Patents

Literature

58 results about "Sorel cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

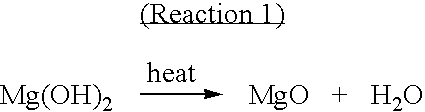

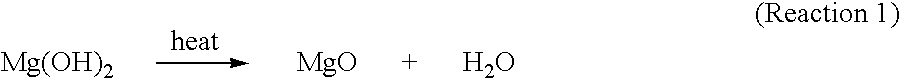

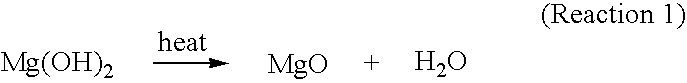

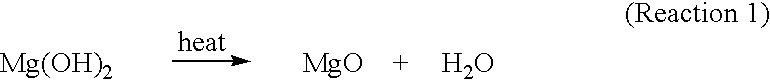

Sorel cement (also known as magnesia cement) is a non-hydraulic cement first produced by Frenchman Stanislas Sorel in 1867. The cement is a mixture of magnesium oxide (burnt magnesia) with magnesium chloride with the approximate chemical formula Mg₄Cl₂(OH)₆(H₂O)₈, corresponding to a weight ratio of 2.5–3.5 parts MgO to one part MgCl₂.

Concrete water-permeable brick using steel slag as aggregate

The invention discloses a concrete permeable brick of steel slag as aggregate, which comprises the following steps: allocating raw material with 70-85% steel slag with grinding value less than 5% and free calcium oxide less than 3%, 10-25% C52.5 low-alkaline cement, 0.5-6% reinforcer, 0-3% coloring powder and 3.5-5% water; blending raw materials in the mixer; distributing; molding; obtaining the product.

Owner:SUZHOU HUAJIA NEW BUILDING

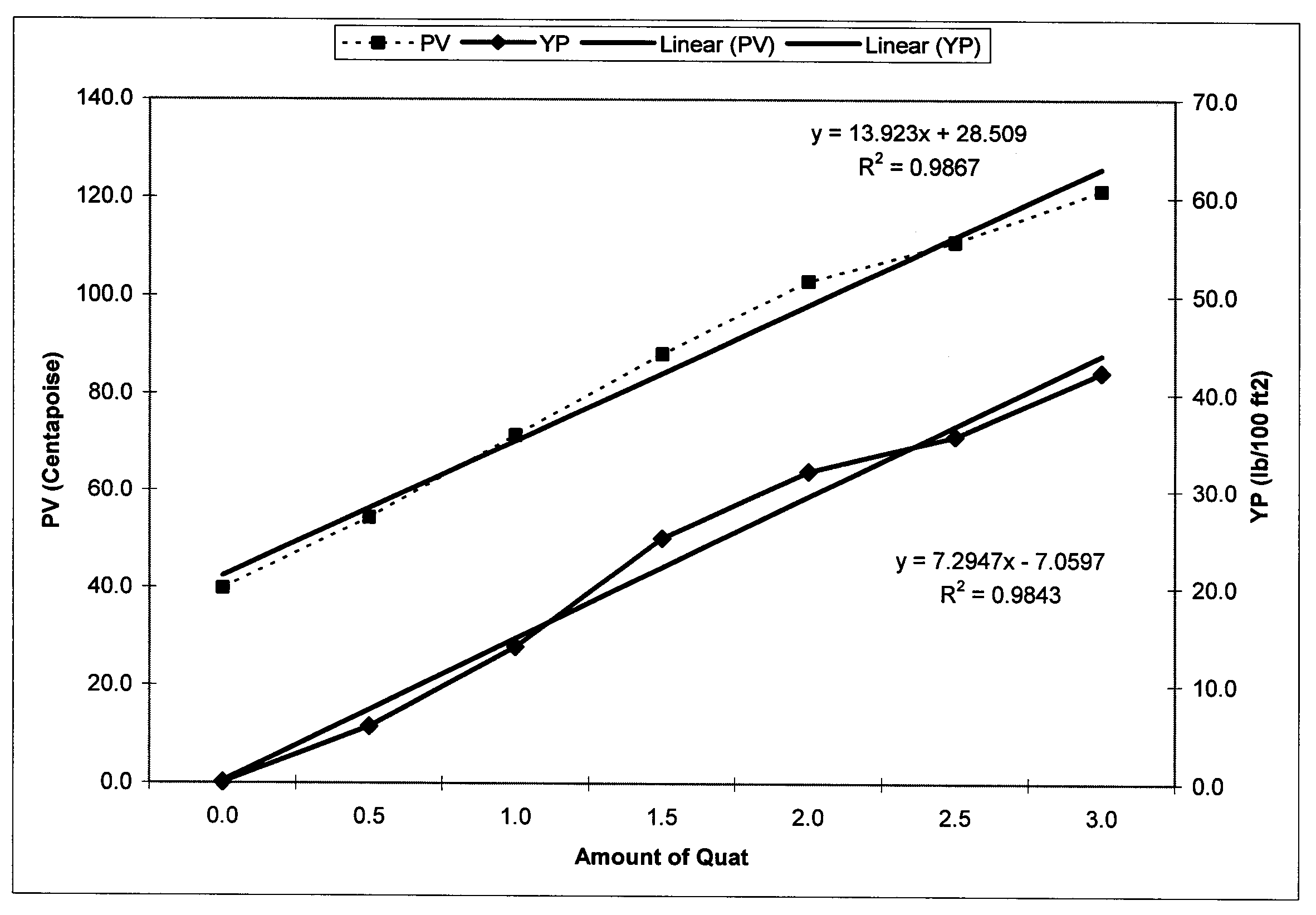

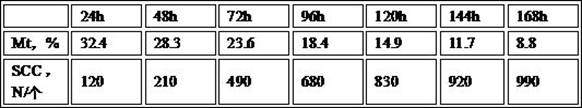

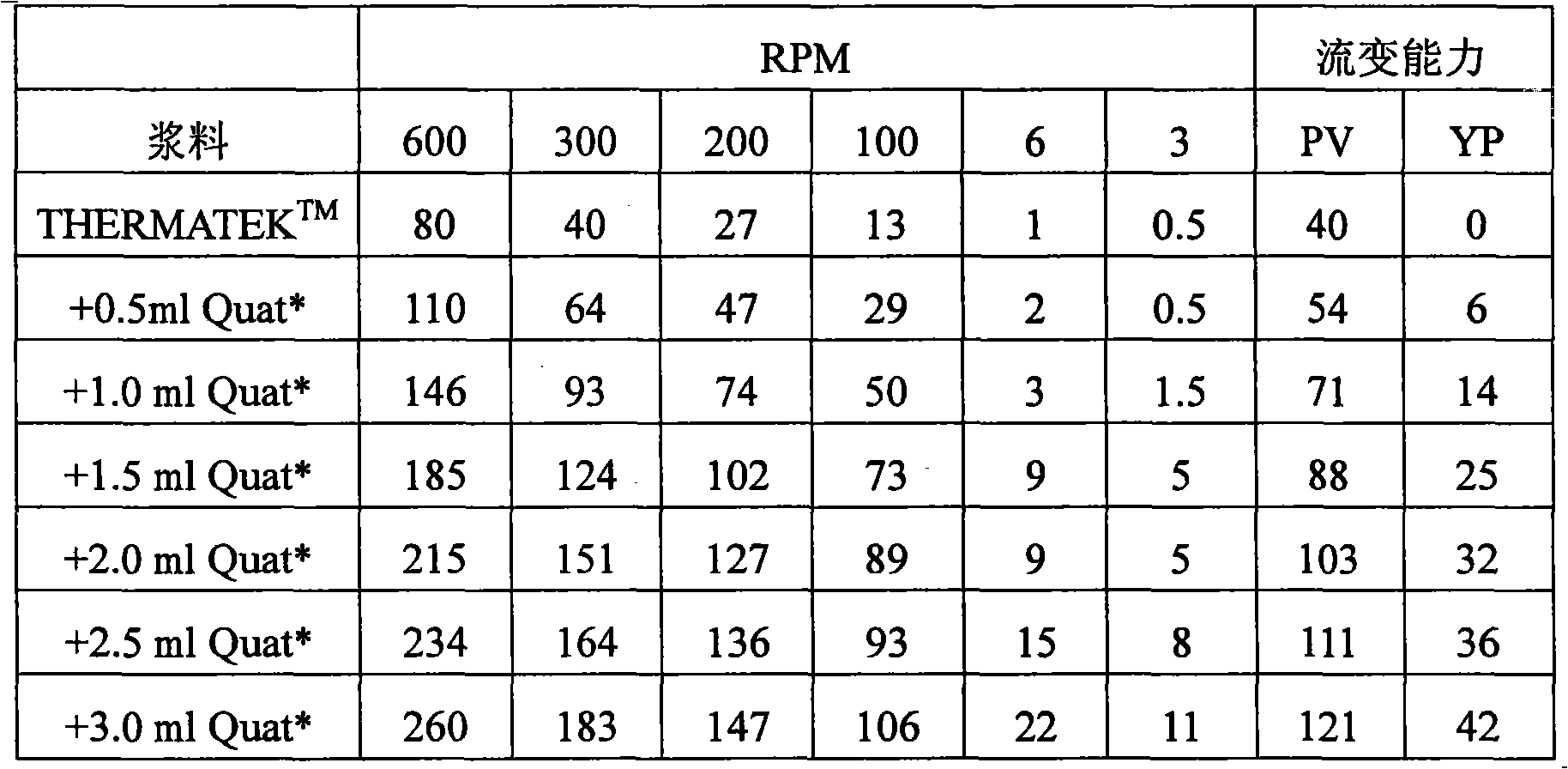

Methods of servicing a wellbore with compositions comprising quaternary material and sorel cements

A method of servicing a wellbore in contact with a subterranean formation comprising viscosifying a cement composition comprising a metal oxide and a soluble salt, placing the viscosified cement composition in the wellbore, and allowing the composition to set. A method of cementing a wellbore comprising preparing a cement composition comprising magnesium oxide, a chloride or phosphate salt, and a quaternary material, placing the cementitious composition into the wellbore, and allowing the cementitious composition to set. A method of viscosifying a Sorel cement comprising contacting the cement composition with quaternary material.

Owner:HALLIBURTON ENERGY SERVICES INC

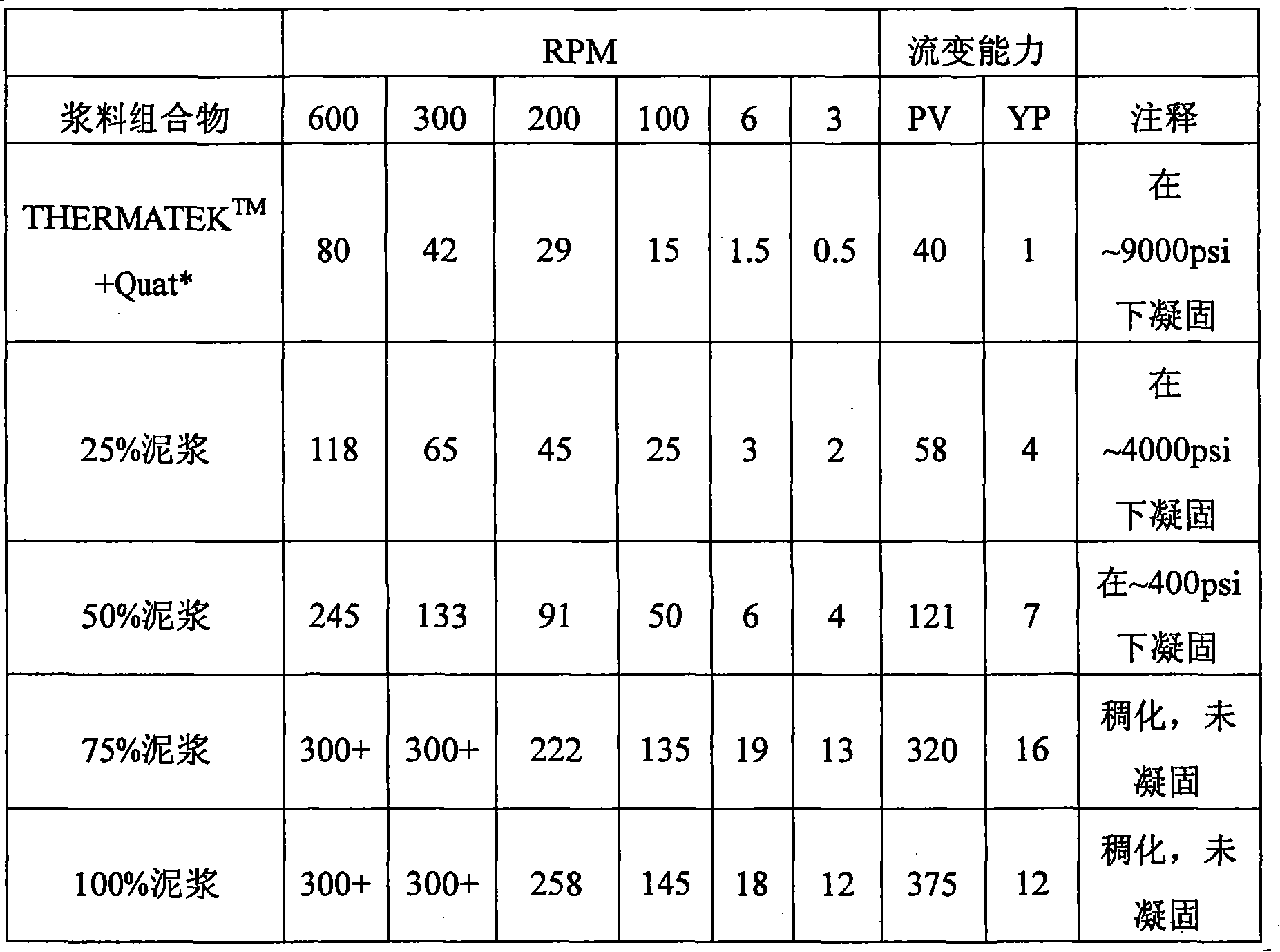

Methods of servicing a wellbore with compositions comprising Sorel cements and oil based fluids

A method of servicing a wellbore in contact with a subterranean formation comprising placing in the wellbore a composition comprising a metal oxide, a soluble salt, a surfactant and an oleaginous fluid, and allowing the composition to set. A method of cementing a wellbore comprising placing a first composition comprising magnesium oxide, a chloride or phosphate salt, an organophilic surfactant and an oleaginous fluid into a wellbore, allowing the composition to set, placing a second cementitious composition into the wellbore, and allowing the second cementitious composition to set. A method of servicing a wellbore comprising placing in the wellbore a composition comprising magnesium oxide, magnesium chloride, an organophilic surfactant, water and an oleaginous fluid wherein the organophilic surfactant is present in an amount of from about 0.25% to about 5% base on the combined weight of the magnesium oxide and magnesium chloride, and the oleaginous fluid is present in a ratio of from about 95:5 cement:oleaginous fluid to about 50:50 cement:oleaginous fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

