Patents

Literature

196results about How to "Good hardening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing preserved kiwi fruit by vacuum freeze drying

InactiveCN102742711AAdjust acidity properlyGood hardening effectConfectionerySweetmeatsLiquid glucoseActinidia

A method for preparing preserved kiwi fruit by vacuum freeze drying. The method comprises steps of: peeling and slicing kiwi fruit, immersing the kiwi fruit in color protecting liquid, and then placing the kiwi fruit in a hardening liquid for hardening; after hardening, conducting an ultrasonic pretreatment in liquid glucose; and then successively carrying out vacuum sugar permeability, prefreezing, vacuum freeze drying, and packing to obtain the preserved kiwi fruit. According to the present invention, glucose lactone is added into a calcium chloride hardening liquid to coagulate protein in the fruit pieces and significantly improve hardening effect. The ultrasonic pretreatment and vacuum sugar permeability avoid a heat treatment process of rapid heating for a long time or short time, so that the kiwi fruit slices are still bright green (quite similar with an original fruit color). Vacuum freeze drying on the kiwi fruit realizes a high nutrient conservation rate.

Owner:NORTHWEST UNIV(CN)

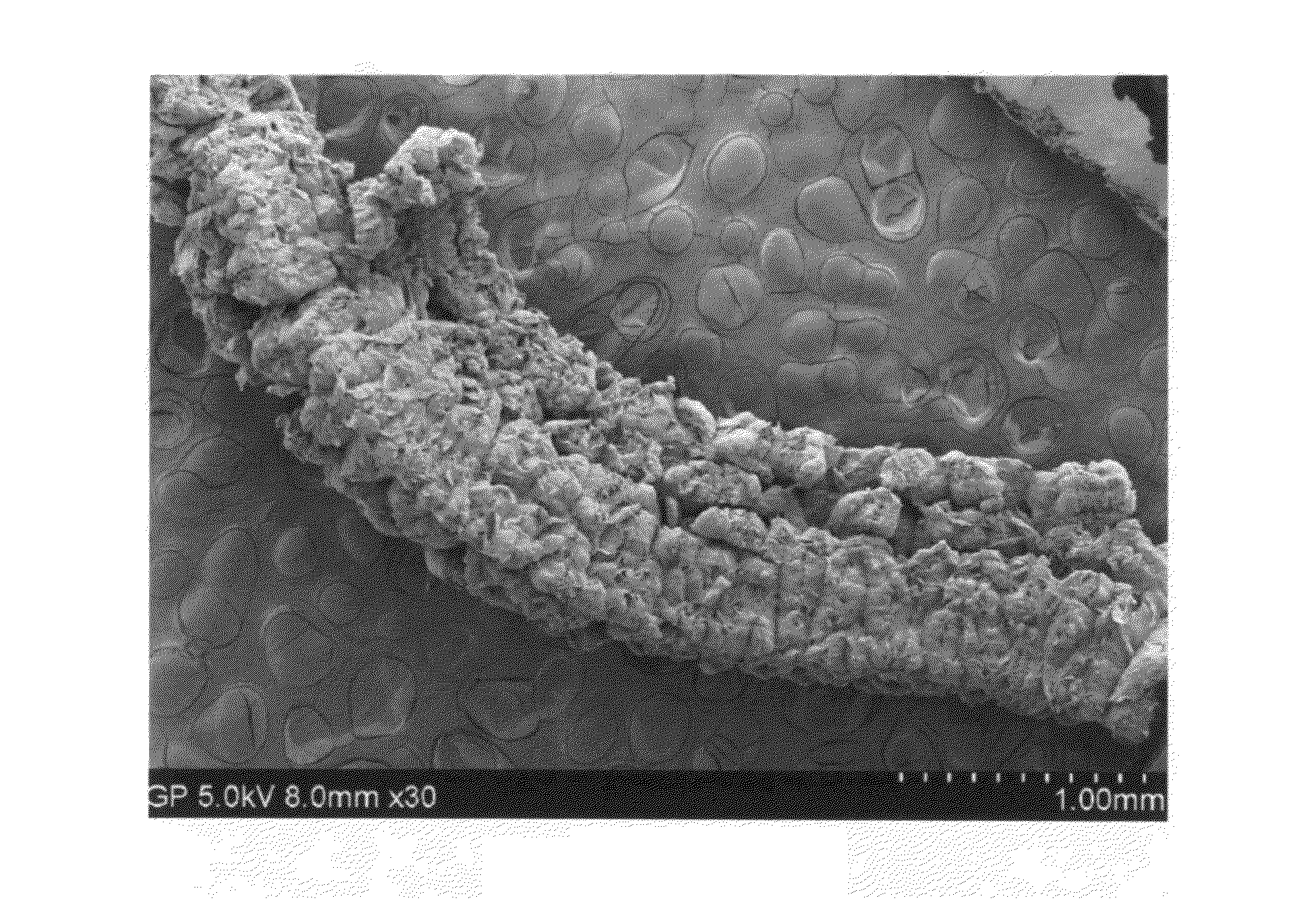

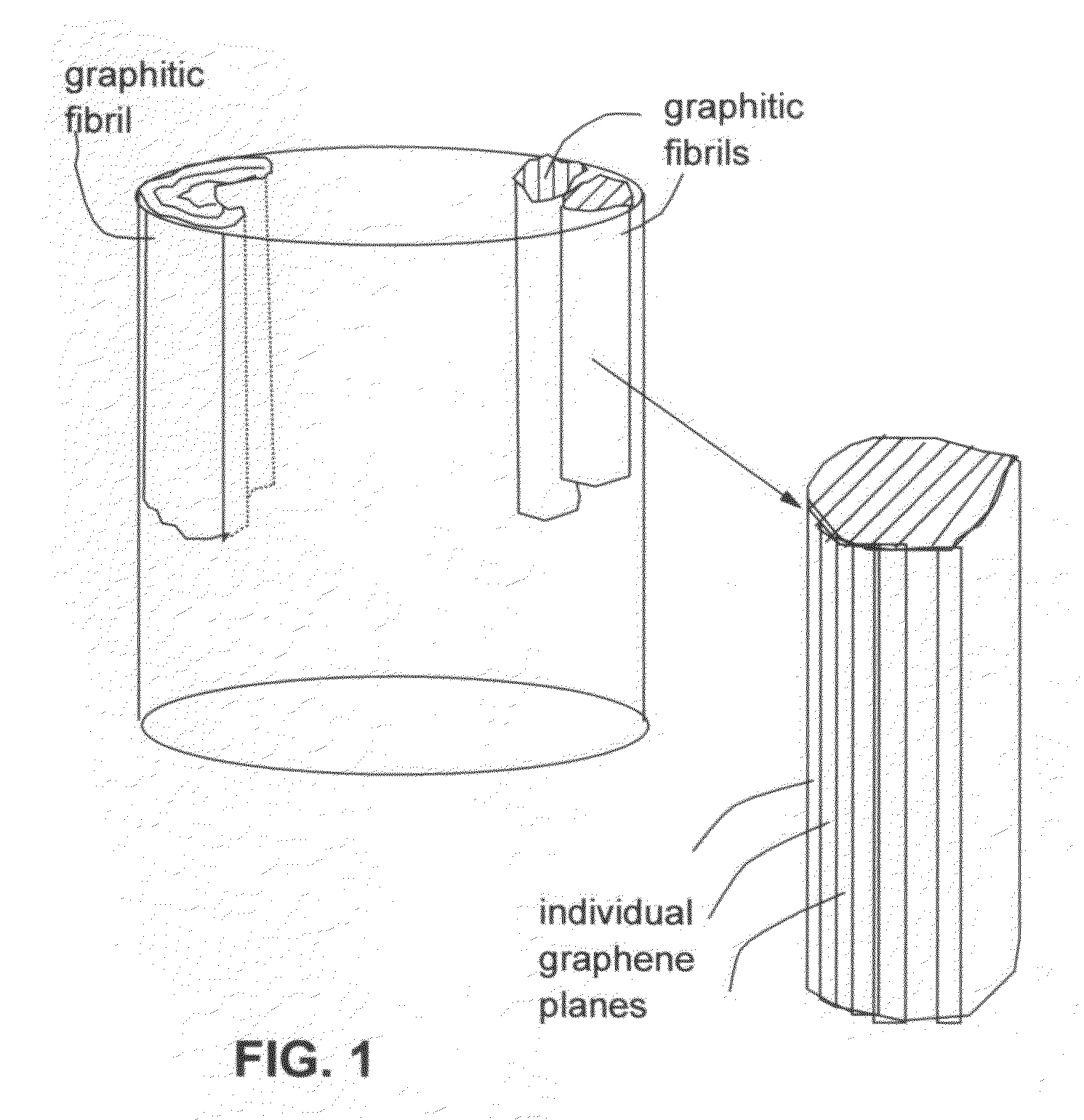

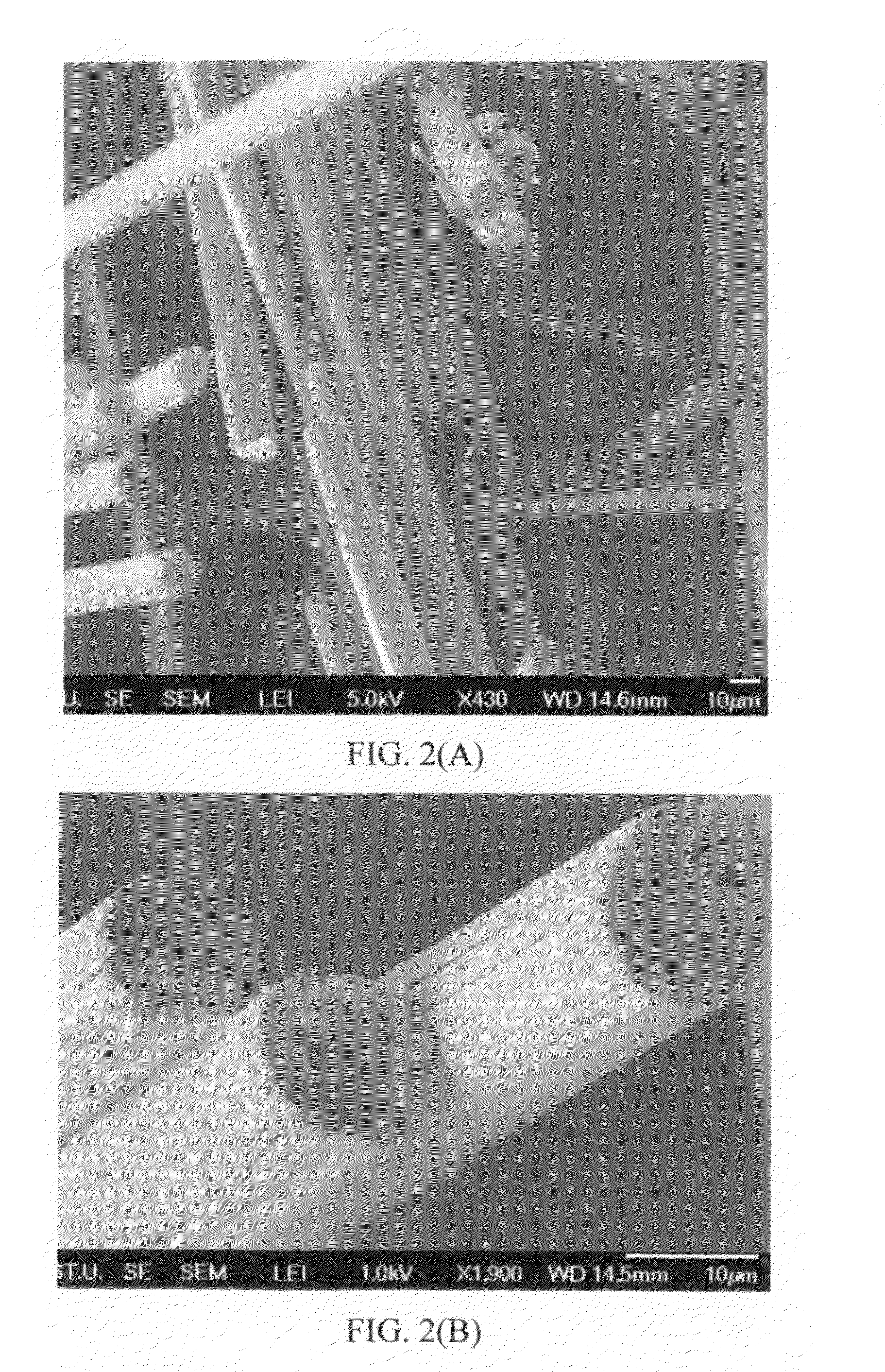

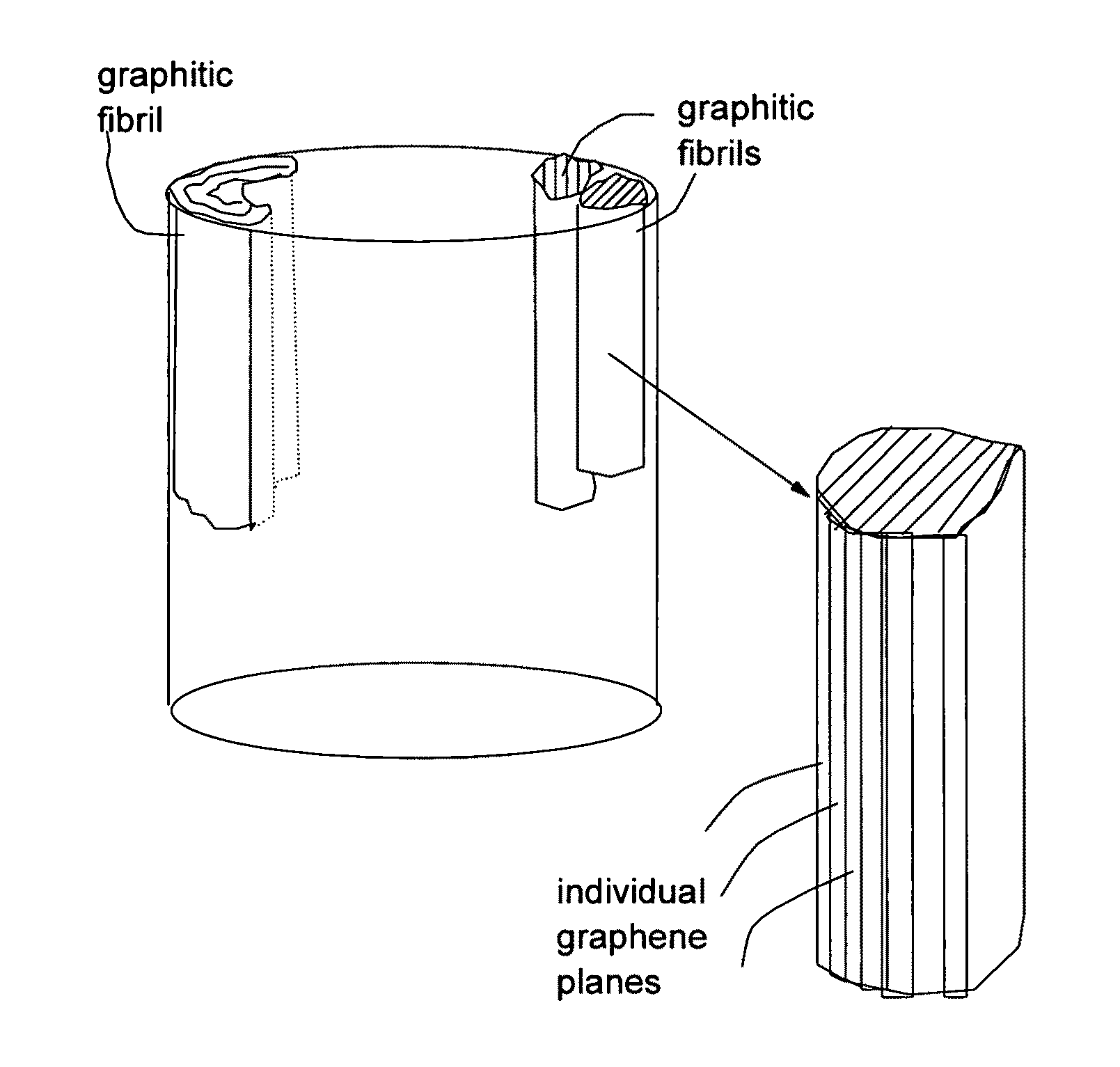

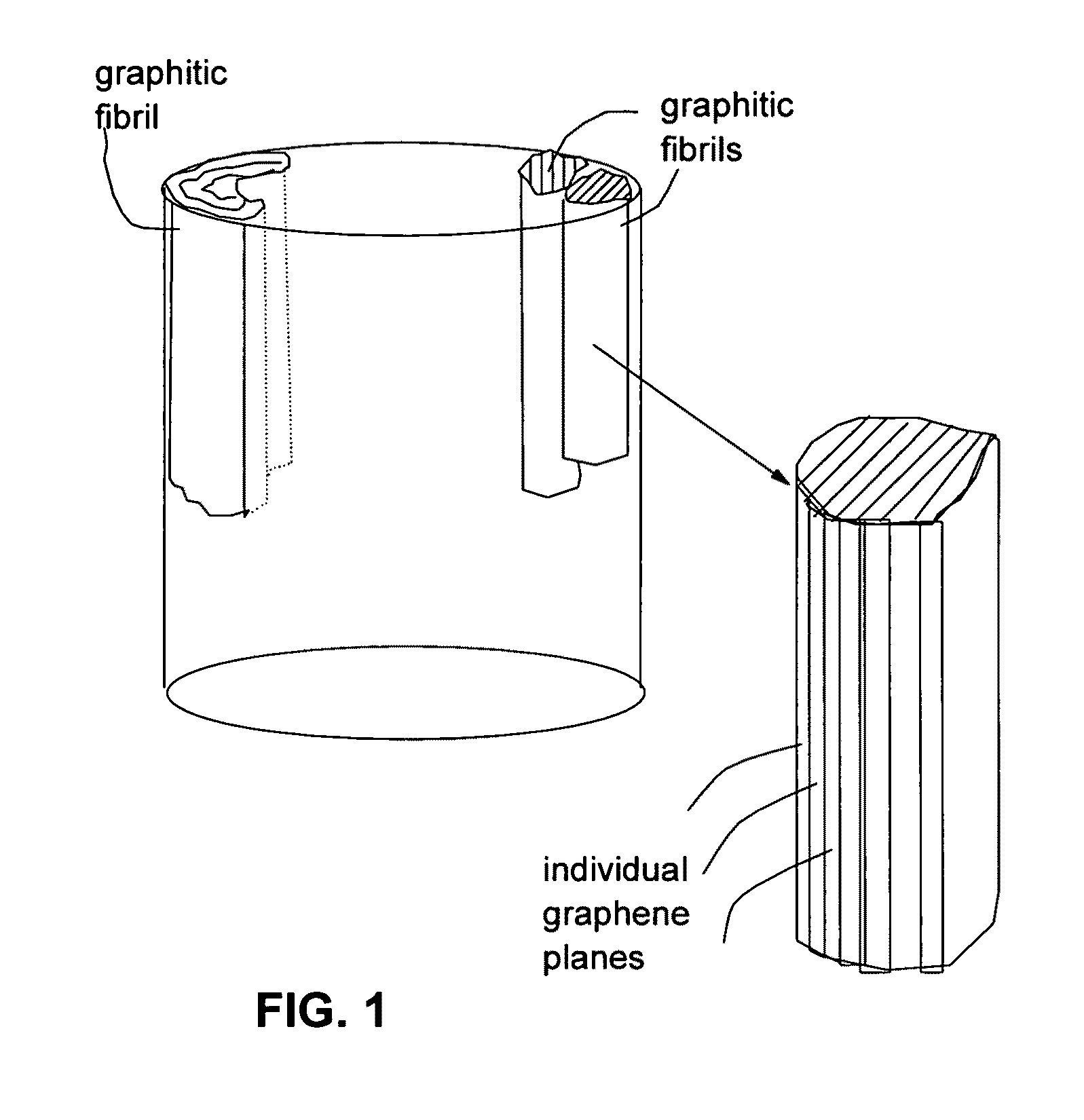

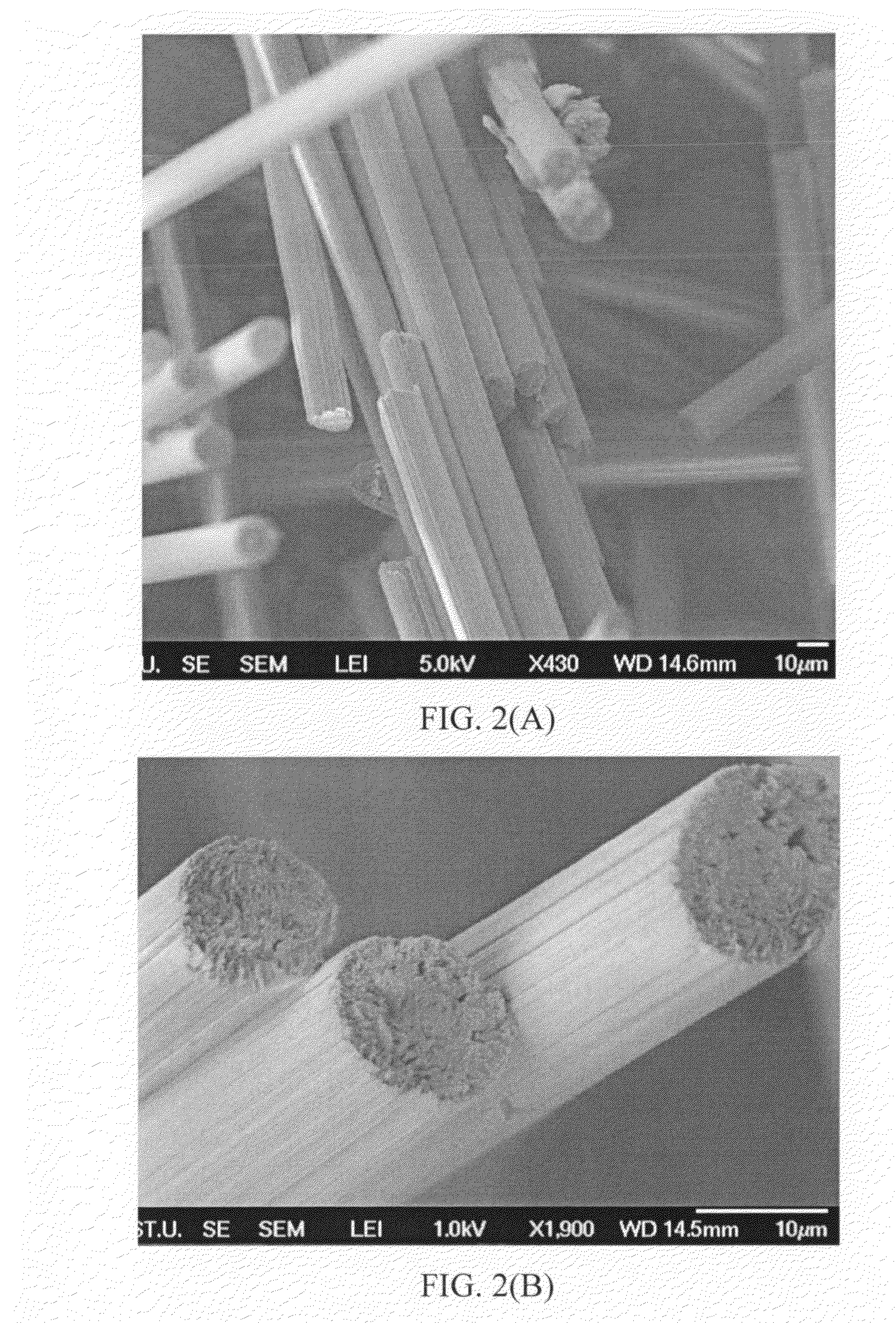

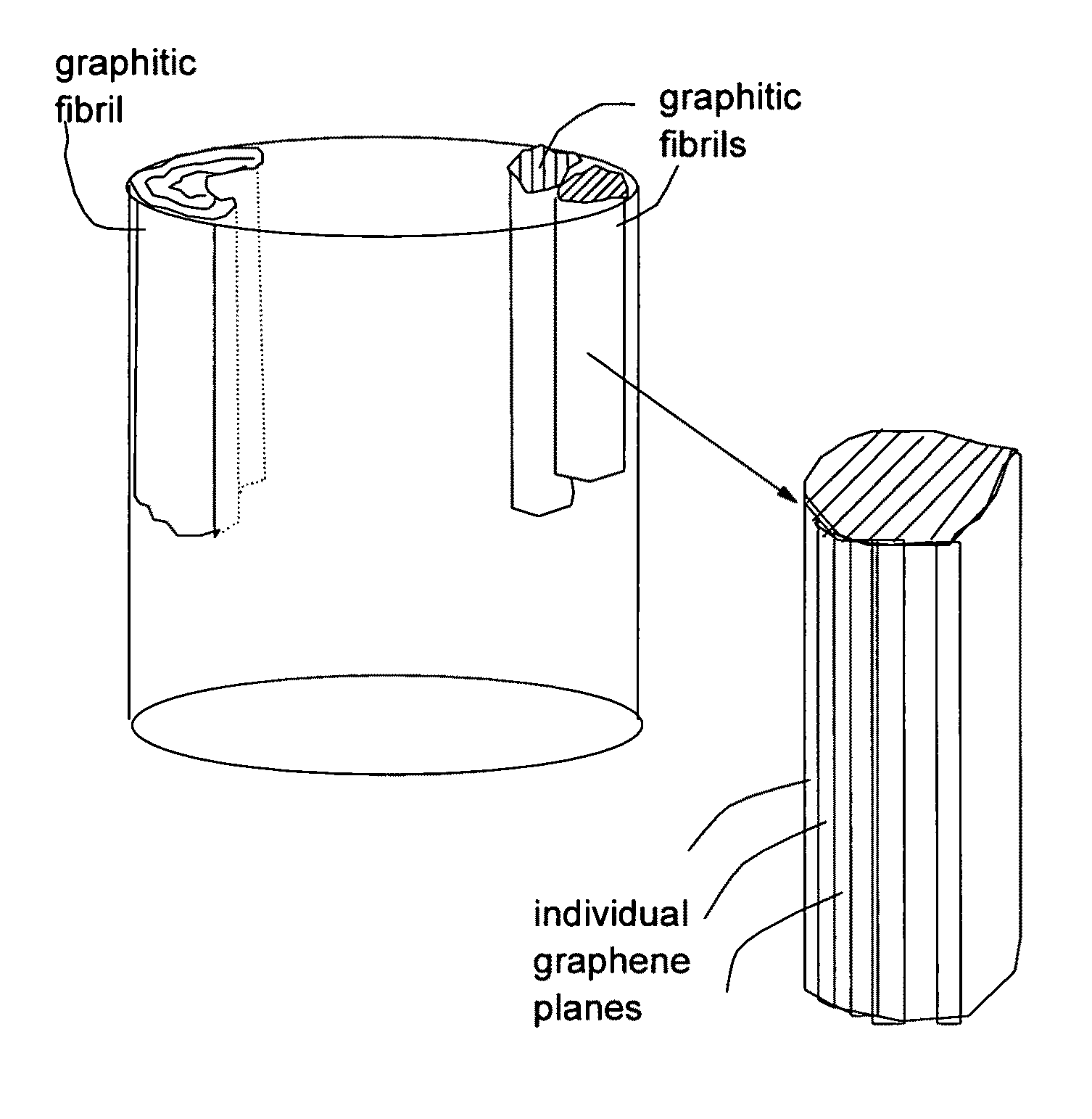

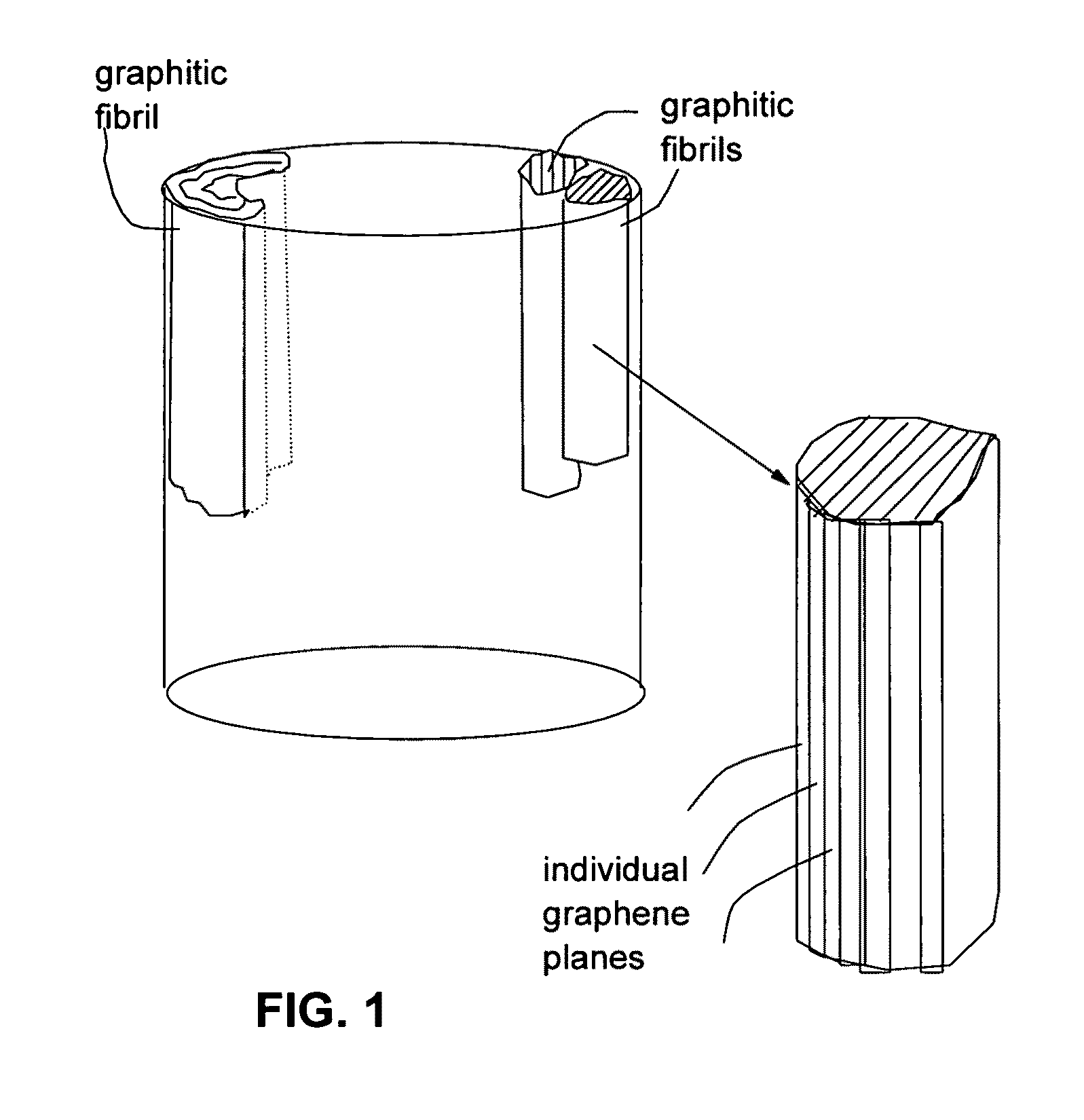

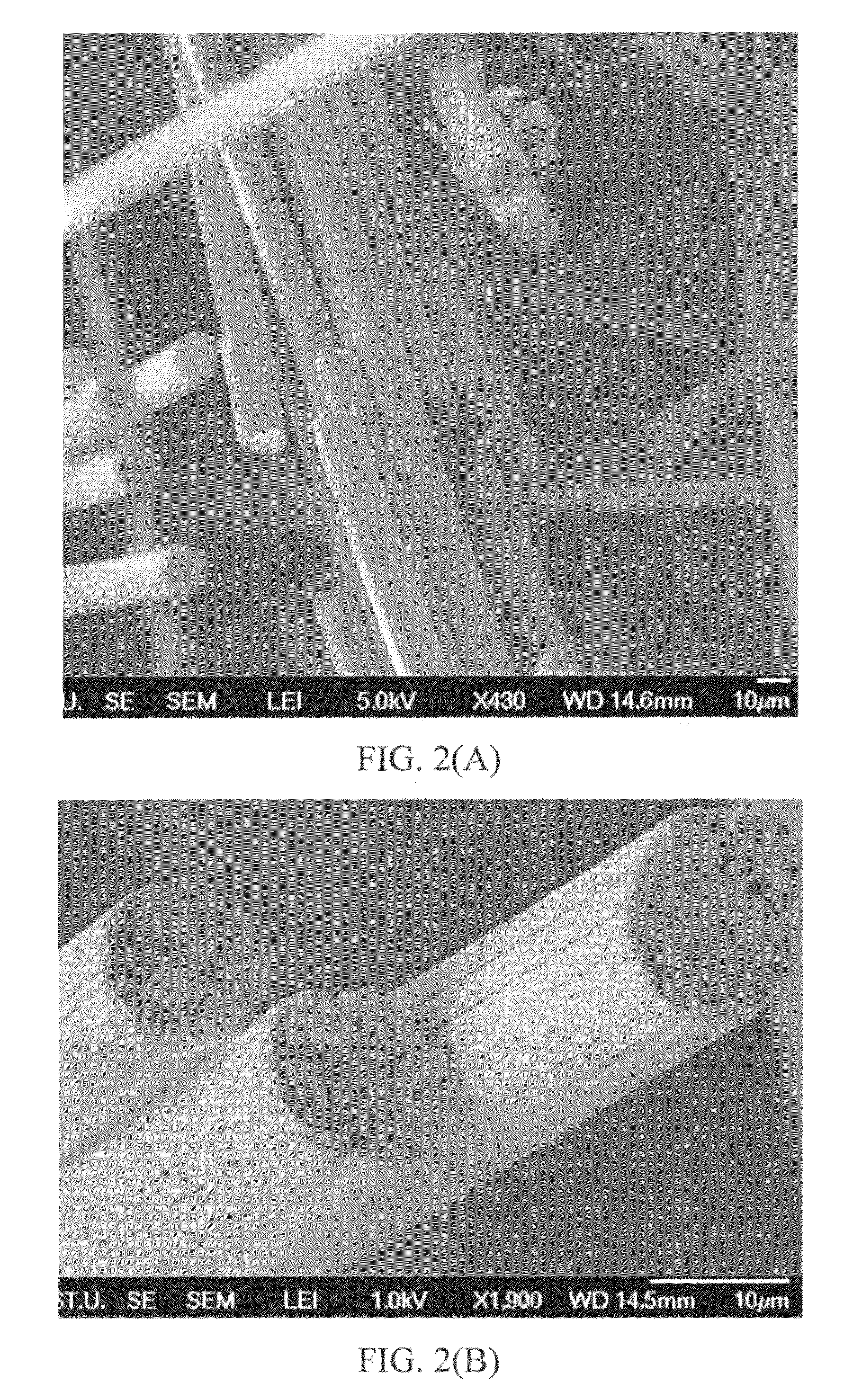

Chemically functionalized submicron graphitic fibrils, methods for producing same and compositions containing same

ActiveUS20110133132A1Different propertyGood hardening effectMaterial nanotechnologyLayered productsMicron scaleFiber

The present invention provides a chemically functionalized submicron graphitic fibril having a diameter or thickness less than 1 μm, wherein the fibril is free of continuous thermal carbon overcoat, free of continuous hollow core, and free of catalyst. The fibril is obtained by splitting a micron-scaled carbon fiber or graphite fiber along the fiber axis direction. These functionalized graphitic fibrils exhibit exceptionally high electrical conductivity, high thermal conductivity, high elastic modulus, high strength and good interfacial bonding with a matrix resin in a composite. The present invention also provides several products that contain submicron graphitic fibrils: (a) paper, thin-film, mat, and web products; (b) rubber or tire products; (c) energy conversion or storage devices, such as fuel cells, lithium-ion batteries, and supercapacitors; (d) adhesives, inks, coatings, paints, lubricants, and grease products; (e) heavy metal ion scavenger; (f) absorbent (e.g., to recover spill oil); (g) sensors; (h) friction and brake components; (i) radiation-shield components; (j) catalyst carrier; and (k) composite materials.

