A kind of bio-based soft porcelain and preparation method thereof

A bio-based, soft porcelain technology, applied in the field of building materials and decorative materials, can solve the problems of waste of bamboo resources, environmental pollution, etc., and achieve the effects of enhancing air permeability, improving dispersion, and rich material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

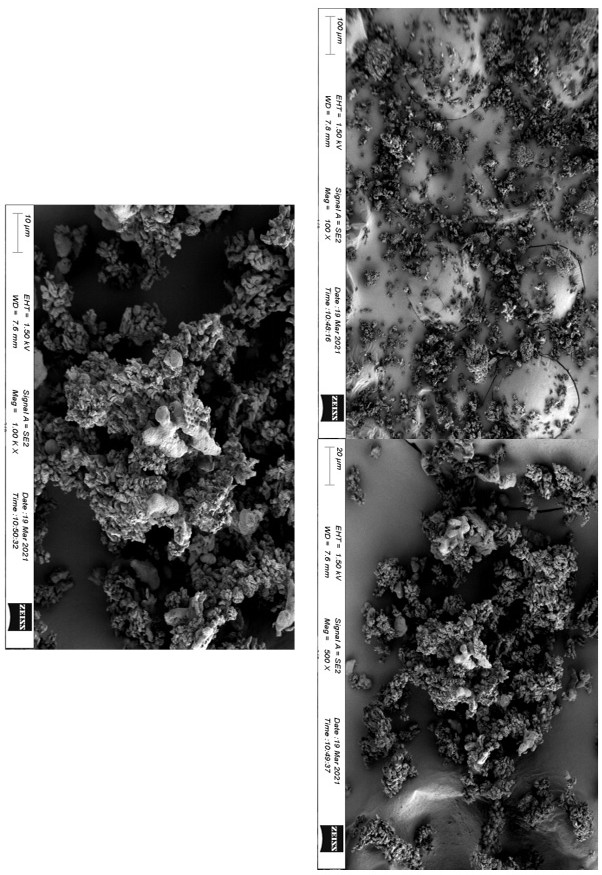

Image

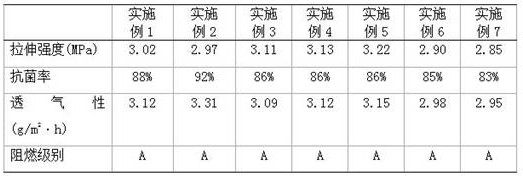

Examples

Embodiment 1

[0031] This bio-based soft porcelain contains the following raw materials by mass: 100 parts of composite powder, 50 parts of polyacrylate emulsion, 15 parts of silane coupling agent, 5 parts of polyether polyurethane, 10 parts of polydimethylsiloxane, waste Fiber 5 servings.

[0032] The processing method of composite powder comprises the steps:

[0033] (1) Wash the egg shells and remove the film, dry and grind them into 2000-mesh fine powder;

[0034] (2) Take 1 kg of egg shell powder, add 50 g of zinc nitrate, 20 g of magnesium carbonate, 10 g of sodium hydroxide and 2.5 kg of pure water to form a solution, and stir for 2 h. After mixing evenly, use spray drying to remove the moisture in the powder.

[0035] (3) Mix the rice husk ash and the egg shell powder obtained in step (2) in a weight ratio of 1:2 with a dry powder mixer and put them into a muffle furnace, set the temperature at 1100 °C, and calcined for 5 hours. Pulverize the block to get composite powder.

[00...

Embodiment 2

[0043] The steps of Example 2 are the same as in Example 1, except that the amount of composite powder added in Example 1 is changed to 130 parts.

Embodiment 3

[0045] The steps of Example 3 are the same as in Example 1, except that the waste fibers in Example 1 are changed into rice husk fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com