Making method of fireproof thermal insulation and noise reduction composite wallboard

The technology of a composite wallboard and a manufacturing method, which is applied in the field of building materials, can solve problems such as difficulty in meeting high fire protection requirements and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

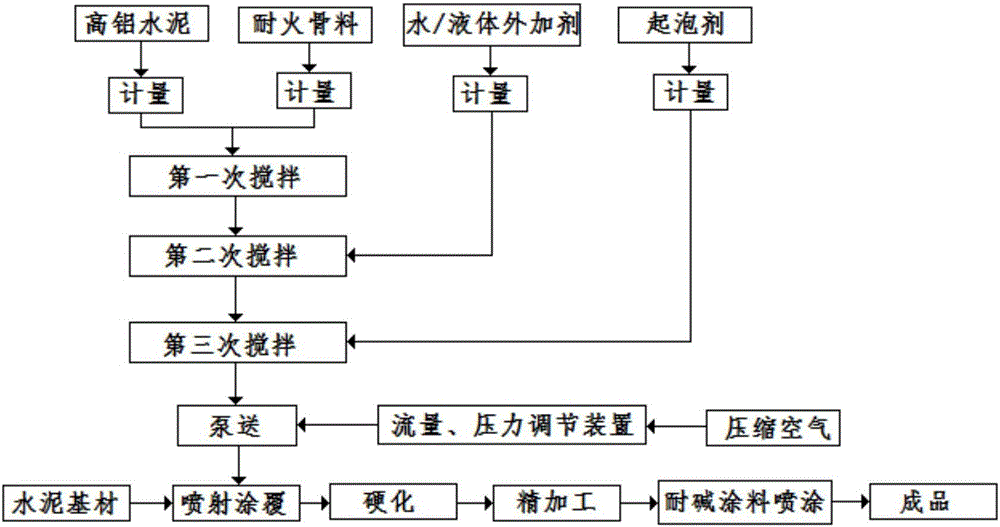

Method used

Image

Examples

Embodiment Construction

[0024] In the present invention, the cement substrate is used as the foundation of the refractory board, and the cement substrate is a dried fiber cement board or a skeleton structure of inorganic materials; the thickness of the board is 5 mm to meet the needs, but the surface of the substrate is required to be rough and not polished.

[0025] Dimensions: 1200 / 2400×300 / 600×(10 / 20 / 50120)mm; the structure within the outer frame of the skeleton can adopt balanced structures such as "field", "feng" and "well".

[0026] Wet expansion rate: ≤0.23%;

[0027] Moisture content: ≤10%, usually 5%

[0028] Drying temperature: 50±5℃

[0029] Deviation limit: length ±5mm

[0030] Width ±3mm

[0031] Thickness ±2mm

[0032] Concrete hollow wall panels: ordinary panels, door frame panels and lintel panels;

[0033] The board length, width and thickness conform to the building modulus, the board length is within 3000mm, and the board width is 300 / 600mm;

[0034] Partition wall thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com