Owner:GLOBAL GRAPHENE GRP INC

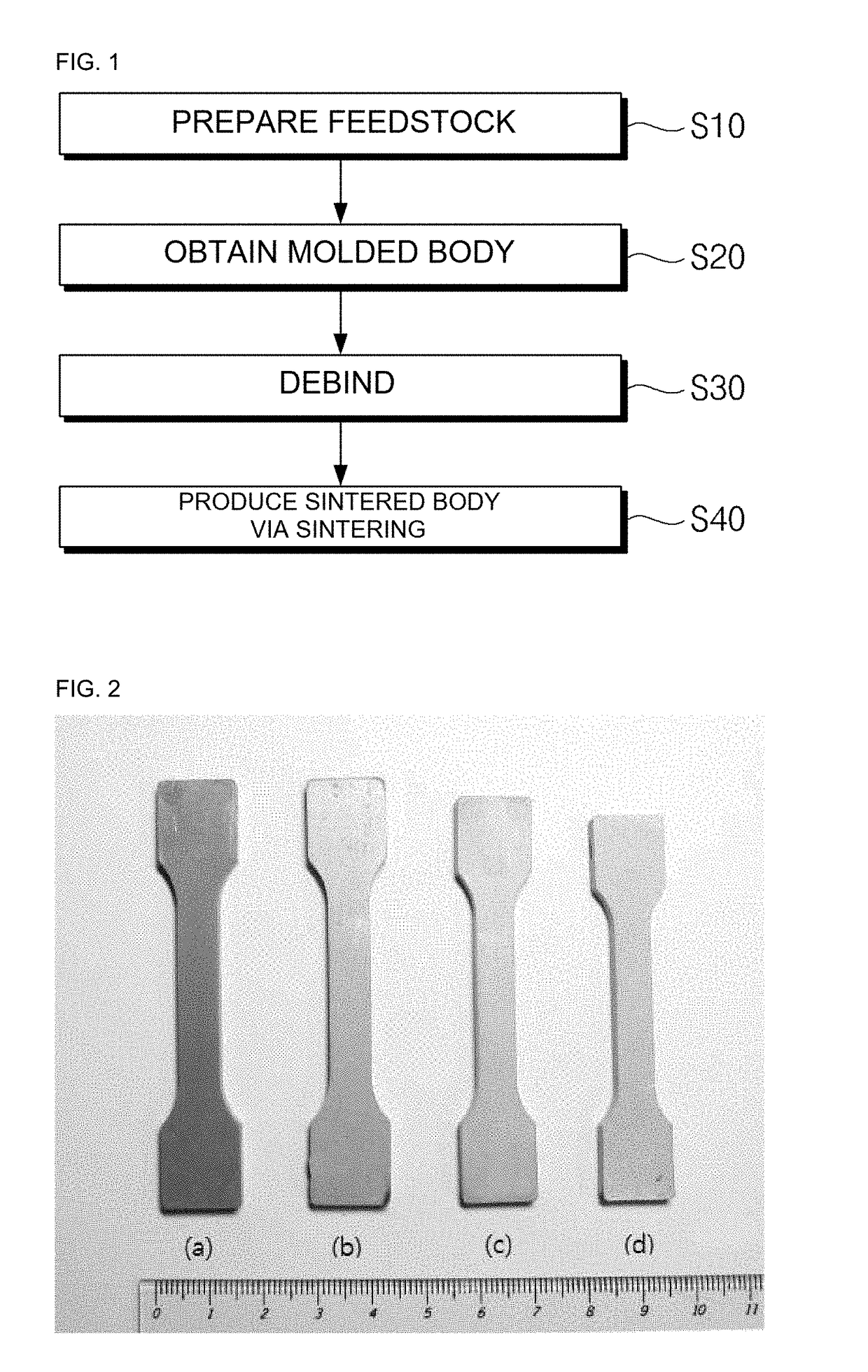

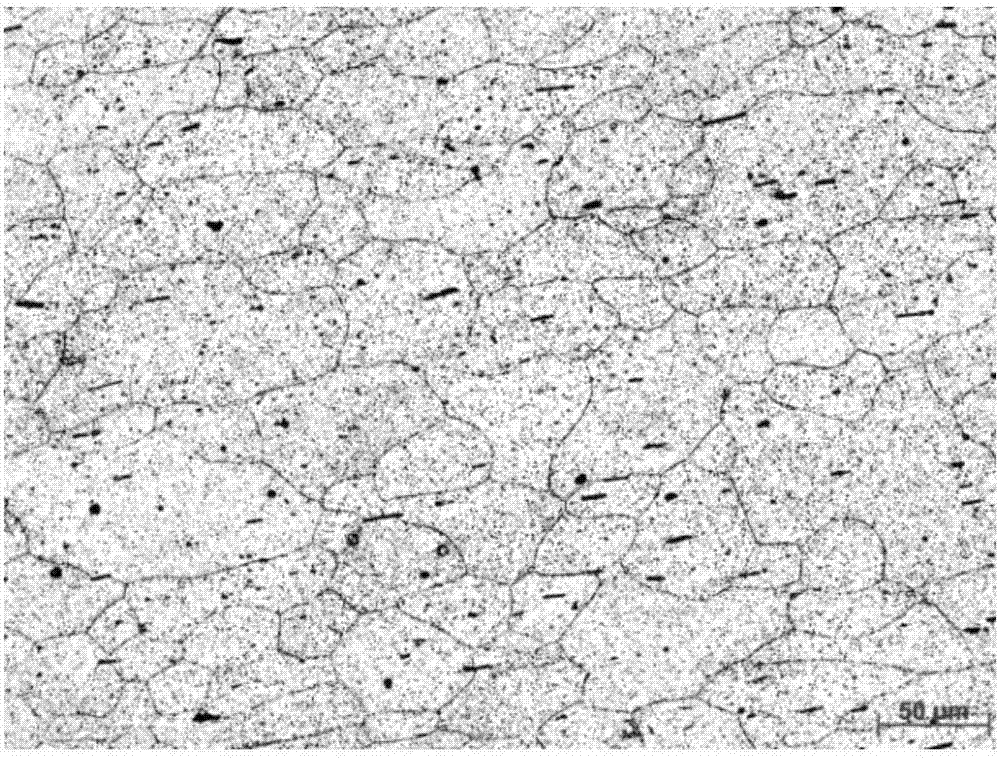

Method for molding aluminum and aluminum alloy powder

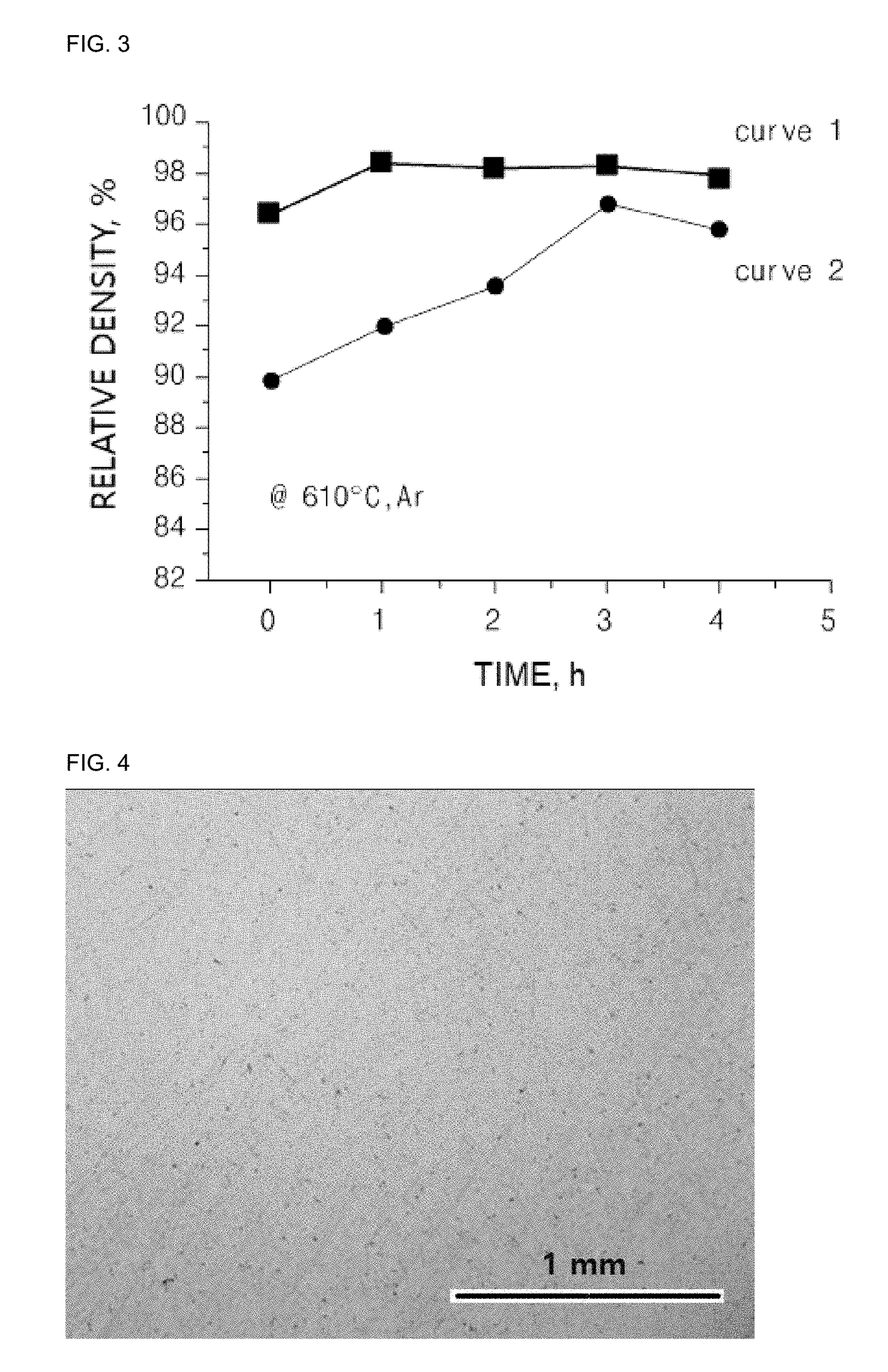

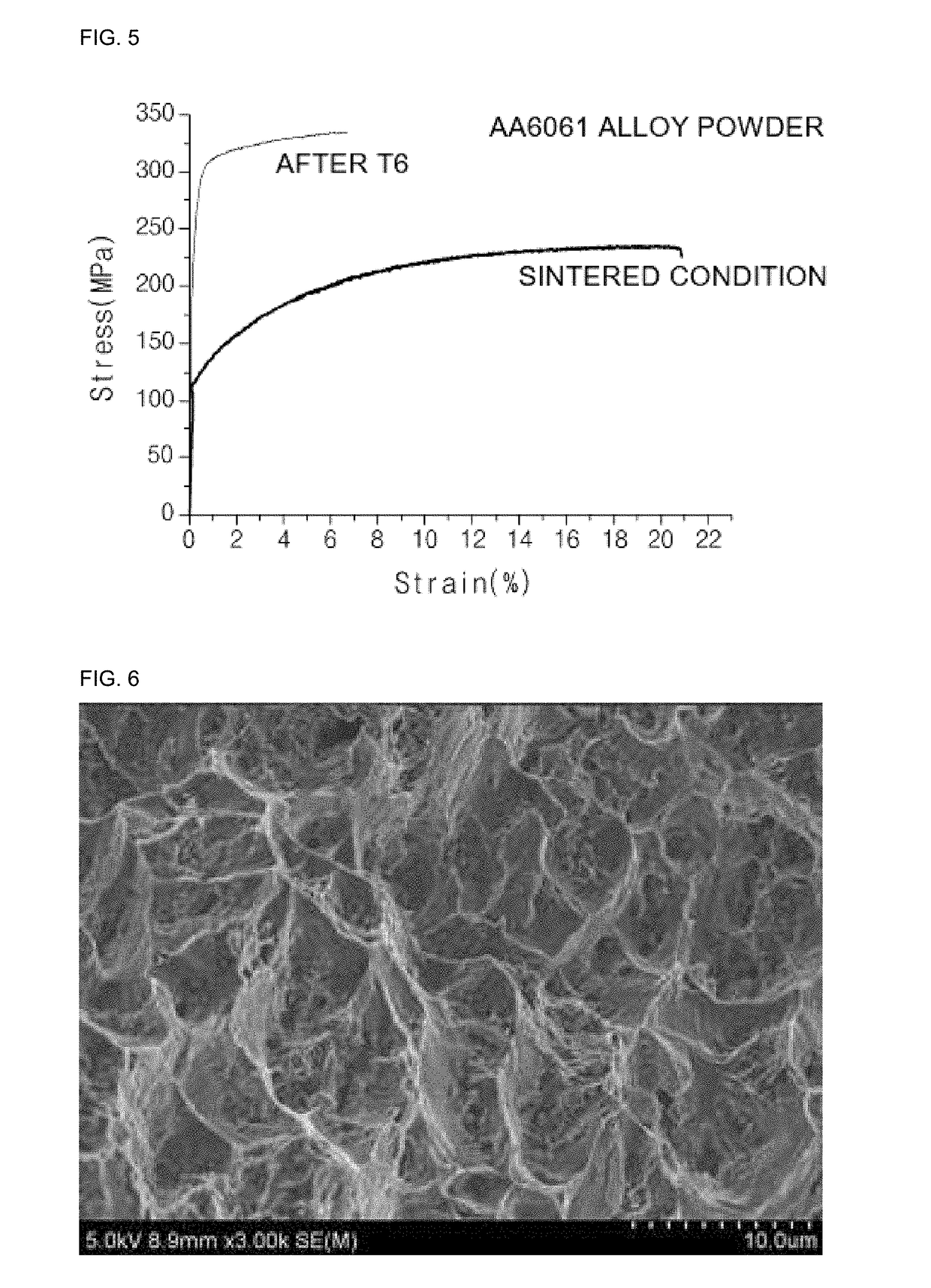

InactiveUS20180304373A1Low densityImprove thermal conductivityTurbinesTransportation and packagingCompression moldingHigh density

A powder molding method of aluminum and aluminum alloy includes: preparing a feedstock by kneading aluminum powder, aluminum alloy powder, or aluminum composite powder containing a reinforcing material with a thermoplastic organic binder; molding the feedstock to a product having a complex shape via powder injection molding, compression molding, or extrusion molding; and then producing a high-density sintered body having relative density of at least 96% by performing debinding and sintering in a single heating process under an argon gas atmosphere.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

Submicron-scale and lower-micron graphitic fibrils as an anode active material for a lithium ion battery

ActiveUS20110136007A1High proportionGood hardening effectElectrode thermal treatmentActive material electrodesFiberCarbon fibers

The present invention provides a lithium ion battery anode material comprising a submicron-scaled graphitic fibril having a diameter or thickness less than 1 μm but greater than 100 nm, wherein the fibril is obtained by splitting a micron-scaled carbon fiber or graphite fiber along the fiber axis direction. This type of graphitic fibril exhibits exceptionally high electrical conductivity, thermal conductivity, elastic modulus, and strength. The anode material exhibits a high reversible capacity and good charge / discharge cycling stability for both low and high charge rate conditions. Another preferred embodiment of the present invention is an anode active material containing a graphitic fibril with a diameter greater than 1 μm but less than 6 μm obtained by splitting a carbon fiber or graphite fiber of at least 6 μm in diameter.

