Patents

Literature

63 results about "Ground granulated blast-furnace slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

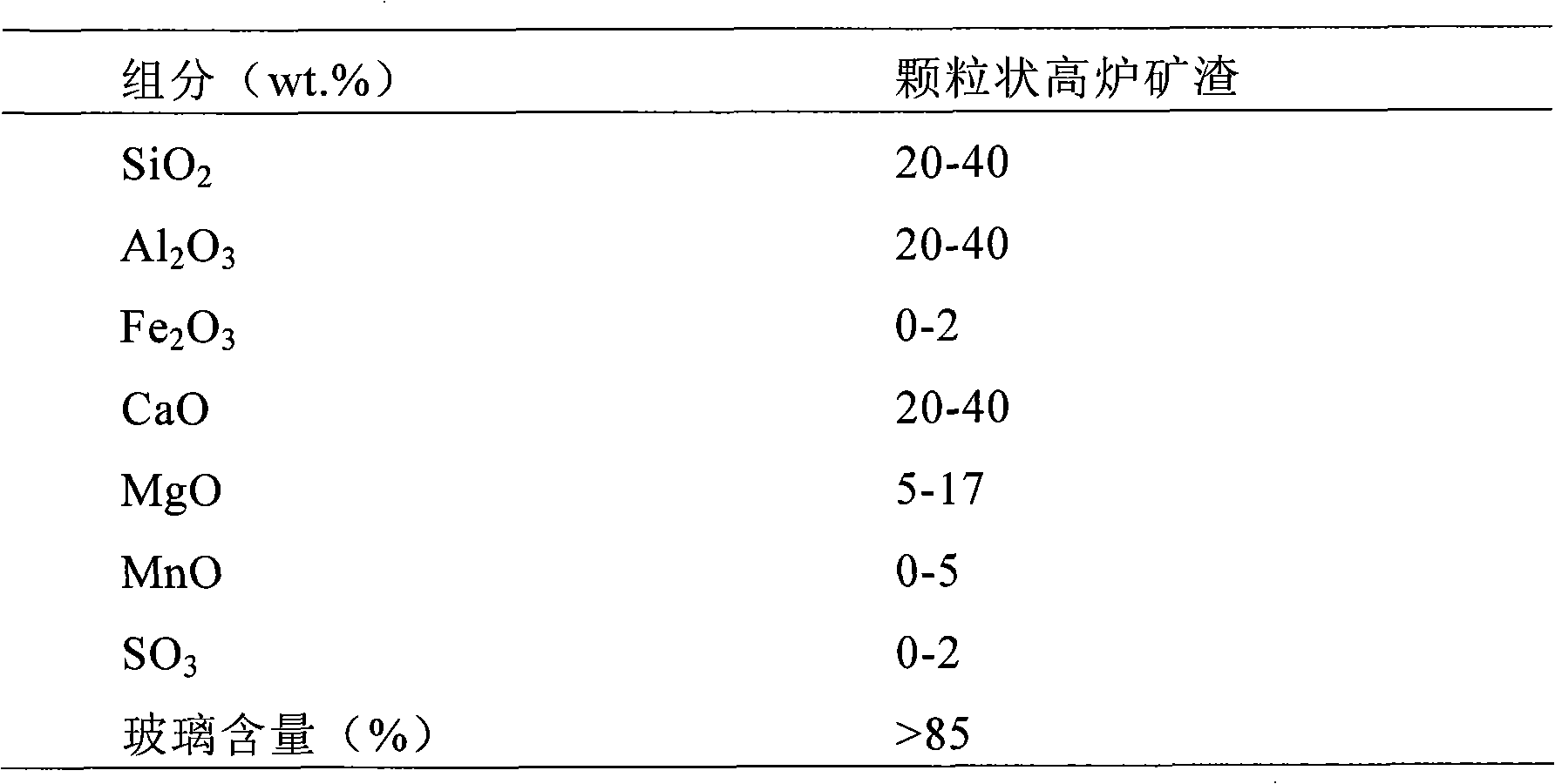

Ground-granulated blast-furnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a by-product of iron and steel-making) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder.

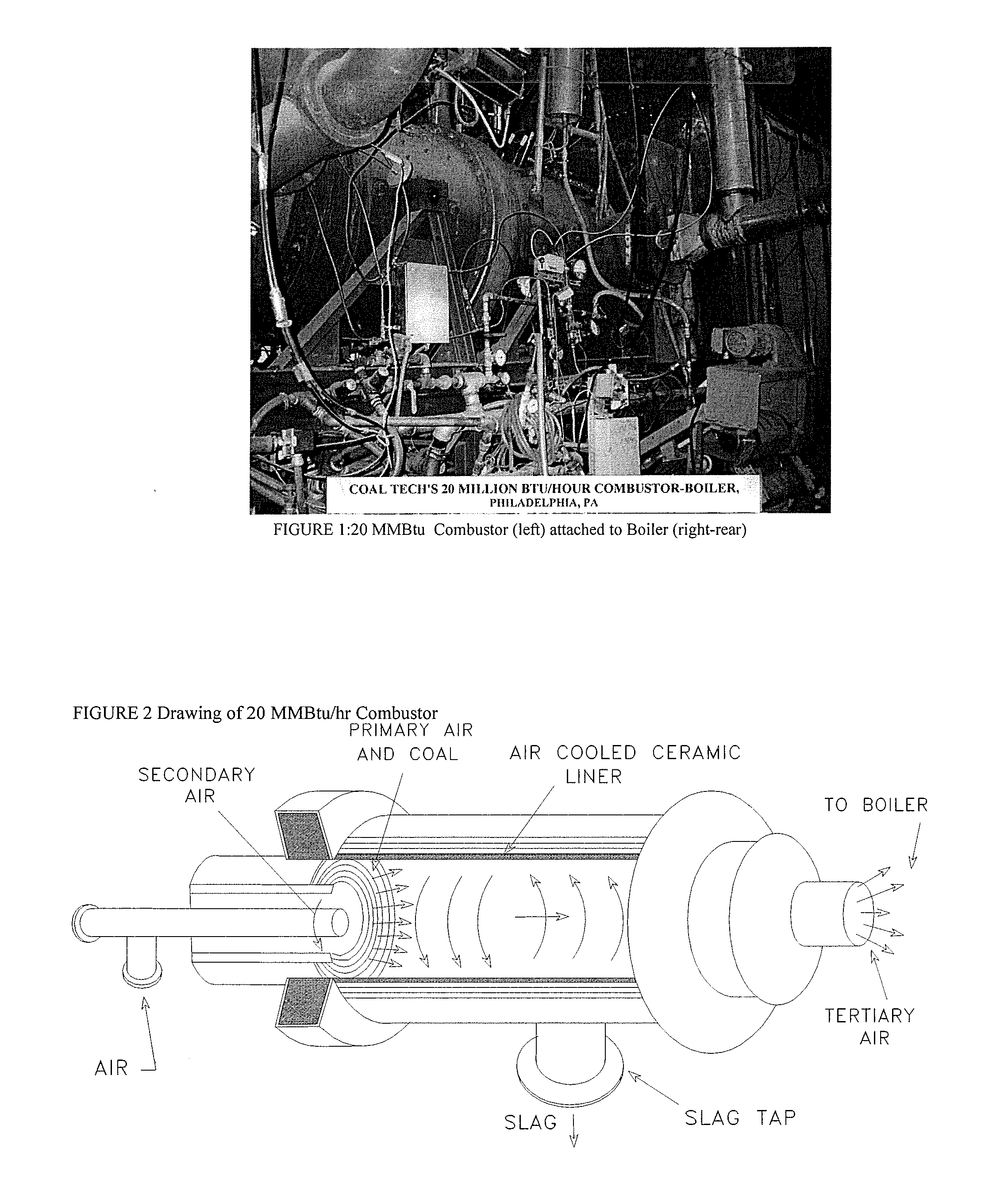

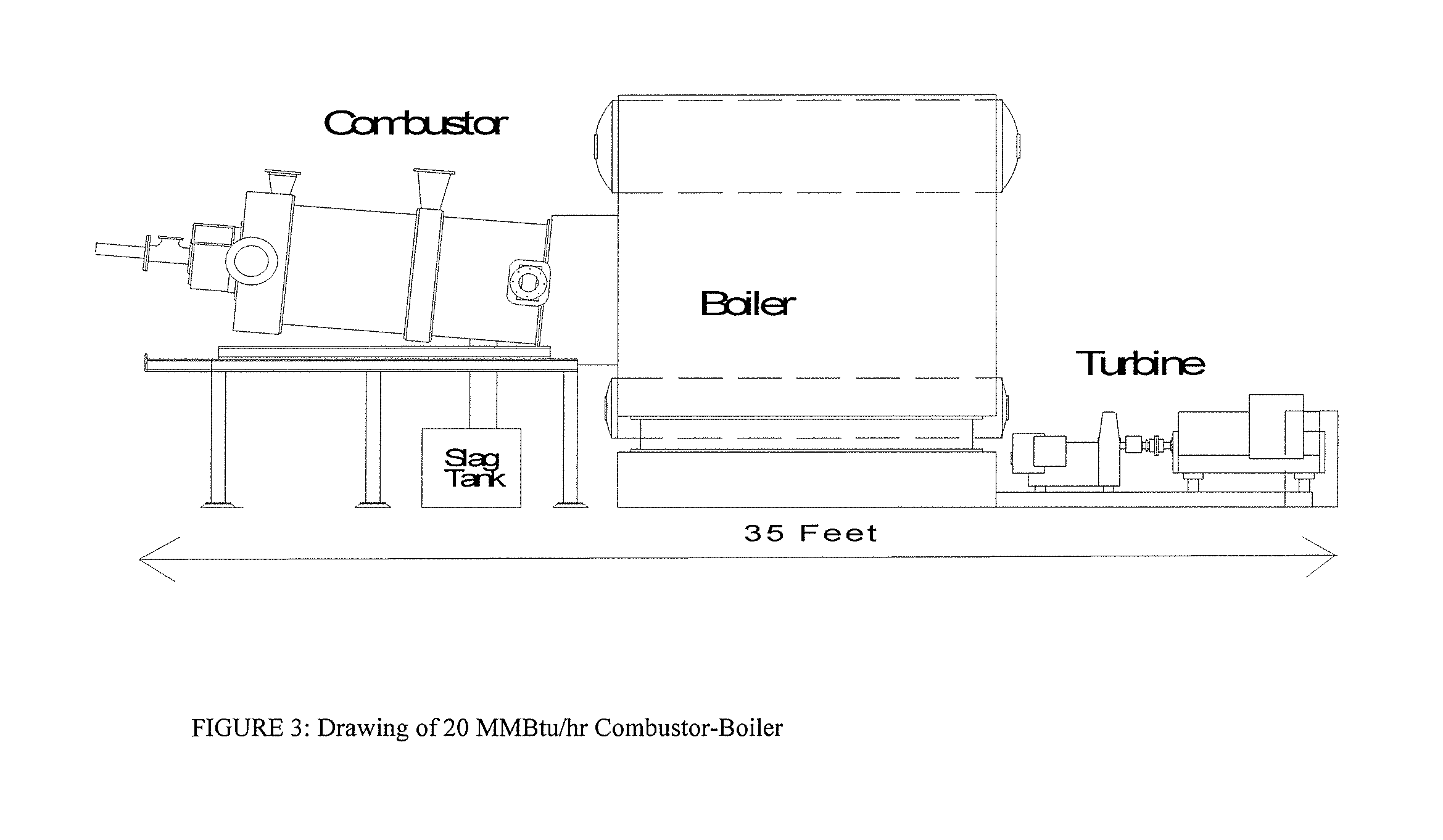

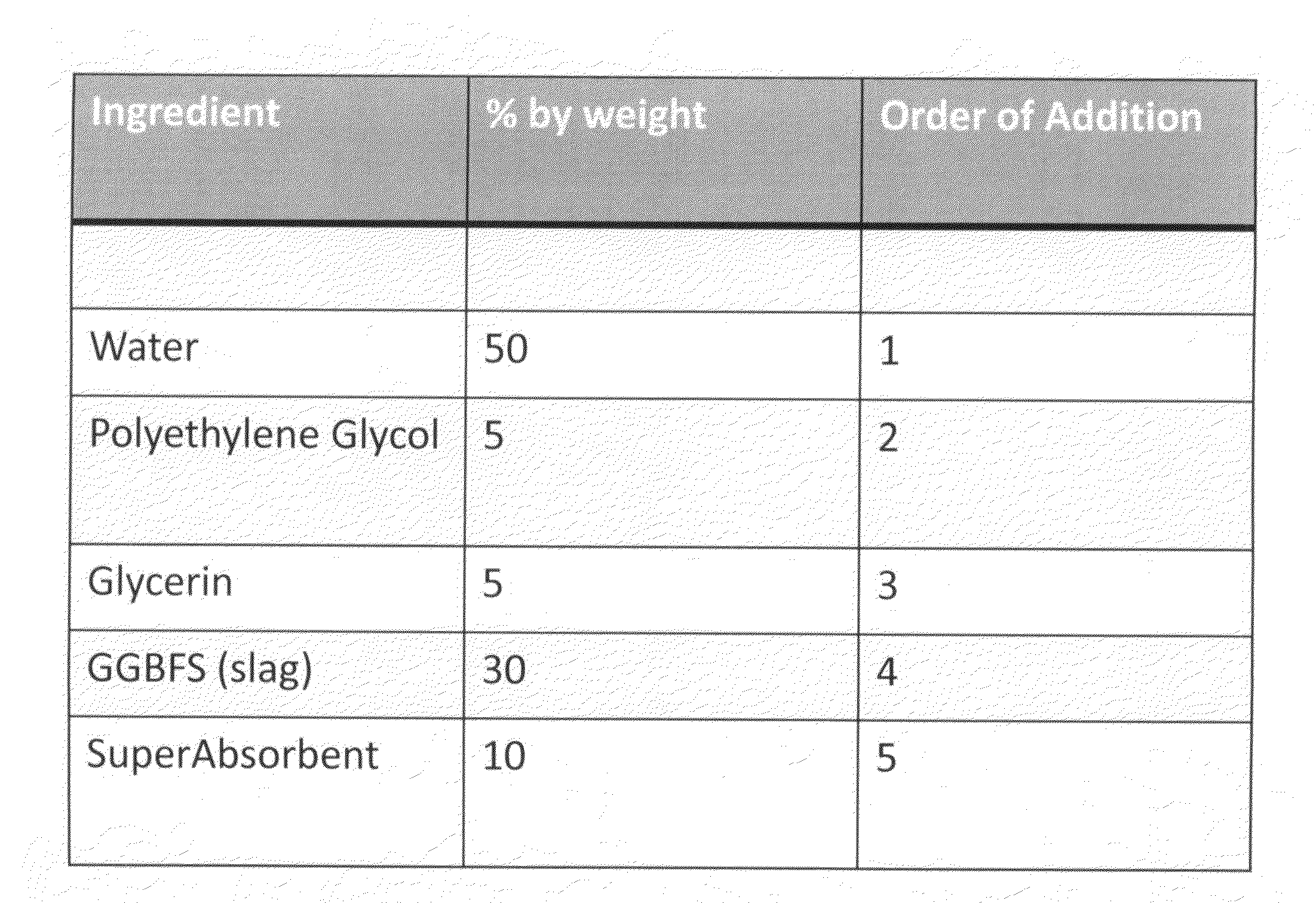

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and CO2 sequestration

InactiveUS8337613B2Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsCombustorEnvironmental remediation

