Hydrophilic adhesive for casting and its prepn

A binder and hydrophilic type technology, which is applied to casting molding equipment, molds, cores, etc., can solve the problems of low refractoriness of sand molds, serious pollution of the environment, and difficulty in sand cleaning of castings, so as to save fuel and man-hours, The effect of abundant resources and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of hydrophilic bonding agent for foundry, it is made up of corn sugar, corn wine, collagen, cornstarch, water, and soybean oil, acrylamide, sulfuric acid, and its weight percent is:

[0026] Corn Sugar 35% Corn Wine 7% Collagen 20%

[0027] Corn Starch 4% Soybean Oil 1% Acrylamide 2%

[0028] Sulfuric acid 1% water 30%.

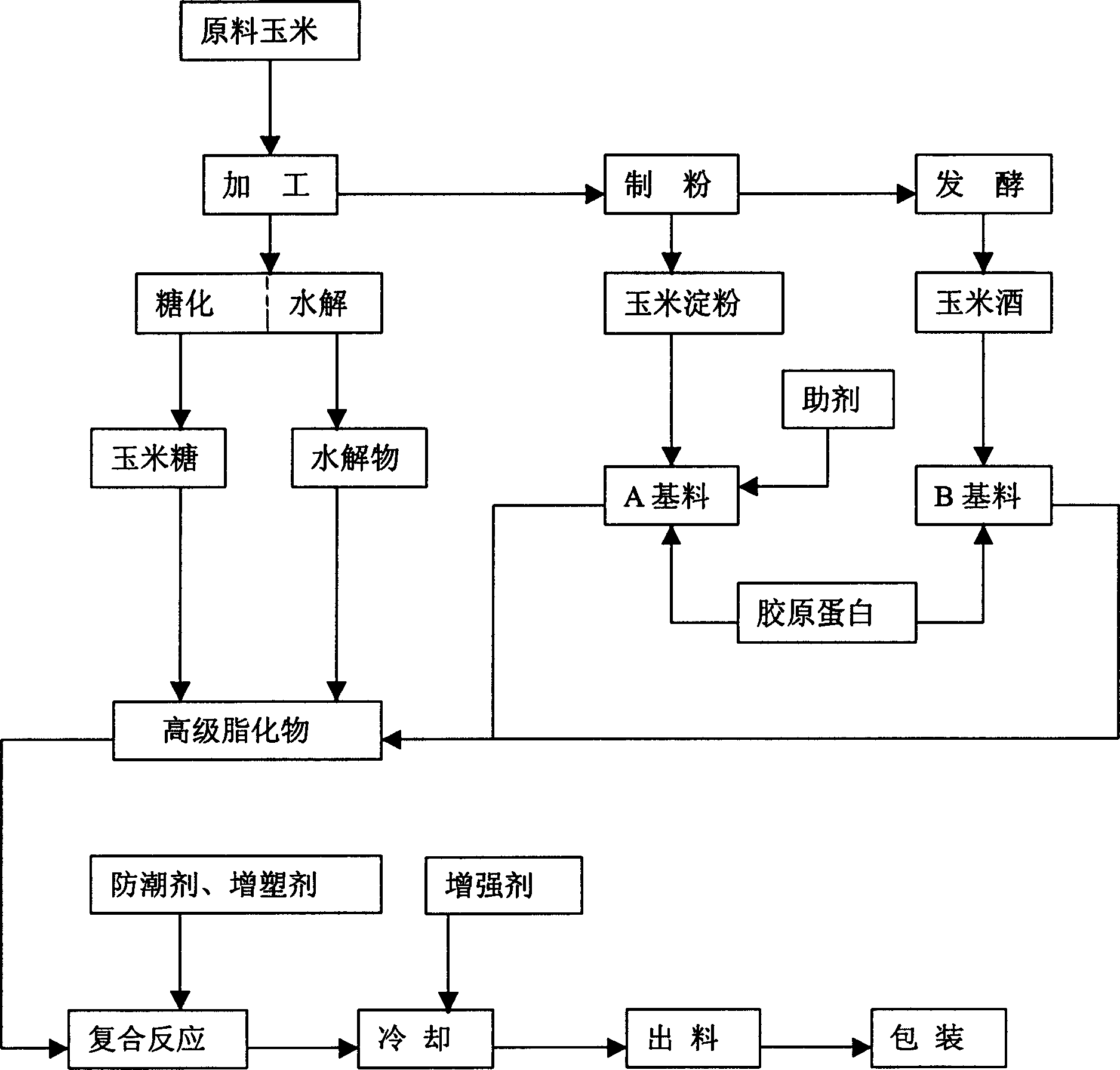

[0029] The production method of the present embodiment (see figure 1 ):

[0030] 1. The raw corn is processed according to the conventional method: corn starch is crushed, soaked, saccharified with glucoamylase, concentrated, and corn sugar is obtained; corn flour is milled, fermented with alcoholic enzyme, and corn wine is obtained.

[0031] 2. Pour 30% water into the dissolver, heat up to 80°C, then add 20% collagen, continue to heat up to 90°C, and stir evenly.

[0032] 3. Pour the stirred protein solution into the two reaction kettles A and B respectively, then add 4% cornstarch and 1% sulfuric acid into the A kettle, raise the temperatu...

Embodiment 2

[0037] A kind of hydrophilic adhesive for foundry, its composition and content (percentage by weight) are as follows:

[0038] Corn Sugar 25% Corn Wine 5% Collagen 15%

[0039] Corn starch 3%, linseed oil 0.5%, nitrogen-free resin 0.5%

[0040] Hydrochloric acid 0.5% water 49%.

[0041] Production method (see figure 1 ):

[0042] 1. The raw corn is made into corn sugar and corn wine according to the conventional process.

[0043] 2. Pour 49% water into the dissolver, raise the temperature to 60°C, then add 15% collagen, continue to heat up to 80°C, and stir.

[0044] 3. Divide the stirred protein solution into two reaction kettles A and B, then add 3% cornstarch and 0.5% hydrochloric acid into the A kettle, raise the temperature to 80°C, and react for 4 hours to prepare the A base material ; Add 5% corn wine into the B kettle, heat up to 80°C, and react for 4 hours to prepare the B base material.

[0045] 4. Pour the above-mentioned reacted A and B base materials into th...

Embodiment 3

[0049] A kind of hydrophilic adhesive for foundry, its component and content (percentage by weight) are as follows:

[0050] Corn hydrolyzate 30%, corn wine 6%, collagen 18%, corn starch 3.2%, soybean oil 0.7%, nitrogen-free resin 1%, phosphoric acid 0.7%, water 40%.

[0051] Production method (see figure 1 ):

[0052] 1. The raw material corn is processed according to the general method: corn flour, inorganic acid hydrolysis, corn hydrolyzate-glucose solution;

[0053] 2. Pour 40% water into the dissolver, raise the temperature to 70°C, then add 18% collagen, continue to heat up to 85°C, and stir.

[0054] 3. Put the stirred protein solution in two reaction kettles A and B respectively, then add 3.2% cornstarch and 0.7% phosphoric acid into kettle A, raise the temperature to 85°C, and react for 5 hours to prepare base A Material; add 6% corn wine in the B kettle, heat up to 85°C, and react for 5 hours to prepare the B base material.

[0055] 4. Pour the above-mentioned A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com