Water-based coating

A technology of water-based paint and fire retardant, applied in the field of paint, can solve the problems such as the inability to effectively protect the strength of the wall stucco bottom layer, the water-soluble paint being susceptible to biological damage, and affecting the appearance of buildings, etc., achieving excellent application value, excellent fire protection effect, The effect of inhibiting the occurrence of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

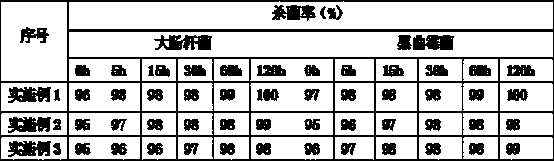

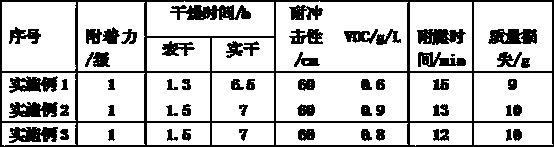

Embodiment 1

[0021] A water-based paint, consisting of the following components by weight: 15 parts of water, 22 parts of acrylic emulsion, 0.4 parts of wetting agent, 0.2 parts of defoamer, 18 parts of titanium dioxide, 13 parts of talcum powder, 0.4 parts of fireproofing agent, 0.3 part of antibacterial agent. Among them, the fireproofing agent is made by mixing expanded vermiculite, glass beads, diatomaceous earth, and fine asbestos in a weight ratio of 2.5:3.5:1.5:1.5; The natural antibacterial agent is a mixture of bamboo leaf extract, ginkgo biloba extract, and pomegranate peel extract in a weight ratio of 1:1:1; the inorganic antibacterial agent is silver-type zeolite antibacterial agent. The components of natural antibacterial agents and inorganic antibacterial agents can be purchased from the market.

Embodiment 2

[0023] A water-based paint, consisting of the following components by weight: 20 parts of water, 25 parts of acrylic emulsion, 0.3 parts of wetting agent, 0.1 part of defoamer, 20 parts of titanium dioxide, 10 parts of talcum powder, 0.5 parts of fireproofing agent, 0.2 part of antibacterial agent. Among them, the fireproofing agent is made by mixing expanded vermiculite, glass beads, diatomite, and fine asbestos in the weight ratio of 2:4:1:2; the antibacterial agent is made by mixing the natural antibacterial agent and inorganic antibacterial agent in the weight ratio of 1:3. The natural antibacterial agent is a mixture of bamboo leaf extract, ginkgo biloba extract, and pomegranate peel extract in a weight ratio of 1:1:1; the inorganic antibacterial agent is silver-type zeolite antibacterial agent. The components of natural antibacterial agents and inorganic antibacterial agents can be purchased from the market.

Embodiment 3

[0025] A water-based paint, consisting of the following components by weight: 30 parts of water, 20 parts of acrylic emulsion, 0.5 parts of wetting agent, 0.3 parts of defoamer, 15 parts of titanium dioxide, 15 parts of talcum powder, 0.3 parts of fireproofing agent, 0.4 part of antibacterial agent. Among them, the fireproofing agent is a mixture of expanded vermiculite, glass beads, diatomite, and fine asbestos in a weight ratio of 3:4:2:1; the antibacterial agent is a mixture of a natural antibacterial agent and an inorganic antibacterial agent in a weight ratio of 1:3. The natural antibacterial agent is a mixture of bamboo leaf extract, ginkgo biloba extract, and pomegranate peel extract in a weight ratio of 1:1:1; the inorganic antibacterial agent is silver-type zeolite antibacterial agent. The components of natural antibacterial agents and inorganic antibacterial agents can be purchased from the market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com