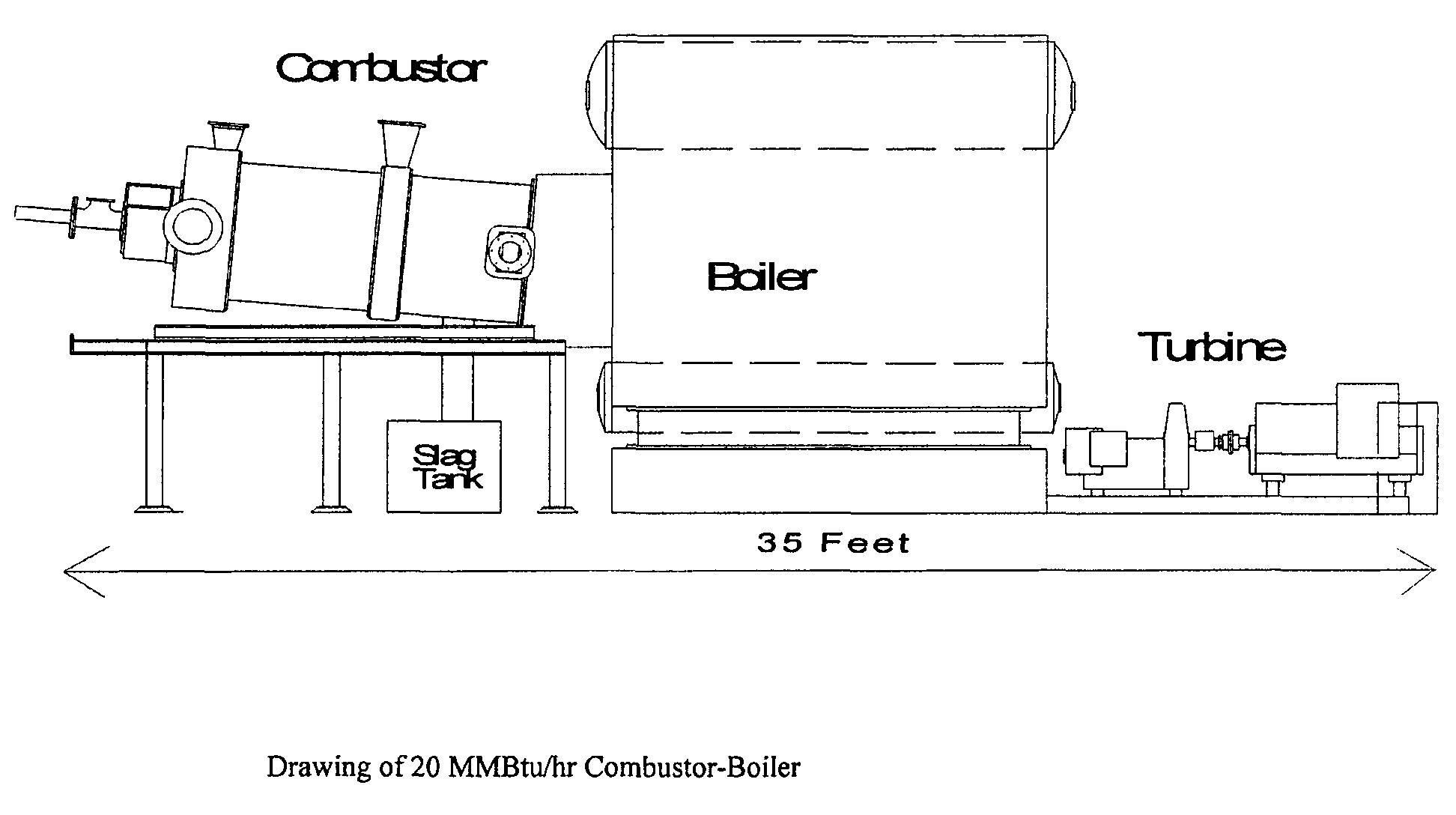

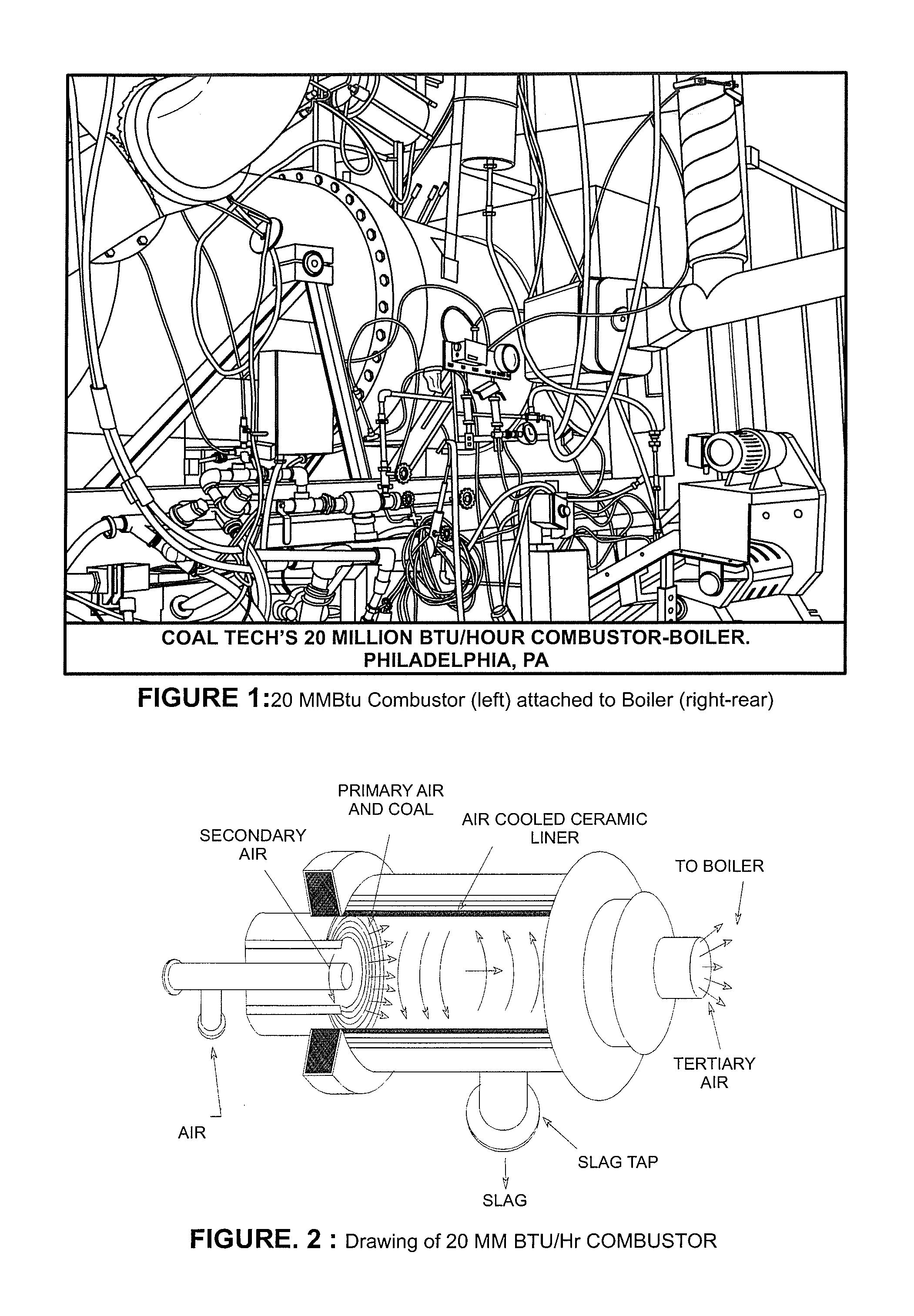

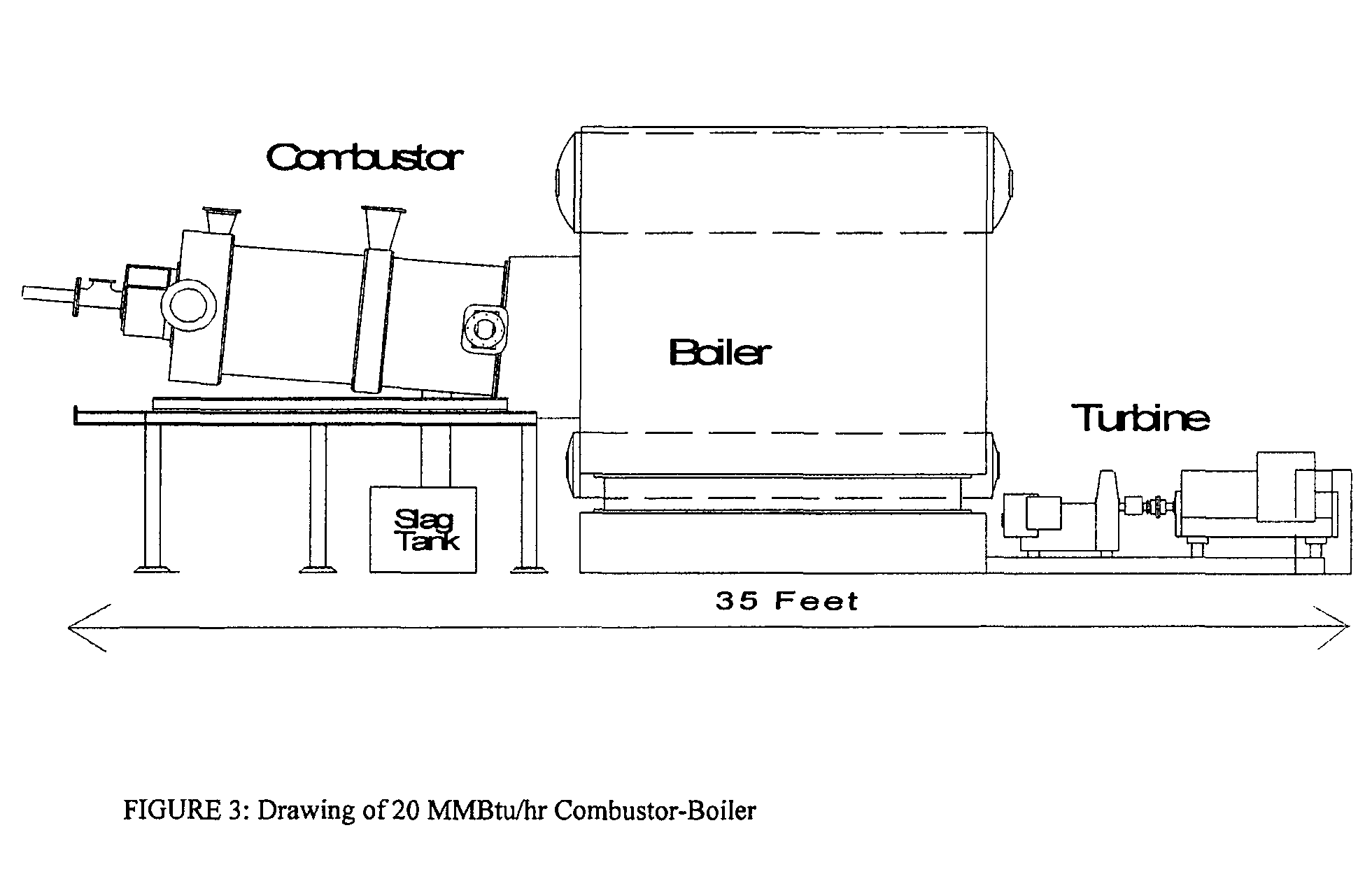

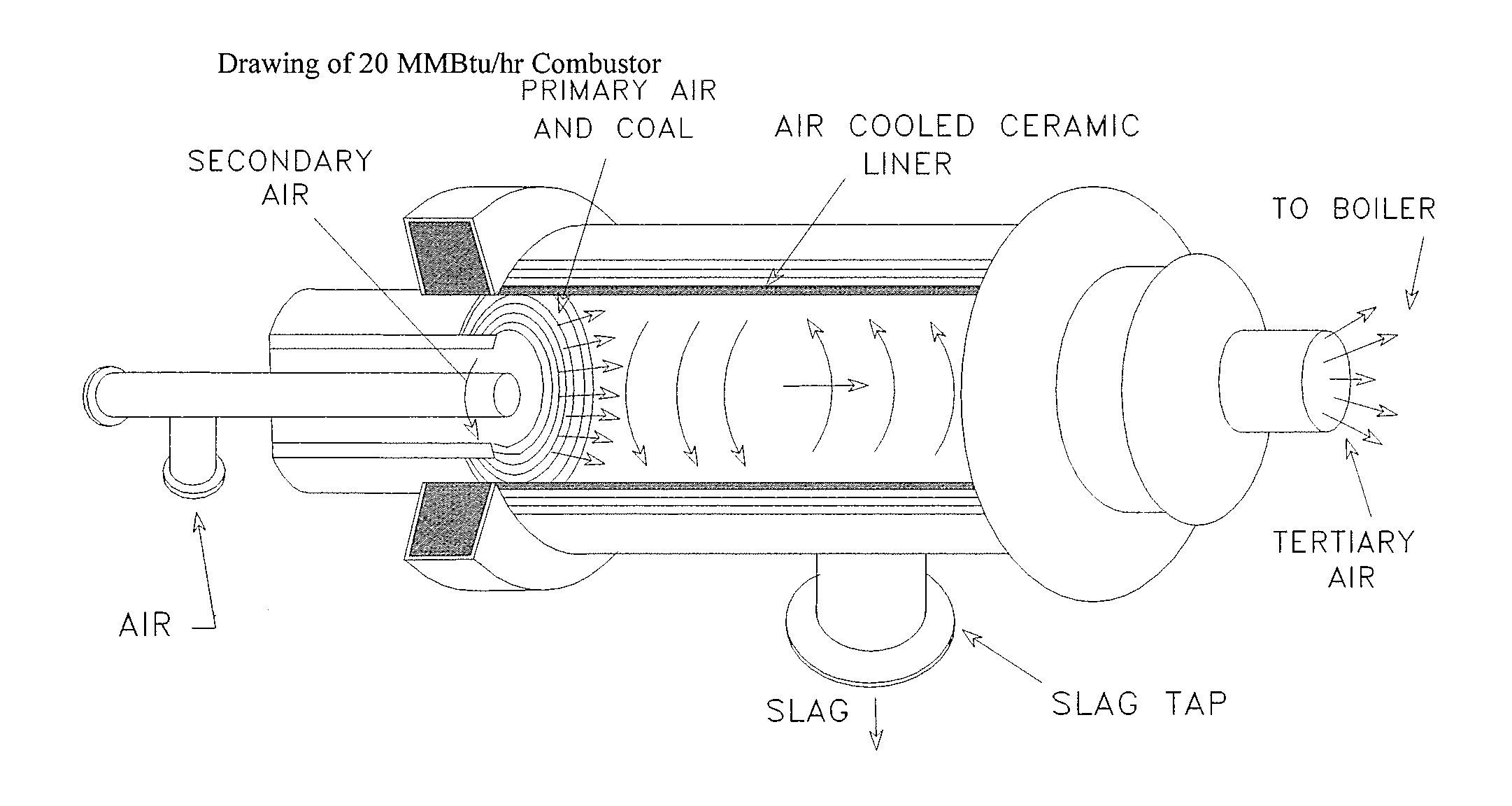

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and co2 sequestration

InactiveUS20110173139A1Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsMaterials scienceChar