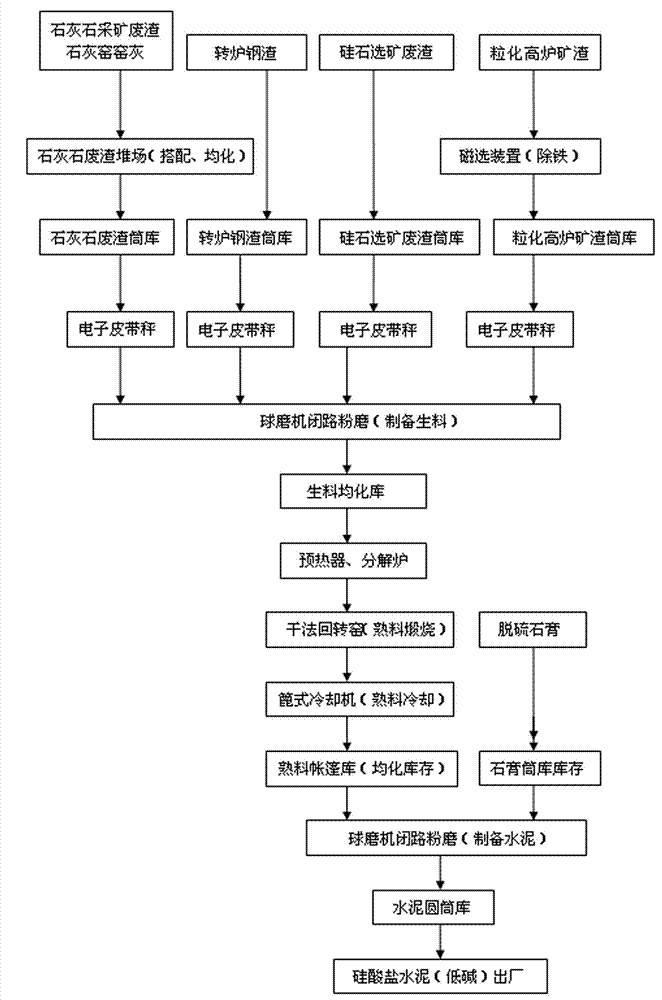

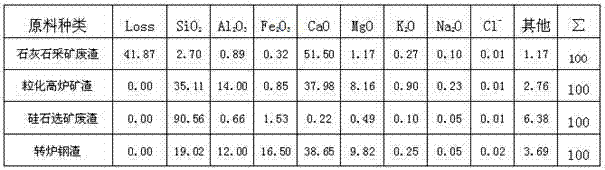

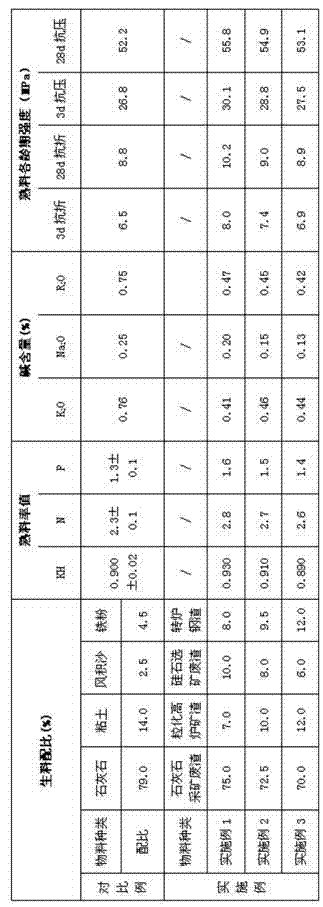

Method for producing low-alkali Portland cement by using industrial solid waste

The invention discloses a method for producing low-alkali Portland cement by using industrial solid waste and aims to overcome the problem that alkali content in cement produced by using traditional methods is high. The method comprises the following steps: A, preparation of the raw materials of 70 to 75% of mining debris of limestone, 7.0 to 12.0% of granulated blast-furnace slag, 6.0 to 10.0% of rejects of silica and 8.0 to 12.0% of converter steel slag; B, clinker calcination; and C, cement grinding. The method provided in the invention has the following characteristics: rejects of silica are used as a silico-regulating material, and not only the characteristic of low alkali content of the rejects of silica is made use of, but also the silica modulus N of the clinker can be adjusted by adjusting the proportion of the rejects of silica so as to inhibit the probability of skinning of a preheater and ring formation in a rotary kiln caused by excessively good burnability of materials. Lime kiln ash, the granulated blast-furnace slag and the converter steel slag are subjected to high temperature calcination, so alkali in the above-mentioned materials greatly volatilizes; therefore, alkali content in the raw materials is decreased, thereby meeting compounding requirements and creating conditions for production of low alkali cement.

Owner:嘉峪关祁连山水泥有限公司

Methods of servicing a wellbore with compositions comprising quaternary material and sorel cements

A method of servicing a wellbore in contact with a subterranean formation comprising viscosifying a cement composition comprising a metal oxide and a soluble salt, placing the viscosified cement composition in the wellbore, and allowing the composition to set. A method of cementing a wellbore comprising preparing a cement composition comprising magnesium oxide, a chloride or phosphate salt, and a quaternary material, placing the cementitious composition into the wellbore, and allowing the cementitious composition to set. A method of viscosifying a Sorel cement comprising contacting the cement composition with quaternary material.

Owner:HALLIBURTON ENERGY SERVICES INC

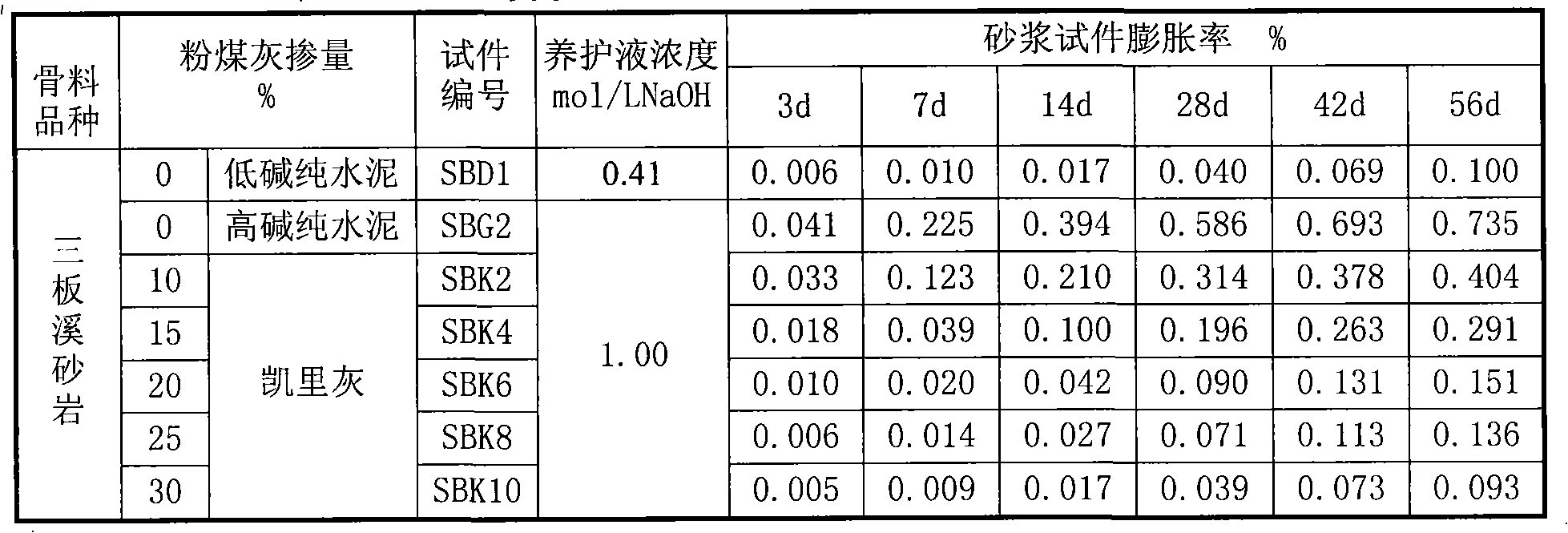

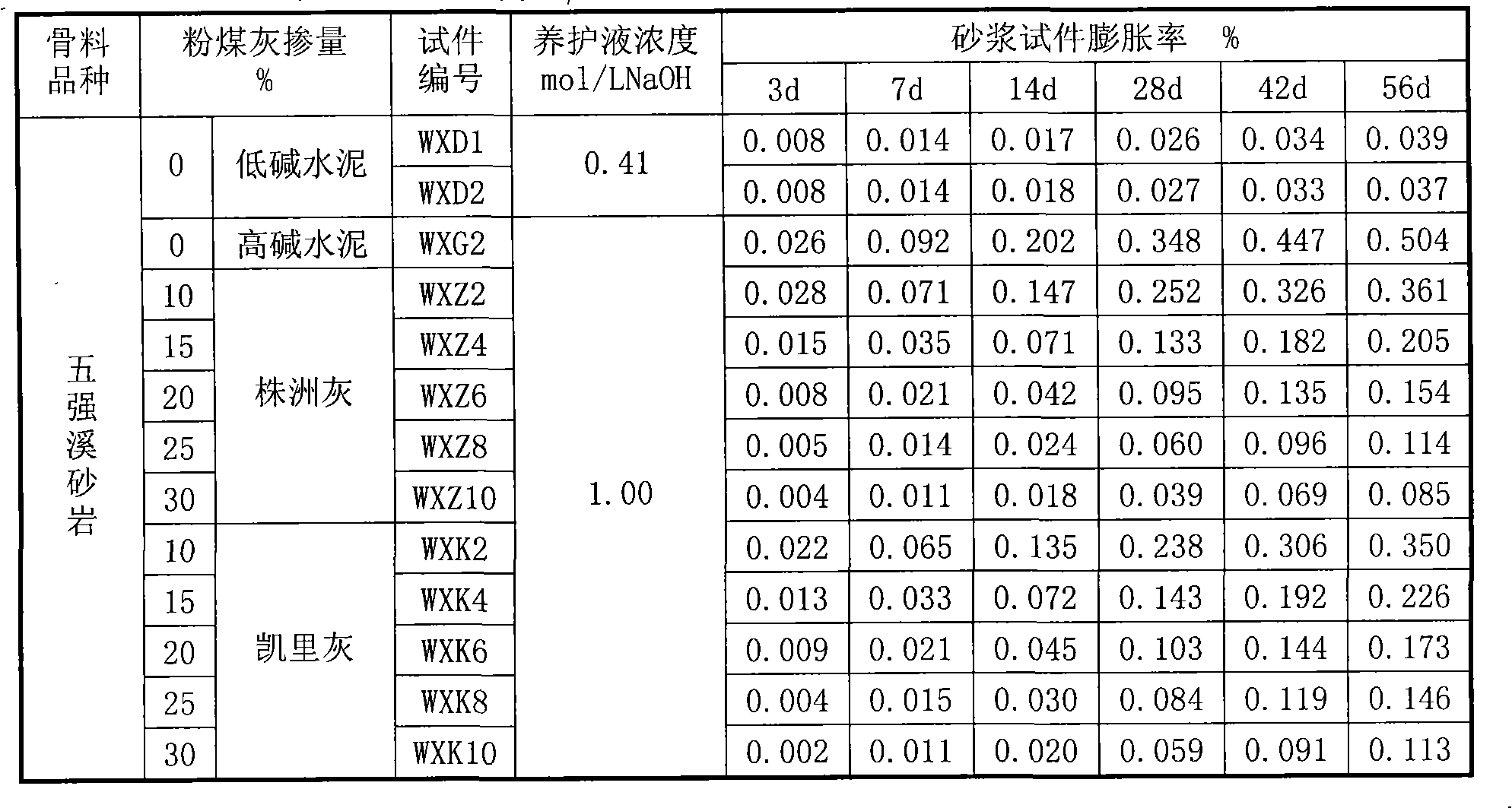

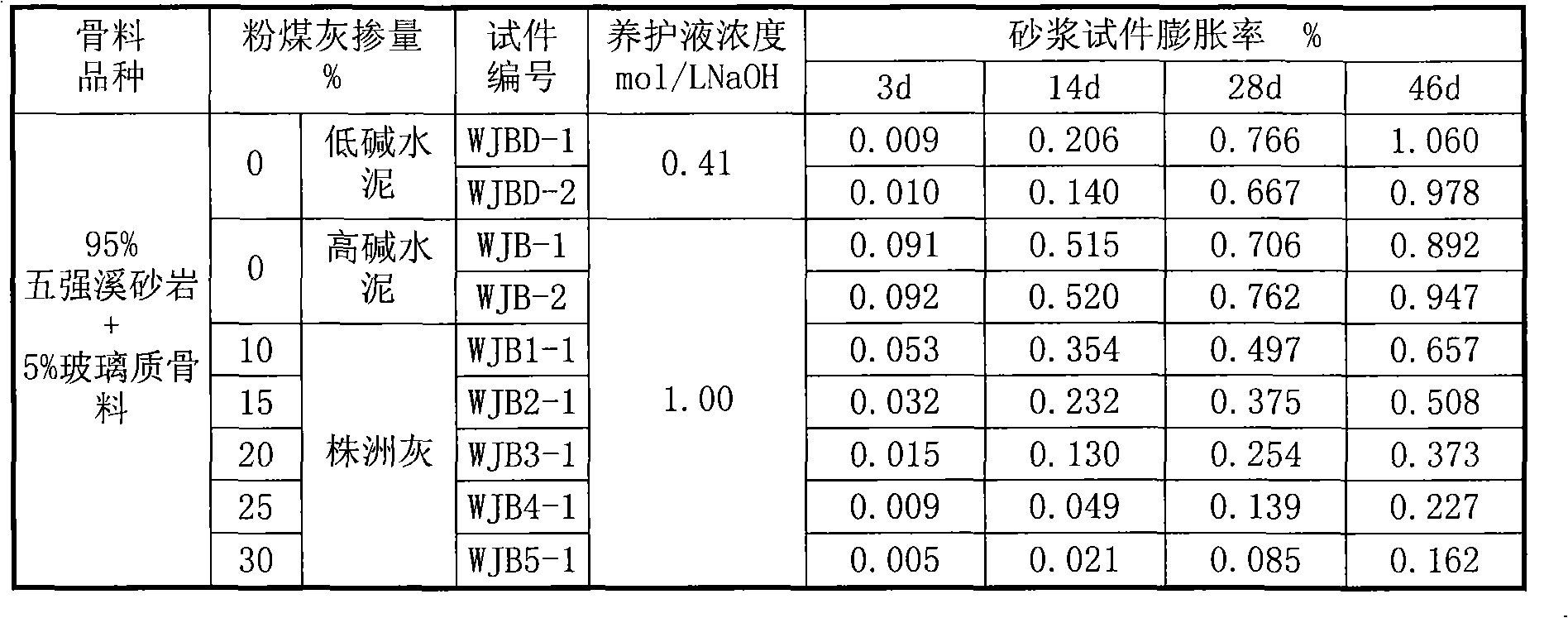

Method for evaluating effectiveness of measure for inhibiting alkali-silica active reaction of concrete aggregate

ActiveCN101514982AIneffective containmentMeet the needs of engineering constructionMaterial testing goodsCement mortarFly ash

A method for evaluating effectiveness of a measure for inhibiting alkali-silica active reaction of concrete aggregate comprises the following steps: using active aggregate used in actual works and low-alkali cement with available alkali Na2O content less than or equal to 0.60% or high-alkali cement with available alkali Na2O content of 0.90%+ / -0.1% to form mortar test pieces by mixing fly ash, and determining an inhibition measure effective where low-alkali cement mortar test pieces are formed and expansion rate of the mortar test pieces in 14 days is equal to or less than 0.040%, and determining the inhibition measure effective where high-alkali cement mortar test pieces mixed with the fly ash are formed and expansion rate of the mortar test pieces in 14 days is equal to or less than 0.050%. Thus, the method can help quickly determine the expansion rate of the mortar test pieces formed with the active aggregate used in actual works, and verify and evaluate the effectiveness of the measure for inhibiting the reaction of the concrete aggregate to meet engineering construction need.

