Ablation-resistance resin for resin film infusion process and preparation method thereof

A resin film and ablation resistance technology, applied in the field of resin and its preparation, can solve the problem that the heat resistance and ablation resistance of the modified resin film cannot meet the requirements of the ablation material, and the heat resistance and toughness cannot meet the ablation resistance. Corrosion materials development requirements, reducing the crosslinking density of phenolic resins and other issues, to achieve the effects of excellent mechanical properties, strong fire resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

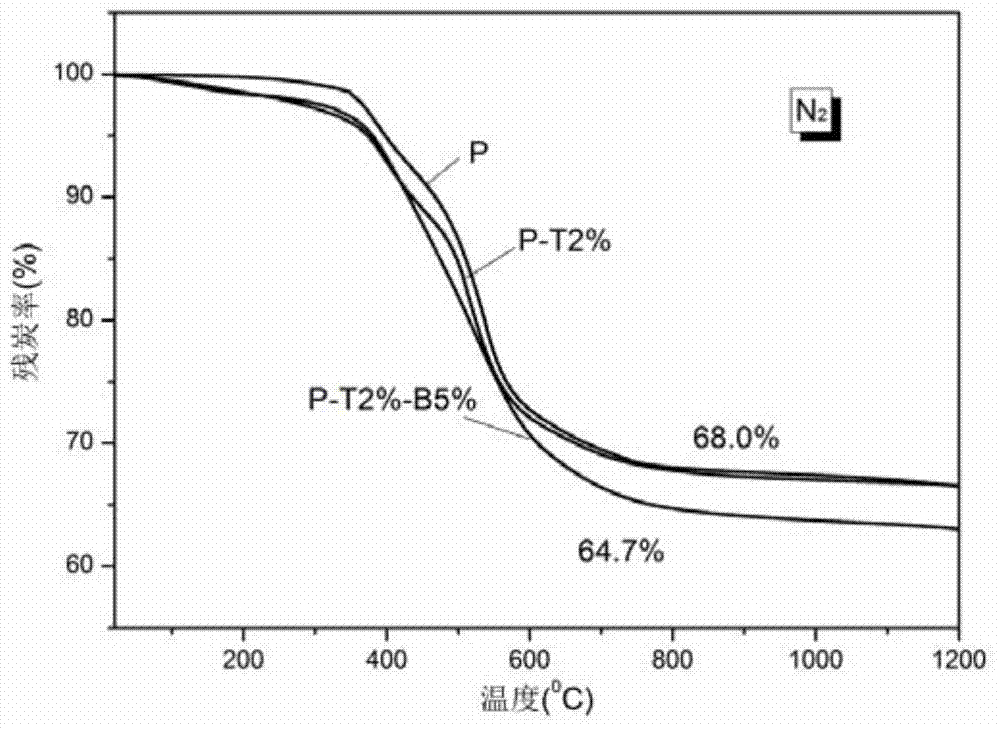

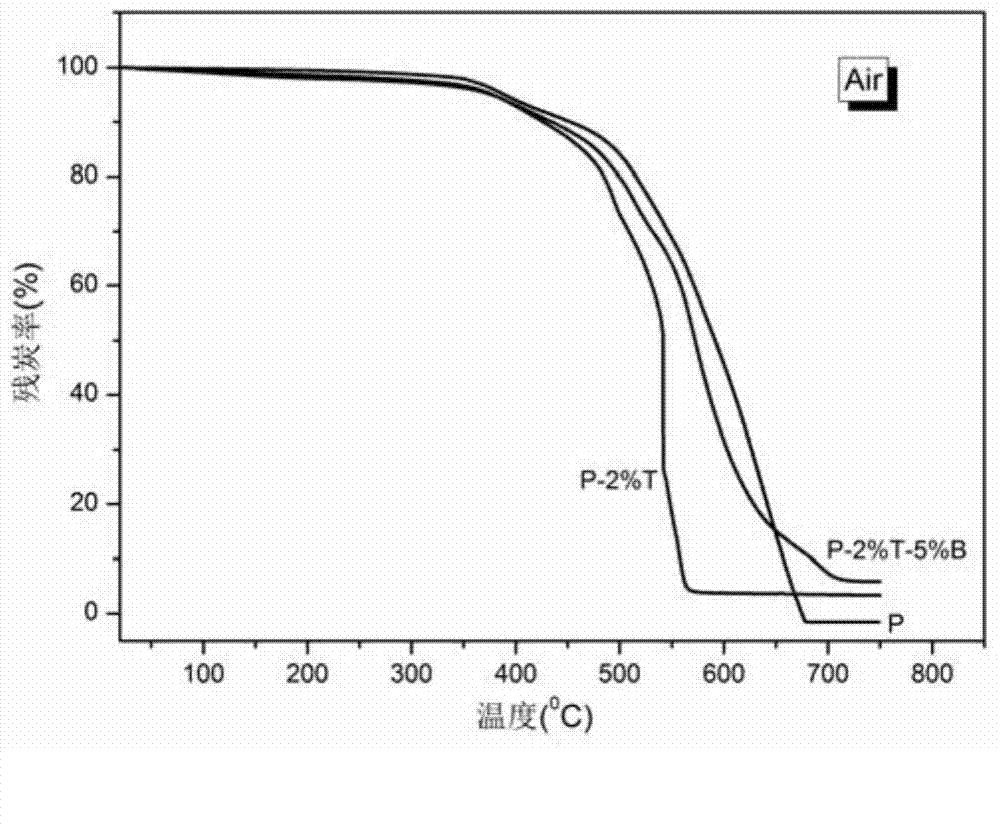

[0025] The ablation-resistant resin for the resin film infiltration process is composed of a mixture of 100 parts of barium phenolic resin, 20 parts of polyester polyurethane and 5 parts of aryl boron phenolic resin in any proportion by mass;

