Fireproof coating composition and fireproof steel material

A technology for fire-resistant coatings and steel materials, which is applied in the field of fire-resistant steel materials and fire-resistant coating compositions. It can solve the problems of unsuitable fire protection for exposed steel beams, poor water resistance and weather resistance, and poor color, and achieve enhanced fire and heat insulation effects. Strong fire resistance, the effect of extending the fire resistance limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

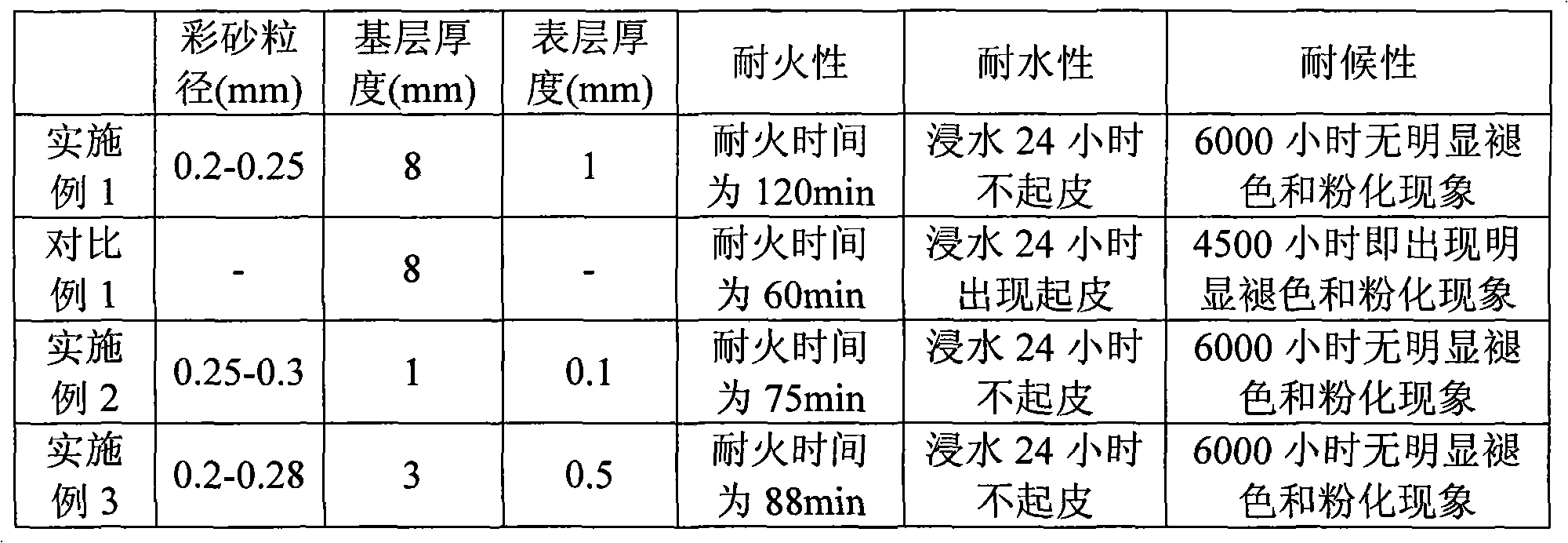

Embodiment 1

[0032] This example is used to illustrate the fireproof coating composition and fireproof steel material of the present invention.

[0033] Add 100kg of silica sand into the muffle furnace, roast at 700°C for 30min, then transfer the roasted silica sand to the sand mixer, and add 0.4kg of Epoxy resin (purchased from Beijing Renchuang Heli Chemical Technology Co., Ltd., E51, with a weight average molecular weight of 800), 0.1kg of phthalocyanine blue (purchased from Dainichi Chemical Co., Ltd., 4920 type), continue to stir, and the temperature drops to At 130°C, add 0.1kg of hexamethylenetetramine to the mixture and stir for 60s to obtain colored sand.

[0034] With 100kg of expanded vermiculite (purchased from Yatong Mineral Powder Factory in Lingshou County, the average particle diameter is 1mm), 80kg of Portland cement (purchased from Tangshan Liujiu Cement Co., Ltd., the particle diameter is 0.01-0.05μm) After mixing evenly with 40 lg of water, add 5 kg of aluminum hydroxi...

Embodiment 2

[0038] This example is used to illustrate the fireproof coating composition and fireproof steel material of the present invention.

[0039] Put 100kg of silica sand into the muffle furnace, roast at 700°C for 30min, then transfer the roasted silica sand to the sand mixer, and add 2.4kg of silica sand at a stirring speed of 120r / min to 160°C Epoxy resin (purchased from Beijing Renchuang Heli Chemical Technology Co., Ltd., E44, with a weight average molecular weight of 3000), 0.5kg of carbon black (purchased from Dainichi Seika Chemical Co., Ltd., H190), continue to stir, and the temperature drops to 130 ° C At this time, add 0.6kg of hexamethylenetetramine to the mixture and stir for 120s to obtain colored sand.

[0040] 100kg of expanded perlite (purchased from Xinyuan Bentonite Factory in Xinyang Industrial City, with an average particle diameter of 0.5mm), 50kg of magnesium hydroxide (purchased from Taixing Chemical Co., Ltd., with an average particle diameter of 0.05mm) and...

Embodiment 3

[0042] This example is used to illustrate the fireproof coating composition and fireproof steel material of the present invention.

[0043] Add 100kg of silica sand into the muffle furnace, roast at 700°C for 30min, then transfer the roasted silica sand to the sand mixer, and add 1.2kg of silica sand at a stirring speed of 120r / min to 160°C Perchlorethylene resin (purchased from Shenzhen Yoshida Chemical Co., Ltd., with a weight-average molecular weight of 1000) and 0.3 kg of carbon black (purchased from Dainichi Seika Chemical Co., Ltd., H190) were stirred for 80 seconds to obtain colored sand.

[0044] 20kg of mineral wool (purchased from Yahua Mineral Wool Factory, with an average particle diameter of 0.1mm), 100kg of aluminum ceramic powder (purchased from Yixing Fengrui Porcelain Industry Co., Ltd., with an average particle diameter of 0.01mm) and 20kg After the water is mixed evenly, add 5kg of antimony trioxide and mix evenly to obtain the first mixture, spray the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com