Owner:POWERCHINA ZHONGNAN ENG

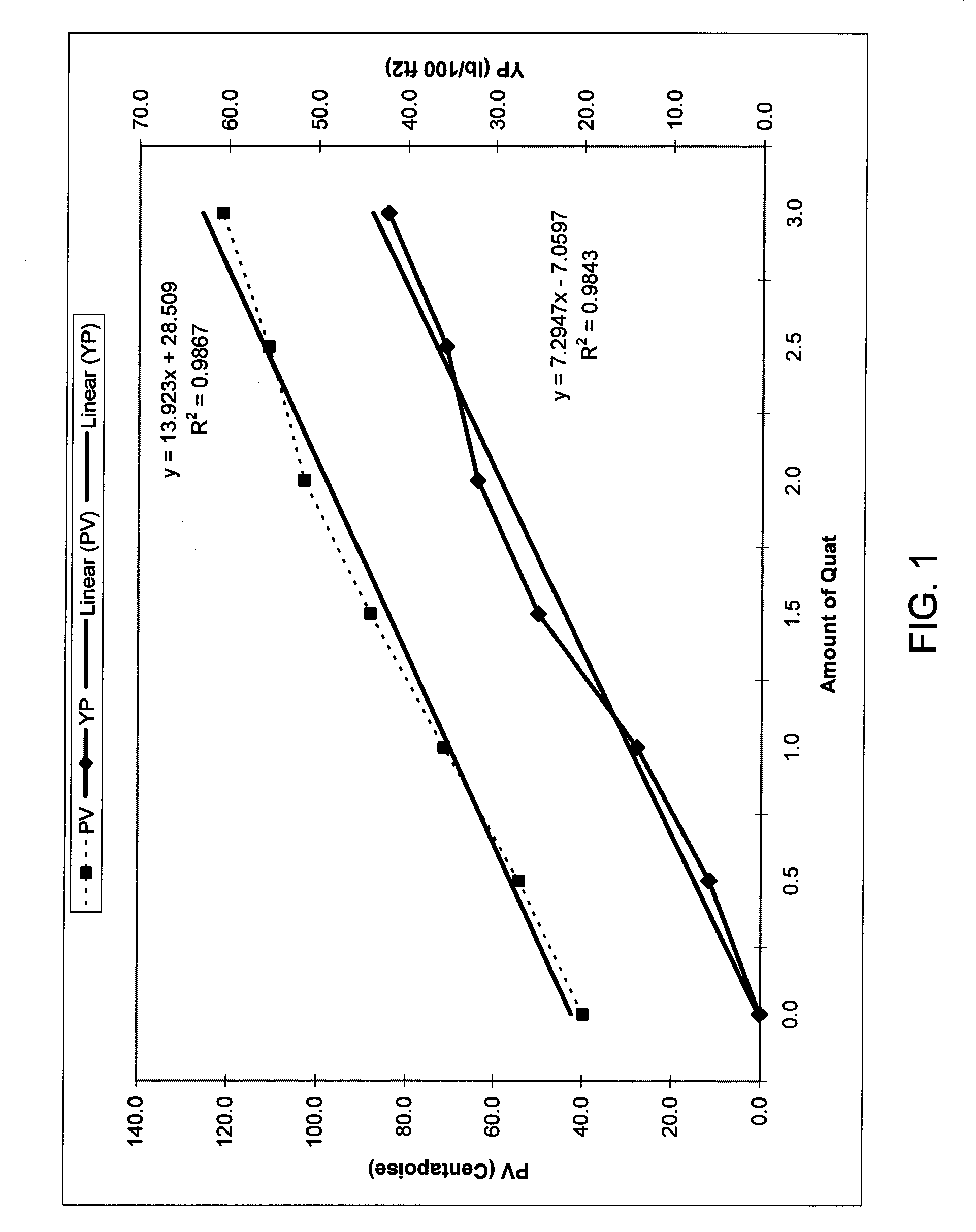

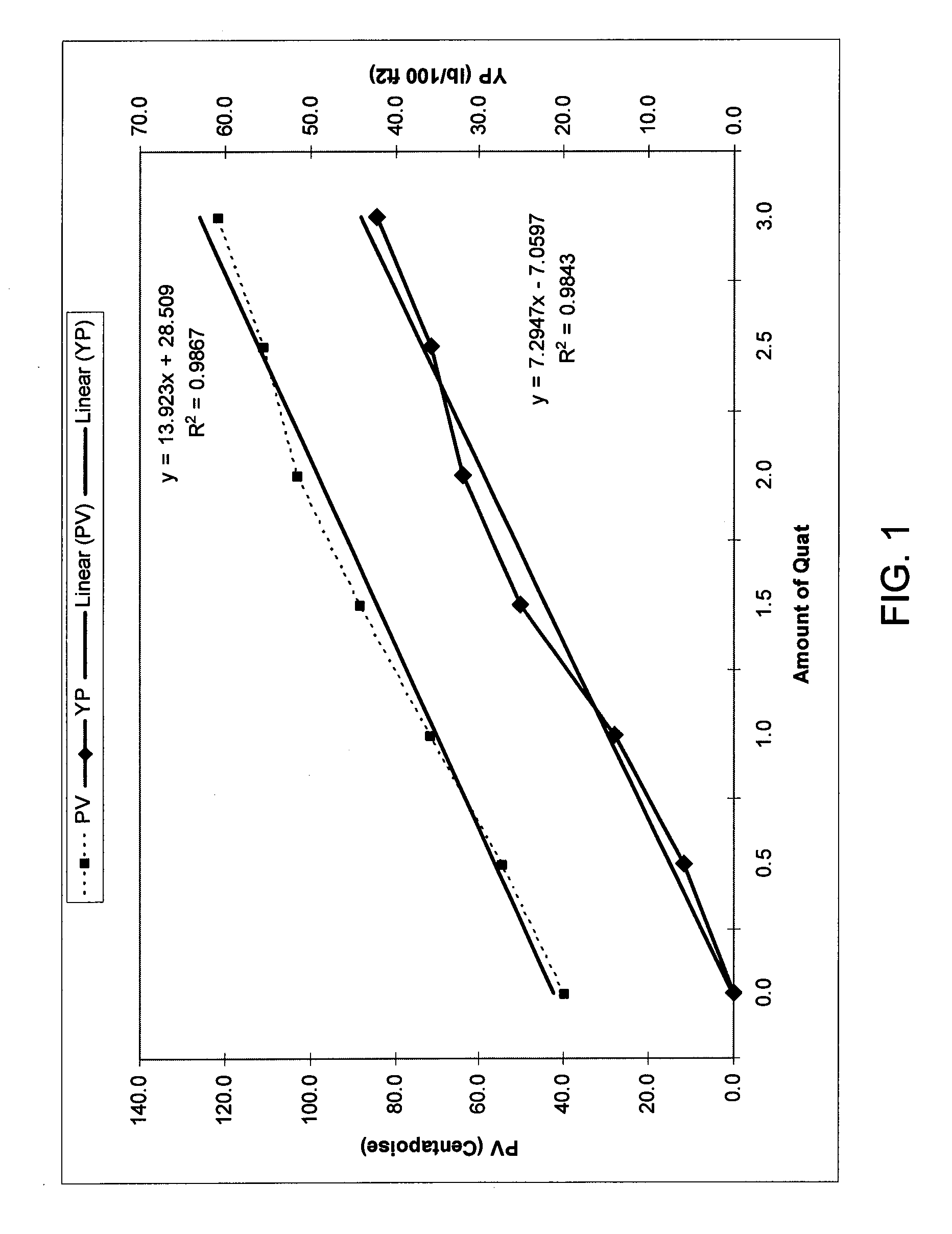

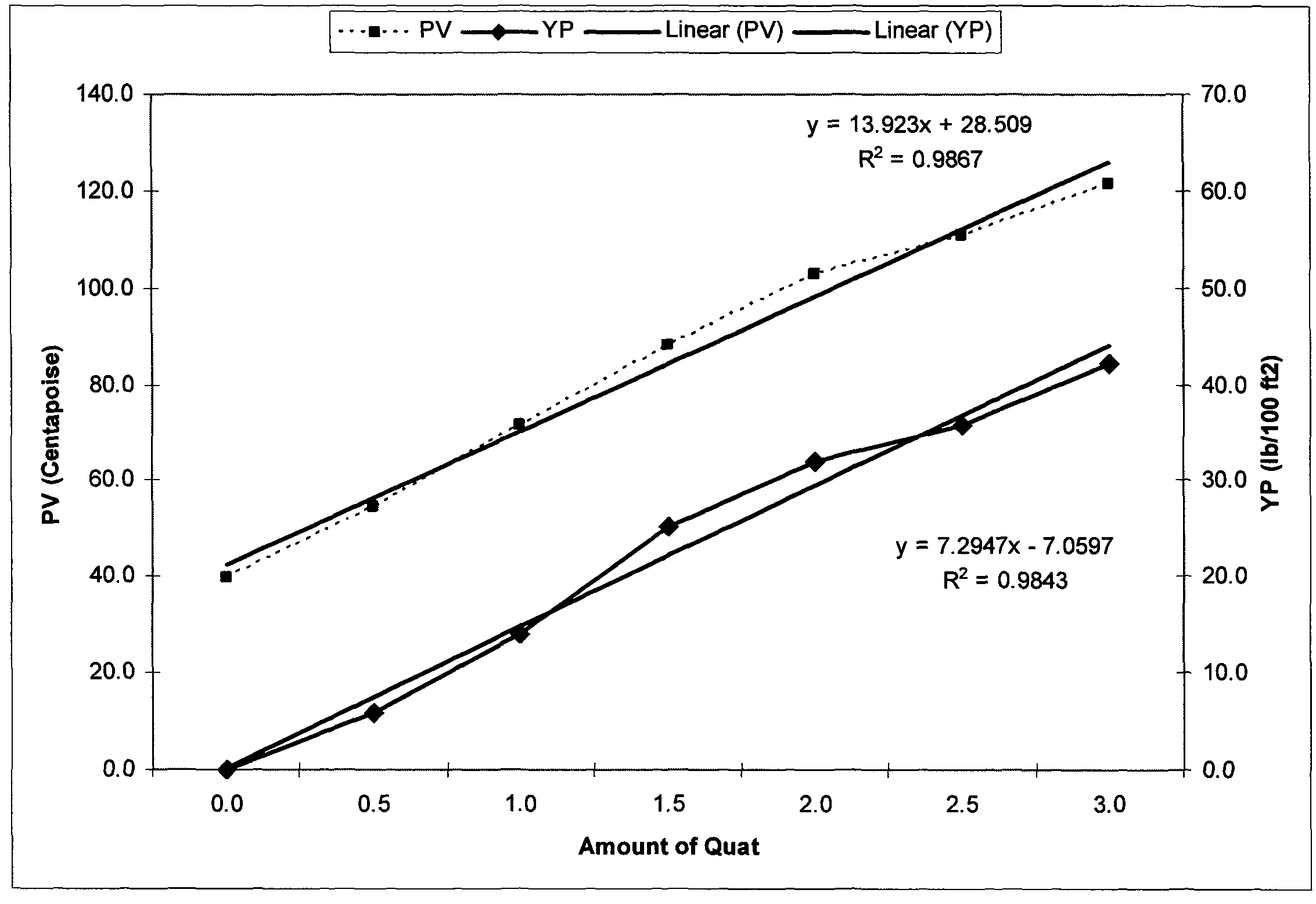

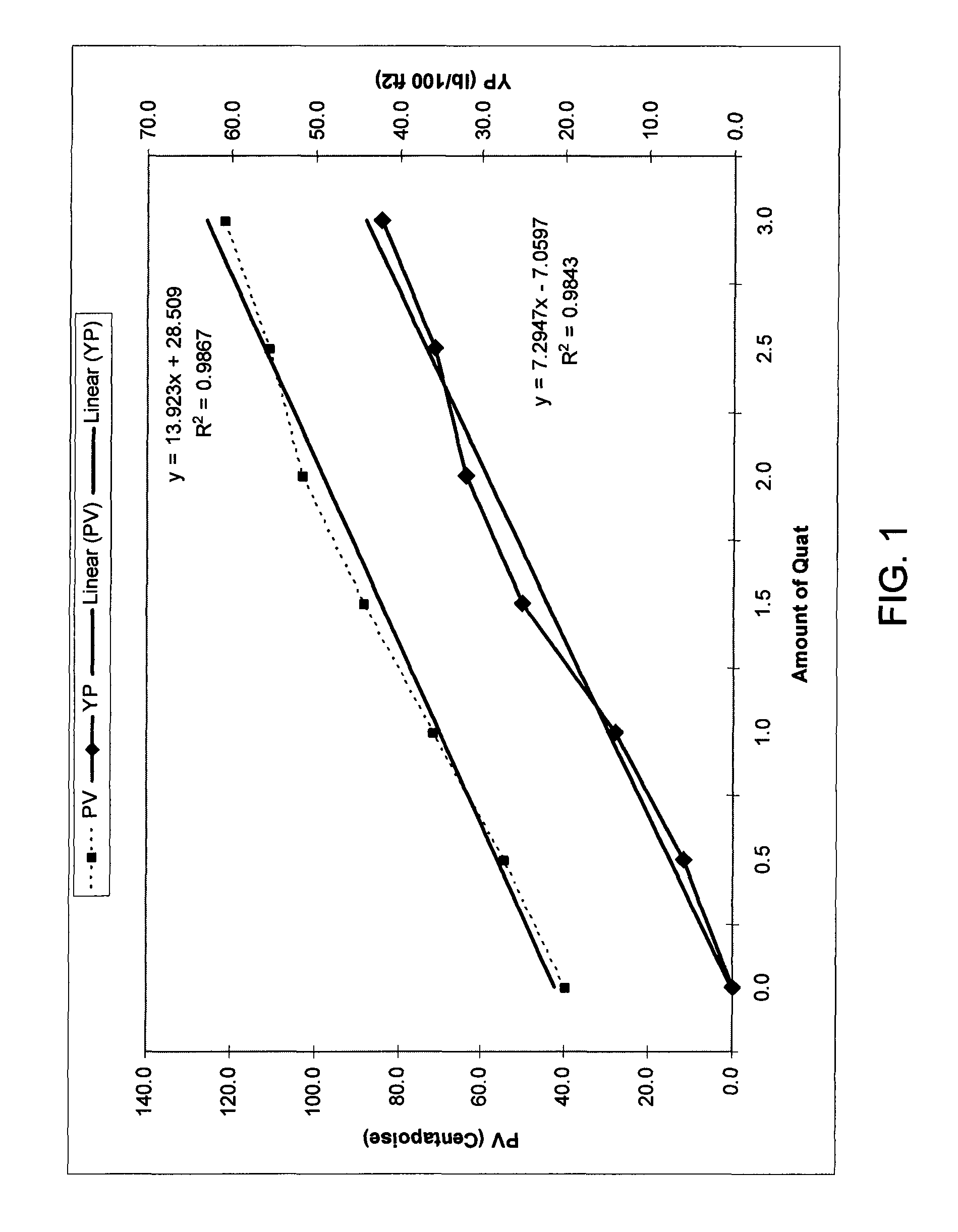

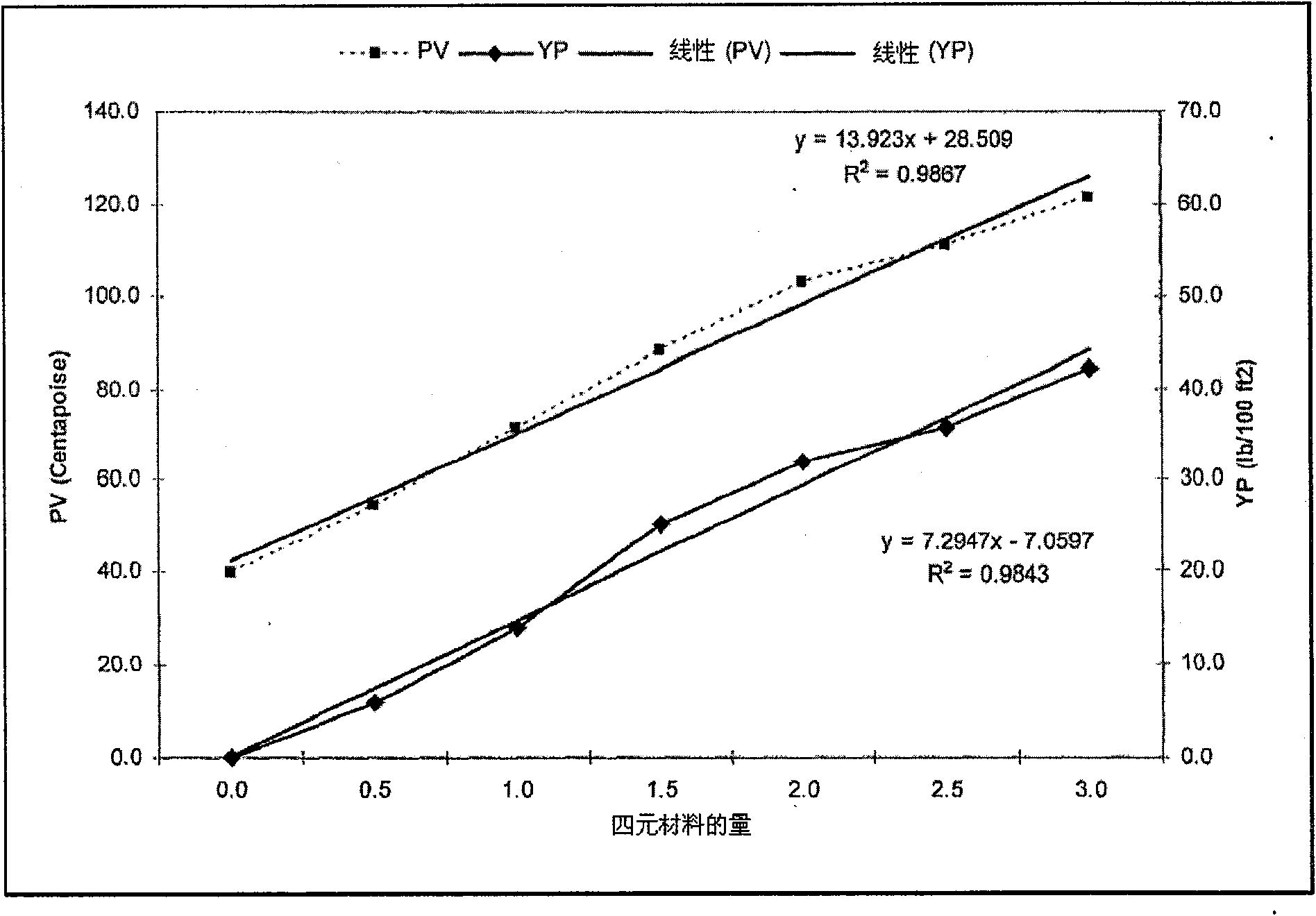

Compositions comprising quaternary material and sorel cements

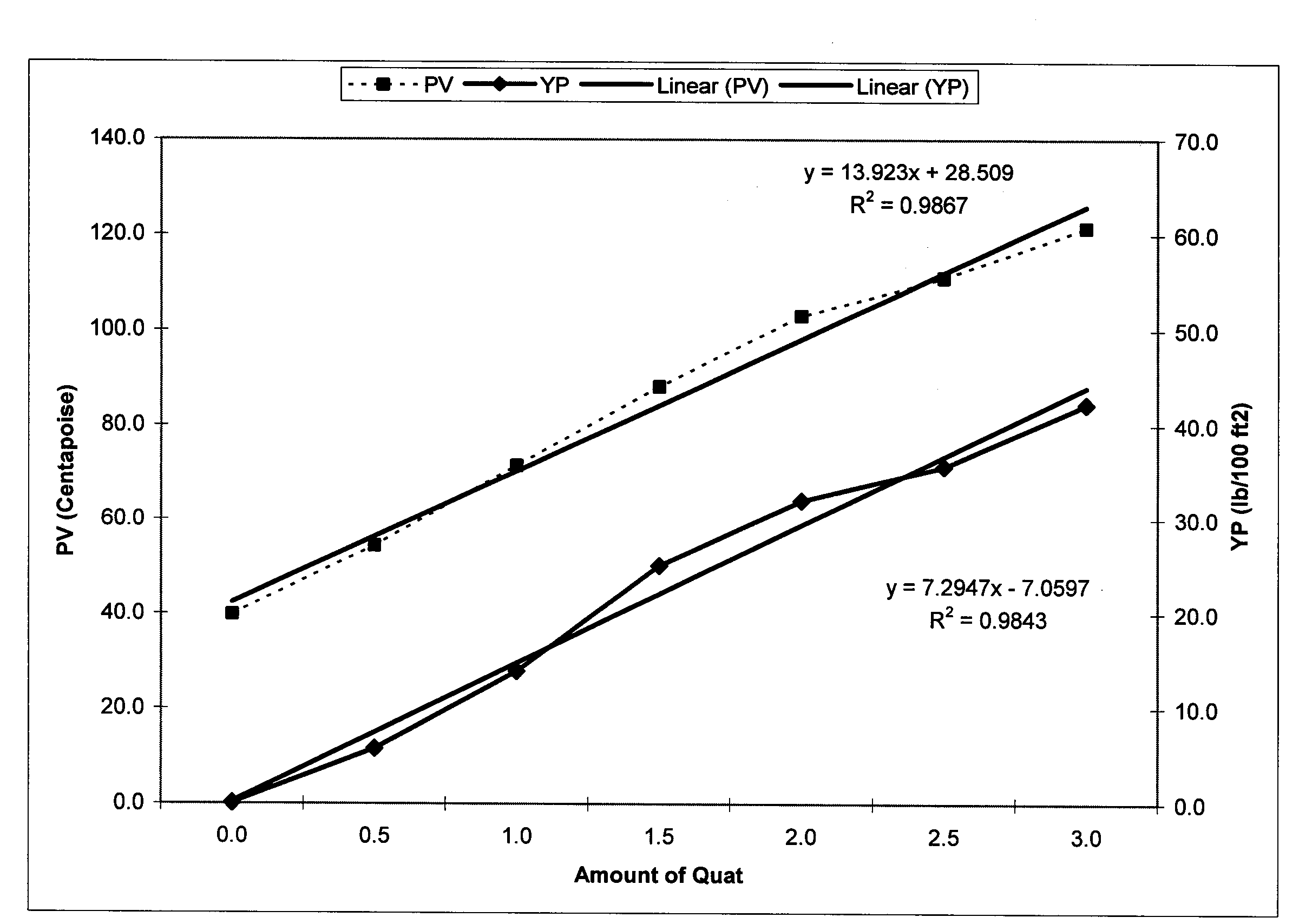

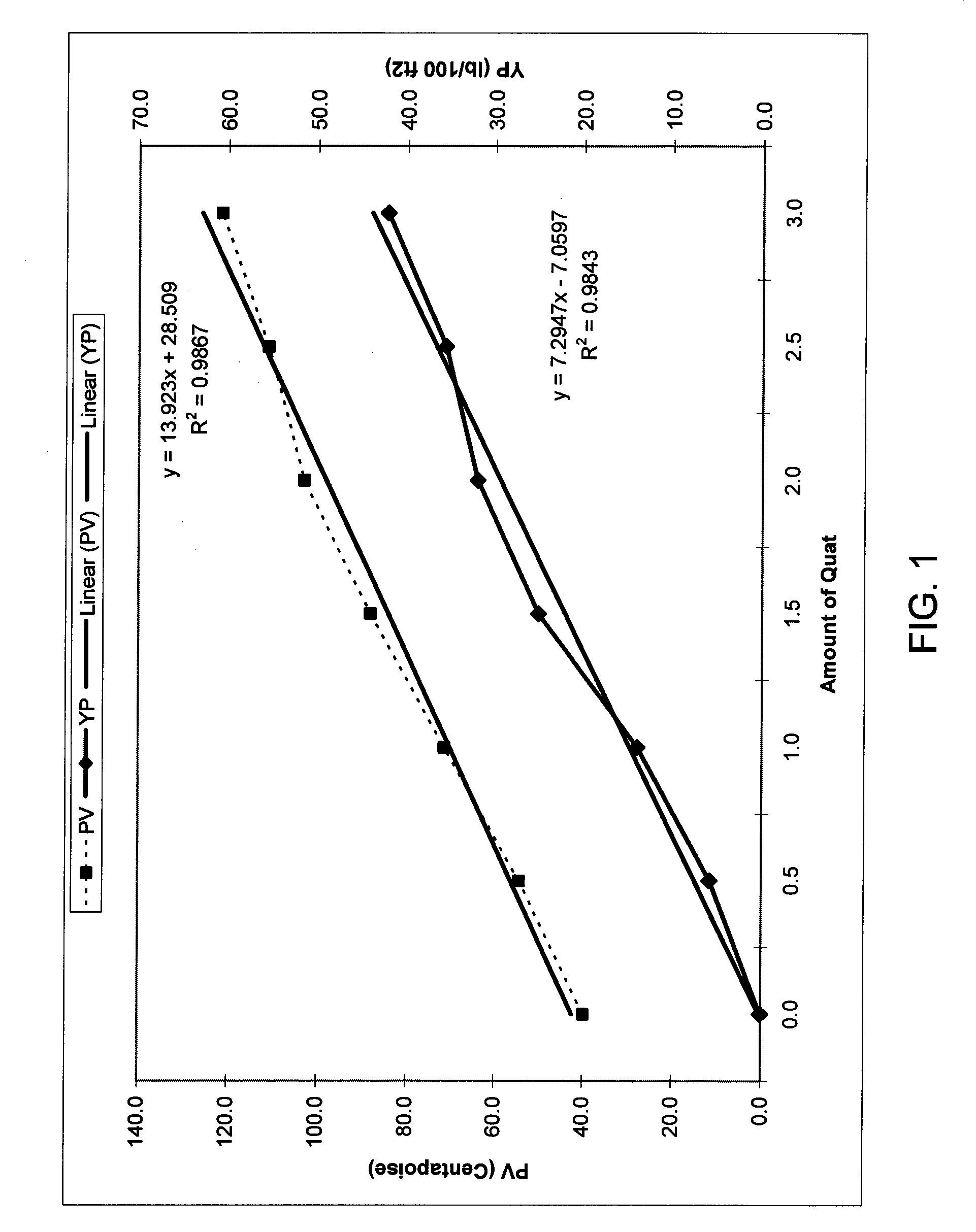

A wellbore servicing composition comprising a metal oxide, a soluble salt and a viscosifier wherein the viscosifier comprises a quaternary amide, a quaternary amide ester, or combinations thereof. A wellbore servicing composition comprising magnesium oxide, a chloride or phosphate salt and a quaternary material. A wellbore servicing composition comprising magnesium oxide, magnesium chloride, and a quaternary material wherein the quaternary material comprises a quaternary amide, a quaternary amide ester or combinations thereof and wherein the quaternary material is present in an amount of from about 0.05 wt. % to about 5 wt. % and a plot of the composition's plastic viscosity as a function of the amount of quaternary material is about linear.

