Gypsum board with air purification function and preparation method thereof

A technology for purifying air and gypsum board, applied in the field of building materials, can solve the problem of ineffective removal of formaldehyde, and achieve the effect of rich pores, reducing air odor, and improving waterproofing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

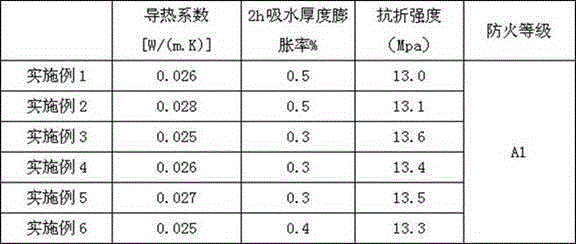

Examples

Embodiment 1

[0021] A gypsum board with the function of purifying air, prepared from the following components in parts by weight: 50 parts of desulfurized gypsum, 20 parts of rock wool, 15 parts of diatomite, 10 parts of shell powder, 3 parts of activated carbon, 1 part of waterproofing agent, 0.3 parts of foaming agent, 0.1 part of binder, 0.1 part of photocatalyst, and 30 parts of water.

Embodiment 2

[0023] A gypsum board with the function of purifying air, prepared from the following components in parts by weight: 80 parts of desulfurized gypsum, 30 parts of rock wool, 25 parts of diatomaceous earth, 20 parts of shell powder, 5 parts of activated carbon, 3 parts of waterproofing agent, 0.8 parts of foaming agent, 0.5 parts of binder, 0.5 parts of photocatalyst, and 55 parts of water.

Embodiment 3

[0025] A gypsum board with the function of purifying air, prepared from the following components in parts by weight: 65 parts of desulfurized gypsum, 25 parts of rock wool, 20 parts of diatomite, 15 parts of shell powder, 4 parts of activated carbon, 2 parts of waterproofing agent, 0.5 parts of foaming agent, 0.3 parts of binder, 0.3 parts of photocatalyst, and 42 parts of water. The waterproofing agent is liquid paraffin, the foaming agent is sodium benzenesulfonate, the binder is casein, and the photocatalyst is nano titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com