Granulated blast furnace slag powder stabilized steel slag type mixture

A technology of granulated blast furnace slag and mixture, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of unutilized granulated blast furnace slag powder, limited environmental protection, and damage to the natural environment Environmental and other issues, to achieve high compactness, reduce emissions, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

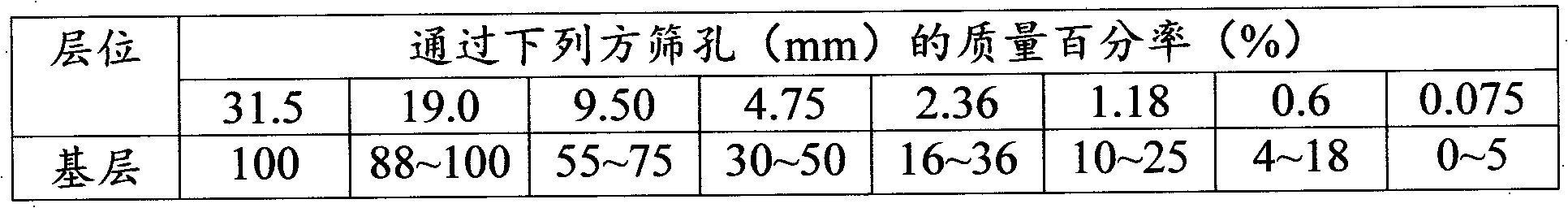

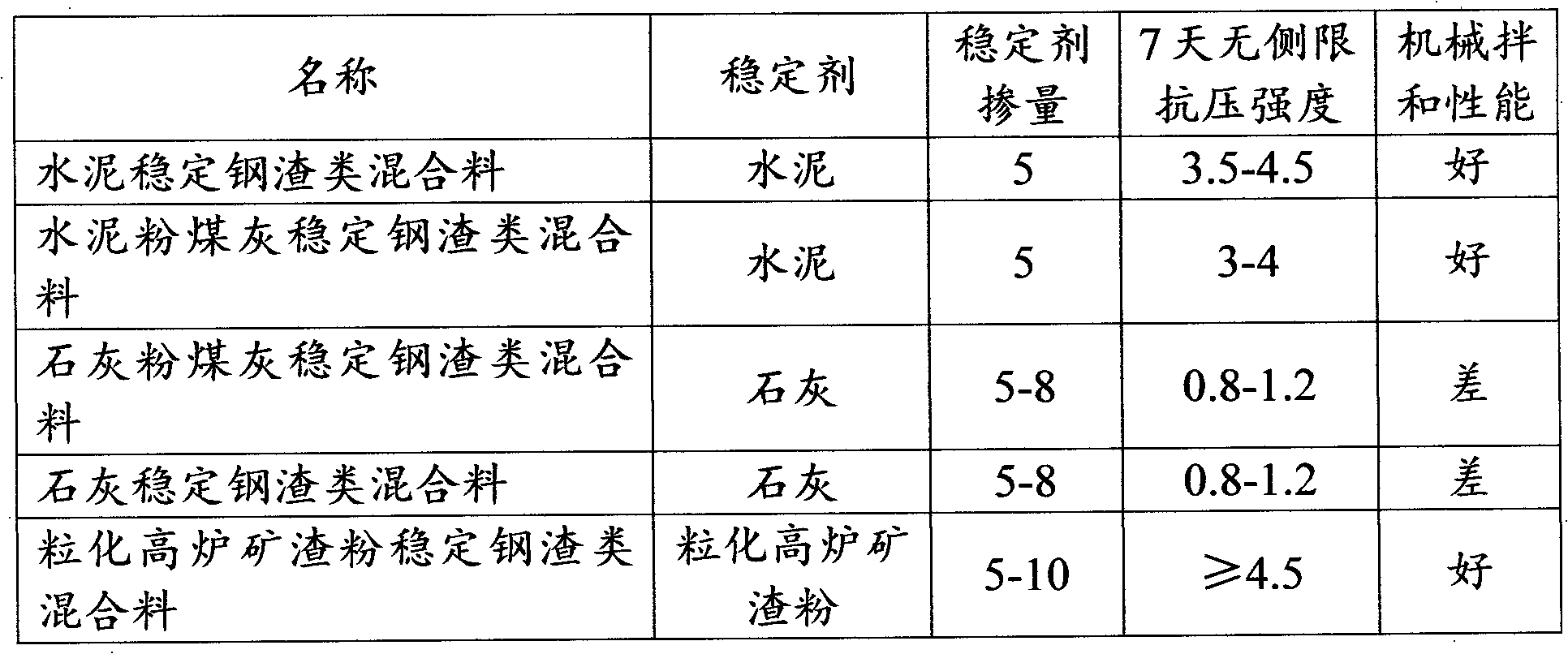

[0017] Example 1: Steel slag aggregate conforms to the gradation in Table 1, mixed with 5% granulated blast furnace slag powder, no fly ash is added, and mechanically stirred according to the optimum water content. The test results of the technical indicators are compared as shown in Table 2:

Embodiment 2

[0018] Example 2: Steel slag aggregate conforms to the gradation in Table 1, mixed with 10% granulated blast furnace slag powder, 5% fly ash, and mechanically stirred according to the optimum water content. The test results of the technical indicators are compared as shown in Table 2:

[0019] Table 2 Comparison table of technical indicators

[0020]

[0021] It can be seen from Table 2 that using granulated blast furnace slag powder as a stabilizer and solidifying steel slag aggregate as a roadbed material has the advantages of high compressive strength and good mechanical mixing performance, and can completely replace the existing technology of using lime and cement as stabilizers The mixture has great application prospects.

[0022] The implementation and test indicators of the above embodiments are implemented and tested according to the industry standard of "The People's Republic of China Ferrous Metallurgy Industry Standard" (YB / T 4184-2009).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com