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

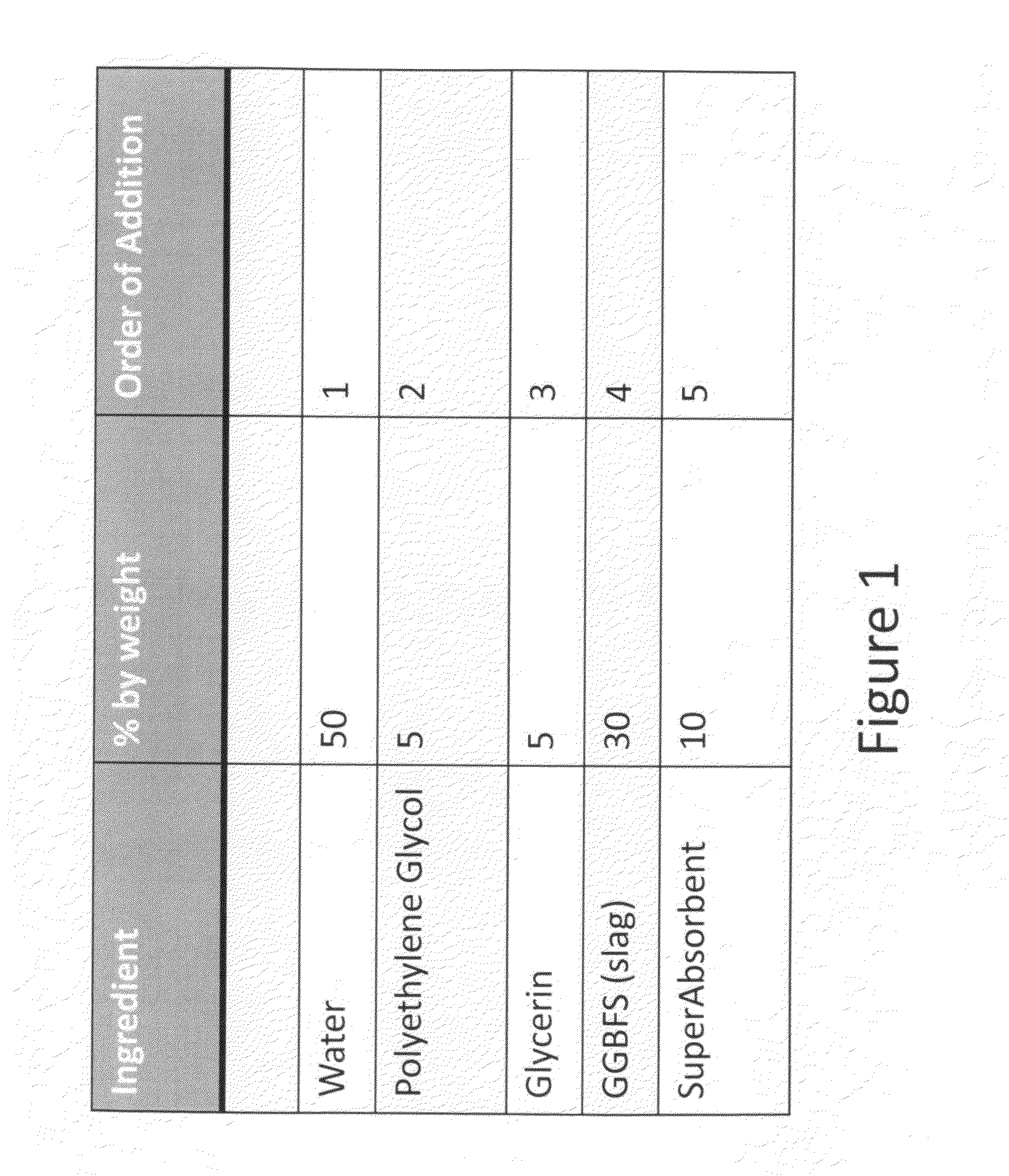

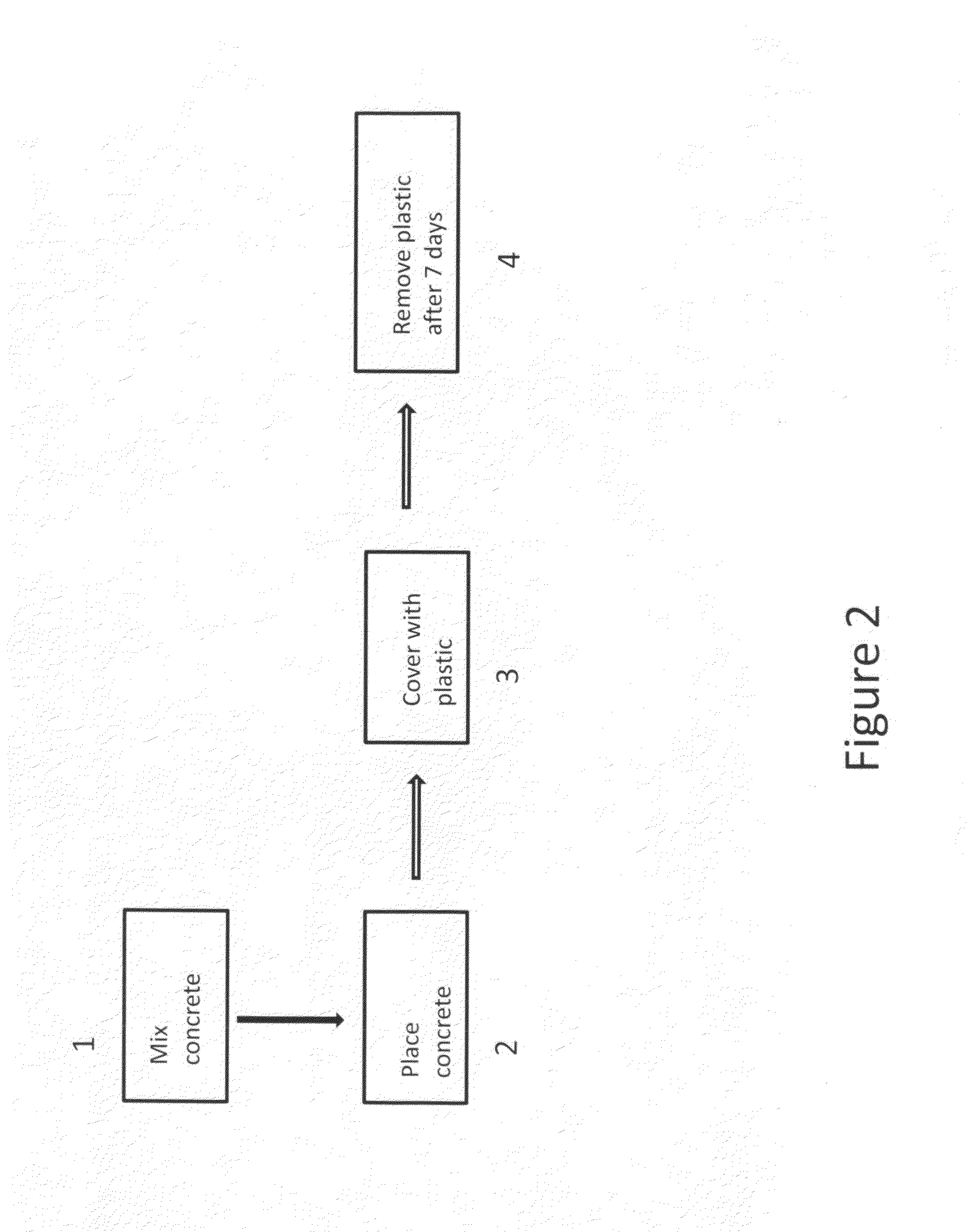

Agent and method for curing pervious concrete

InactiveUS20100285224A1High bonding strengthSolid waste managementPretreated surfacesCross-linkControl manner

The use of pervious concrete has been rapidly growing as a means to meet burgeoning stormwater regulations. A difficulty in placement of pervious concrete has been the need to rapidly cover the material after placement and leave it covered for seven days to ensure moisture is not lost and the cement paste fully cures. Surface unraveling is a common cause of failure of pervious concrete installations due to rapid moisture loss from the cement paste of the freshly placed pervious concrete mixture.By adding to the pervious concrete mixture an internal curing agent which holds and releases moisture in a controlled manner to the cement paste as it cures, the likelihood of under-cured cement paste and surface raveling of the pervious concrete is greatly reduced. This invention comprises materials and methods for their use which provide a source of moisture with controlled release for curing of the cement portion of pervious concrete.A further feature of this invention is the use of a partial sodium salt of a cross-linked polypromancic acid (CAS 009033-79-8) along with ground-granulated blast furnace slag, amorphous silica and crystalline silica to provide a superabsorbent material which readily disperses in cement paste, absorbs water from the cement paste and then releases it slowly over time, with the superabsorbent material remaining inert and non-absorbent once all the moisture is released.Utilization in conventional concrete either as an internal or as a topical cure is a further feature of this invention.

Owner:FISHER DALE

Slag cement

InactiveUS7491268B2Many timesBeneficial economics of adding limestoneCompressive strengthGround granulated blast-furnace slag

A slag cement includes ground granulated blast furnace slag and ground limestone combined in a predetermined weight ratio. Limestone and granulated blast furnace slag (GBFS) are fed to a grinding apparatus in a ratio of about 3-5% limestone by weight. The limestone is a cheaper raw material than the GBFS, resulting in a reduction in production costs for the slag cement. Moreover, the addition of limestone to the GBFS surprisingly results in improved compressive strength.

Owner:BUZZI UNICEM USA +1

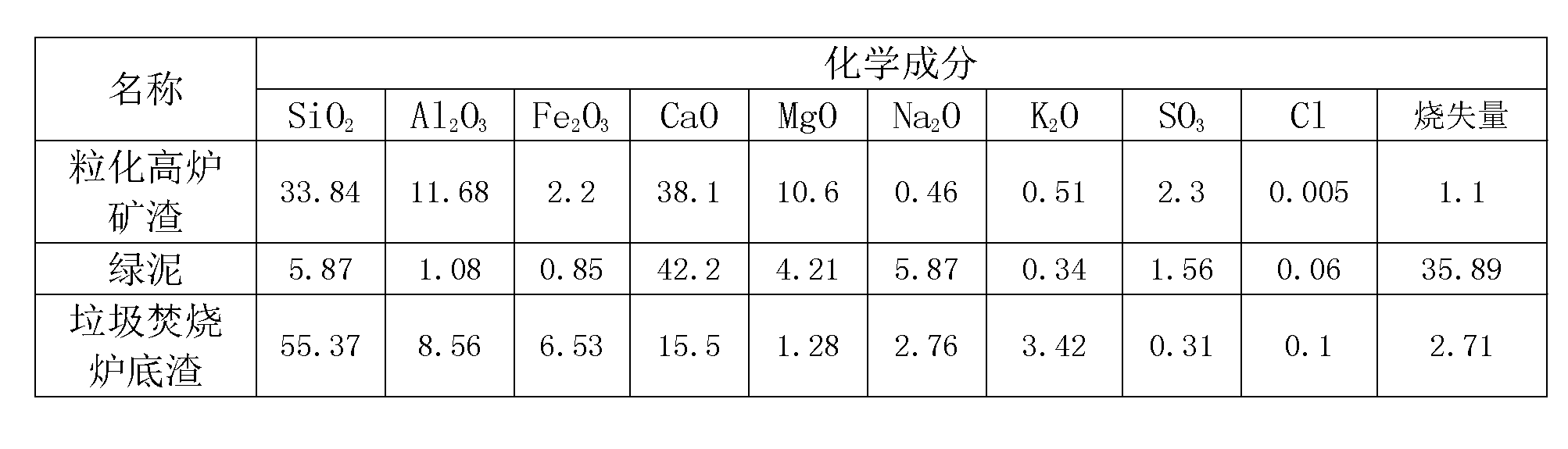

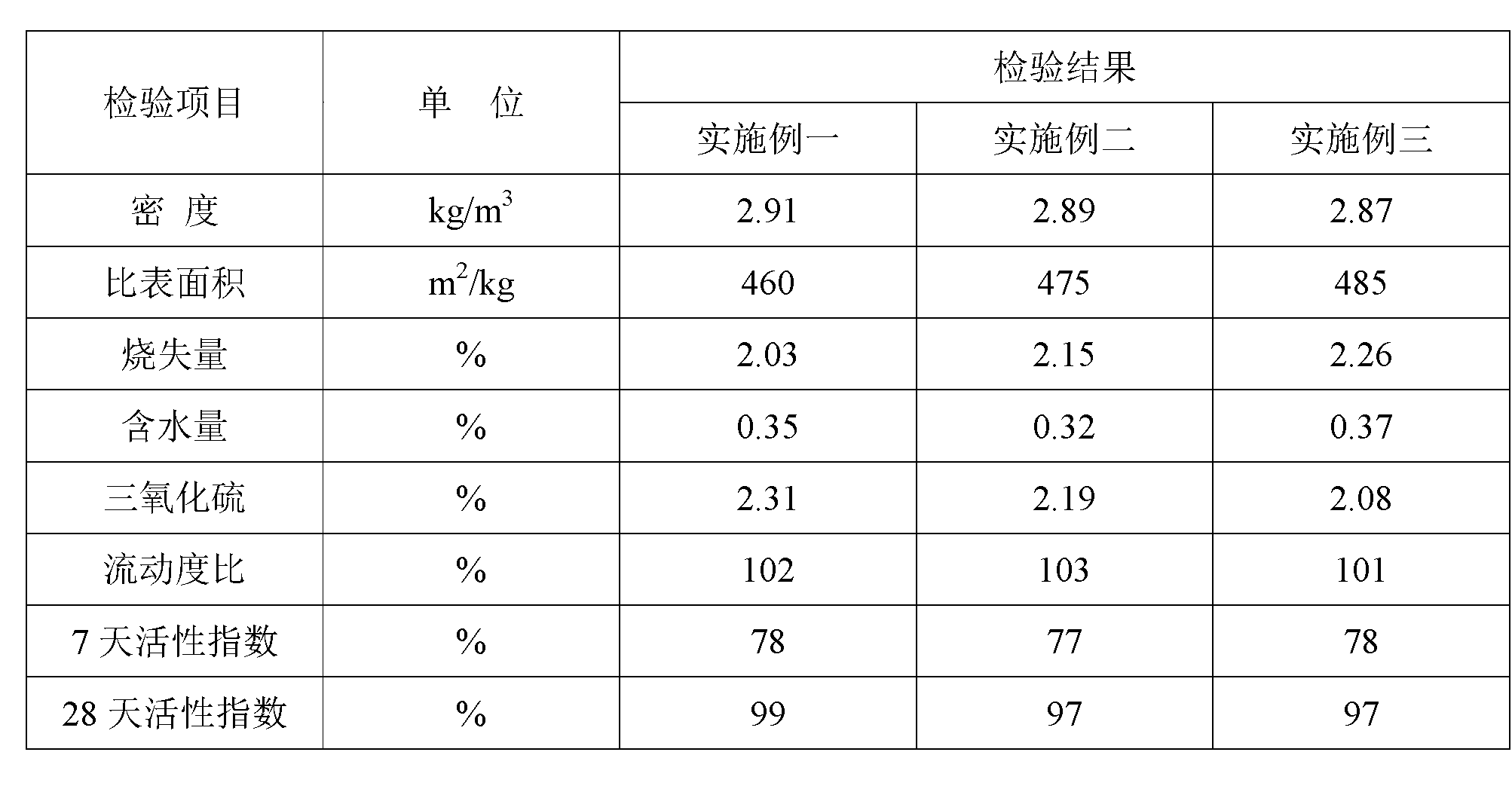

Composite ground granulated blast furnace slag for concrete

InactiveCN103304162AReduce moisture contentImprove microstructureCement productionResource utilizationEconomic benefits

The invention relates to a composite ground granulated blast furnace slag for concrete. The slag is prepared by grinding utilizing grinding equipment and then uniformly mixing household garbage incinerator bottom slag, granulated blast-furnace slag, mixed materials and an activity activator, the specific surface area of the slag is 450m<2> / kg-550m<2> / kg, and the water content is less than 0.5%. The production technology is simple, industrial wastes such as the household garbage incinerator bottom slag, the granulated blast-furnace slag and green mud which can be greatly and easily obtained as main raw materials, the optimal superimposed effects and grain composition of all the components can be fully exerted through optimal compounding, and the obtained composite ground granulated blast furnace slag can be used for substituting part cement in concrete, so that resources and energy sources are saved, the industrial production is benefited, environmental protection, energy saving and emission reduction are benefited, a new method is developed for the resource utilization of the municipal solid waste incinerator bottom slag, and the slag has a good social effect and a good economic benefit.

Owner:HAINAN LANDAO ENVIRONMENTAL PROTECTION IND

White cementitious compositions

A cementitious composition includes (i) white Portland cement having a fineness of about 350-550 m2 / kg, D90 between about 11-50 μm, and total combined iron oxide, manganese oxide, and chromium oxide <1.0% by weight (ii) light color pozzolan such as white silica fume, and (iii) at least one light color particulate material, such as ground granulated blast furnace slag (GGBFS) having a fineness greater than that of the white Portland cement, a D90 less than that of the white Portland cement, and total combined iron oxide, manganese oxide, and chromium oxide content <3.0% by weight and / or coarse limestone powder having a D90 greater than that of the white cement. The cementitious composition may include one or more of aggregates, fibers, or admixture. The cementitious composition can be a dry blend, fresh cementitious mixture, or hardened cementitious composition. The cementitious composition can be precast concrete, stucco, GFRC, UHPC or SCC.

