Method for evaluating effectiveness of measure for inhibiting alkali-silica active reaction of concrete aggregate

A concrete aggregate and active reaction technology, which is applied in the field of evaluating the effectiveness of concrete aggregate alkali-silicic acid active reaction inhibition measures, can solve problems such as imperfect inhibition efficiency, difficult time to meet, active aggregate activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

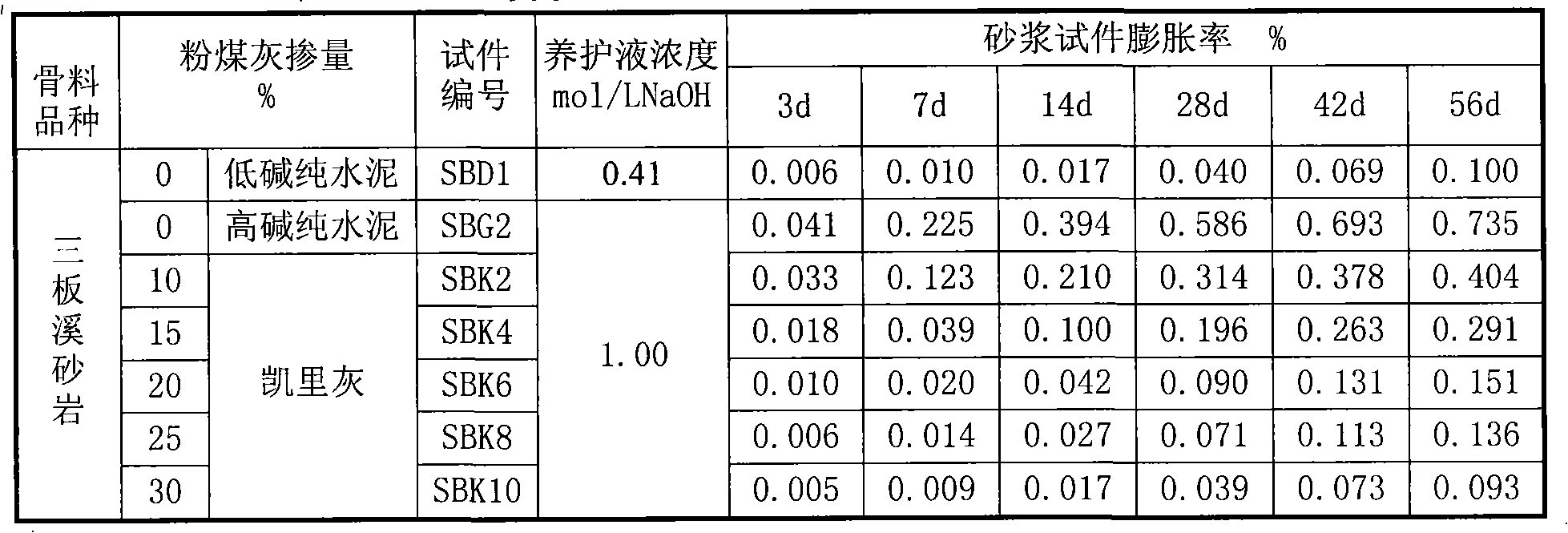

Embodiment 1

[0020] Example 1: Refer to the current DL / T5151-2001 "Hydraulic concrete sand and gravel aggregate test procedures" in the mortar bar rapid method (400g cementitious material, five grades of sand, 1:2.25 lime sand Ratio, 0.47 water-cement ratio), using the Sanbanxi Hydropower Station sandstone artificial sand and low-alkali cement (effective alkali Na2O content ≤ 0.60%) to form a mortar rod rapid method test piece, the test piece is placed in 80 ℃ water soaked for 24 hours to determine the base length Then, the specimen was immersed in a NaOH solution with a temperature of 80°C and the same alkali concentration as the mortar specimen hole solution (NaOH concentration ≤0.41mol / L) for curing, and the expansion rate of the specimen was measured according to different ages.

[0021] At the same time, refer to the current DL / T5151-2001 "Hydraulic concrete sand and gravel aggregate test procedures" in the mortar bar rapid method (400g cementitious material, five grades of sand, 1:2.25 l...

