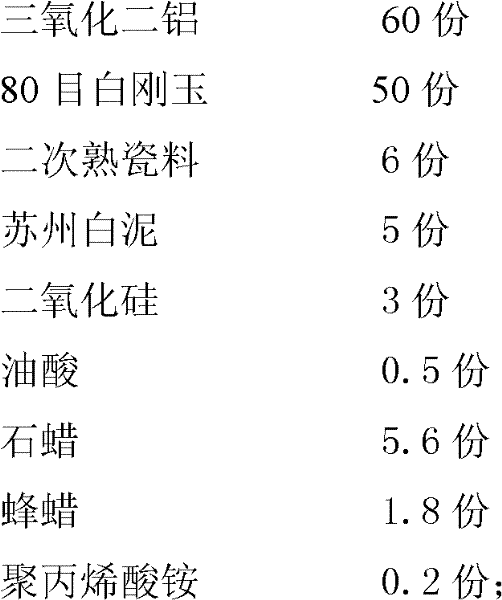

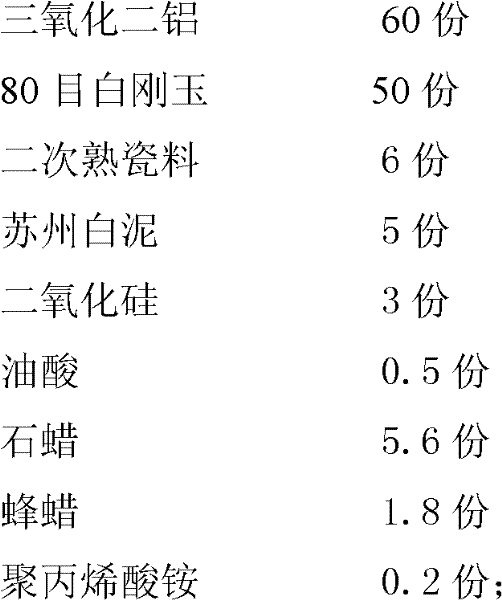

High-temperature fireproof kiln material and preparing method thereof

The invention discloses a high-temperature fireproof kiln material, which comprises the following components, by weight, 40 to 80 parts of aluminum oxide, 40 to 60 parts of 80-mesh white corundum, 1 to 10 parts of secondary ripe porcelain, 2 to 8 parts of Suzhou lime sludge, 1 to 4 parts of silicon dioxide, 0.2 to 1.0 part of oleic acid, 3.2 to 7.8 parts of paraffin wax, 1.2 to 2.4 parts of wax and 0.1 to 0.5 part of ammonium polyacrylate. Air holes of the kiln material utilizing the secondary ripe porcelain as raw materials are more compact and higher in density, and the kiln material is much lower in contractibility rate and high in heat and shock resistance stability, is not easy to burst when used at a high temperature, capable of bearing high temperature ranging from 1800 DEG C to 2000 DEG C, long in service life and has excellent performances of high strength, high fire resistance, high wear resistance and the like by the aid of the secondary ripe porcelain which is resistant tohigh temperature and high in wear resistance. Further, the secondary ripe porcelain as waste can be recycled, so that cost is saved, waste can be changed into treasure, and pollution to the environment is reduced. The high-temperature fireproof kiln material is simple in preparing process, easy to control in conditions and can be produced in large scale industrially.

Owner:CHANGSHU INNOVATION CERAMICS

Production technology of fire-resistant power cable

ActiveCN105632595AEasy to operateReduce manufacturing costPlastic/resin/waxes insulatorsInsulated cablesPolyolefinCopper wire

The invention relates to a production technology of a fire-resistant power cable. The production technology comprises the steps of copper wire drawing, copper wire softening, wrapping of a mica tape on the surface of the softened copper wire to form a fire-resistant layer, extrusion of an upper teflon insulating layer out of the copper wire wrapped with the fire-resistant layer through a fluorine plastic extruder for preparation of core wires, cooling of the core wires, pair twisting of the core wires for formation of a cable, extruding formation of the cabled core wires and flame-retardant low-smoke flame-retardant polyolefin insulation sheath material through a single-screw extruder and power cable coiling and storage. The preparation technology is simple and easy to control and realize, and the power cable prepared by the production technology has excellent electrical transmission performance and mechanical tensile performance, higher flame-retardant and fire-resistant capacity and long service life.