Owner:ROMAN CEMENT

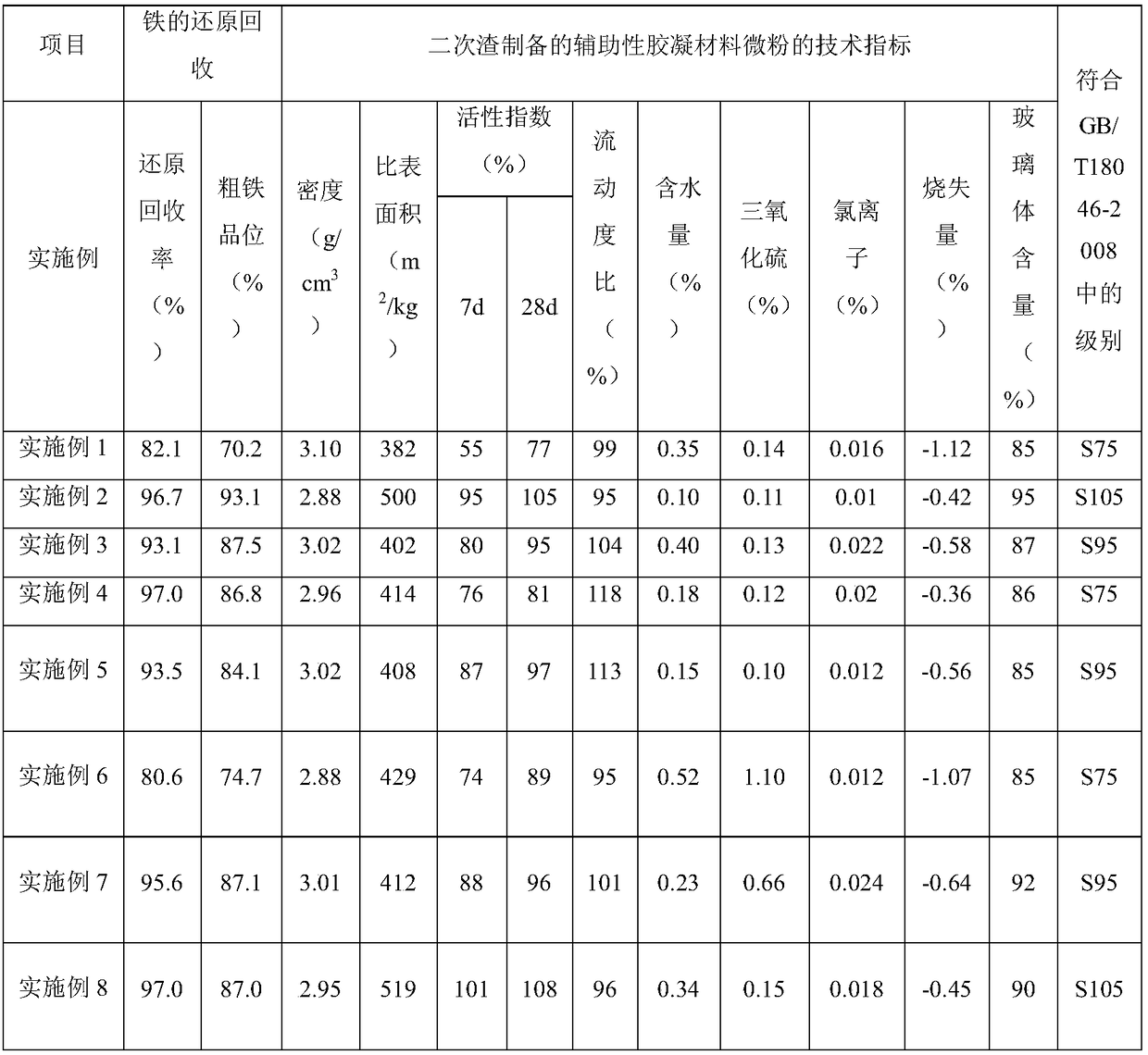

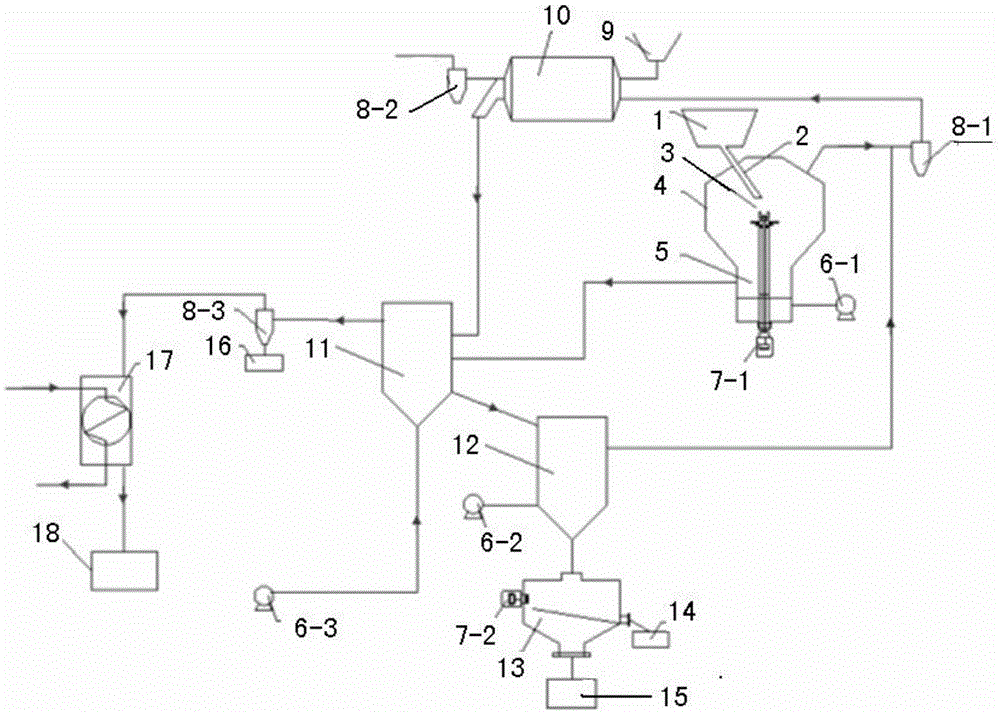

Method for reducing and recovering iron from steel slag and preparing auxiliary cementing material from secondary slag

ActiveCN108658483AIncrease added valueEffective large-scale comprehensive utilizationSolid waste managementCement productionReducing atmosphereMixed materials

The invention discloses a method for reducing and recovering iron from steel slag and preparing an auxiliary cementing material from secondary slag. The method comprises the following steps: uniformlymixing the converter steel slag, a reducing agent and a component adjusting material, performing melting back under the condition that high temperature forms a reducing atmosphere, performing water quenching cooling, separating the metal iron, drying the secondary slag, and performing grinding to obtain the auxiliary cementing material. The method disclosed by the invention can reduce and recoverthe iron in the steel slag by 80% or more; and the prepared auxiliary cementing material is similar to granulated blast furnace slag powder, technical indexes of the auxiliary cementing material meetrelevant requirements of a standard ''ground granulated blast furnace slag used for cement and concrete'' GB / T18046-2008 in China, and the auxiliary cementing material can be used as a cement mixed material and a concrete admixture. The method disclosed by the invention reduces Fe2O3 and FeO in the steel slag into the metal iron for recovery and utilization, changes chemical components of the steel slag to make the components similar to those of granulated blast furnace slag, improves gelling activity, and realizes overall, high-added-value, and more effective large-scale comprehensive utilization of the steel slag.