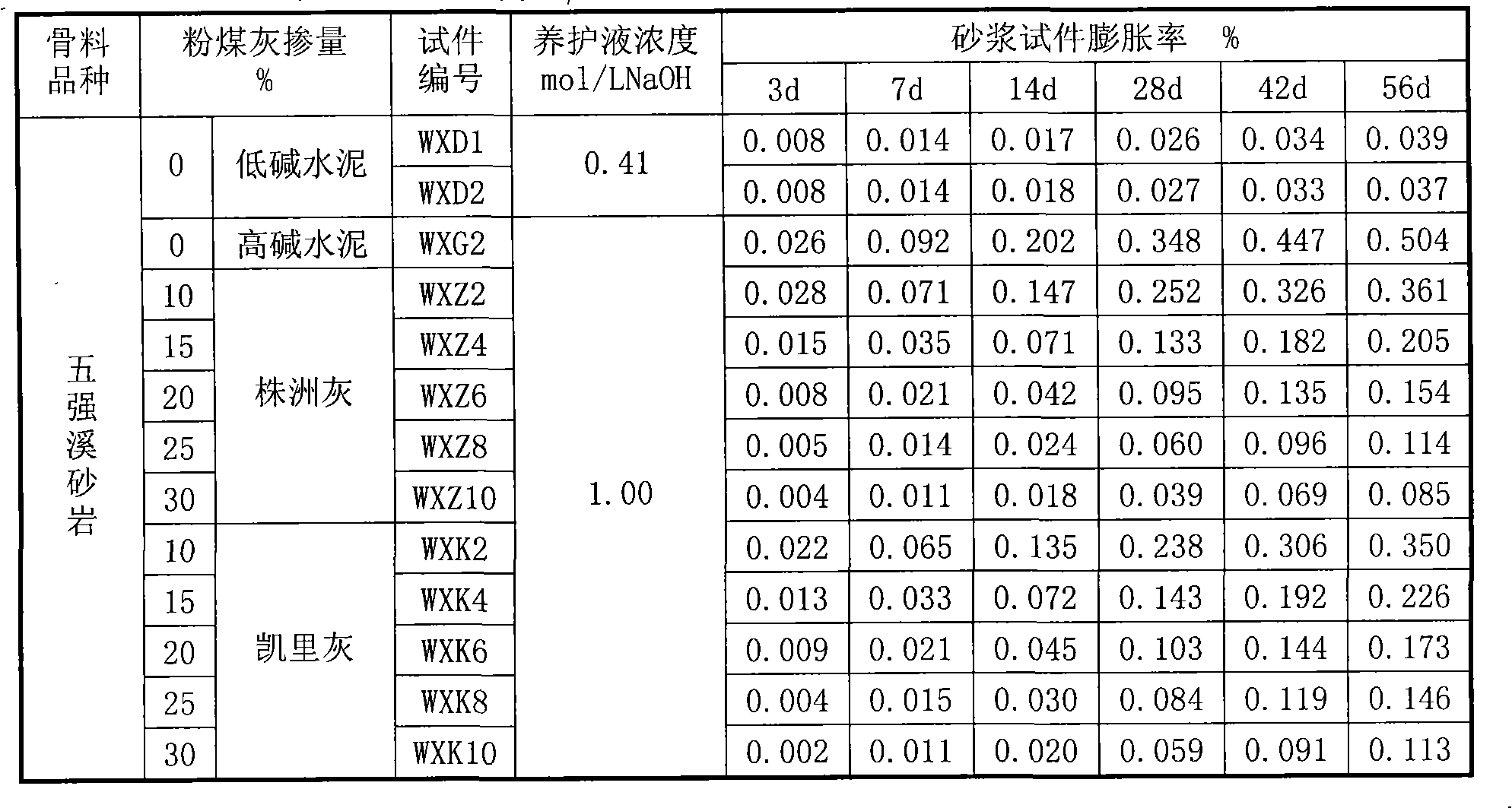

Embodiment 2

[0028] Example 2: Refer to the current DL / T5151-2001 "Hydraulic concrete sand and gravel aggregate test procedures" in the mortar bar rapid method (400g cementitious material, five grades of sand, 1:2.25 lime sand Ratio, 0.47 water-cement ratio), using the Wuqiangxi Hydropower Station sandstone artificial sand and low-alkali cement (effective alkali Na2O content ≤ 0.60%) forming mortar rod rapid method test specimens, the specimens are placed in 80 ℃ water soaked for 24 hours to determine the base Then, the specimen is immersed in a NaOH solution with a temperature of 80°C and the same alkali concentration as the mortar specimen hole solution (NaOH concentration ≤0.41mol / L) for curing, and the expansion rate of the specimen is measured according to different ages. .