Owner:HALLIBURTON ENERGY SERVICES INC

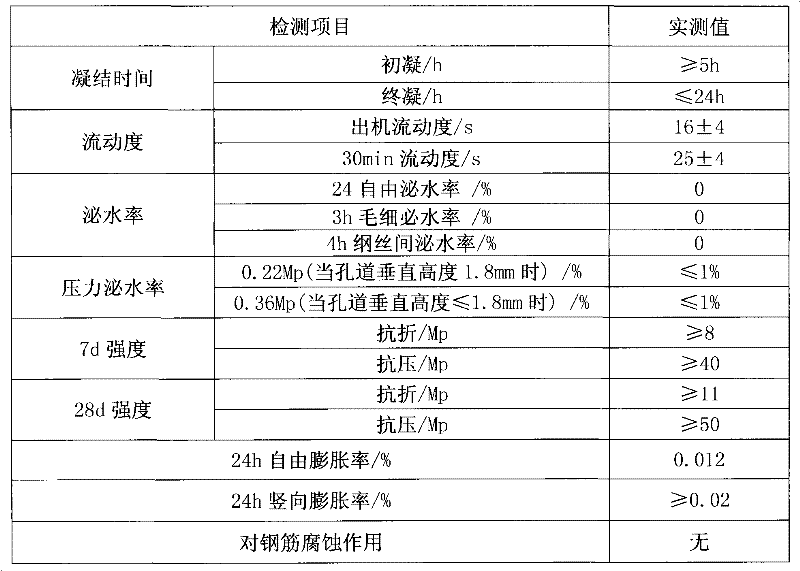

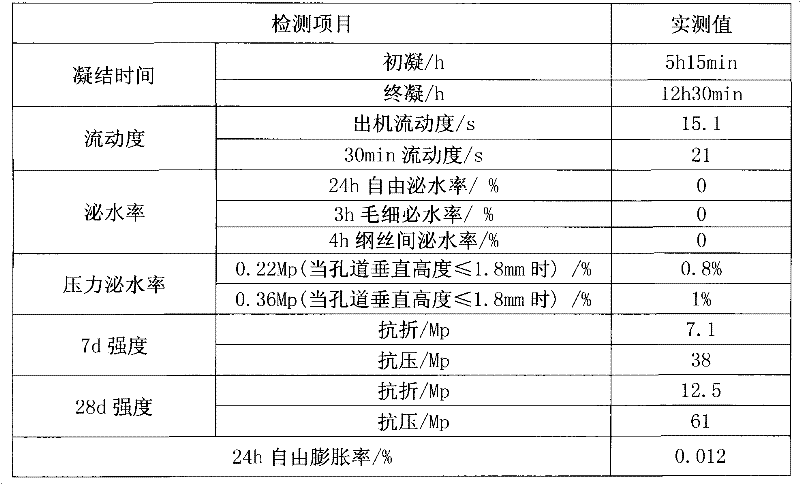

Grouting material, premix of grouting material, and preparation method of premix

The invention relates to a premix of a grouting material. The premix is characterized in that the premix comprises the following components, by weight, 65-90% of ordinary portland cement with the strength level of 42.5MPa or low alkaline cement with the strength level of greater than 42.5MPa, wherein the water demand for normal consistency is less than 25%, and the tricalcium aluminate content is lower than 8%; 2-29.696% of an ultrafine mineral admixture with a specific surface area of greater than 450m<2> / kg, a water demand ratio of less than 95%, and a 28d activity index of greater than 90%; 5-15% of calcium sulphoaluminate; 0.1-1.5% of a melamine water reducer; 0.002-0.2% of a cellulose polymer, an acrylic polymer or polyoxyethylene; 0.1-1.0% of a carbohydrate, a hydroxycarboxylic acid compound and salts thereof, a sulfate, a carbonate, or calcium formate; 0.002-0.1% of vinyl acetate-ethylene copolymerized rubber powder; and 0.1-1.0% of a chromate or a borate.

Owner:王小清

Stone pavement anti-efflorescence method

The invention provides a stone pavement anti-efflorescence method. The stone pavement anti-efflorescence method comprises the following steps: (1) cleaning stones, and naturally air-drying or drying the stones; (2) adding water in a bonding material which is composed of low-alkali cement, bentonite, rosin resin, redispersible powder, cellulose ether, water repellent and water reducing agent, and adding the mixture in a grinding machine for high-speed stirring so as to obtain stone glue; (3) paving after mixing the stones and the stone glue uniformly and at a low speed in a mixer, and firmly sealing stone gaps by using the stone glue; (4) after the pavement, painting a waterproof agent on the whole surfaces of the stones. The raw materials of the stone pavement anti-efflorescence method are rational in formula, good in compatibility, relatively low in cost and nontoxic; the pavement technology is simple and easy to operate; the path leading to efflorescence of the stones can be well cut off, and products such as Ca(OH)2 and salts and water invasion are reduced, so that the stones have no efflorescence phenomenon for a long time. Procedures and expense for later maintenance are reduced.

Owner:GUANGXI FULIN LANDSCAPE CONSTR CO LTD

Compositions comprising sorel cements and oil based fluids

A wellbore servicing composition comprising a metal oxide, a soluble salt, a surfactant and an oleaginous fluid. A wellbore servicing composition comprising magnesium oxide, a chloride or phosphate salt, an organophilic surfactant and an oleaginous fluid. A wellbore servicing composition comprising magnesium oxide, magnesium chloride, an organophilic surfactant, water and an oleaginous fluid wherein the organophilic surfactant is present in an amount of from about 0.25% to about 5% base on the combined weight of the magnesium oxide and magnesium chloride, and the oleaginous fluid is present ratio of from about 95:5 cement:oleaginous fluid to about 50:50 cement:oleaginous fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

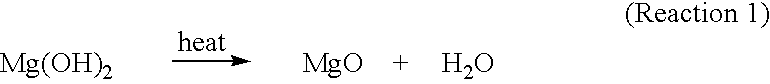

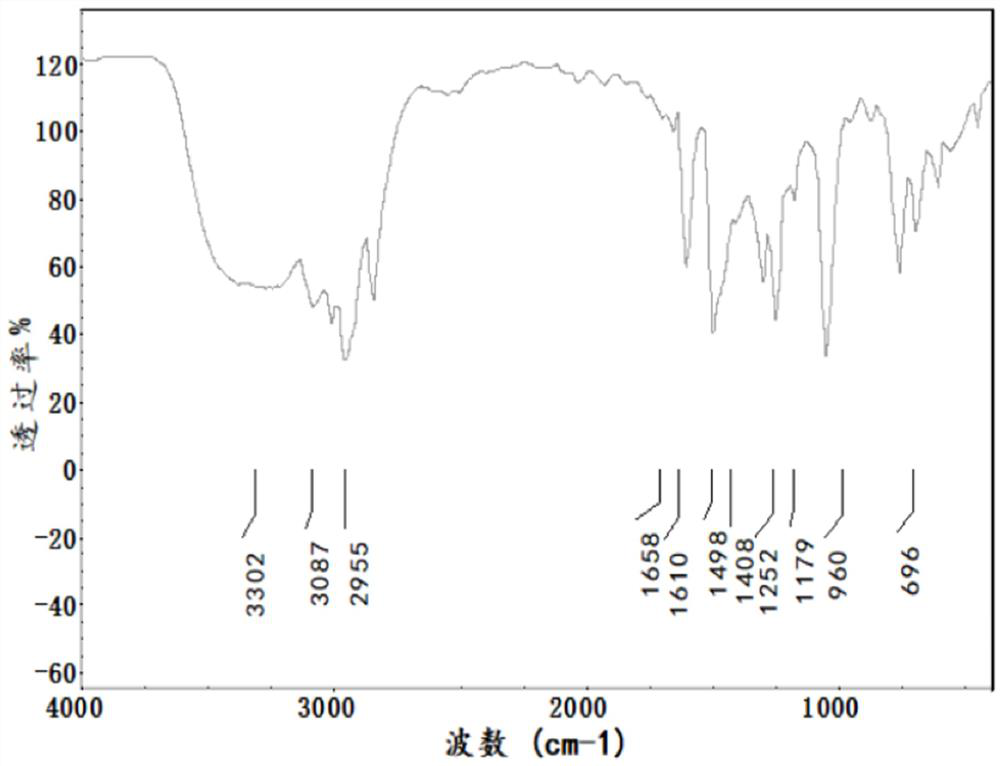

Magnesium chloride in alcoholic solvent for sorel cement

InactiveUS20140076561A1Overcome problemsHigh compressive strengthDrilling compositionSealing/packingChemical compoundChloride

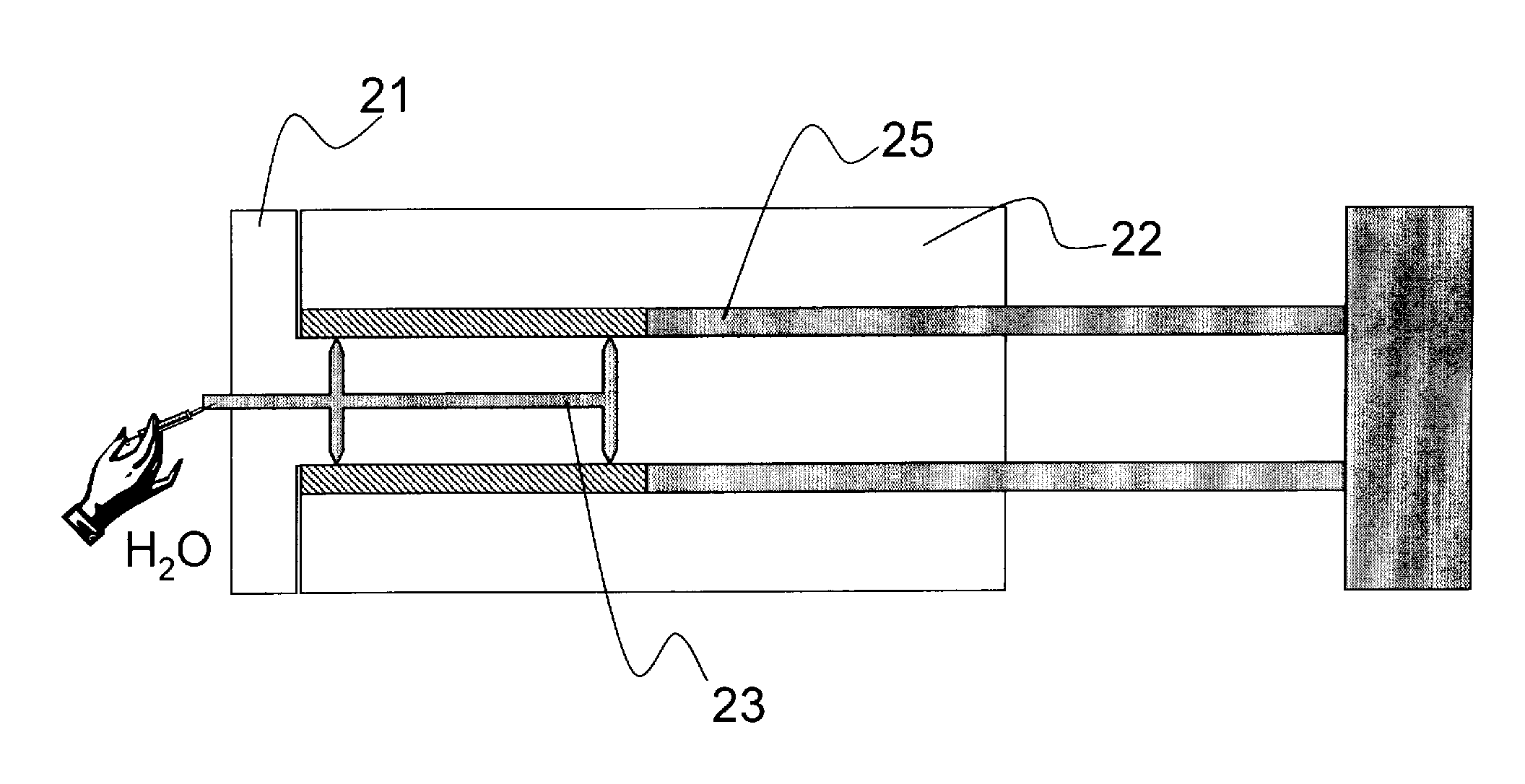

A non-hydraulic cement composition including: (i) a non-aqueous liquid phase comprising one or more organic compounds characterized by: (a) having at least one hydroxyl group on a carbon atom, (b) being a liquid when pure under Standard Laboratory Conditions, and (c) being at least soluble in water; (ii) one or more magnesium chloride compounds selected from the group consisting of: magnesium chloride, a magnesium chloride hydrate, and any combination thereof; and (iii) magnesium oxide; wherein the one or more organic compounds comprise at least 40% by weight of the non-aqueous liquid phase excluding the weight of any dissolved solids. A method of treating a well including the steps of: (A) forming the non-hydraulic cement composition; and (B) introducing the non-hydraulic cement composition into the well.