Owner:SOUTH CHINA UNIV OF TECH

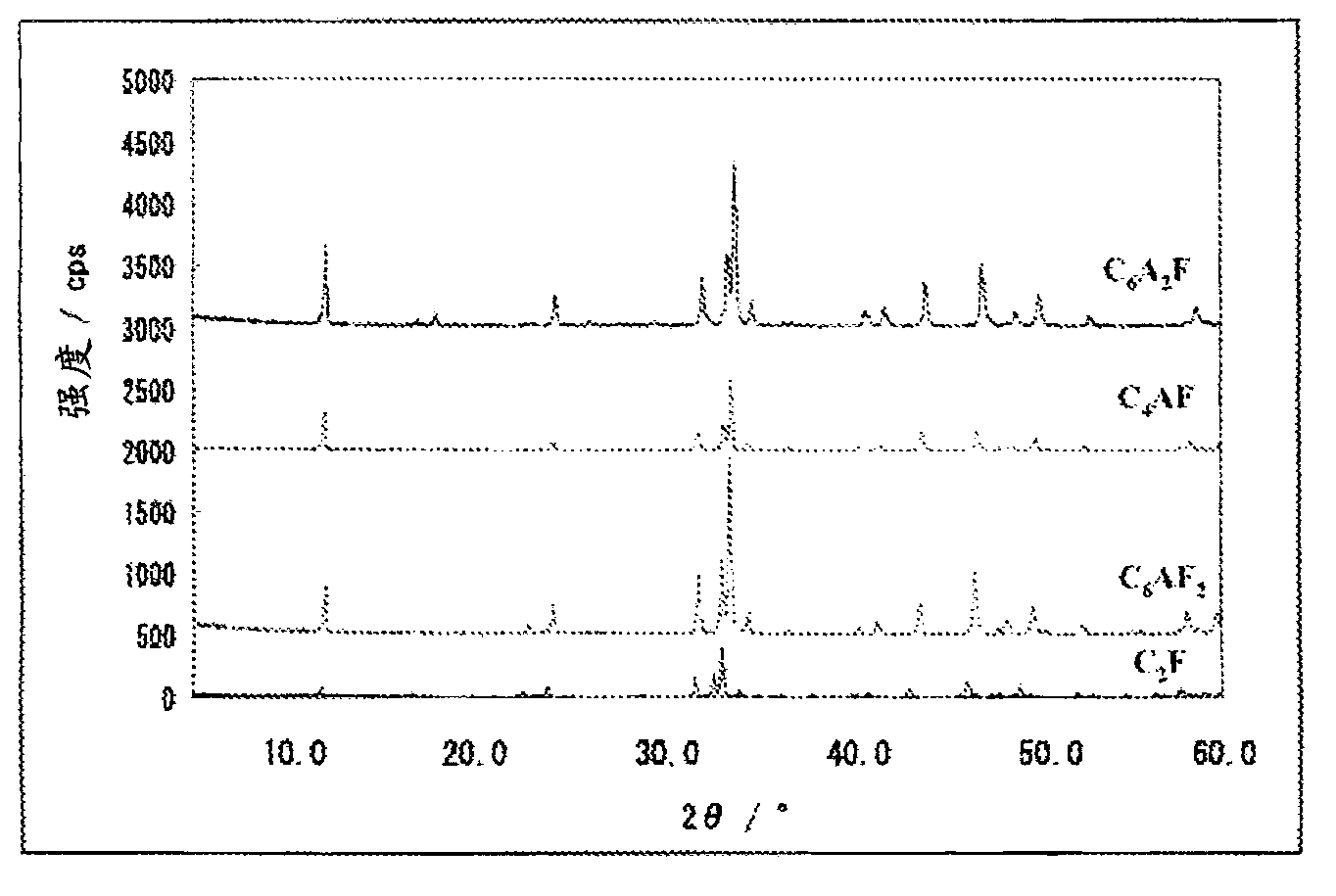

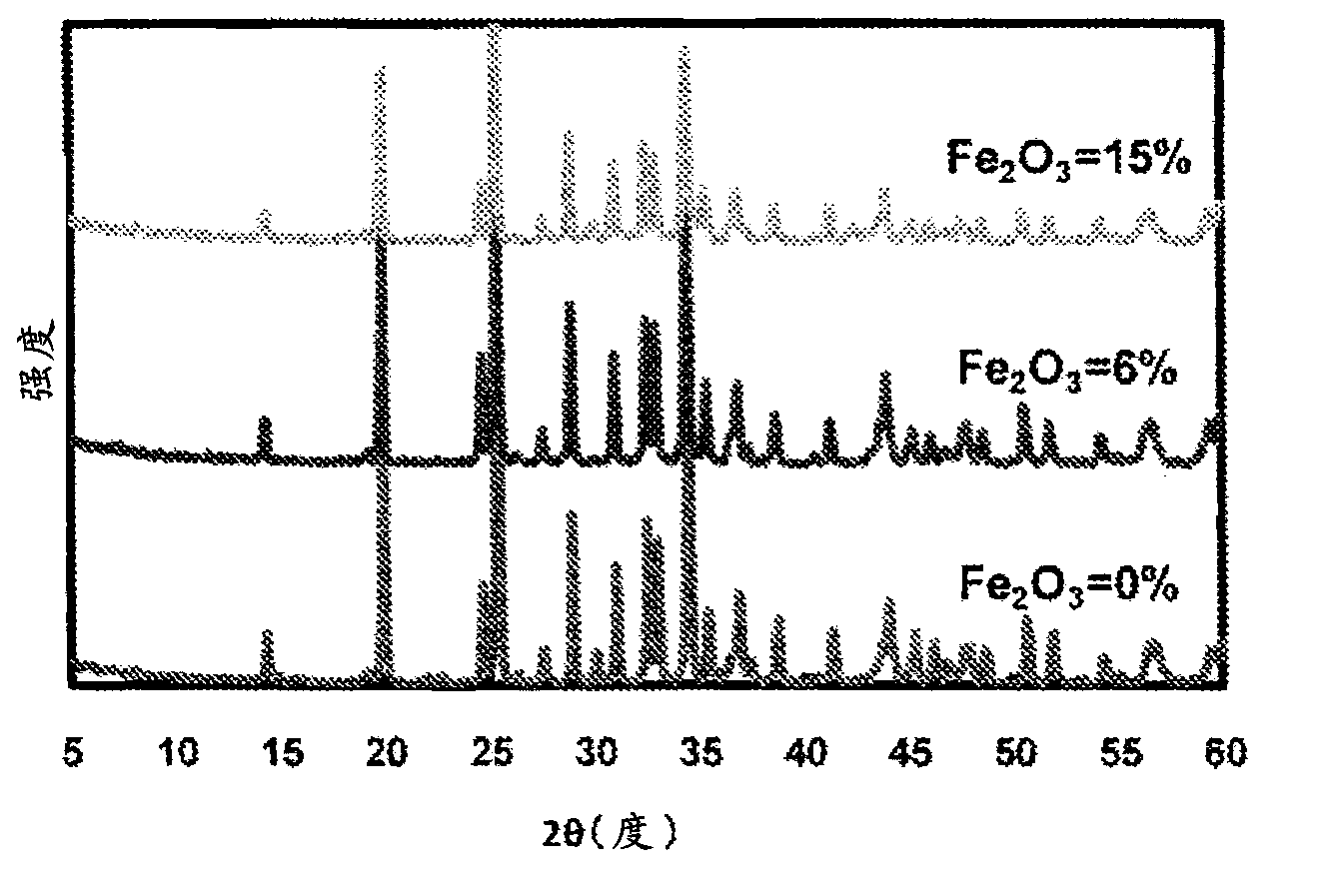

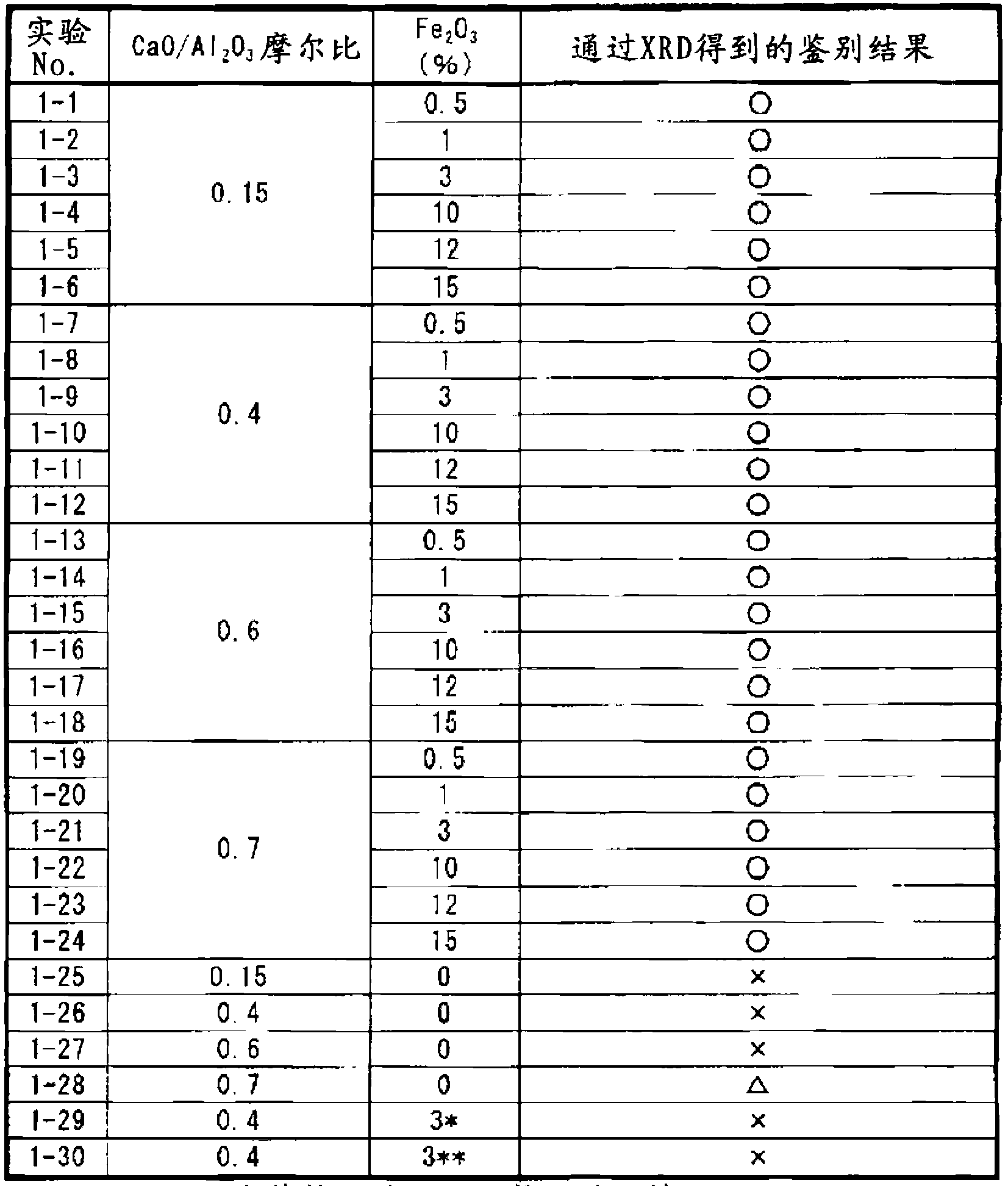

Calcium ferroaluminate compound, cement admixture and process for producing same, and cement composition

ActiveCN102869633AExcellent penetration resistancePlenty of time to operateSolid waste managementIron compoundsSelf-healingSludge

Provided is a cement admixture which gives cured cement concrete that imparts excellent non-corrodible properties to the reinforcing bars present therein, has resistance to external infiltration of chloride ions, and can be inhibited from becoming porous because Ca-ion eluviation occurs little and that has self-healing ability. Also provided is a cement composition. The cement admixture is characterized by comprising a calcium ferroaluminate compound which is based on CaO, Al2O3, and Fe2O3, has a Fe2O3 content of 0.5-15 mass%, and has a CaO2Al2O3 structure, the CaO / Al2O3 ratio being in the range of 0.15-0.7 by mole. It is preferred that the admixture have a degree of fineness of 2,000-7,000 cm2 / g in terms of Blaine specific surface area and that a latent hydraulic substance and / or a pozzolanic substance (pozzolanic substance and the like) be used in combination with the calcium ferroaluminate compound. The pozzolanic substance and the like preferably comprise one or more substances selected from a group consisting of ground granulated blast furnace slag, fly ash, silica fume, metakaolin, incineration ash of pulp sludge, incineration ash of sewage sludge, and waste glass powder. It is preferred that the ratio of the calcium ferroaluminate compound to the pozzolanic substance and the like be from 10 / 1 to 1 / 10 by mass. The cement composition comprises cement and the cement admixture.

Owner:DENKA CO LTD

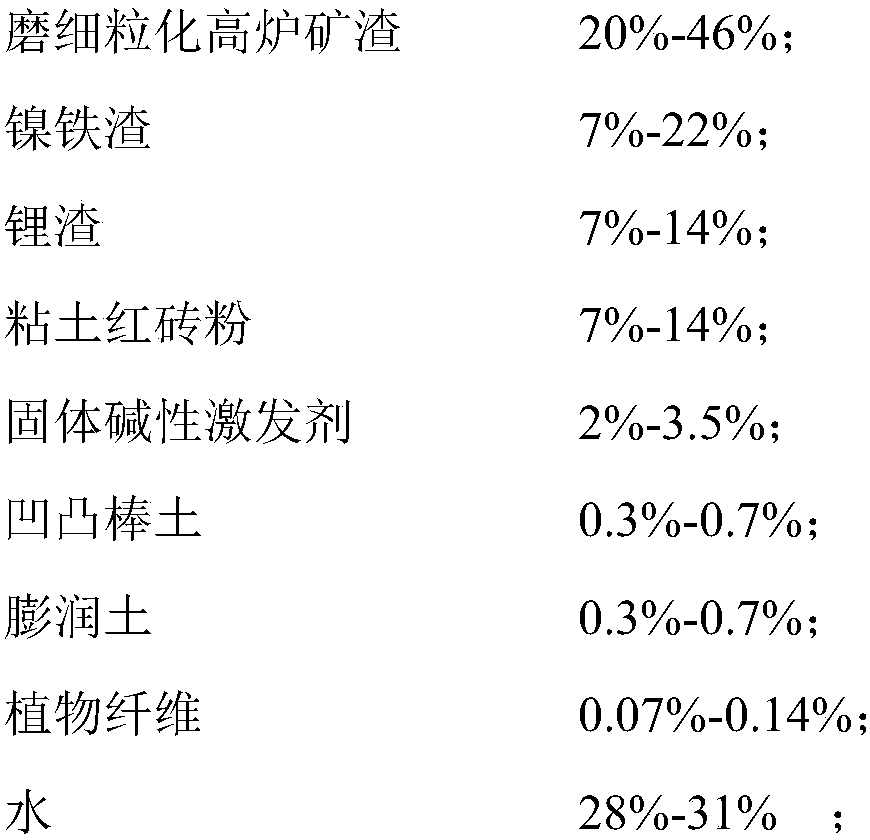

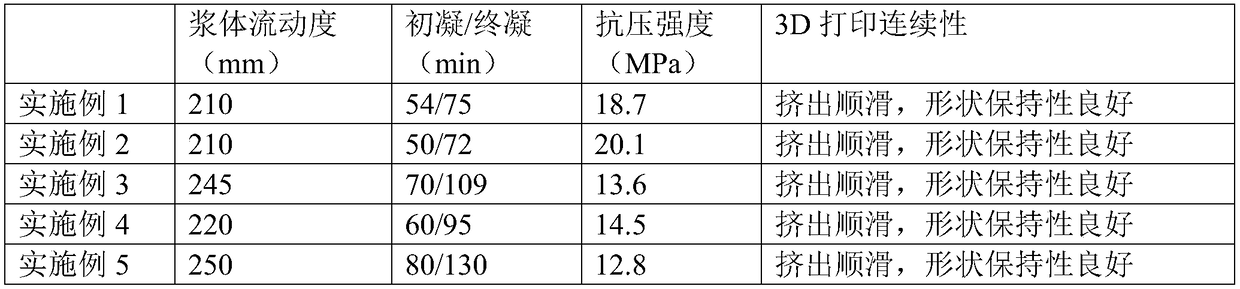

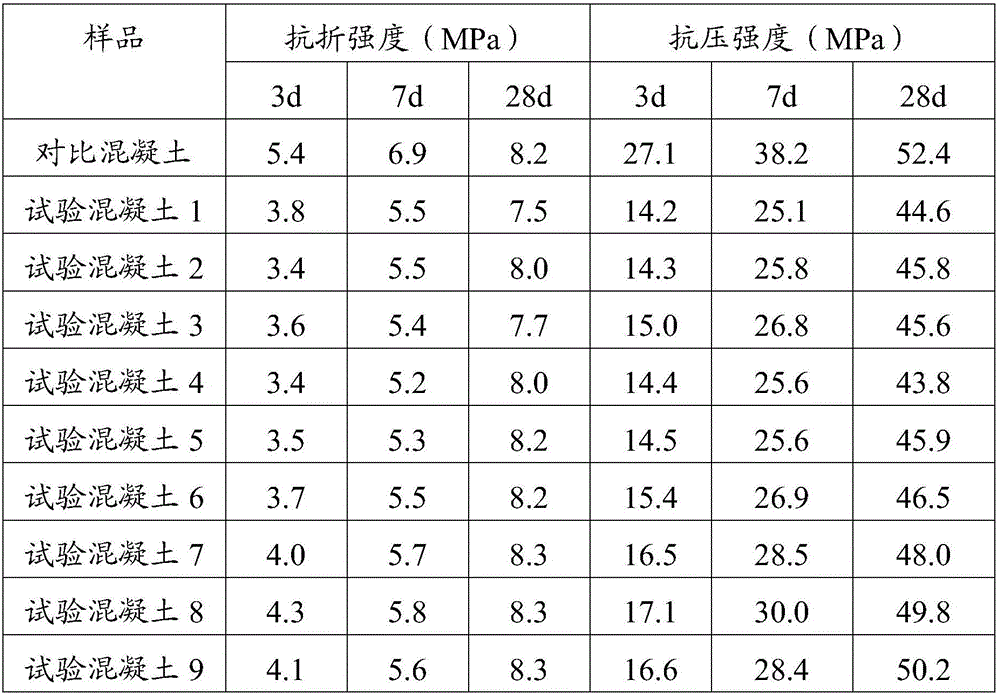

Alkali-activated cementitious material for 3D printing

InactiveCN109336475AStrength mentionedMeet the printing process requirementsAdditive manufacturing apparatusFiberLithium

The invention discloses a novel alkali-activated cementitious material for 3D printing. The novel alkali-activated cementitious material for the 3D printing is prepared from following raw materials inpercentage by weight: 20%-46% of ground granulated blast furnace slag, 7%-22% of nickel iron slag, 7%-14% of lithium slag, 7%-14% of red brick powder, 2%-3.5% of a solid alkali activator, 0.3%-0.7% of attapulgite, 0.3%-0.7% of bentonite, 0.07%-0.14% of plant fiber and 28%-31% of water. The novel alkali-activated cementitious material for the 3D printing has good workability, has good cohesive property and high stability due to the characteristics of quick setting, rapid hardening and early strength and completely meets the material performance requirement of the 3D printing technology.

Owner:SOUTHEAST UNIV

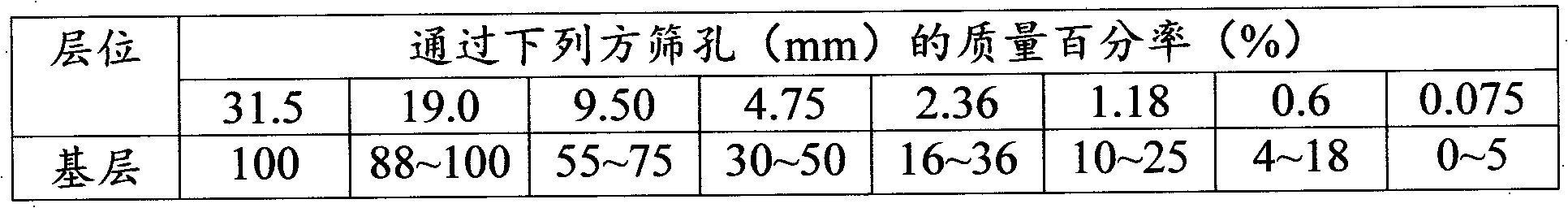

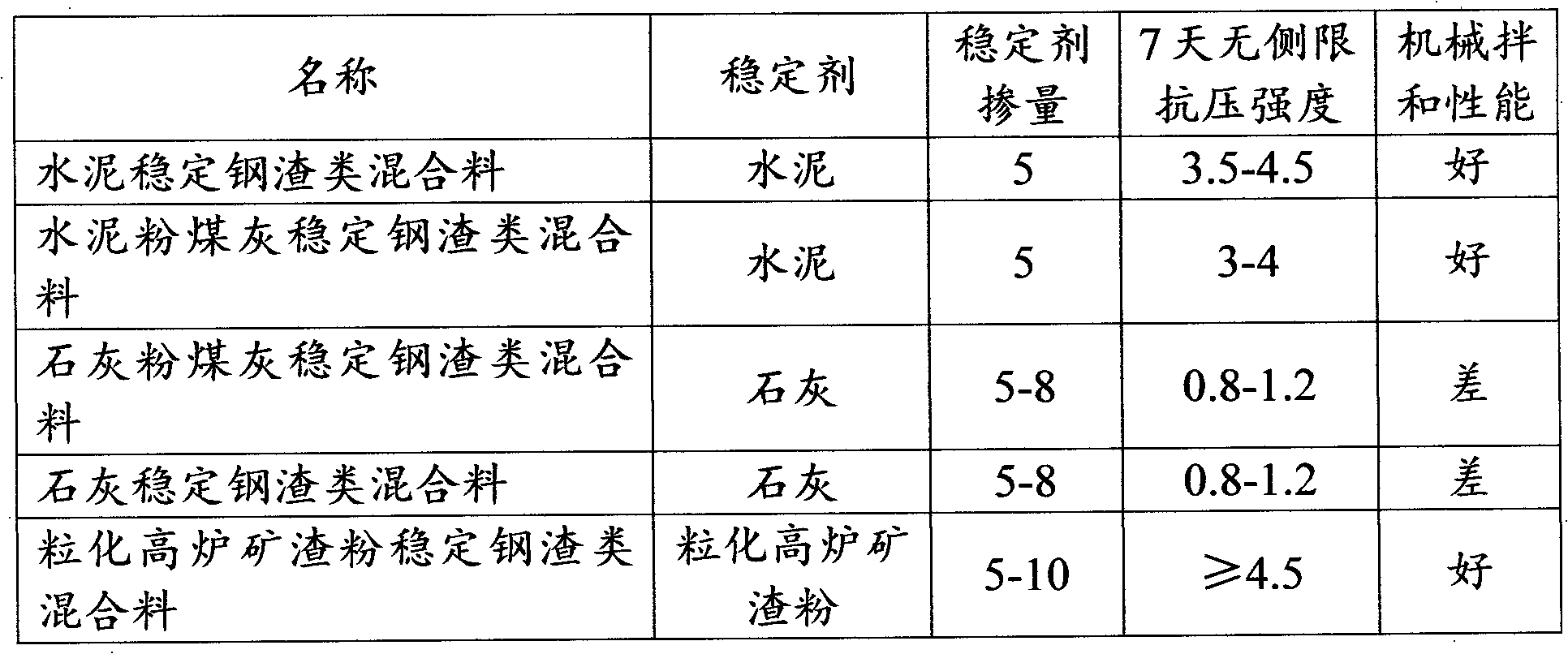

Granulated blast furnace slag powder stabilized steel slag type mixture

ActiveCN102219461AHigh compressive strengthImprove mechanical propertiesSolid waste managementCalcium hydroxideRoad surface

The invention discloses a granulated blast furnace slag powder stabilized steel slag type mixture which is a mixture formed in a way that granulated blast furnace slag powder with the weight percentage of 3-10 percent is added into steel slag after stabilizing treatment, the doping of coal ash is allowed, and water is added and blended. For the granulated blast furnace slag stabilized steel slag type mixture, the characteristic that steel slag produces calcium hydroxide when meeting water is utilized to excite the granulated blast furnace slag powder to generate gelatination, so that the mixture is cemented and solidified, the compression strength is high, the mechanical blending performance is good, pollution does not exist during blending, the tightness is high, and the durability of the road surface can be improved. Simultaneously, for the gel material of the roadbed mixture, the granulated blast furnace slag powder is selected to replace cement and lime, namely, ironmaking-accompanying resource replaces cement and lime produced by natural limestone, so that waste resources are sufficiently utilized, non-renewable resources are protected, and the emission of carbon dioxide can be reduced.

