Assembly gravity type retaining wall structure and construction method thereof

A retaining wall and gravity-type technology, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of large structure size, difficulty in guaranteeing construction quality, long cast-in-place and maintenance time, etc., and achieve structural Dimensions, meeting the requirements of anti-slip and anti-overturning stability, and the effect of meeting the needs of railway subgrade engineering construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

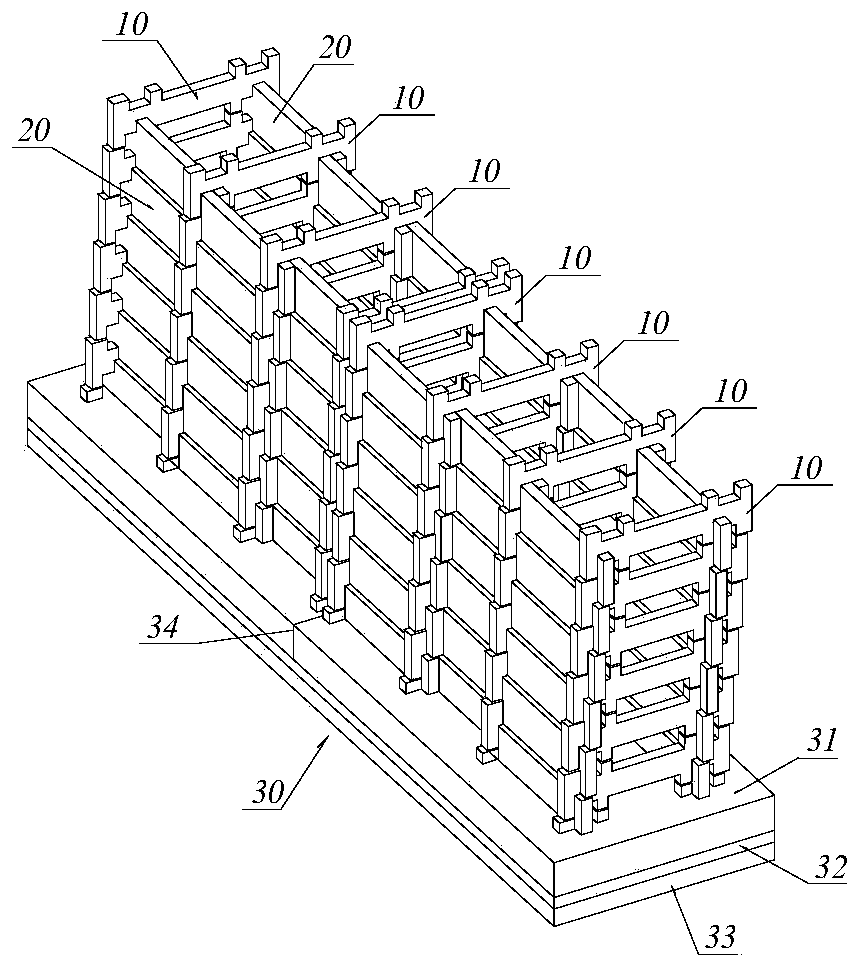

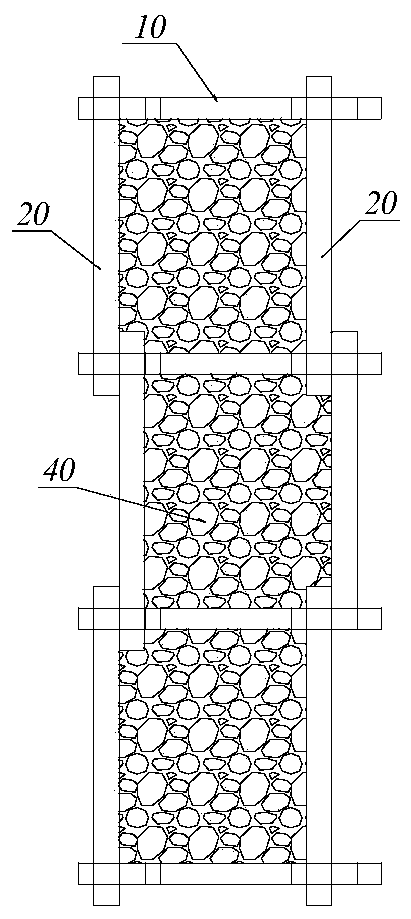

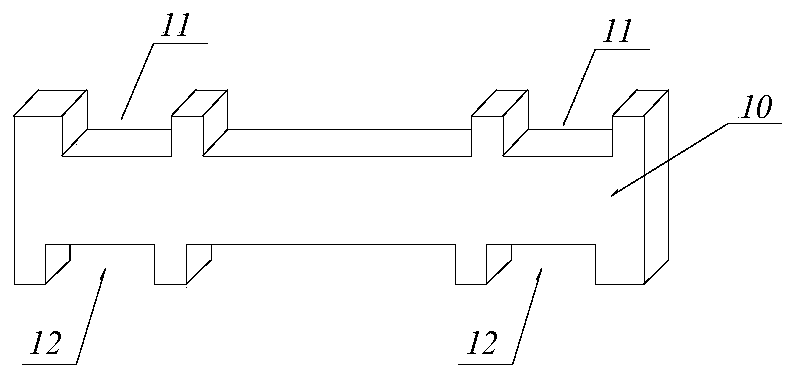

[0026] refer to figure 1 and Figure 7 , an assembled gravity retaining wall structure of the present invention includes a foundation 20 and a gravity retaining wall body located thereon. The gravity retaining wall is composed of a prefabricated wall and backfill material 40 filled in its inner cavity. The prefabricated wall is vertically assembled by multi-layer assembled units, and each layer of assembled units is included in the The skeleton boards 10 arranged at intervals in the line direction and the soil retaining plates 20 arranged at intervals in the vertical line direction are connected by slots to form a continuous box body. Two adjacent layers of assembled units are connected through the draw-in grooves on their skeleton plates 10 and soil retaining plates 20 , and the bottom of the lowermost assembled unit is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com