Owner:HALLIBURTON ENERGY SERVICES INC

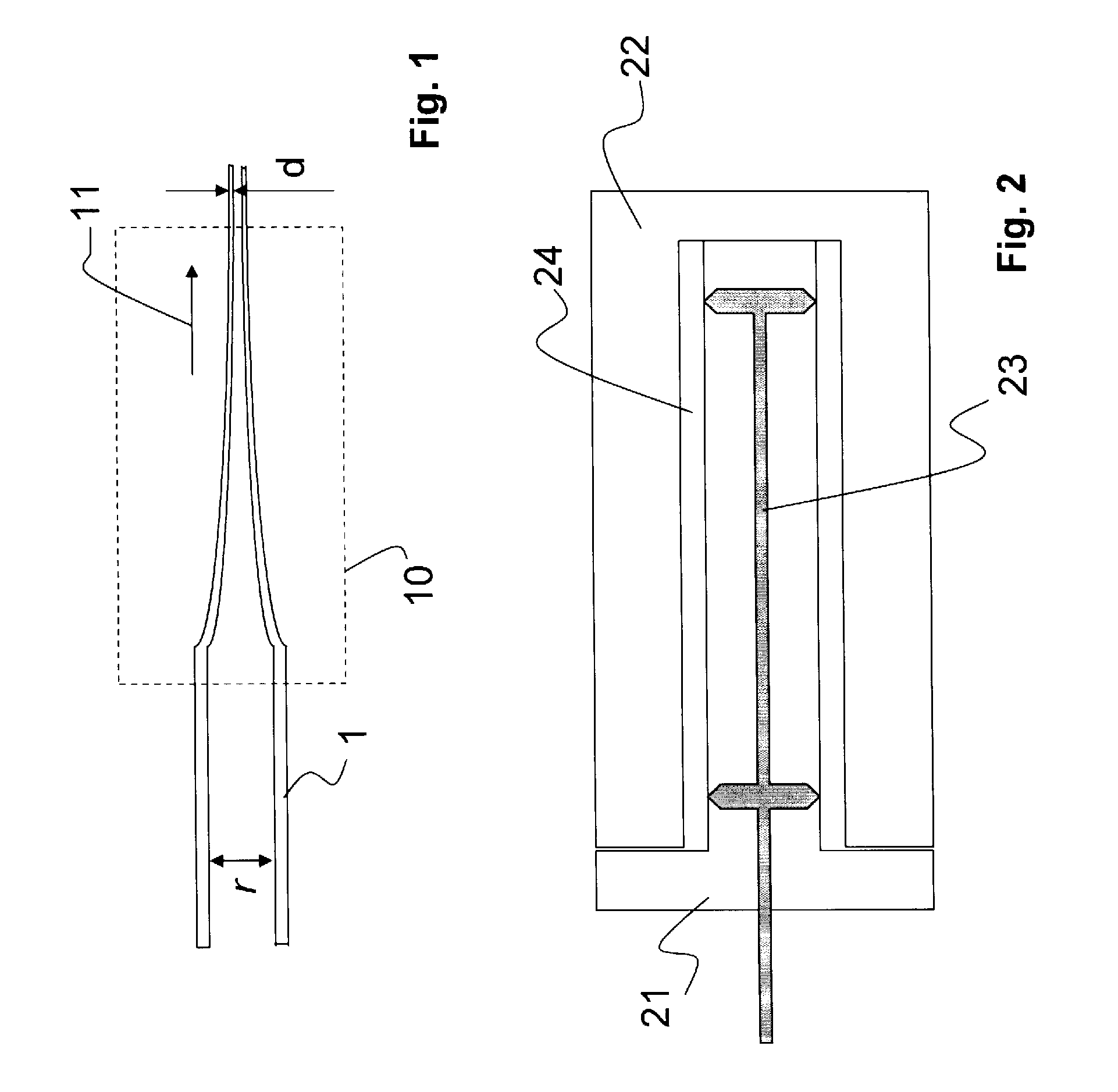

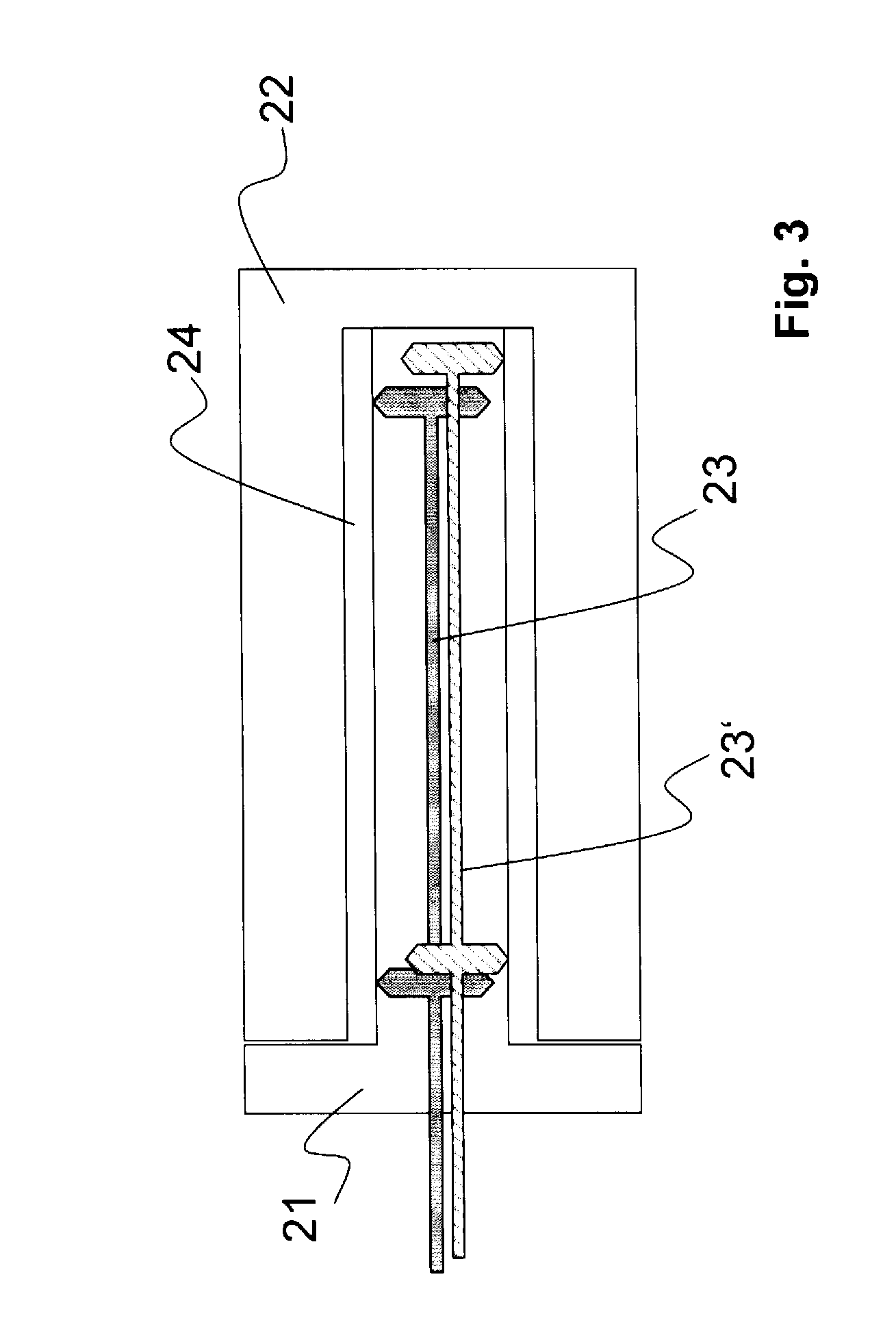

Endoprosthesis and Method for Manufacturing Same

InactiveUS20100262229A1Simple and inexpensive methodPrevent restenosisStentsSurgeryPolyphosphateProsthesis

The invention relates to intraluminal endoprosthesis, preferably a stent consisting essentially of a base body and optionally a coating covering the surface of the base body at least partially. The invention is characterized in that the base body and / or the coating has at least one compound from the group of polyphosphates, magnesium oxyhalides, preferably Sorel cement. Furthermore, a method is described for manufacturing such an intraluminal endoprosthesis.