Owner:浙江哈斯科节能技术有限公司

Slag cement

InactiveUS20060230986A1Many timesBeneficial economics of adding limestoneCompressive strengthMaterials science

A slag cement includes ground granulated blast furnace slag and ground limestone combined in a predetermined weight ratio. Limestone and granulated blast furnace slag (GBFS) are fed to a grinding apparatus in a ratio of about 3-5% limestone by weight. The limestone is a cheaper raw material than the GBFS, resulting in a reduction in production costs for the slag cement. Moreover, the addition of limestone to the GBFS surprisingly results in improved compressive strength.

Owner:BUZZI UNICEM USA +1

Cementitious binders, activators and methods for making concrete

ActiveUS20150107491A1StrengthHigh strengthSolid waste managementCement productionEtherGround granulated blast-furnace slag

A cementitious binder comprises at least 90% by weight of a hydraulically-active material comprising ground granulated blast furnace slag (GGBS) and / or pulverised fuel ash (PFA), and at least 0.1% by weight of CaO in an activator composition for the hydraulically-active material. The cementitious binder does not comprise any Portland cement and is, therefore, more environmentally friendly. The binder further comprises a superplasticiser such as a polycarboxylate ether (PCE). A concrete, mortar, grout, screed or render may be formed from a mixture of the cementitious binder, aggregate particles, water and superplasticiser.

Owner:DAVID BALL GROUP

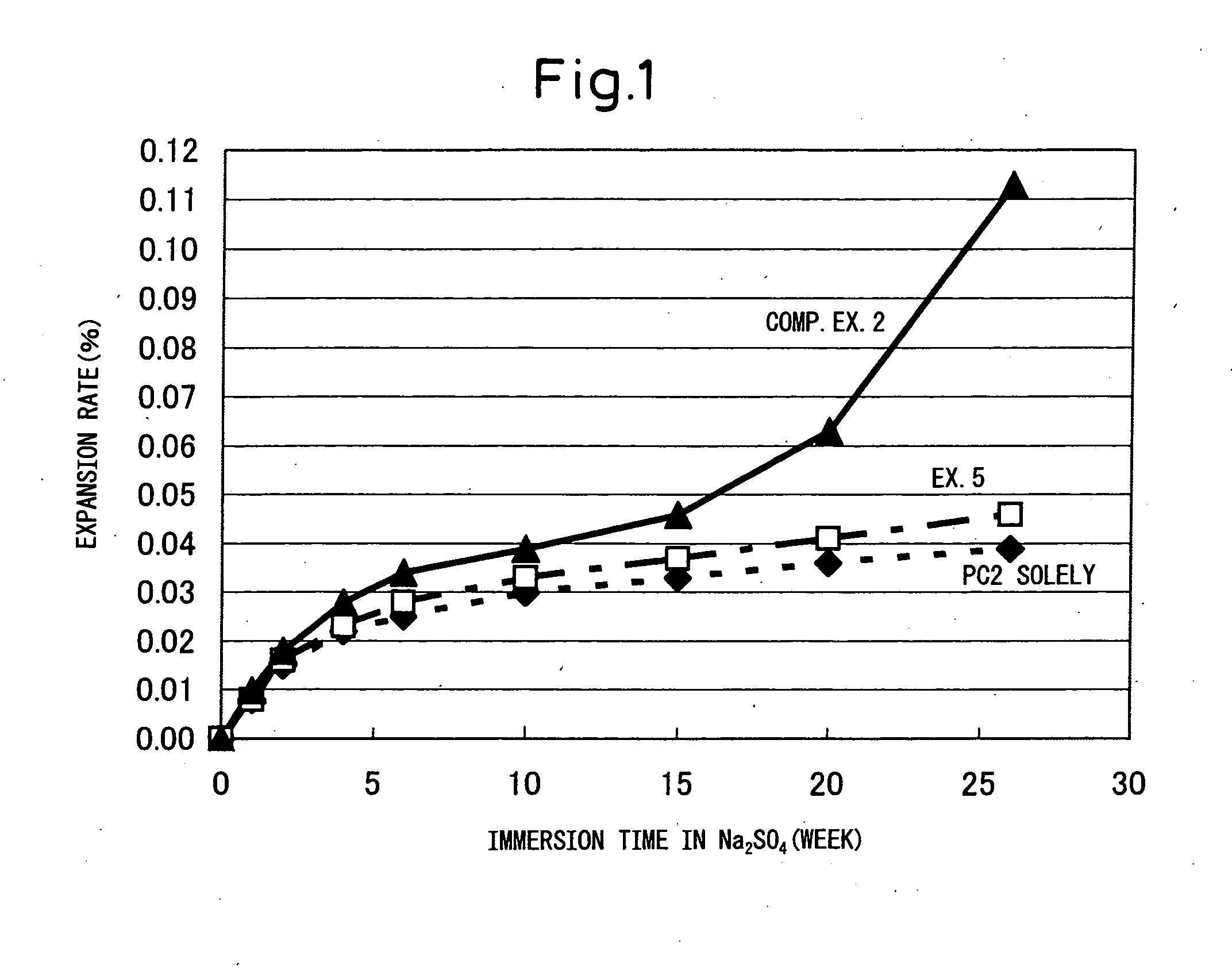

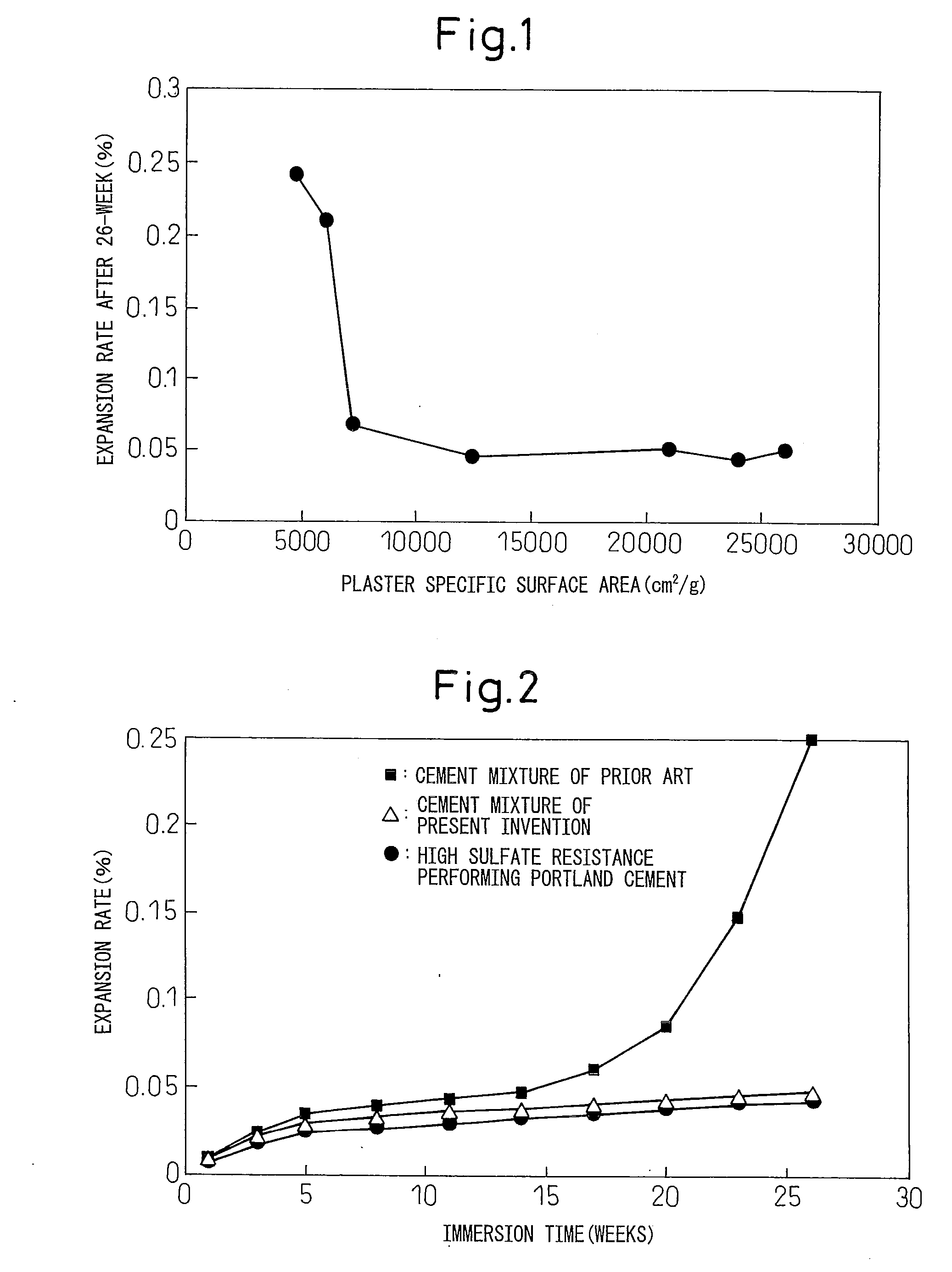

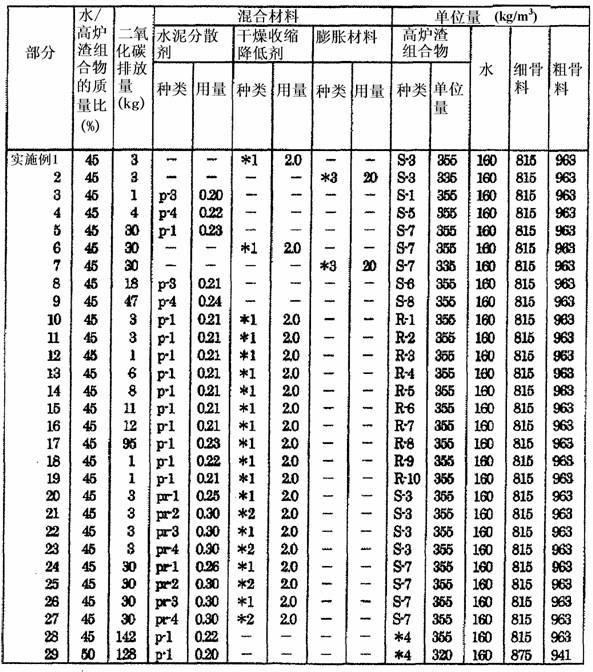

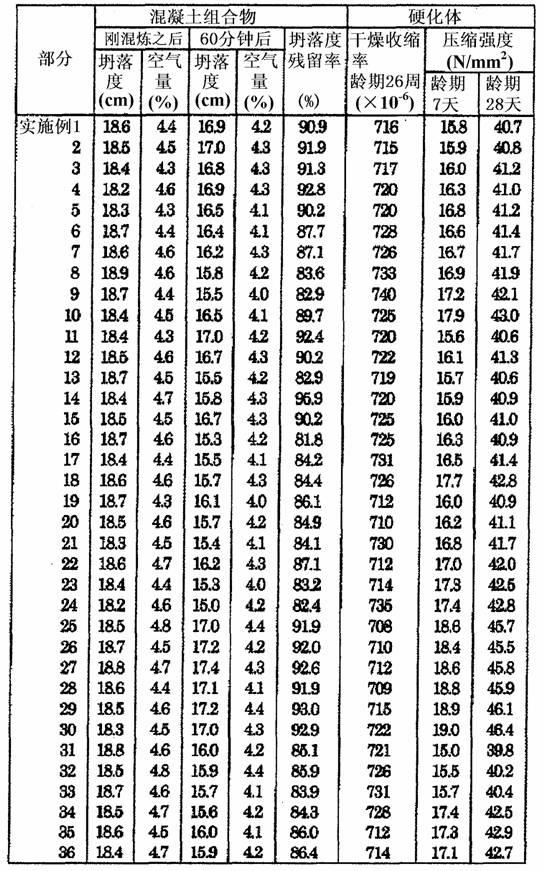

Sulfate resistant ground granulated blast furnace slag, sulfate resistant cement, and method of production of same

In sulfate resistant cement obtained by mixing ground granulated blast furnace slag, Portland cement, and high-dissolution rate gypsum for raising the sulfate resistance, the high-dissolution rate gypsum differs in grain size and specific gravity from the Portland cement, so uniform mixture is not easy. To obtain sulfate resistant cement exhibiting homogeneous initial solidification, it is important to uniformly mix the blast furnace slag, Portland cement, and high-dissolution rate gypsum.Therefore, by premixing ground granulated blast furnace slag with an alumina content of 12 to 17.5% with high-dissolution rate gypsum and then mixing in Portland cement, it is possible to obtain uniformly mixed sulfate resistant cement.At this time, the high-dissolution rate gypsum may be hemihydrate gypsum, type III anhydrous gypsum, or anhydrous gypsum with a specific surface area of 8000Blaine or more.