[0026] The preparation method of the ablation-resistant resin for the resin film infiltration process of the present invention comprises the following steps:

[0027] 1) Place the barium phenolic resin solution on the polytetrafluoroethylene film and spread it flat, then put it into a vacuum drying oven, and after vacuum drying, drop to room temperature and take it out to obtain the prepolymer of the barium phenolic resin;

[0028] 2) mixing the polyester polyurethane and the aryl boron phenolic resin with the thermosetting barium phenolic resin obtained in step 1) in any proportion, and stirring evenly to obtain the mixture;

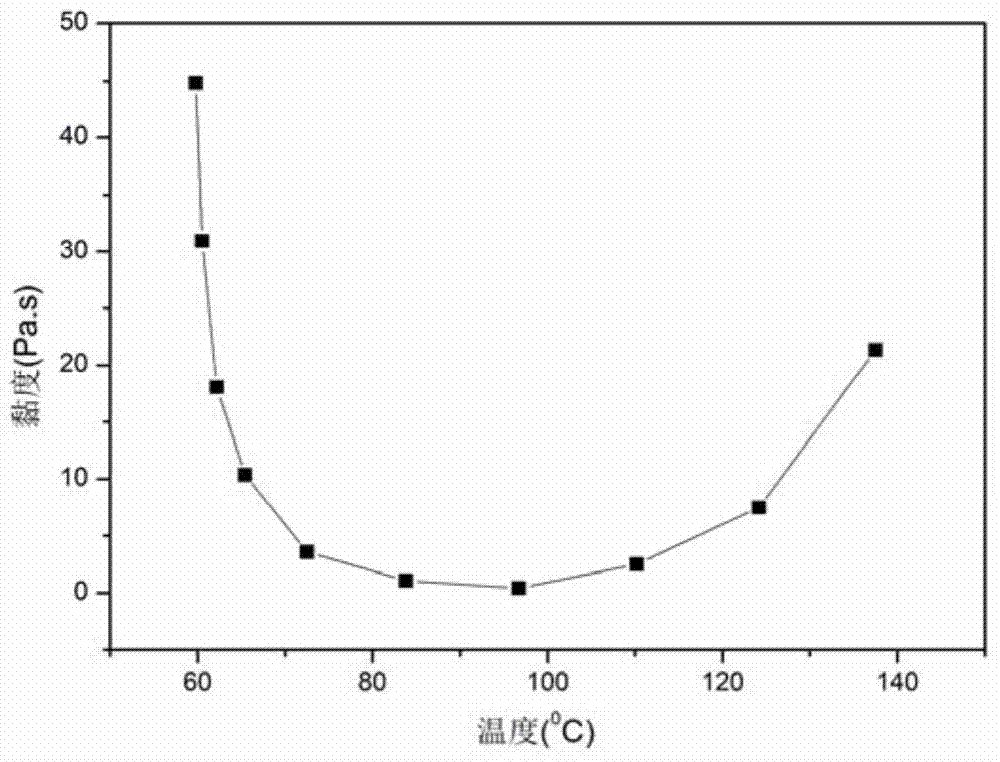

[0029] 3) The mixture obtained in step 2) and mixed in any proportion is placed in an oven and reacted at a te...

Embodiment 2

[0035] The ablation-resistant resin for the resin film infiltration process of the present invention is composed of 100 parts by mass of barium phenolic resin and 4 parts of polyester polyurethane;

[0036] The preparation method of the ablation-resistant resin for the resin film infiltration process of the present invention comprises the following steps:

[0037] 1) Place the barium phenolic resin solution on the polytetrafluoroethylene film and spread it flat, then put it into a vacuum drying oven, and after vacuum drying, drop to room temperature and take it out to obtain the prepolymer of the barium phenolic resin;

[0038] 2) mixing the polyester polyurethane with the barium phenolic resin obtained in step 1) in any proportion, and stirring evenly to obtain the mixture;

[0039] 3) The mixture obtained in step 2) and mixed in any proportion is placed in an oven and reacted at a temperature of 100°C. After the reaction is completed, the ablation heat-resistant resin for th...

Embodiment 3

[0045] The ablation-resistant resin for the resin film infiltration process of the present invention is a mixture of 100 parts by mass of barium phenolic resin, 4 parts of polyester polyurethane and 2 parts of aryl boron phenolic resin in any proportion. composition;

[0046] The preparation method of the ablation-resistant resin for the resin film infiltration process of the present invention comprises the following steps:

[0047] 1) Place the barium phenolic resin solution on the polytetrafluoroethylene film and spread it flat, then put it into a vacuum drying oven, and after vacuum drying, drop to room temperature and take it out to obtain the prepolymer of the barium phenolic resin;

[0048] 2) mixing the polyester polyurethane and the aryl boron phenolic resin with the tungsten phenolic resin obtained in step 1) in any proportion, and stirring evenly to obtain the mixture;

[0049] 3) The mixture obtained in step 2) mixed in any proportion is placed in an oven and react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com