[0029] At the same time, refer to the current DL / T5151-2001 "Hydraulic concrete sand and gravel aggregate test procedures" in the mortar bar rapid method (400g cementitious material, five grades of sand, 1:2.25 lime-s...

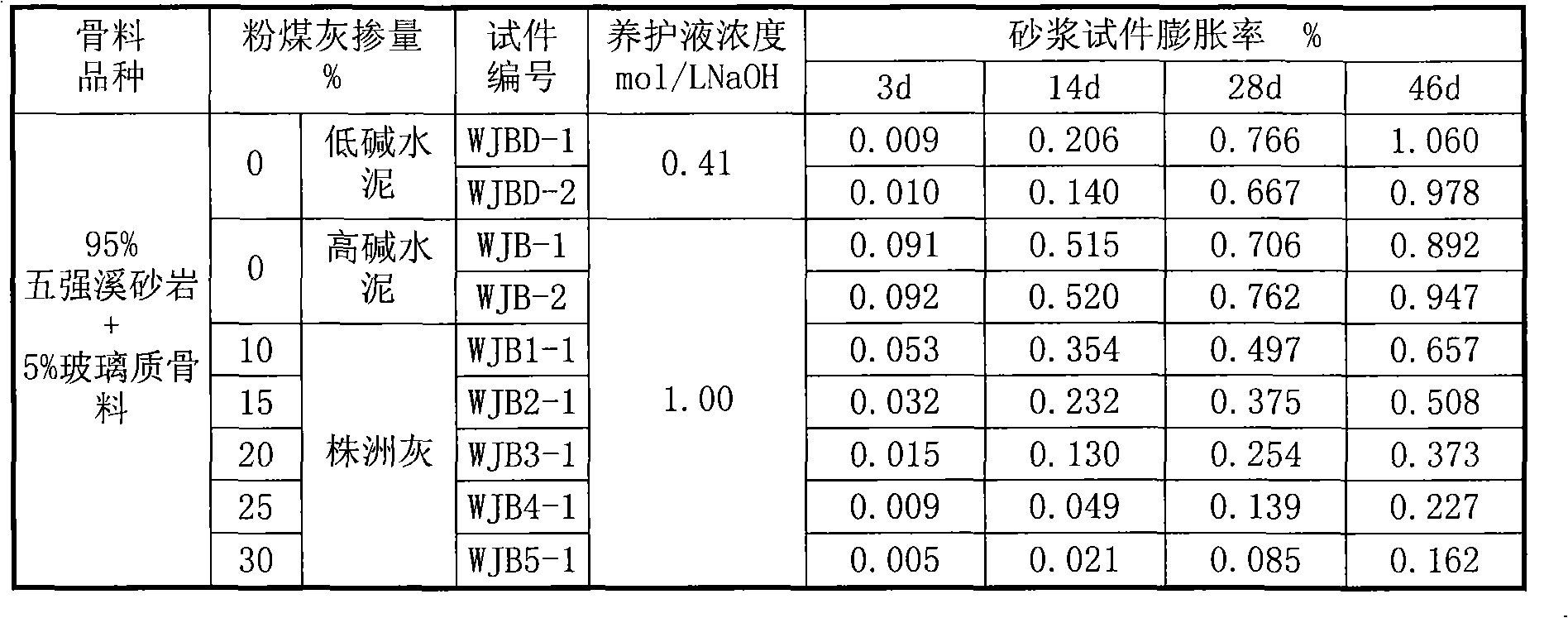

Embodiment 3

[0036] Example 3: Use Wuqiangxi sandstone mixed with 5% high-activity glassy aggregate to configure artificial active aggregate. Refer to the current DL / T5151-2001 "Test Procedure for Hydraulic Concrete Sand and Stone Aggregate" for the alkali activity of aggregate The tested mortar bar rapid method (400g cementitious material, five grades of sand, 1:2.25 ash-sand ratio, 0.47 water-cement ratio), used the artificial active aggregate and low-alkali cement (effective alkali Na2O content ≤ 0.60%) to shape The mortar rod rapid method test piece, the test piece is placed in 80 ℃ water for 24 hours to determine the base length, and then the test piece is immersed in the temperature of 80 ℃ and the alkali concentration of the mortar test piece hole solution (NaOH concentration ≤ 0.41mol / L ) Soak and cure in the same NaOH solution, and measure the expansion rate of the specimens according to different ages.

[0037] At the same time, refer to the current DL / T5151-2001 "Hydraulic concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com