Owner:TIANCHANG FUXIN ELECTRONICS

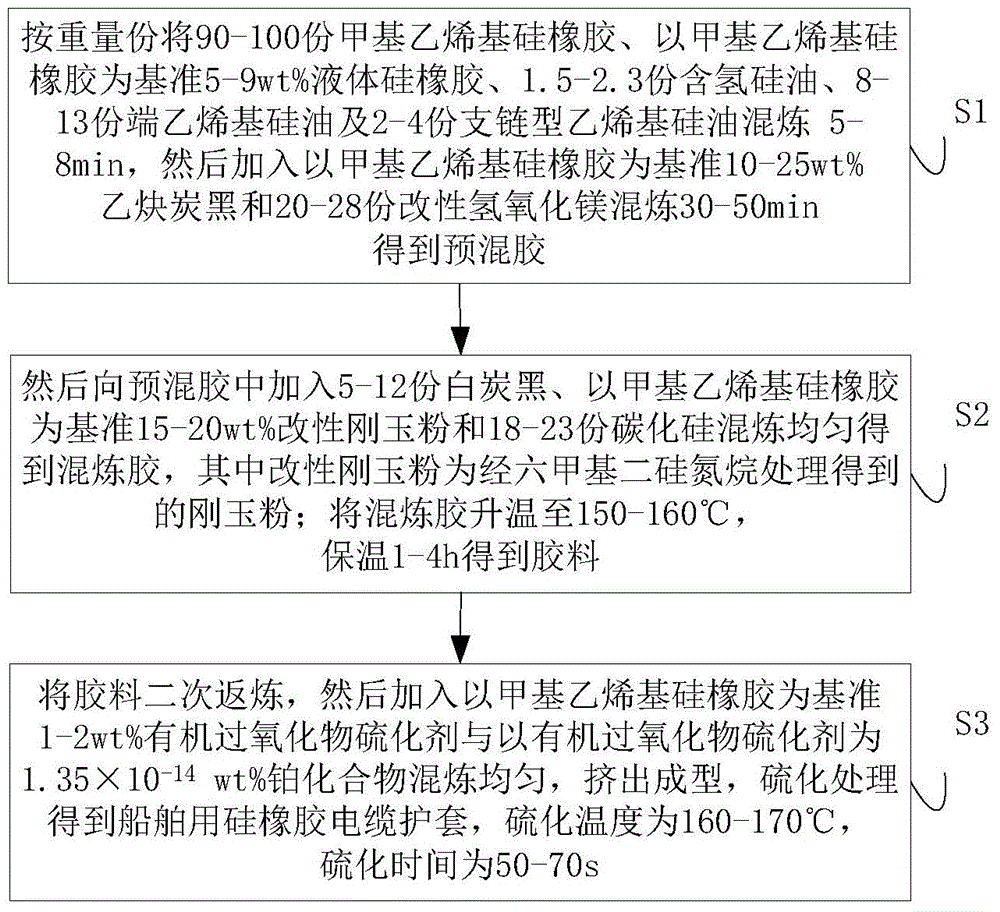

Preparation process for silicone rubber cable sheath used for ship

InactiveCN104788964AImprove conductivityHigh hardnessPlastic/resin/waxes insulatorsInsulated cablesVulcanizationPolymer science

The invention discloses a preparation process for a silicone rubber cable sheath used for a ship. The preparation process comprises the following steps: mixing methyl vinyl silicone rubber, liquid silicone rubber, hydrogen-containing silicone oil, vinyl-terminated silicone oil and branched-chain vinyl silicone oil for 5 to 8 mi, then adding acetylene carbon black and modified magnesium hydroxide and carrying out mixing for 30 to 50 min so as to obtain premixed rubber; adding white carbon black, modified corundum powder and silicon carbide into the premixed rubber, carrying out uniform mixing so as to obtain mixed stock, heating the mixed stock to a temperature of 150 to 160 DEG C and maintaining the temperature for 1 to 4 h so as to obtain a rubber compound; and subjecting the rubber compound to secondary remilling, then adding an organic peroxide vulcanizing agent and a platinum compound and successively carrying out uniform mixing, extrusion molding and vulcanization so as to obtain the silicone rubber cable sheath used for the ship. The silicone rubber cable sheath prepared in the invention has the advantages of stable fire resistance, good insulating properties and good mechanical properties; and the preparation process is simple and poses little environmental pollution.

