Processing method of fire resistant mica tape and structure

A technology of refractory mica and processing method, which is applied to mica, inorganic insulators, etc., can solve the problems of affecting fire-resistant insulation performance, looseness, fracture, etc., and achieve the effects of improving fire-resistant insulation performance, stable fire-resistant performance, and increasing bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

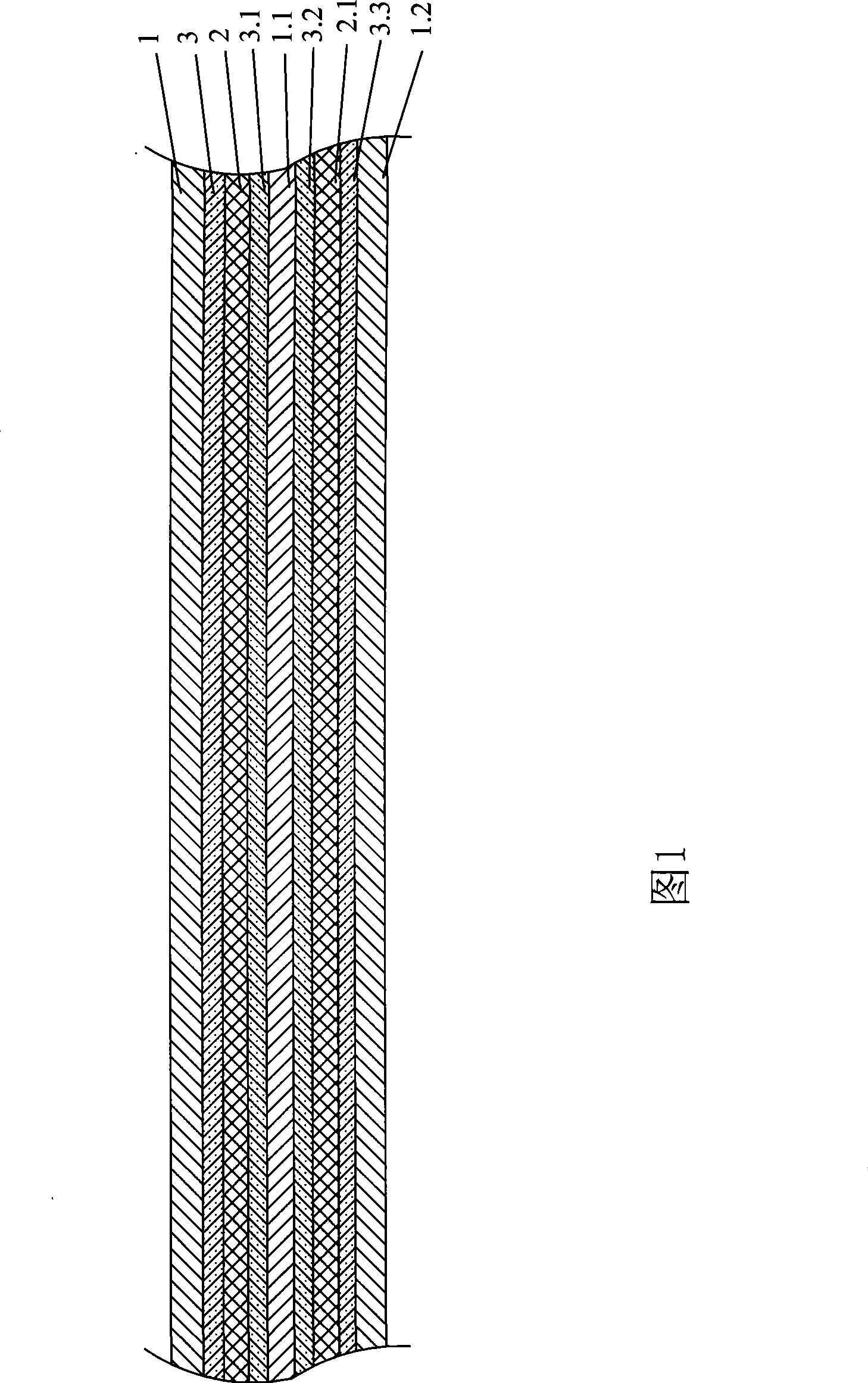

[0044] It is composed of three layers of non-alkali glass fiber cloth and two layers of mica bonded by silicone resin, among which are the layer of non-alkali glass fiber cloth, the layer of silicone resin, the layer of mica, the layer of silicone resin, the layer of non-alkali glass fiber cloth Layer, silicone resin layer, mica layer, silicone resin layer, non-alkali fiber cloth layer.

[0045] The overall processing method of the above-mentioned mica tape is as follows: after the front and back of the non-alkali glass fiber cloth are immersed in the silicone resin glue, a layer of mica paper is laid on it, and after the mica paper is fully infiltrated, a layer of front and back is soaked in silicone. Resin glue non-alkali glass fiber cloth, on top of which a layer of mica paper is flattened, on top of which a layer of front and back is immersed in organic silicon resin glue non-alkali glass fiber cloth as a whole, and then dried and compounded by a dry compound machine. This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com