Preparation method of high-performance concrete mineral admixture

A high-performance concrete and mineral technology, applied in the field of building materials, can solve the problems of strong water fixation rate and low strength, and achieve the effects of easy operation, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

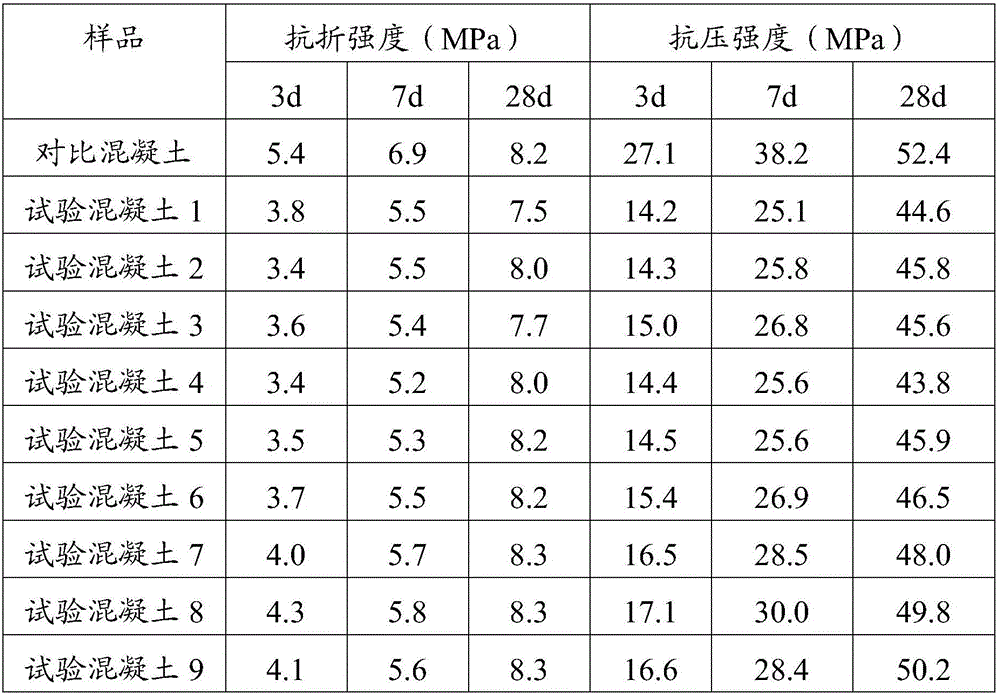

Examples

preparation example Construction

[0020] A kind of preparation method of high-performance concrete mineral admixture of the present invention, this preparation method comprises following specific operation steps:

[0021] (1), raw material preparation:

[0022] Take the converter steel slag and make it smaller than 5mm in particle size through hot-steaming process to obtain hot-steamed converter steel slag, and then grind the hot-steamed converter steel slag to a fineness of 300-400m 2 / kg Blaine specific surface area of the powder, heat stewing furnace to turn steel slag powder, standby;

[0023] Take granulated blast furnace slag and grind it to a fineness of 400-500m 2 / kg Blaine specific surface area powder, to get granulated blast furnace slag powder, standby;

[0024] Take limestone and grind it into powder to get limestone powder, set aside;

[0025] (2) Preparation of admixture:

[0026] The high-performance concrete mineral admixture is obtained by mixing the following raw materials evenly in pa...

Embodiment 1

[0030] Take the converter steel slag and make it smaller than 5mm in particle size through hot-steaming process to get hot-steamed converter steel slag, and then grind the hot-steamed converter steel slag to a fineness of 400m 2 / kg Blaine’s specific surface area powder, heat and stew the furnace to turn into steel slag powder, and set aside; take the granulated blast furnace slag and grind it into a fineness of 450m 2 / kg Blaine specific surface area powder, get granulated blast furnace slag powder, for subsequent use; get limestone and grind it into powder, get limestone powder, for subsequent use; Mix 100kg of powder evenly to obtain the high-performance concrete mineral admixture of the present invention.

Embodiment 2

[0032] Take the converter steel slag and make it smaller than 5mm in particle size through hot-steaming process to get hot-steamed converter steel slag, and then grind the hot-steamed converter steel slag to a fineness of 300m 2 / kg Blaine’s specific surface area powder, heat and stew the furnace to turn into steel slag powder, and set aside; take the granulated blast furnace slag and grind it into a fineness of 500m 2 / kg Blaine specific surface area powder to get granulated blast furnace slag powder for subsequent use; get 500 kg of hot stewed furnace steel slag powder and 500 kg of granulated blast furnace slag powder and mix evenly to obtain high-performance concrete mineral admixture of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com