Preparation method of biomass nano cellulose carbon aerogel

A nanocellulose and carbon aerogel technology is applied in the field of carbon aerogel preparation, which can solve the problems of lack of raw materials and complicated preparation process, and achieve the effects of good conductivity, low density and rich source of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

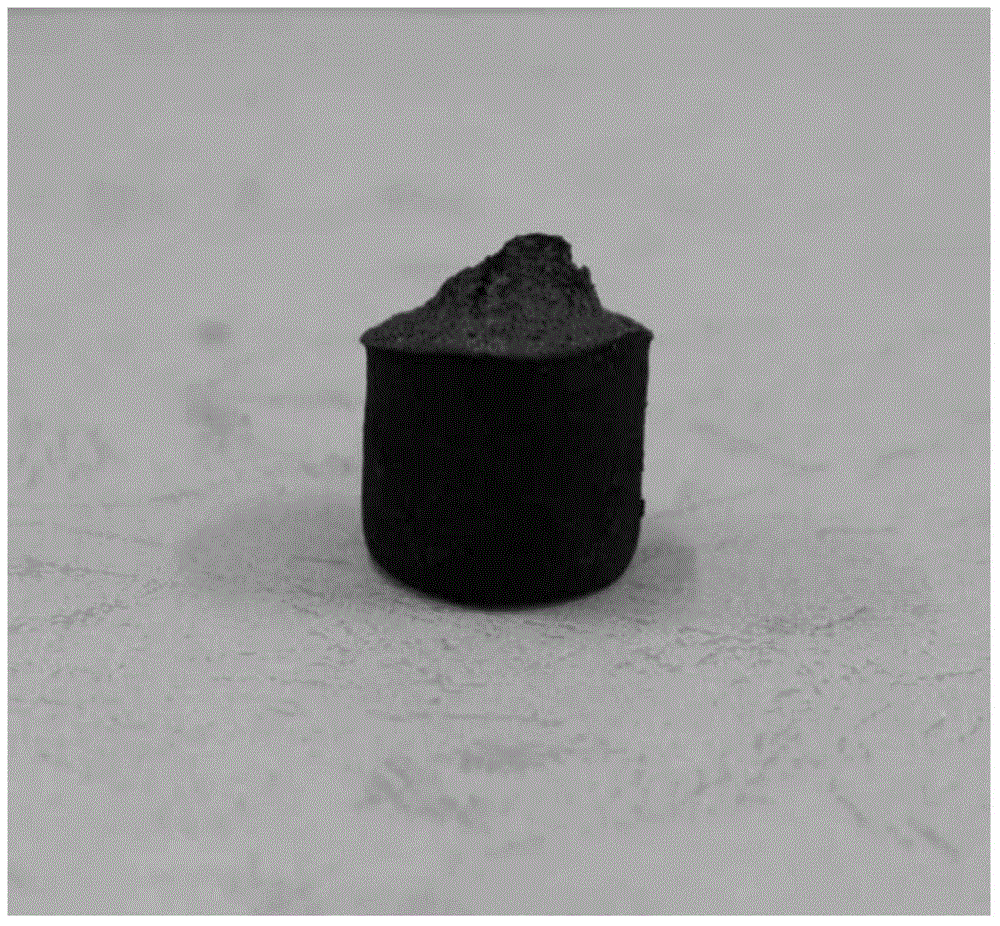

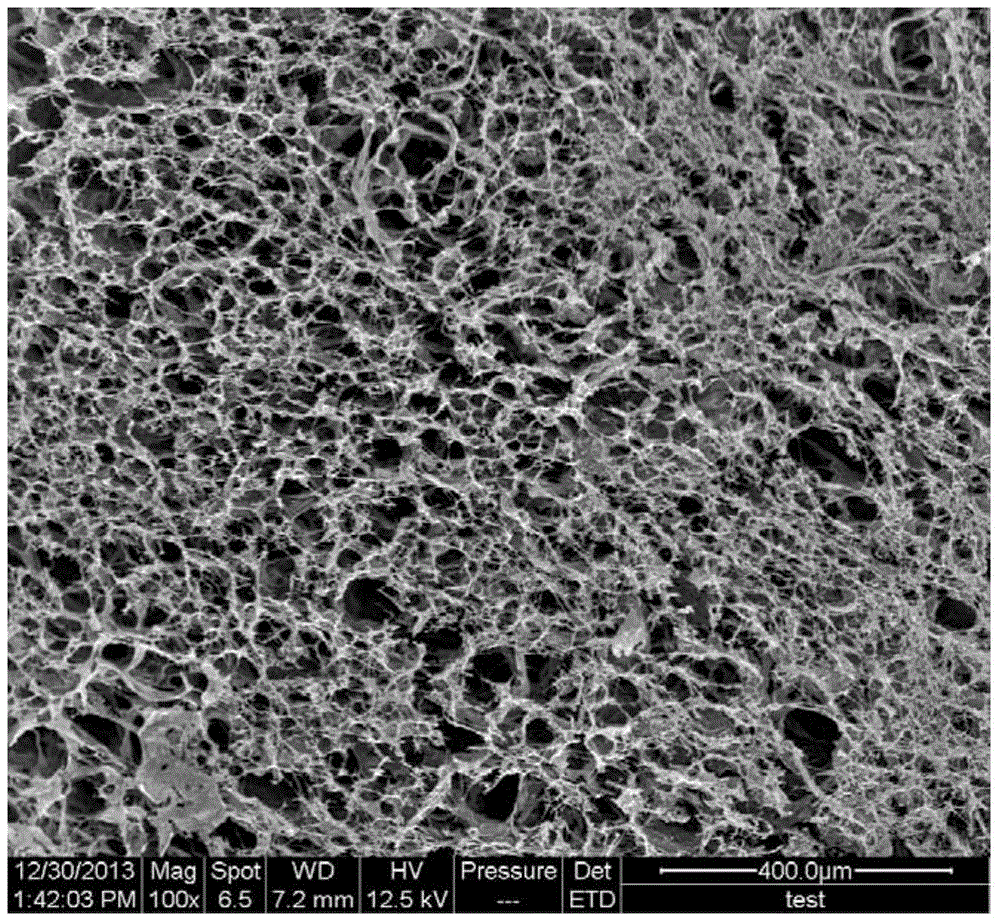

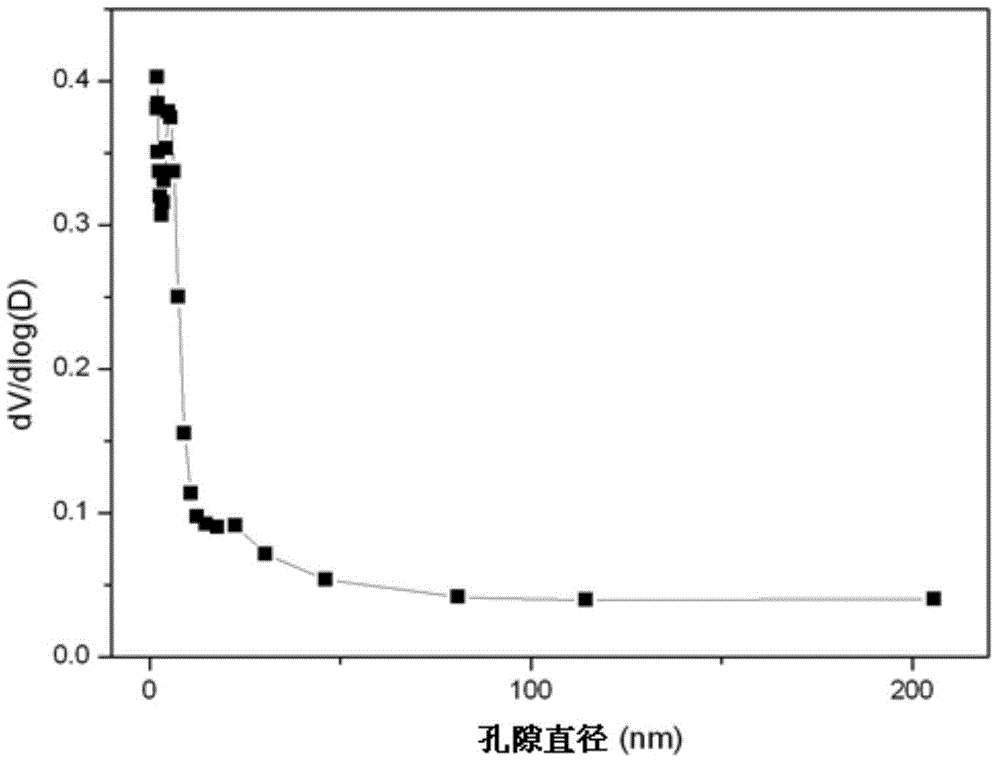

[0019] Specific embodiment one: the preparation method of biomass nanocellulose carbon airgel in this embodiment is carried out according to the following steps:

[0020] 1. Biomass material treatment: treat the biomass material with acidified sodium chlorite, and then use a potassium hydroxide solution with a concentration of 1% to 10% by mass to obtain purified cellulose;

[0021] 2. Prepare purified cellulose aqueous solutions with different concentrations;

[0022] 3. Mechanical treatment: The purified cellulose aqueous solution is subjected to ultrasonic treatment, the working power is 800-1200w, the ultrasonic treatment time is 10-60min, and then the high-pressure homogenization treatment is continued, the treatment time is 5-60min, and the primary pressure is 40-60min. 90bar, and the secondary pressure is 300-450bar to obtain a nanocellulose aqueous suspension, and the nanocellulose aqueous suspension is allowed to stand for 5-10 hours, and then the nanocellulose hydrog...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the biomass material in Step 1 is wood powder or crop processing residue powder, and is sieved with a 60-mesh sieve before use. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, the specific steps of treating the biomass material with acidified sodium chlorite are:

[0029] Add the biomass material to distilled water, then add sodium chlorite and glacial acetic acid, seal the container, heat it in a constant temperature water bath at 75°C for 0.5-1.5 hours, then continue to add sodium chlorite and glacial acetic acid, and seal the container. Heat in a constant temperature water bath at 75°C for 0.5-1.5h, repeat this 5 times, and then wash the sample until neutral. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com