Owner:NIPPON STEEL ESMENT KANTO +1

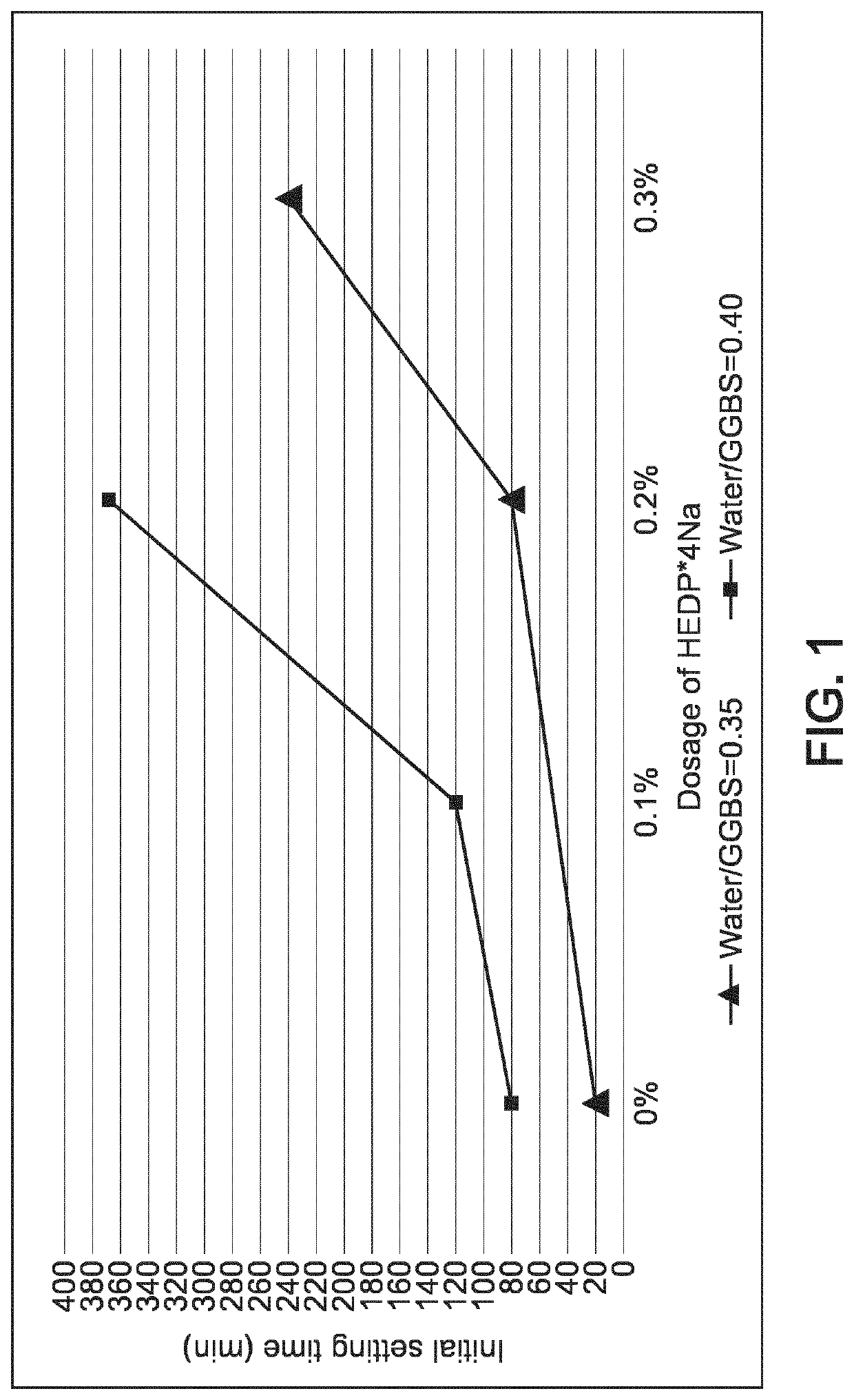

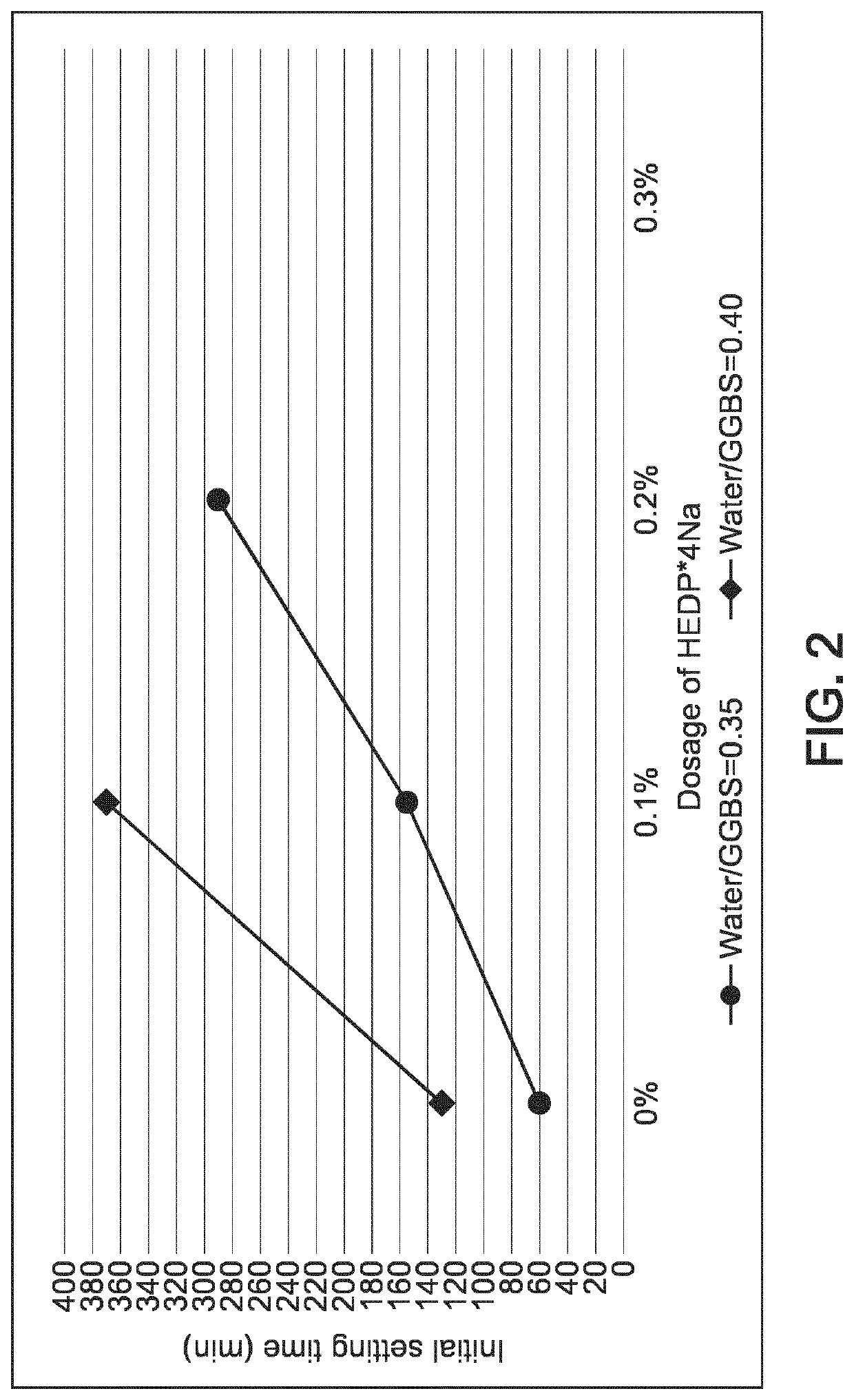

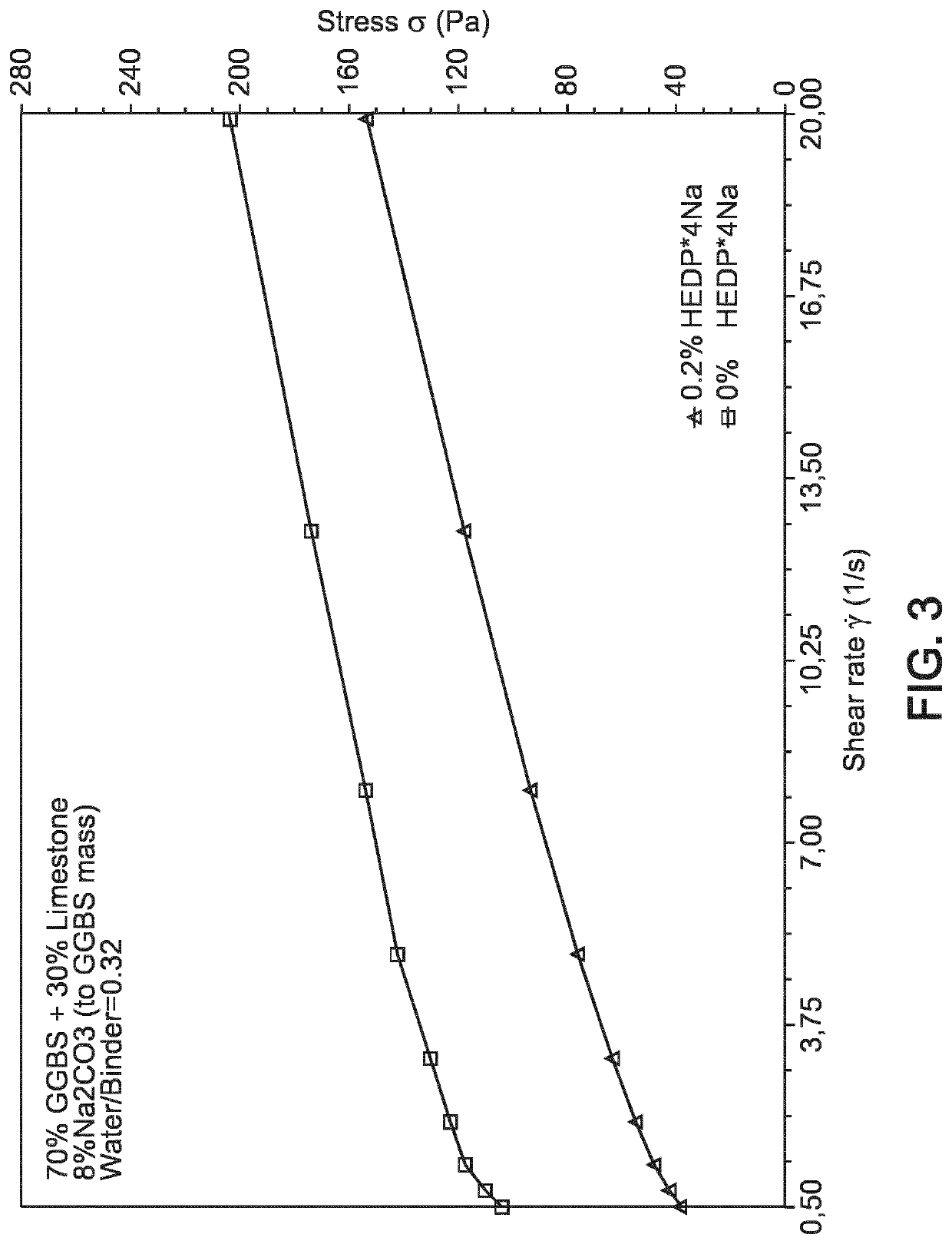

Ground granulated blast furnace slag based binder, dry and wet formulations made therefrom and their preparation methods

ActiveUS20210238094A1Reduction in initial water demandIncrease ultimate strengthDrilling compositionScreedMining engineering

A slag-based binder has at least one slag, optionally at least one CO3-containing mineral powder, optionally at least one co-binder different from the slag and mineral powder, at least one activator of the water / slag reaction, optionally at least one co-activator different from the one activator, at least one chelatant and / or at least one source of chelatant, said chelatant being preferably a scale inhibitor, and, optionally, at least one superplasticizer different from the chelatant. A kit is provided to make the binder. The binder is combined with an aggregate to make a dry concrete or mortar. A method for the preparation of a wet formulation (binder / water or concrete-mortar / water) is disclosed as is method of manufacturing buildings or civil engineering works or elements thereof, coatings, fillers, screeds, tiles, adhesives and / or internal or external insulation systems from the wet formulation. The binder is a substitute to OPC-based compositions and is environmentally friendly.

Owner:ECOCEM MATERIALS LTD +2

Hydraulic binder comprising a ground blast furnace slag

ActiveUS20120234209A1Improve shrinkageIncreased riskSolid waste managementCement productionSulfatePortland cement

The present invention concerns a hydraulic binder comprising a ground blast furnace slag in an amount comprised between 30% and 95% by mass on the binder, Portland cement clinker in an amount equal to or greater than 5% by mass on the binder, and at least one sulphate as activator, characterised in that said slag has the following properties and composition by mass: grinding fineness greater than 4000 cm2 / g Blaine glass content greater than 80% SiO2: 30-40% Al2O3: 9-13% CaO: 34-42% with a (CaO+MgO) / (Al2O3+SiO2) ratio greater than 1; and in that said sulphate is contained in a total amount, expressed as SO3, comprised between 0.6% and 4.5% by mass on the binder.

Owner:ITALCEMENTI

Dry-type floor heat conduction caulking material

InactiveCN101628803AImprove performanceExtended inflation timeSolid waste managementGraphiteThermal expansion

The invention discloses a dry-type floor thermal heat conduction material which comprises the following components by weight percent: 9 to 10 percent of thermal expansion agent, 38 to 40 percent of graphite powder, 38 to 40 percent of white cement, 1.5 to 2 percent of natural gypsum, 1.5 to 2 percent of anhydrite, 2.8 to 3 percent of lime, 5.2 to 5.5 percent of calcium aluminate cement, 0.2 to 0.5 percent of fly ash and 0.2 to 0.5 percent of ground granulated blast furnace slag. The dry-type floor thermal caulking material can be caulked between floor heating tanks and floor heating pipes to play the heat-conduction role well.

Owner:蔡春

Heavy weight concrete composition using slag byproducts

ActiveUS8221541B2Reduce carbon dioxide emissionsProtect environmentSolid waste managementBallastwayChemical admixtureElectric arc furnace

Disclosed is a heavyweight concrete composition using slag byproducts, including: ground granulated blast furnace slag; slow-cooled electric-arc-furnace oxidizing slag or atomized steel slag used as a fine aggregate; a coarse aggregate; water; and a chemical admixture based on 100 parts by weight high-early-strength cement. Thus, the heavyweight concrete composition contains a large quantity of steel slag and blast-furnace slag that are byproducts in iron-making and steel-making processes, thereby remarkably reducing an amount of emission of carbon dioxide and maximizing the recycling of waste resources for preserving the natural environment. As a result, an eco-friendly heavyweight concrete product can be made.

Owner:KOREA RAILROAD RES INST

A process for the production of reactive blast furnace slag

InactiveCN101405237ASave resourcesEnergy efficiencySolid waste managementNanotechnologyZeta potentialGeopolymer

The invention particularly relates to a process for increasing the reactivity of ground granulated blast furnace slag using surface activation through short mechanical activation time (10-60 min) and it starts to hydrate in short time (48 h or less) when mixed with water without any chemical additive and completely hydrates in maximum 28 days forming cementitious product. The products produced by the process of present invention may be of different particle sizes and shapes, different specific surface areas, different surface charge (Zeta potential) and different reactivity. The reactive blast furnace slag shall be useful in Portland Slag Cement (PSC), Geopolymer, immobilisation and stabilisation of toxic wastes and newer nano-composite materials.

Owner:COUNCIL OF SCI & IND RES

Hydraulic binder comprising a ground blast furnace slag

ActiveUS8328931B2Fast curingReduce environmental impactSolid waste managementCement productionSulfatePortland cement

The present invention concerns a hydraulic binder comprising a ground blast furnace slag in an amount comprised between 30% and 95% by mass on the binder, Portland cement clinker in an amount equal to or greater than 5% by mass on the binder, and at least one sulphate as activator, characterised in that said slag has the following properties and composition by mass: grinding fineness greater than 4000 cm2 / g Blaine glass content greater than 80% SiO2: 30-40% Al2O3: 9-13% CaO: 34-42% with a (CaO+MgO) / (Al2O3+SiO2) ratio greater than 1; and in that said sulphate is contained in a total amount, expressed as SO3, comprised between 0.6% and 4.5% by mass on the binder.

Owner:ITALCEMENTI

Sulfate resistant cement

ActiveUS20100101458A1Enhance sulfate resistance performanceImprove the immunitySolid waste managementSulfateGypsum

Mixed cement containing mainly ground granulated blast furnace slag with an alumina ratio of 12 to 17.5 mass % and Portland cement, wherein a ratio of mixture of the ground granulated blast furnace slag is made 10 to 60 mass % and wherein plaster having a specific surface area of 7000 cm2 / g or more is mixed in by a ratio of 2 to 4 mass % converted to SO3 mass. By using this mixed cement as a concrete material, it is possible to suppress expansion of the concrete even if in contact with soil containing residual sulfates over a long period.

Owner:NIPPON STEEL CORP +1

Cement based carbon dioxide curing agent and preparation method thereof

InactiveCN104891878AEffective absorptionReduce pollutionSolid waste managementCeramicwareFoaming agentGround granulated blast-furnace slag

The invention relates to a cement based carbon dioxide curing agent and a preparation method thereof. The curing agent comprises, by mass, including ground granulated blast furnace slag, cement, water, foaming agent, gypsum, MgO, the mass ratio is: 29.4%-46.7% of ground slag powder, 11.8%-26.7% of cement, 34.9%-44.1% of water, 0.8%-1.8% of a foaming agent, 1.2%-3.3% of desulfurized gypsum, and 0.5%-2.7% of MgO. The cement based carbon dioxide curing agent provided by the invention plays a very important role in implementing the sustainable development strategy, saving energy and utilizing waste, and protecting environment, and has broad prospects.