Owner:GLOBAL GRAPHENE GRP INC

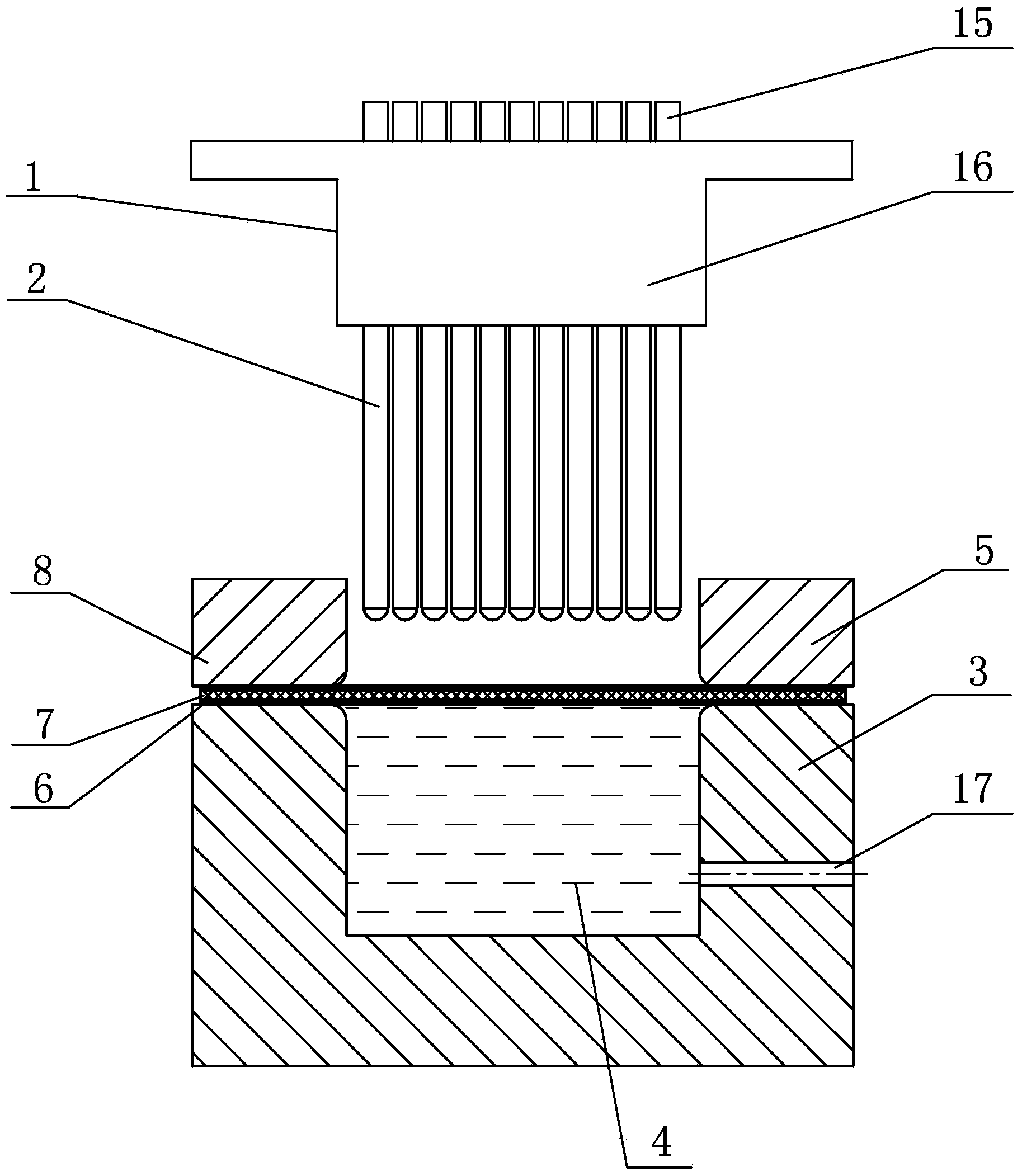

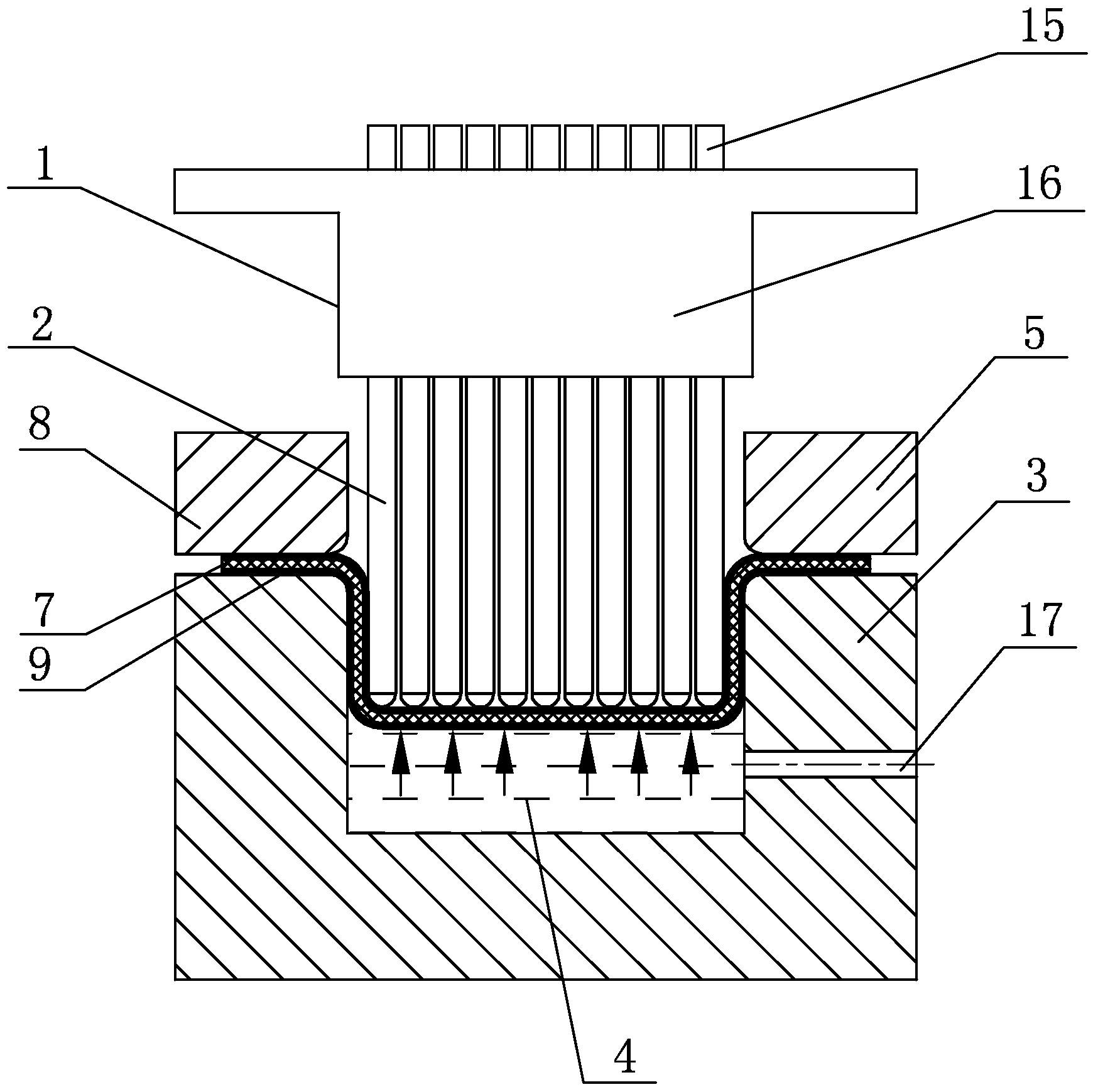

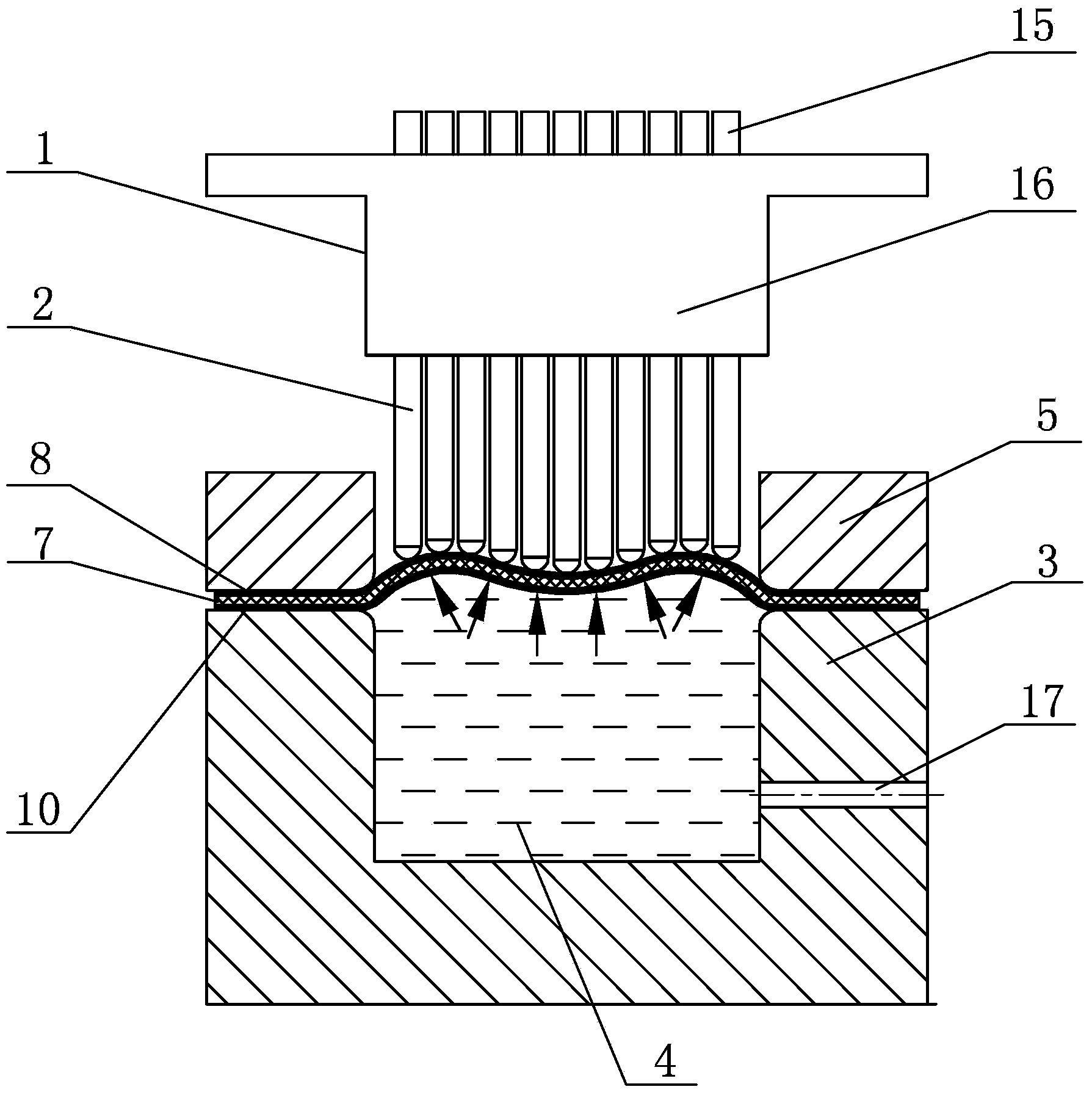

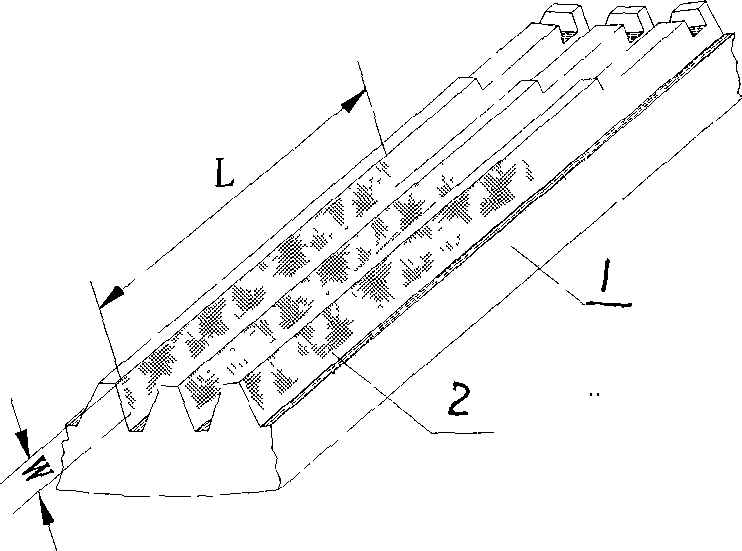

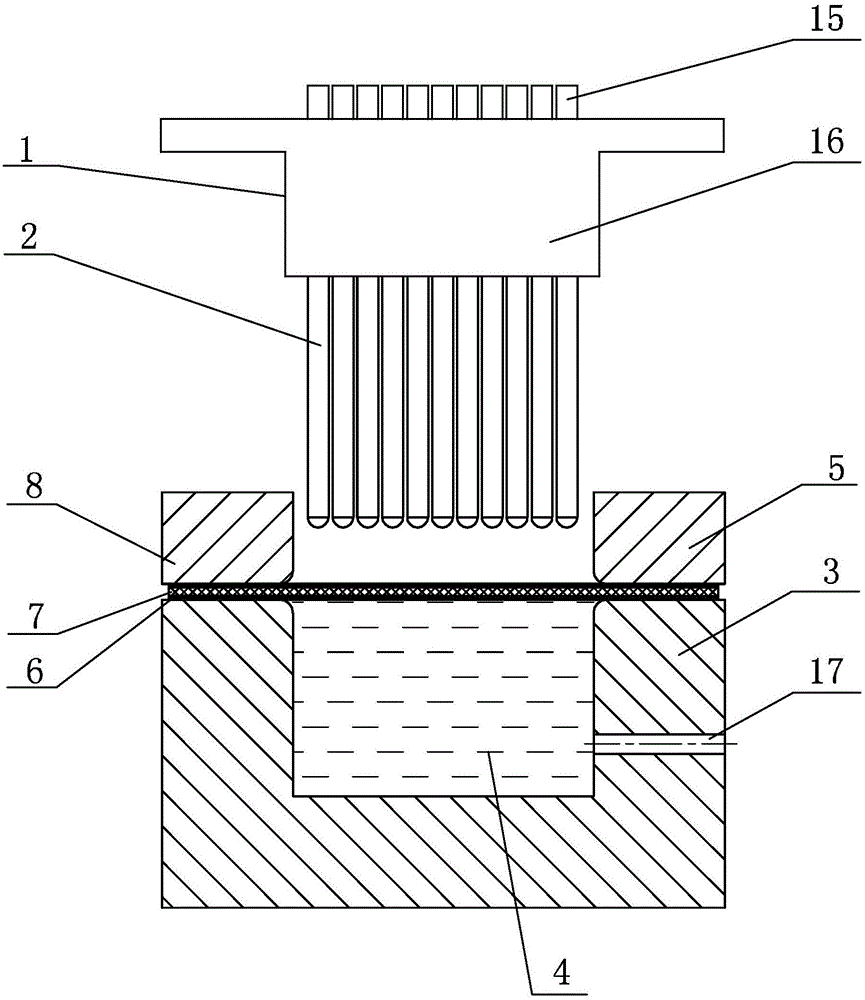

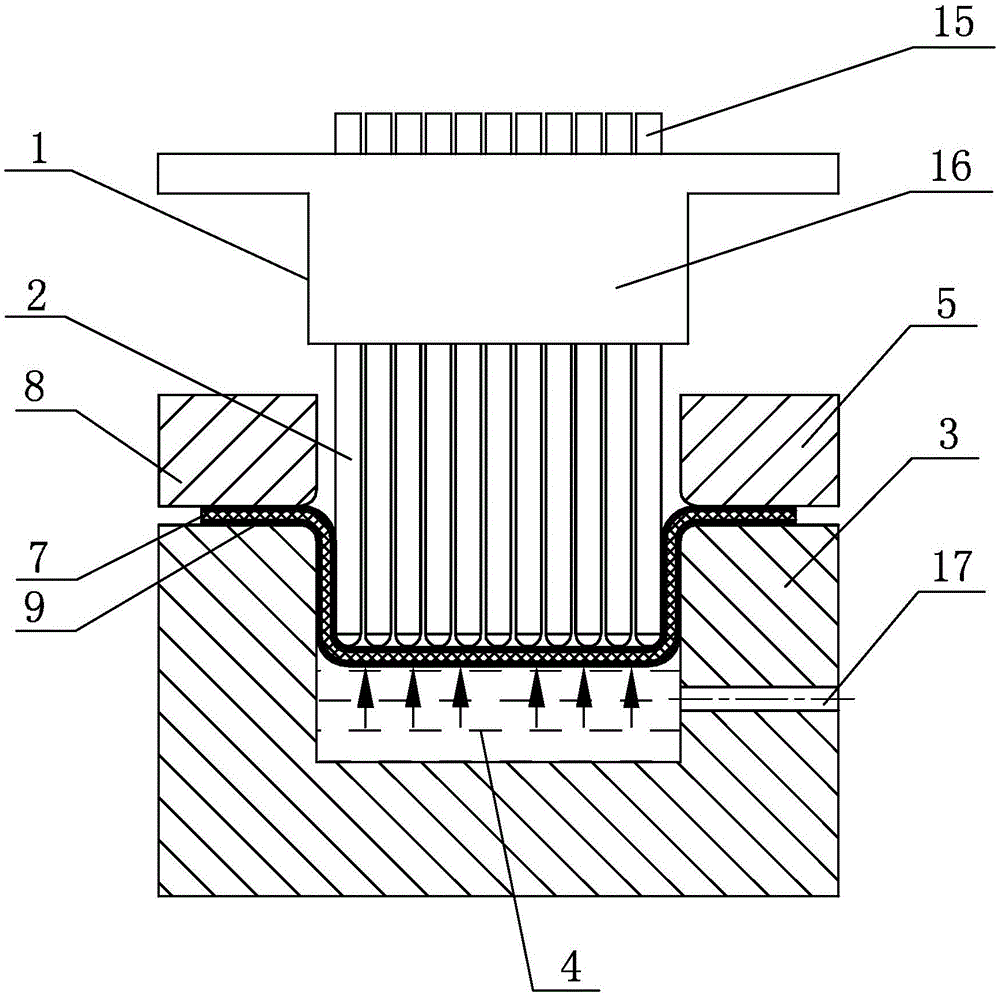

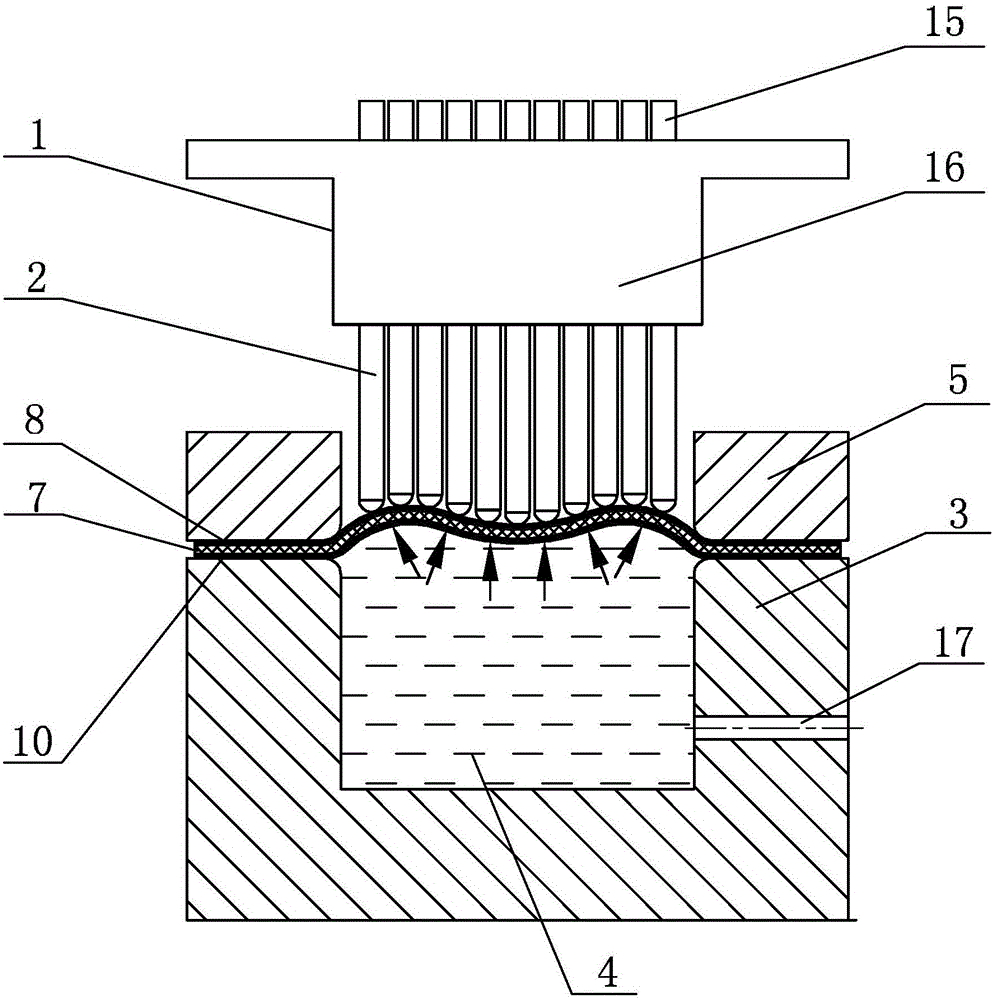

Multi-point male die liquid-filling drawing forming device and method for plate

The invention discloses a multi-point male die liquid-filling drawing forming device and a multi-point male die liquid-filling drawing forming method for a plate, relates to a device and a method for forming thin-walled curved plate parts, and aims to solve the problem of difficulty in forming of thin-walled and deep-cavity parts with complicated curved surfaces. A plurality of small punches are independently arranged; the upper ends of the small punches penetrate into through holes in a male die body; the upper end of each small punch is connected with a linear driving device; a female die is a semi-closed cavity of which the upper end is opened and the lower end is closed; an elastic base plate and a metal protection plate are superposed on the upper end surface of the female die from bottom to top. The heights of the small punches are adjusted to realize the construction of an outer contour of a multi-point male die; a to-be-formed plate blank, the elastic base plate and the metal protection plate are sequentially arranged on the upper end surface of the female die; a blank holder moves down to be assembled with the female die, and the multi-point male die moves down and applies a drawing force to the to-be-formed plate blank; meanwhile, a liquid medium is filled into an inner cavity of the female by the aid of a pressurizing system until drawing is completed to obtain parts of a required shape. The device and the method are used for forming the plate, and the thin-walled and deep-cavity parts with the complicated curved surfaces can be formed.