Owner:BIOTRONIK MESS UND THERAPIEGERAETE GMBH & CO

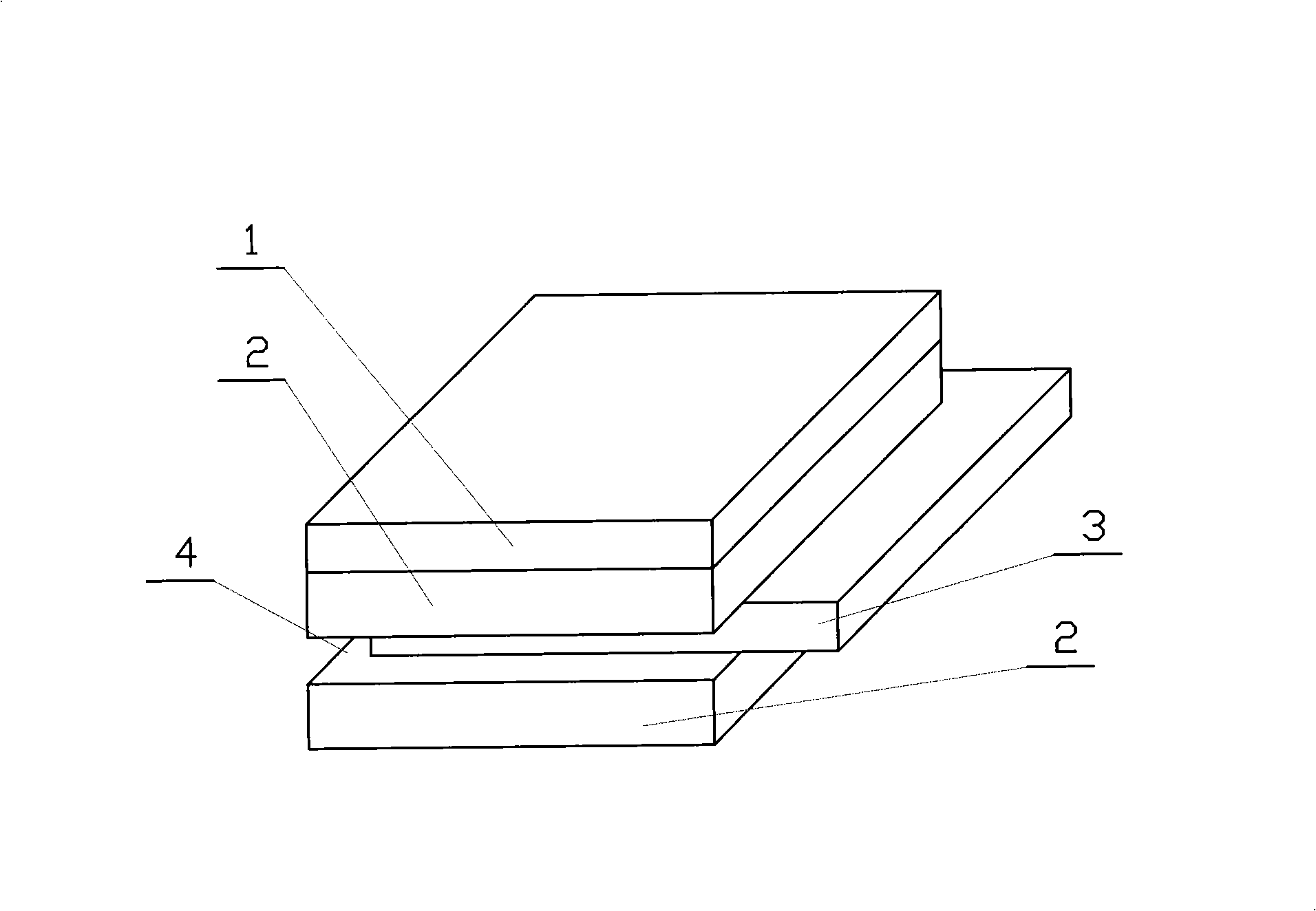

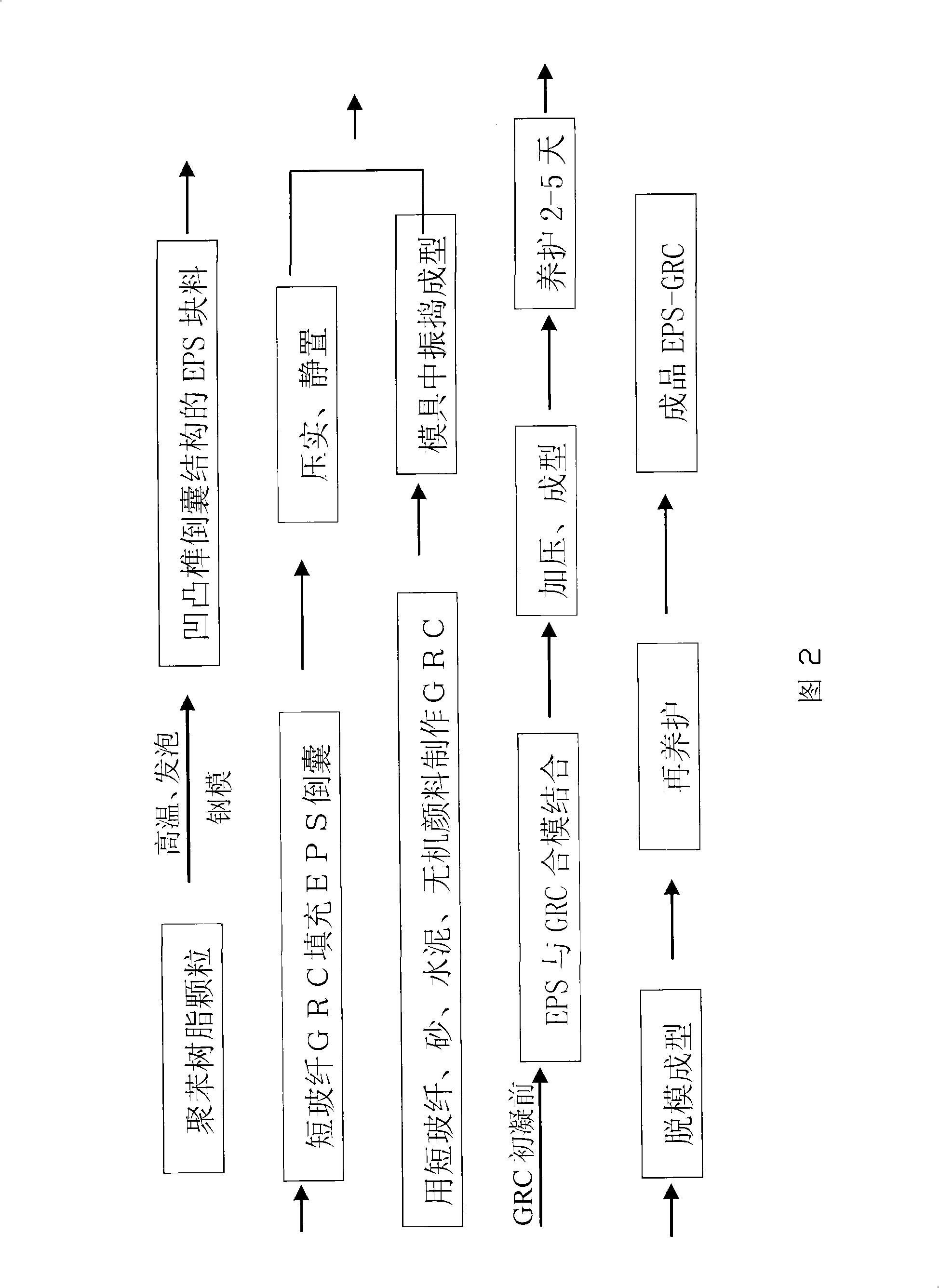

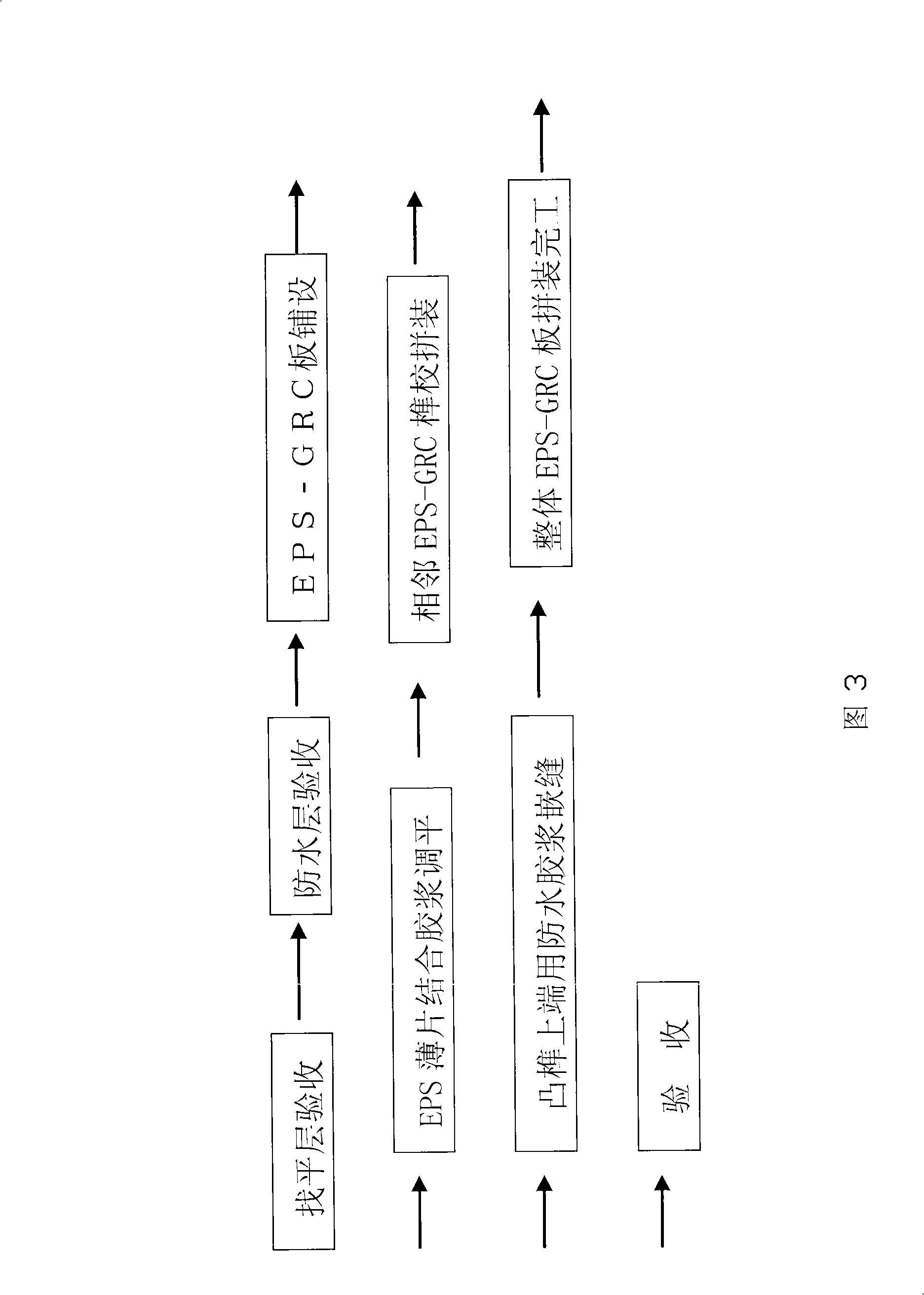

Thermal insulation insulating panel of polyphenyl glass fibre cement and making method thereof

InactiveCN101338587ABig playImprove ergonomicsCovering/liningsCeramic shaping apparatusManufacturing technologyThermal bridge

The invention relates to a polystyrene glass fiber cement thermal baffle and a manufacturing technology thereof. A polystyrene plate EPS is connected with the lower end surface of a glass fiber reinforced cement plate GRC, and a tenon and a tusk are arranged on the middle end surface of the polystyrene plate EPS. The manufacturing technology comprises the steps that forming is performed by adopting polystyrene resin grain is molded through high temperature foaming in a steel die; an inverted capsule structure is manufactured on the contact surface between the polystyrene plate EPS and the glass fiber reinforced cement plate GRC, and a pre mixed short glass fiber reinforced cement plate GRC is filled in the capsule, to form composite layers which are firmly meshed; alkali-resistant glass fiber and low-alkali cement, sand, water, inorganic pigment and brightening agent are matched and evenly stirred, then are put into a die to be compounded with the polystyrene plate EPS, and then is demolded and maintained. The polystyrene glass fiber cement thermal baffle has the advantages of thermal insulation and high tensile facing, and has the function for breaking cold / thermal bridges. The polystyrene glass fiber cement thermal baffle can be applied to the moisture protection, the thermal insulation, the sound insulation and the decoration of the roof coverings, walls and floors of various buildings.

Owner:陈卫

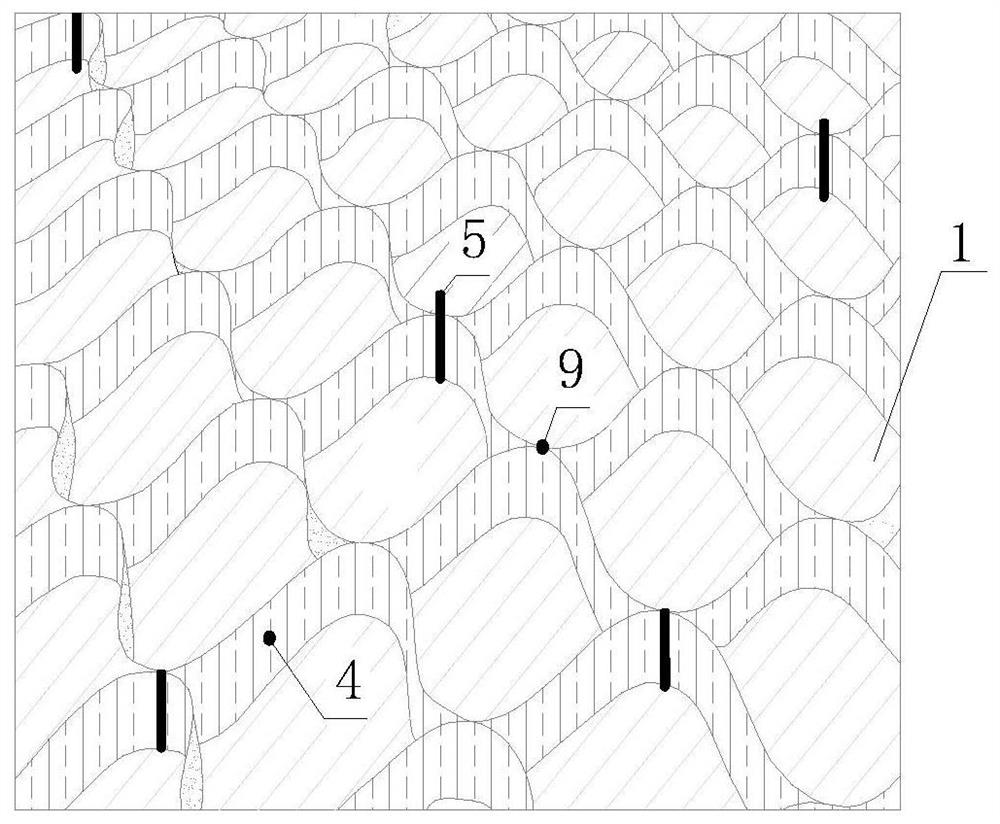

Modified ecological fiber reinforced recycled aggregate lightweight wall material and preparation method

InactiveCN106278125AEvenly distributedImprove sound insulationSolid waste managementFiberFoam concrete

The invention discloses a modified ecological fiber reinforced recycled aggregate lightweight wall material and a preparation method. The modified ecological fiber reinforced recycled aggregate lightweight wall material comprises the following components in parts by mass: 15-36 parts of Sorel cement, 5-15 parts of ground granulated blast furnace slag, 10-25 parts of ceramsite, 12-40 parts of recycled lightweight aggregate, 8-20 parts of pottery sand, 0.1-0.6 part of modified ecological fibers, 0.1-2 parts of foaming agents, 0.2-1.0 part of thickening agent and 10-30 parts of water. The preparation method comprises the steps of putting the Sorel cement, the ground granulated blast furnace slag, the modified ecological fibers and the thickening agent, which are required for preparation, together and stirring the materials for 8-15 minutes, then adding water and the foaming agents, which are required for preparation, to the mixture in sequence and further stirring the materials for 10-15 minutes, thus obtaining a slurry mixture. The lightweight wall material and the preparation method have the beneficial effects that the ecological fibers have good tensile deformation resistance and are lighter, so the foam concrete has toughness; China has abundant ecological plant resources, thus saving plenty of resources and being beneficial to the human living environment.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Magnesium chloride in alcoholic solvent for sorel cement

A non-hydraulic cement composition including: (i) a non-aqueous liquid phase comprising one or more organic compounds characterized by: (a) having at least one hydroxyl group on a carbon atom, (b) being a liquid when pure under Standard Laboratory Conditions, and (c) being at least soluble in water; (ii) one or more magnesium chloride compounds selected from the group consisting of: magnesium chloride, a magnesium chloride hydrate, and any combination thereof; and (iii) magnesium oxide; wherein the one or more organic compounds comprise at least 40% by weight of the non-aqueous liquid phase excluding the weight of any dissolved solids. A method of treating a well including the steps of: (A) forming the non-hydraulic cement composition; and (B) introducing the non-hydraulic cement composition into the well.

Owner:HALLIBURTON ENERGY SERVICES INC

Pressure gasified, water-repellent, drying free agent for bonding coal in gasified industry type

This invention discloses a binding material for producing industrial waterproof briquette capable of being pressurization-gasified without drying process. The binding material is powdery, and is formed by: pulverizing Sorel cement 50%, bentonite 15%, steel slag 20%, and graphite tailing 10%, and trisodium phosphate 5%, and mixing. The briquette produced from the binding material has such advantages as high cold strength, good waterproof property, convenient transportation, low cost, simple process, convenient maintenance, high thermal stability, high gasification rate, and good sulfur-fixation effect. The binding material can solve the problems of low waterproof capacity, low gasification rate, low combustion efficiency, low thermal strength and no air permeability faced by conventional briquette.

Owner:陈福才

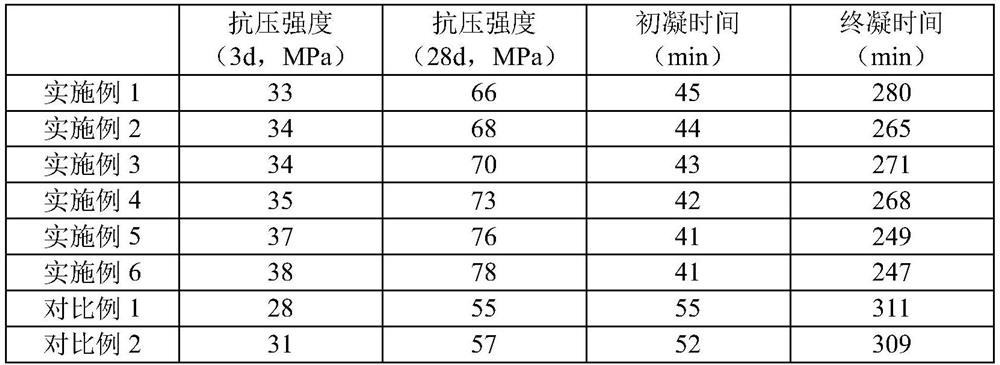

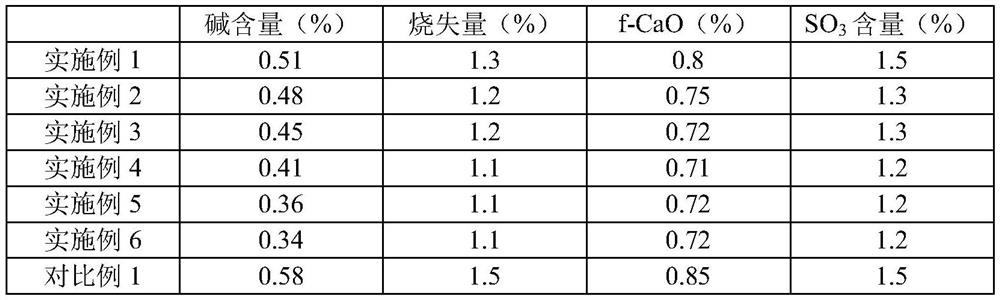

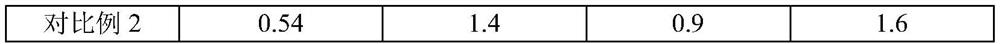

Low-alkali cement clinker, low-alkali high-strength cement, and preparation method thereof

ActiveCN111732352AReduce crackingLarge crystal sizeCement productionBridge engineeringPhysical chemistry

The invention discloses low-alkali cement clinker, low-alkali high-strength cement and a preparation method thereof, and belongs to the technical field of cement manufacturing. The low-alkali cement clinker is mainly prepared from the following raw materials in parts by weight: 810-840 parts of limestone, 50-70 parts of low-alkali sandstone, 25-35 parts of sulfate slag, 80-100 parts of wet fly ashand 12-16 parts of fluorine-containing iron ore; wherein the mass fraction of CaO in the limestone is not less than 50%. The low-alkali high-strength cement comprises the low-alkali cement clinker and an admixture in a weight ratio of (55-75) : (25-45). The low-alkali cement clinker is low in alkalinity, high in later strength and suitable for bridge engineering construction, the probability thatcement prepared from the cement clinker cracks in the using process is reduced, and the service life of engineering is prolonged.

Owner:南阳中联卧龙水泥有限公司

Compositions comprising Sorel cements and oil based fluids

A wellbore servicing composition comprising a metal oxide, a soluble salt, a surfactant and an oleaginous fluid. A wellbore servicing composition comprising magnesium oxide, a chloride or phosphate salt, an organophilic surfactant and an oleaginous fluid. A wellbore servicing composition comprising magnesium oxide, magnesium chloride, an organophilic surfactant, water and an oleaginous fluid wherein the organophilic surfactant is present in an amount of from about 0.25% to about 5% base on the combined weight of the magnesium oxide and magnesium chloride, and the oleaginous fluid is present ratio of from about 95:5 cement:oleaginous fluid to about 50:50 cement:oleaginous fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

Method for producing low-alkali cement from iron ore mining waste soil

InactiveCN111170662AAlleviate a large number of ecological and environmental problems caused by stockpilingAlleviate ecological and environmental problemsCement productionMineral SourcesMining engineering

The invention discloses a method for producing low-alkali cement from iron ore mining waste soil, belonging to the technical field of cement preparation. Aiming at the problem of high cost of raw materials for producing low-alkali cement in the prior art, the invention provides the following scheme: the low-alkali cement is prepared from, in parts by weight, 85-89 parts of limestone, 3-10 parts ofsandstone, 0-8 parts of iron ore mining waste soil and 1-3 parts of an iron correction material through batching, ball milling and calcining. The iron ore mining waste soil is used as a raw materialfor producing the low-alkali cement, and the qualified low-alkali cement is prepared, so a large amount of the iron ore mining waste soil is recycled, the waste is turned into wealth, the utilizationrate of mineral resources is increased, considerable ecological environment problems caused by stockpiling of the iron ore mining waste soil are effectively relieved, and great promotion effects are achieved on energy saving and environmental protection strengthening; and the method is low in cost, low in energy consumption and beneficial for increasing the yield of the low-alkali cement.