Owner:ANHUI TIANCAI CABLE GRP

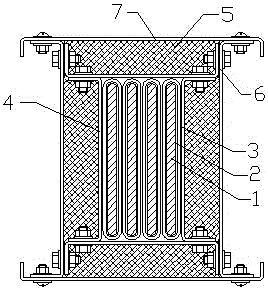

Ceramic silicone rubber fireproof bus duct

InactiveCN105098685AImprove insulation performanceSufficient fire resistanceTotally enclosed bus-bar installationsFilm-coated tabletMaterials science

The invention discloses a ceramic silicone rubber fireproof bus duct. The bus duct comprises conductors arranged side by side, each conductor is wrapped in an insulating film coating and a ceramic silicone rubber coating successively, all the conductors are installed in an inner casing in a sealed manner, an outer casing is arranged outside the inner casing, and alumina silicate fibrofelt is filled between the inner casing and the outer casing. The bus duct can satisfy routine performance requirements for power transmission and distribution safety, insulation and heat insulation performance and fireproof performance are very high, structural design is ingenious and reasonable, it is ensured that the whole bus duct has sufficient insulation and machinery performance, the structure is compact, the size is small, the weight is low, the bus duct is suitable for onsite installation on different space occasions, manufacture and installation are very convenient, and the installation quality is ensured.

Owner:ZHENJIANG GARDERMOEN INTELLIGENT POWER TECH CO LTD

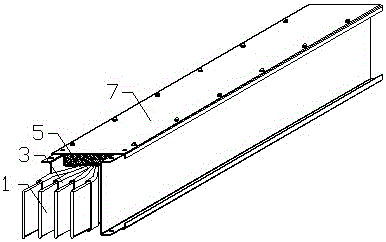

Fireproof anticorrosion cable tray and processing technology thereof

PendingCN108695785AHigh fire resistanceStrong anti-corrosion resistanceElectrical apparatusFire rescueHeat sinkCable tray

The invention relates to a fireproof anticorrosion cable tray and a processing technology thereof, and belongs to the technical field of distribution equipment. The fireproof anticorrosion cable traycomprises a box, a box cover, an extinguishing device and a heat radiation device, the upper and lower surfaces of the box cover are provided with first and second smoke sensors respectively, and theheat radiation device is arranged in the sidewall of the box; the fire extinguishing device comprises a carbon dioxide gas cylinder, an internal nozzle and external nozzles, the internal nozzle is arranged in the inner sidewall of the box, the external nozzles are arranged over the box cover, and a carbon dioxide gas cylinder is communicated with the internal and external nozzles via a pipeline; and the heat radiation device comprise a silica gel heat conducting sheet, a first heat conducting plate and a second heat conducting plate, and one side surface of the second heating conducting plateis provided with metal radiating fin. Due to cooperation among the first smoke sensor, the second smoke sensor and the extinguishing device, the fireproof anticorrosion cable tray can extinguish fireactively, and the fireproof anticorrosion cable tray is much safer.

Owner:荣马电器有限公司

Fire-proof paint

The invention discloses fire-proof paint. The fire-proof paint consists of, linseed oil 100-120 parts, organic silicon resin 50-60 parts, dimethylbenzene 10-12 parts, asbestos 1-2 parts, magnesium hydrate 2-4 parts, water glass 6-10 parts and acrylic resin 2-4 parts. The fire-proof paint can overcome shortcomings of traditional paint, and ingredients of the paint can enable the paint to have a strong fireproof function.

Owner:QIDONG XINDA ELECTROMECHANICAL MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com