Owner:HOHAI UNIV

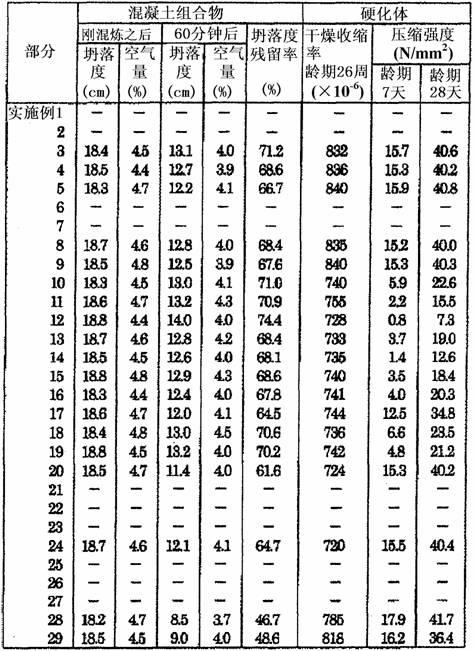

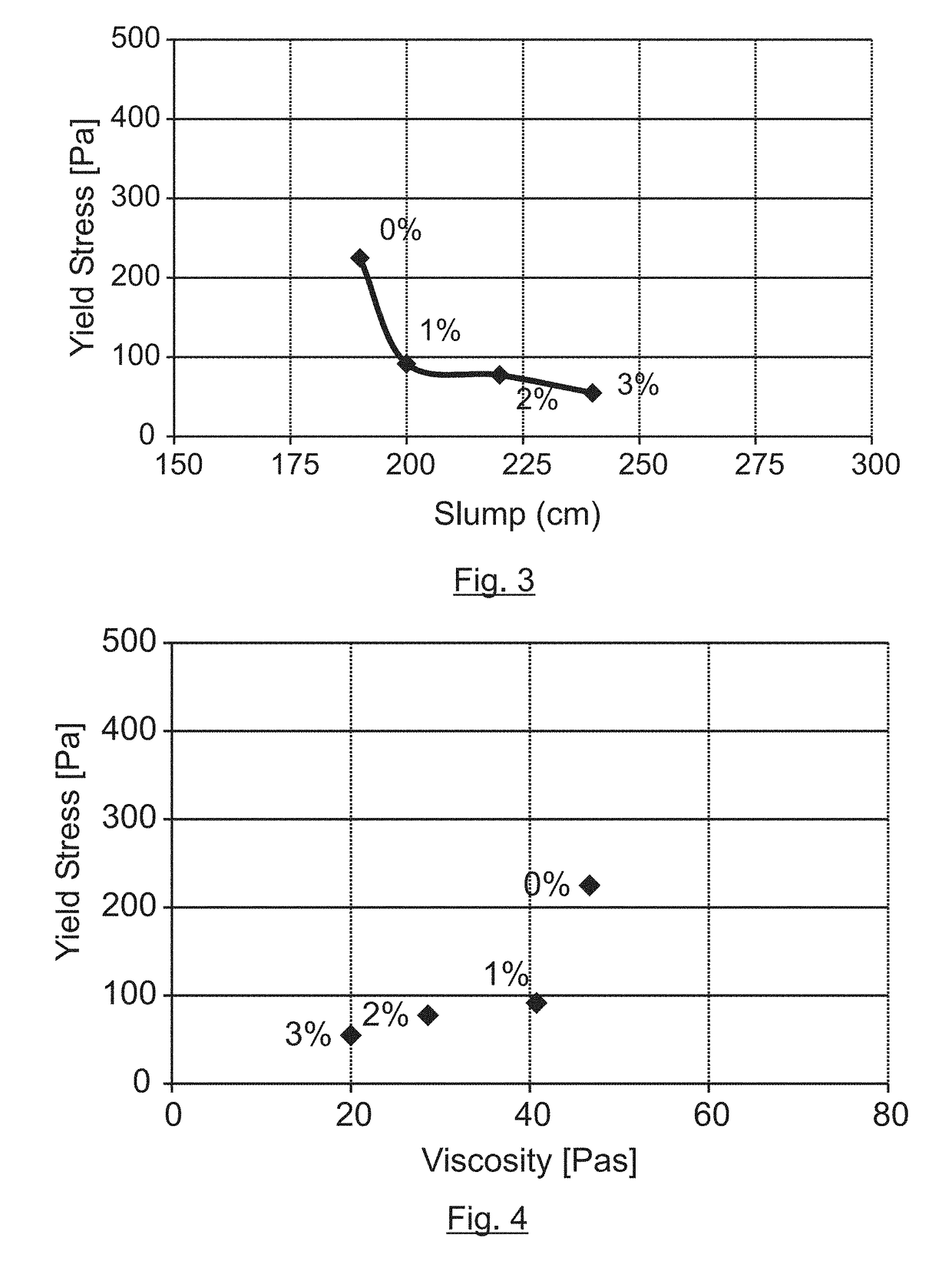

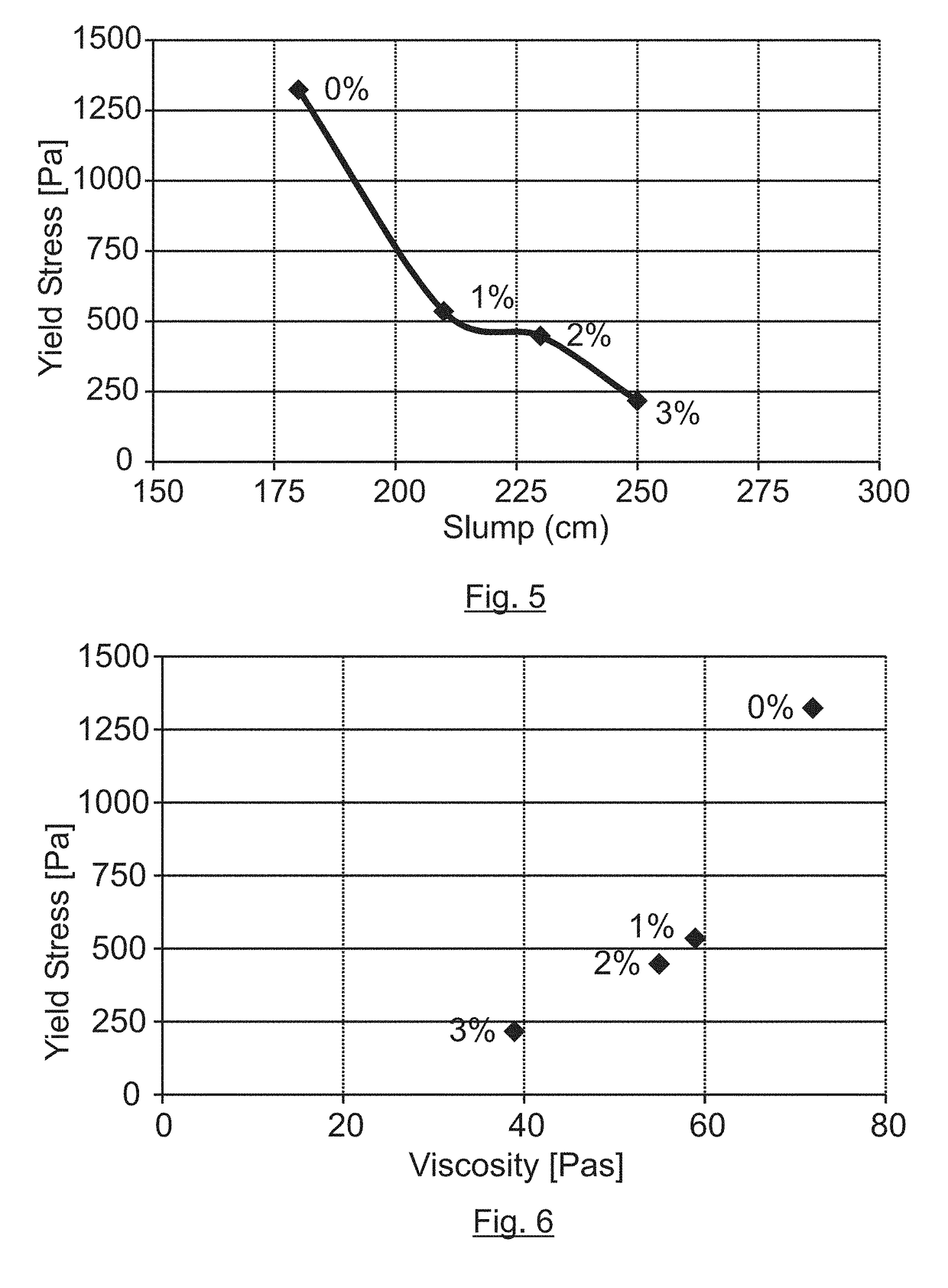

Concrete composition using blast furnace slag composition

Owner:TAKEMOTO YUSHI KK

Composition for use as a two component back filled grout comprising extracted silicate

InactiveUS20160075852A1Solid waste managementCement productionSODIUM SILICATE SOLNUltimate tensile strength

A multi-component cementitious composition with at least a binder and a hardener component, wherein the binder component includes ground granulated blast furnace slag and water and wherein the hardener component includes a sodium silicate solution containing at least 42 wt.-%, preferably at least 45 wt.-% or sodium silicate (Na2SiO3). Such multi-component cementitious compositions have been found to provide excellent early strength in excess of 0.5 mPa after hardening for just 2 h with a gel time in the range of 10 to 20 s. In addition the binder components are stable or at least remixable for up to 4 d in the absence of the hardener, which makes them particularly suitable for back filled grouts.

Owner:SIKA TECH AG

High-intensity concrete admixture and preparation method and application thereof

ActiveCN106630738AHigh compressive strengthImprove crack resistanceActivated carbonOctenyl succinate

The invention discloses a high-intensity concrete admixture. The high-intensity concrete admixture is prepared from the following raw materials in parts by weight: blast-furnace slag 200 parts, edible fungi residues 35-45 parts, gypsum 10-15 parts, gneiss 10-20 parts, shale 25-35 parts, activated carbon slag 30-40 parts, attapulgite 20-30 parts, pine and cypress ash 15-18 parts, polypropylene fibers 2-4 parts, corn stigma 0.2-0.5 part and an additive 1-3 parts. The additive consists of glutinous rice glue, starch octenylsuccinate, fish glue and glucomannan according to the weight ratio of 500: 20: 1-3: 5. The blast-furnace slag is ground granulated blast-furnace slag powder, and the Brinell specific surface area is 500-600 m(2) / kg. The high-intensity concrete admixture has the effects that the compressive property of the concrete is enhanced, the brittleness of the concrete is reduced, and the working preforamnce of the high-intensity concrete is improved.

Owner:柳州市大星混凝土有限公司

Modified ecological fiber reinforced recycled aggregate lightweight wall material and preparation method

InactiveCN106278125AEvenly distributedImprove sound insulationSolid waste managementFiberFoam concrete

The invention discloses a modified ecological fiber reinforced recycled aggregate lightweight wall material and a preparation method. The modified ecological fiber reinforced recycled aggregate lightweight wall material comprises the following components in parts by mass: 15-36 parts of Sorel cement, 5-15 parts of ground granulated blast furnace slag, 10-25 parts of ceramsite, 12-40 parts of recycled lightweight aggregate, 8-20 parts of pottery sand, 0.1-0.6 part of modified ecological fibers, 0.1-2 parts of foaming agents, 0.2-1.0 part of thickening agent and 10-30 parts of water. The preparation method comprises the steps of putting the Sorel cement, the ground granulated blast furnace slag, the modified ecological fibers and the thickening agent, which are required for preparation, together and stirring the materials for 8-15 minutes, then adding water and the foaming agents, which are required for preparation, to the mixture in sequence and further stirring the materials for 10-15 minutes, thus obtaining a slurry mixture. The lightweight wall material and the preparation method have the beneficial effects that the ecological fibers have good tensile deformation resistance and are lighter, so the foam concrete has toughness; China has abundant ecological plant resources, thus saving plenty of resources and being beneficial to the human living environment.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Foundry molding sand containing blast furnace slag

The invention discloses foundry molding sand containing blast furnace slag. The foundry molding sand is prepared from the raw materials in parts by weight: 40-55 parts of mudstone particle, 3-5 parts of waste aluminum powder, 7-9 parts of graphite powder, 6-8 parts of bentonite, 2-5 parts of plant ash, 4-6 parts of granular blast furnace slag and 8-12 parts of water. The foundry molding sand is prepared by the steps: 1) weighing the plant ash, the granular blast furnace slag and the bentonite according to the proportion, and adding water accounting for the total quantity of 35-40 percent. With the adoption of the foundry molding sand, as coal powder is not added, and straw powder and the plant ash are mainly used as antisticking additives, the cost is lowered, and the surface smoothness of a casting is also improved.

Owner:黄俞丰

Durable granulated blast furnace slag building block

The invention discloses a durable granulated blast furnace slag building block and belongs to the technical field of a building material. The durable granulated blast furnace slag building block is prepared according to the following steps: crushing granulated blast furnace slag and sieving, thereby acquiring refined granulated blast furnace slag; mixing and stirring the acquired refined granulated blast furnace slag and sulfuric acid, soaking and filtering, thereby acquiring the pretreated granulated blast furnace slag; stirring, mixing and fermenting paper-making black liquor, chitosan solution, soybean protein powder and biogas slurry, thereby acquiring a fermentation liquor; mixing the pretreated granulated blast furnace slag and the fermentation liquor, soaking and filtering, therebyacquiring the modified granulated blast furnace slag; mixing and stirring the modified granulated blast furnace slag, gypsum, quicklime, cement, water, modified charring cocoanut fiber and silane coupling agent, thereby acquiring a mixed slurry; injecting the mixed slurry into a mold, pressing and forming, thereby acquiring a blank; placing the blank into a curing chamber and curing, thereby acquiring the durable granulated blast furnace slag building block. The durable granulated blast furnace slag building block provided by the invention has excellent mechanical properties and durability.

Owner:杨忠华

Construction castable material with controllable flow or slump

Owner:CEMEX INNOVATION HLDG LTD

Device and method of utilizing blast furnace slag as heat carrier to prepare biomass oil

InactiveCN105567342AAchieve recyclingAchieve waste heatLiquid carbonaceous fuelsHydrocarbon oils treatmentChemical industryHeat carrier

The invention discloses a device and method of utilizing blast furnace slag as a heat carrier to prepare biomass oil. The device comprises a granulating cavity, a dryer, a pyrolysis reactor, a counterflow moving bed heat exchanger, a vibration separator and a condensation separator, a granulator is arranged in the granulation cavity, and a blast furnace slag fluidizing cabin is arranged at the bottom of the granulation cavity. The device is characterized in that the granulation cavity is used for smashing and granulating blast furnace slag through the granulator to obtain blast furnace slag grains; at the same time, the blast furnace slag fluidizing cabin outputs fluidizing air to exchange heat with the blast furnace slag grains, the blast furnace slag grains after heat exchange are output into the pyrolysis reactor, and generated high-temperature flue gas is output into the dryer to dry microalgae biomass; the pyrolysis reactor is used for mixing microalgae powder with granulated blast furnace slag grains, and the microalgae powder is pyrogasified to generate biomass pyrolysis gas. The device and method can be widely applied in the field of power, environment protection, chemical industry and steel and iron.

Owner:CHONGQING UNIV

Preparation method of high-performance concrete mineral admixture

InactiveCN106587690AReduce manufacturing costAvoid pollutionSolid waste managementGranularityResource saving

The invention provides a preparation method of a high-performance concrete mineral admixture. The method comprises the following steps: taking converter slag, processing the converter slag through a hot braising technology to make the granularity less than 5 mm in order to obtain hot-braised converter slag, and grinding the hot-braised converter slag to form powder with the Blaine specific surface area of 300-400 m<2> / kg in order to obtain hot-braised converter slag powder; taking granulated blast furnace slag powder, and grinding the granulated blast furnace slag powder to form powder with the Blaine specific surface area of 400-500 m<2> / kg in order to obtain granulated blast furnace slag powder; taking and grinding limestone to form powder in order to obtain limestone powder; and uniformly mixing 1-5 parts by weight of the hot-braised converter slag powder, 4-10 parts by weight of the granulated blast furnace slag powder and 0-1.6 parts by weight of the limestone powder to obtain the high-performance concrete mineral admixture. The method has the advantages of reuse of industrial wastes, resource saving, reduction of the making cost of concrete, simple process, simple operation, easiness in operation, and easiness in wide application.

Owner:福建省建筑材料工业科学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com