Fireproof anticorrosion cable tray and processing technology thereof

A cable trough box, fire-resistant technology, applied in electrical components, fire rescue and other directions, can solve the problems of large cable load, cable aging, only pay attention to the fire resistance performance of the bridge, and achieve improved safety performance, strong anti-corrosion resistance, and fire resistance. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

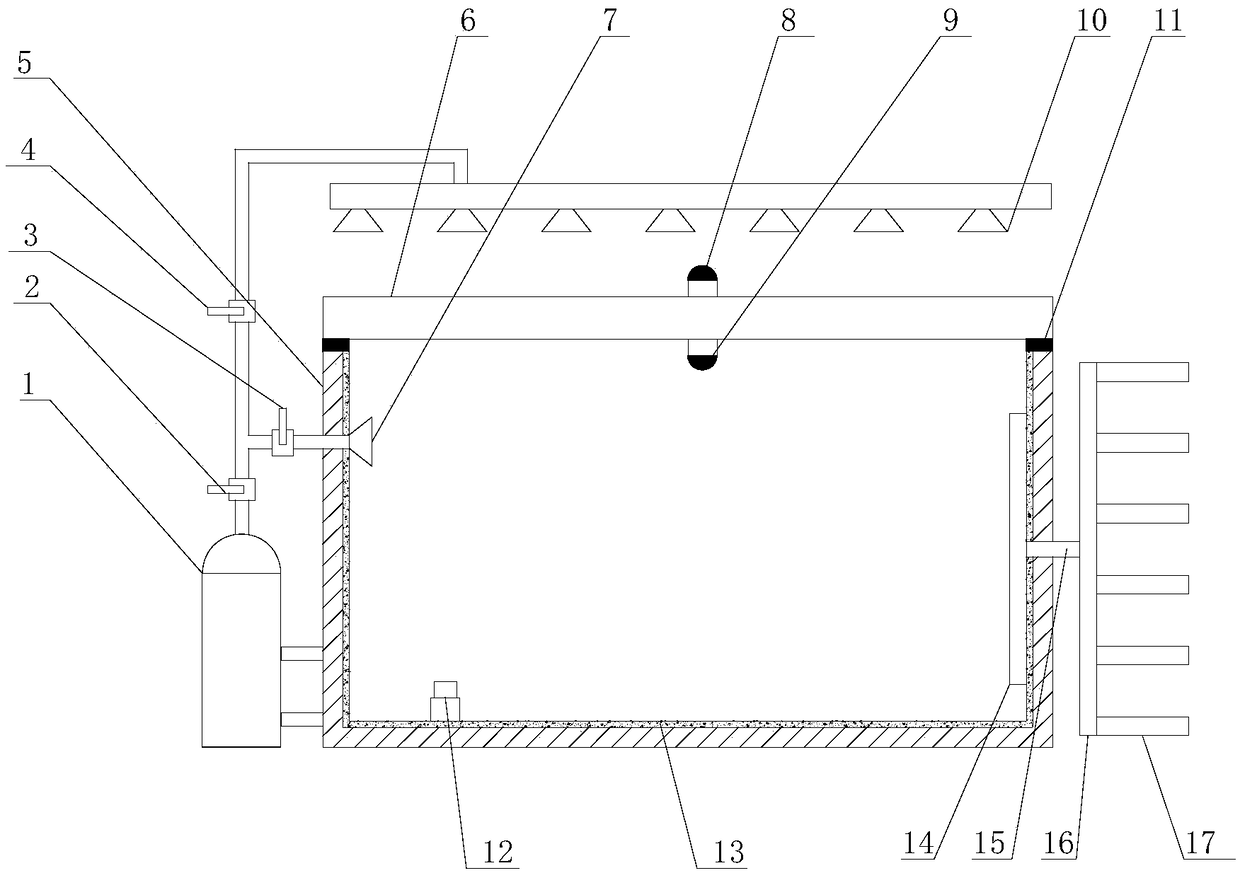

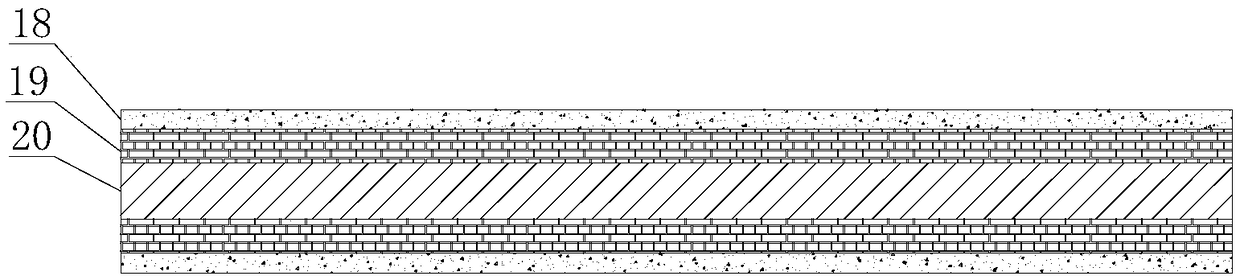

[0046] The fire-resistant and anti-corrosion cable groove box of the present embodiment is as figure 1and 2 As shown, it comprises a cuboid box body 5, a box cover 6, a fire extinguishing device and a cooling device, the box cover 6 is arranged on the top of the box body 5, the upper surface of the box cover 6 is provided with a first smoke sensor 8, and the lower surface of the box cover 6 A second smoke sensor 9 is provided, the fire extinguishing device is arranged near the box body 5, and there is one heat dissipation device, which is arranged on the side wall of the box body 5;

[0047] The fire extinguishing device includes a carbon dioxide gas cylinder 1, an inner nozzle 7 and an outer nozzle 10, the carbon dioxide gas cylinder 1 is fixedly connected to the side wall of the box body 5 through a fixing frame, the inner nozzle 7 is arranged on the inner side wall of the box body 5, and the outer nozzle 10 is seven One and evenly distributed above the box cover 6, the car...

Embodiment 2

[0071] The structure of the fire-resistant and anti-corrosion cable groove box of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0072] The processing technology of the fire-resistant and anti-corrosion cable groove box includes the following steps:

[0073] (1) making the alloy core body layer, the specific steps are as follows:

[0074] a. Ingredients: The mass percentage of the chemical composition in the alloy core layer is: Cr: 0.16%, Mn: 2.55%, Zn: 1.18%, Al: 9.12%, Ni: 1.48%, Mo: 0.08%, Nd: 0.07 %, Ce: 0.02%, Eu: 0.08%, Lu: 0.15%, the balance is Fe;

[0075] b. batching the raw materials of the alloy core layer according to the mass percentage of each component of the alloy core layer, and melting the raw materials of the alloy core layer after batching;

[0076] c, performing continuous casting and rolling on the raw materials of the smelted alloy core layer to obtain an alloy core plate;

[0077] d. Heat and forge the alloy core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com