Owner:大冶尖峰水泥有限公司

Application of detoxic chromium dregs as cement admixture

ActiveCN1792958AShorten the setting timeHigh rate of increase in strength valueCement productionPolymer scienceSlag

An application of detoxicated Cr slags in preparing early-strenthening low-alkali cement and its products is disclosed. Said cement is prepared through proportionally mixing said detoxicated Cr slags with clinker and natural bihydrated gypsum. Its advantages are high quality of cement and no secondary pollution.

Owner:SICHUAN YINHE CHEM

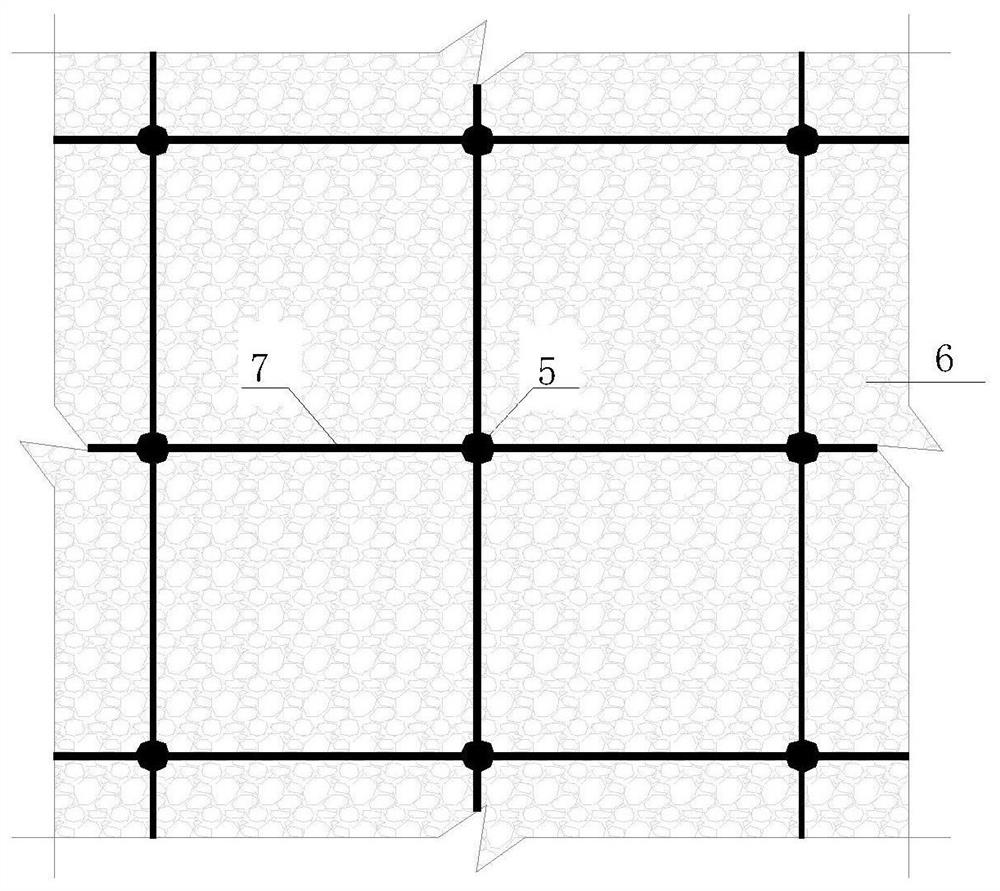

Production method of heat insulating composite building block

InactiveCN1785630AImprove energy savingImprove integrityCeramic shaping apparatusMaterials scienceSorel cement

An insulating composite building block with high insulating effect is composed of a hollow building block and a core. Its preparing process includes such steps as proportionally mixing flyash with Sorel cement, stirring while adding additive, filling the mixture into hollow building block, natural foaming, and natural curing.

Owner:孙永成

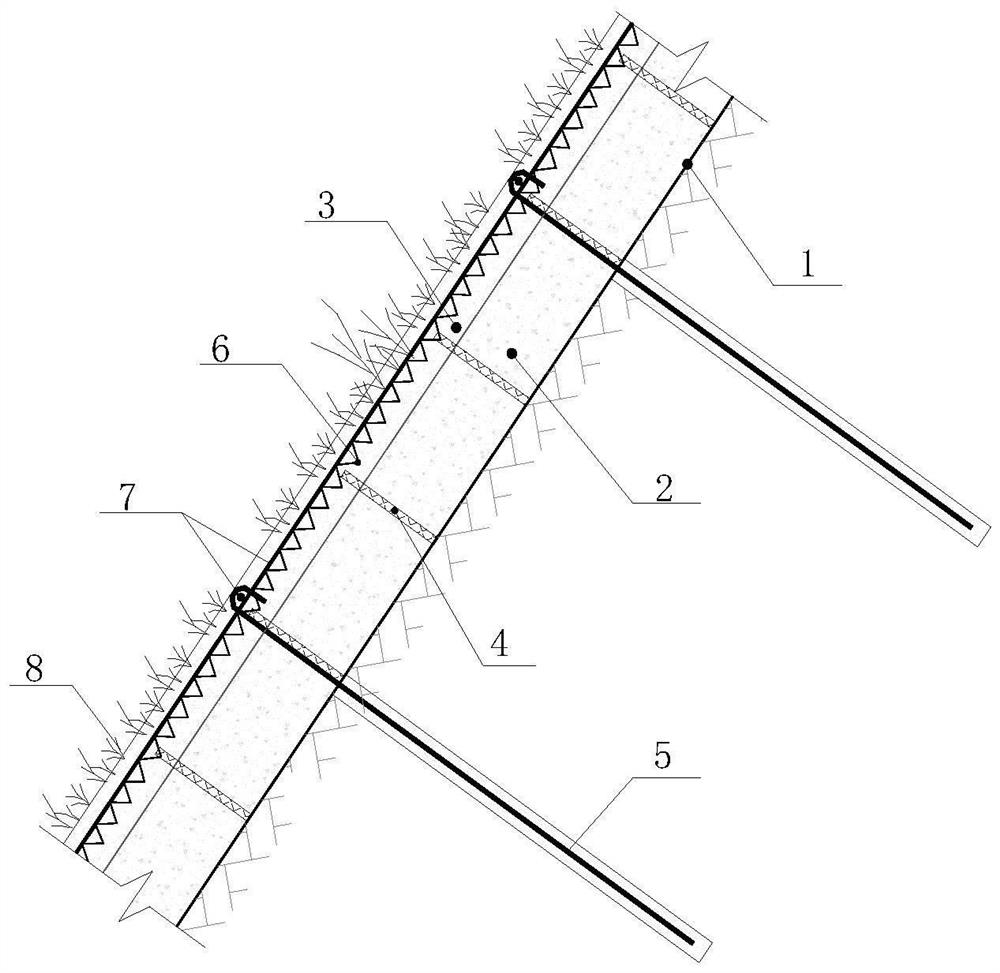

Open-pit copper mine rock slope ecological greening system and construction method

PendingCN113575202AReduce pollutionImprove the ecological environmentGrowth substratesCulture mediaEnvironmental resource managementBiology

The invention discloses an open-pit copper mine rock slope ecological greening system. The greening system comprises an open-pit copper mine rock slope, a geocell and a vegetation base material, the geocell is fixed on the open-pit copper mine rock slope through a steel bar anchor rod, the vegetation base material is filled in the geocell, the vegetation base material comprises copper tailings, plant fibers, low-alkali cement, an aggregate agent, a water-retaining agent, a pH regulator and an organic fertilizer, the vegetation base material comprises a vegetation base material bottom layer and a vegetation base material surface layer, and the vegetation base material bottom layer is arranged close to the open-air copper mine rock slope. According to the greening system, a large amount of tailing solid waste existing in a copper mine is used as a main raw material to prepare the slope greening planting base material, so that the purpose of treating waste with waste is achieved, the greening cost is reduced, pollution caused by tailing solid waste stockpiling is reduced, and the ecological environment of a mining area and the surrounding of the mining area is improved. The open-pit copper mine rock slope ecological greening system does not need large mechanical equipment during construction, and is simple and convenient in construction method, good in long-term stability, short in construction period and low in manufacturing cost.

Owner:KUNMING PROSPECTING DESIGN INST OF CHINA NONFERROUS METALS IND

Compositions comprising quaternary material and sorel cements

Owner:HALLIBURTON ENERGY SERVICES INC

Preparation method of saltpetering-resistant cement colored decorative mortar

ActiveCN112341125AImprove mechanical propertiesGood construction performanceSolid waste managementSpray coatingMelamine

The invention relates to the field of preparation of building materials, in particular to a preparation method of saltpetering-resistant cement colored decorative mortar. According to the invention, the modified lithium slag and the modified melamine water reducing agent are added into the cement-based colored decorative mortar, so that the saltpetering phenomenon of the material can be effectively prevented, and the decorative mortar with no saltpetering and good mechanical properties and constructability is prepared; the cement color decorative mortar is high in adhesive strength with a baselayer, various in color and shape and capable of meeting the aesthetic requirements of different groups; the mortar is convenient to apply and allows smearing, rooling and even spray coating operation, so that the construction time is saved, and particularly, compared with ceramic tiles, the advantages are larger at internal and external corners and other difficult-to-construct parts; in addition, the mortar has great durability, and the phenomena of hollowing and peeling are avoided; the manufacturing cost and the production energy consumption are very low, and the economic and environment-friendly values are higher.

Owner:GUIZHOU ZHENGHE AERATED CONCRETE CO LTD

Coal slime curing and upgrading agent

InactiveCN112646630AImprove cold compressive strengthHigh strengthSolid fuelsFuel additivesAcrylonitrileCross linker

The invention relates to the technical field of coal washing and coal slime treatment, in particular to a coal slime curing and upgrading agent which comprises a hardening agent, a curing agent, a polymer cross-linking agent, a water absorbent and a sulfur-fixing agent, and the hardening agent is one or a mixture of more of anhydrous magnesium chloride, magnesium oxychloride cement and Sorel cement for coal slime. The curing agent is a mixture of one or more of halogen powder (MgO) or heavy magnesium oxide halogen powder for the coal slime, and the polymer cross-linking agent is a mixture of one or more of polyacrylate, starch acrylate polymer and starch- acrylonitrile graft copolymer for the coal slime. In the invention, the strength of the coal slime is naturally improved without drying, and the coal slime is naturally dehydrated; and compared with drying of common coal slime, the field space is greatly saved, and the storage pressure is greatly relieved. In addition, the sulfur-fixing agent is added into the curing upgrading agent, so that the problem of high emission caused by high sulfur content in the coal slime is greatly improved.

Owner:刘明锐

Compositions comprising quaternary material and sorel cements and methods of servicing a wellbore with the same

A wellbore servicing composition is described comprising a metal oxide, a soluble salt and a viscosifier wherein the viscosifier comprises a quaternary amide, a quaternary amide ester, or combinationsthereof. A method of servicing a wellbore in contact with a subterranean formation is also described, the method comprising viscosifying a cement composition comprising a metal oxide and a soluble salt, placing the viscosified cement composition in the wellbore, and allowing the composition to set.

Owner:HALLIBURTON ENERGY SERVICES INC

Saltpetering-preventing cement mortar and maintenance method

InactiveCN111153651AGuaranteed design strengthGuaranteed economyIn situ pavingsRoads maintainenceCellulosePortland cement

The invention provides a saltpetering-preventing cement mortar and a maintenance method. The cement mortar comprises the following components: ordinary Portland cement, sand, ultrafine silicon powder,attapulgite powder, bentonite and cellulose ether. The surface of a paving material is immediately covered with a plastic film after the hard paving construction is finished. The saltpetering-preventing cement mortar has the advantages that the cement design strength and the economy can be ensured, the saltpetering is inhibited in the later period of cement mortar; and the film covering method after construction can accelerate the development of the internal structure of the cement mortar and accelerate the improvement of the closing amount of internal ducts of the cement mortar, so that thesaltpetering phenomenon is fundamentally reduced.

Owner:HANGZHOU LANDSCAPING

Waste curing agent containing modified blast furnace slag

The invention discloses a waste curing agent containing modified blast furnace slag. The waste curing agent is prepared by mixing the following components in parts by weight: 1.4-2.2 parts of caustic soda, 1-1.5 parts of cement, 3.2-5.4 parts of gypsum, 1-2 parts of triethanolamine, 1.3-2.2 parts of alkyl glycoside, 0.6-0.8 part of alum, 0.6-1.2 parts of calcium lignosulphonate, 0.4-1.2 parts of modified nano blast furnace slag, 1-2 parts of sodium chloride, 1-2 parts of magnesium chloride, 1.5-2.3 parts of polyacrylamide, 0.9-1.8 parts of aluminum sulfate, 0.3-0.7 part of dicalcium silicate and 0.6-0.8 part of tricalcium aluminate. In addition to hardening effect of a common curing agent, the waste curing agent containing the modified blast furnace slag further reasonably utilizes the waste and changes the waste into things of value; the hardening effect is strengthened by the nano modified blast furnace slag.

Owner:HEFEI BAOLI ENVIRONMENTAL PROTECTION TECH

Alkali-resistant cement paste plugging method

PendingCN113700452ATo achieve the purpose of solidificationReduce retarding effectDrilling compositionSealing/packingPhysical chemistryCement paste

The invention discloses an alkali-resistant cement paste plugging method. The method comprises the following steps of 1, analyzing chemical components of gushing water in a well, according to the components, utilizing alkali halide gushing out from the well, preparing a formula of indoor plugging alkali-resistant cement paste, testing, calculating the amount of the required plugging alkali-resistant cement paste, storing a certain amount of underground alkali halide on site to prepare the alkali-resistant cement paste, observing the static pressure of the gushing water, measuring the specific gravity of cement paste in the well, calculating the pressure of a water burst formation, and calculating the specific gravity of counterweight cement paste according to the well depth and the well diameter. The invention not only provides a method for controlling gushing by water emitting, but also thoroughly solves the problem of limited resource exploitation, changes the limitation of a trona exploitation fracturing water-soluble mining process, ensures the purity of the cement paste, enhances the cementing strength of the cement paste, enhances the rigidity of the cement paste after coagulation, ensures the well completion rate, and the environmental protection pressure is also reduced.

Owner:HENAN ZHONGYUAN CHEM

Pressure gasified, water-repellent, drying free gasified coal bonding agent for industry

This invention discloses a binding material for producing industrial waterproof briquette capable of being pressurization-gasified without drying process. The binding material is powdery, and is formed by: pulverizing Sorel cement 50%, bentonite 15%, steel slag 20%, and graphite tailing 10%, and trisodium phosphate 5%, and mixing. The briquette produced from the binding material has such advantages as high cold strength, good waterproof property, convenient transportation, low cost, simple process, convenient maintenance, high thermal stability, high gasification rate, and good sulfur-fixation effect. The binding material can solve the problems of low waterproof capacity, low gasification rate, low combustion efficiency, low thermal strength and no air permeability faced by conventional briquette.

Owner:陈福才

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com