Owner:HARBIN INST OF TECH

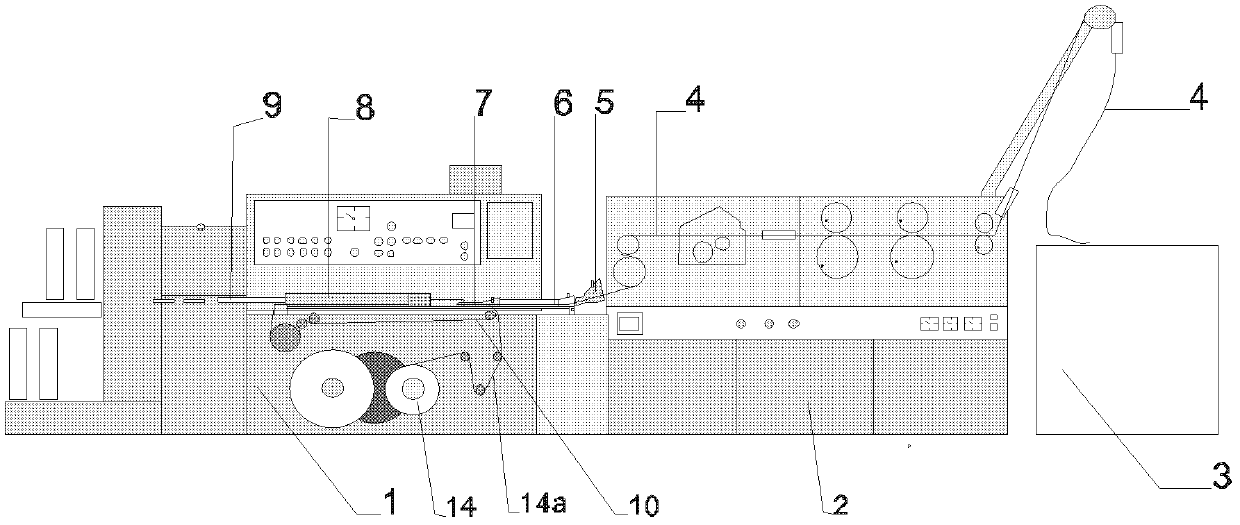

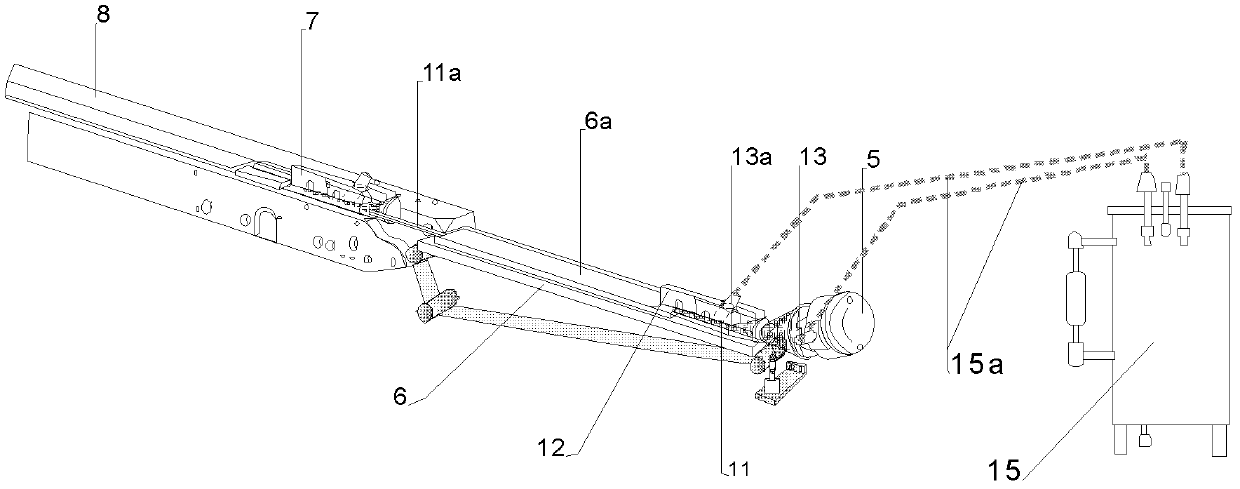

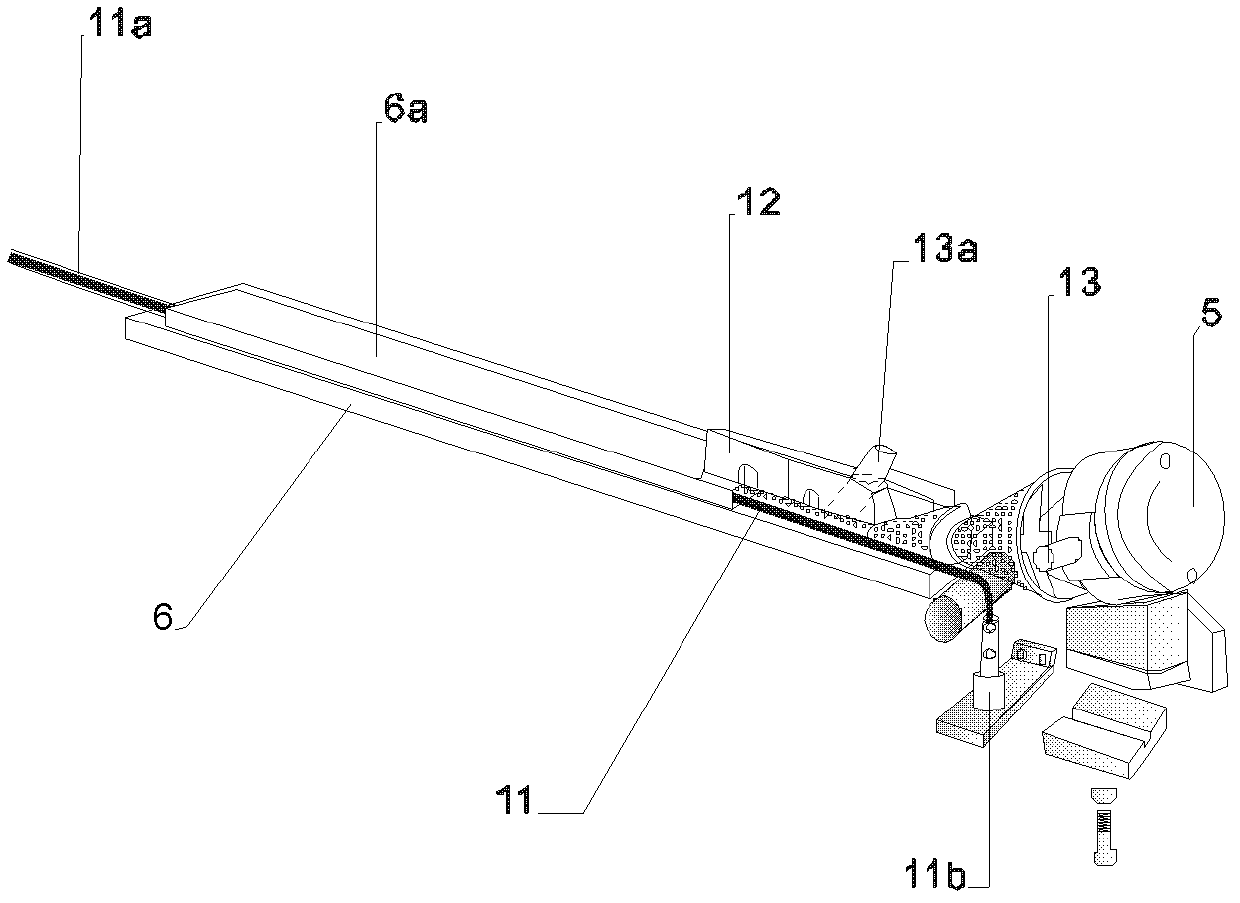

Device for manufacturing hollow filter stick

The invention discloses a device for manufacturing a hollow filter stick with a special shape. A certain distance is spaced between a forming machine and an opener; a steam hardening device is mounted within the section of the distance and comprises a group of high pressure air nozzles, a forming tongue, a cloth band mechanism used for clamping a tow band to move forward, a cigarette gun passage and a steam generator, wherein the cloth band mechanism is connected with a host driving device; the high pressure air nozzles are connected with the opener and used for receiving the tow band conveyed by the opener while output ends of the high pressure air nozzles are communicated with the forming tongue; the tow band is conveyed into the forming tongue; and a strip-shaped hollow mould is fixed on the front end of the forming tongue. The invention has the advantage that a better hardening promoting effect can be obtained because the steam hardening device and a plasticizer heating device (the steam generator) are added. Moreover, in the product, the curing time of the filter stick is largely shortened by using modified glyceride.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD

Al-zn-mg alloy product with reduced quench sensitivity

This relates to an aluminum alloy product, in particular an age-hardenable Al—Zn—Mg type alloy product for structural members, the alloy product combining a high strength with high toughness and reduced quench sensitivity, and having a chemical composition including, in wt. %: Zn about 3 to 11%, Mg about 1 to 3%, Cu about 0.9 to 3%, Ge about 0.03 to 0.4%, Si max. 0.5%, Fe max. 0.5%, balance aluminum and normal and / or inevitable elements and impurities. Furthermore, this relates to a method of producing such aluminum alloy products.

Owner:ALERIS ALUMINUM KOBLENZ GMBH

High strength precoated sand

InactiveCN101927318AImprove bonding and strengtheningImprove density and strengthFoundry mouldsFoundry coresAluminiumFirming agent

The invention discloses high strength precoated sand, comprising the components of raw sand, a binder, a firming agent, a coupling agent and a lubricant, wherein the dosage of the firming agent is 60-70% of that of the binder; the dosage of the coupling agent is 1-3% of that of the binder; the dosage of the binder is 5-8% of that of the raw sand; the dosage of the lubricant is 1-2% of that of the raw sand; the binder comprises the following ingredients in parts by weight: 60-70 parts of phenolic resin, 10-30 parts of high alumina bauxite powder and 10-20 parts of ferric oxide powder; and the firming agent comprises the following ingredients in parts by weight: 70-80 parts of hexamine, 15-25 parts of potassium nitrate and the balance water. The precoated sand of the invention has higher strength and stronger toughness.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Fireproof material for mending furnace as well as preparation method and using method thereof

The invention discloses a fireproof material for a mending furnace as well as a preparation method and a using method thereof. The fireproof material for the mending furnace comprises magnesia, magnesium powder, aluminium oxide, calcium oxide and sodium hexametaphosphate, wherein the total weight of the fireproof material for the mending furnace is used as a reference, the total content of the magnesia and the magnesium powder accounts for 80-90 percent by weight; the content of the aluminium oxide accounts for 3-7 percent by weight; the content of the calcium oxide accounts for 3-7 percent by weight; the content of the sodium hexametaphosphate accounts for 3-7 percent; and the main components of the magnesia and the magnesium powder are MgO. The fireproof material for the mending furnace is high in adhesive ratio, good in stickiness, solidification and hardness, and low in resilience value during mending; and therefore, a mending layer formed by the fireproof material for the mending furnace is good in anti-erosion performance and long in service life.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

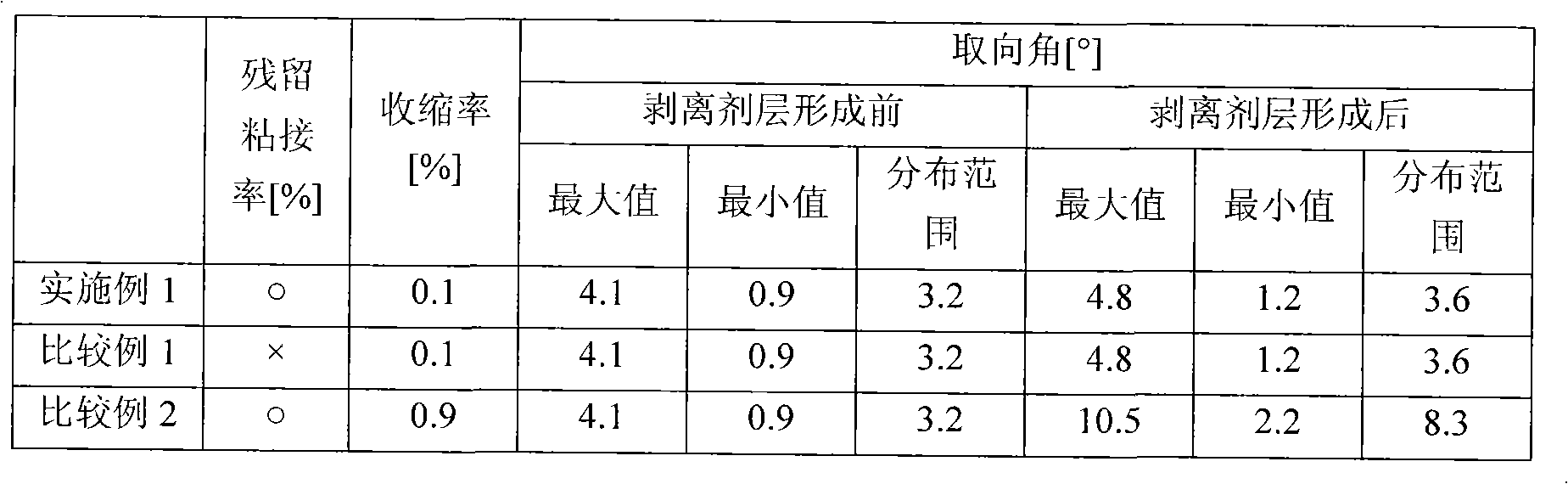

Stripping film, polarizing film with stripping film and two-sided bonding sheet without base material

ActiveCN101537726AGood hardening effectSmall orientation angle distribution rangeSynthetic resin layered productsPolarising elementsPolyesterFilm base

The present invention relates to a stripping film, a polarizing film with the stripping film and a two-sided bonding sheet without base material. the present invention provides the stripping film capable of implementing a high precision examination through a cross Nickle method and having a good peeling performance. the stripping film of the invention is formed by setting a stripping layer on a stripping film base material. The stripping film base material is a polyester film extending bidirectionally or unidirectionally. A stripper layer hardens an organopolysiloxane having alkenyl with 6-10 of carbon atoms in a molecule and a addition reaction type silicon resin composition of a MQ resin with alkenyl in a molecule, and covers by a film. In a sample sampled by the stripping film, a distribution range of an inclination angle (orientation angle) of an orientation main shaft of the stripping film base material is less than 5 DEG relative to an straight line shaft of a random direction.

Owner:LINTEC CORP

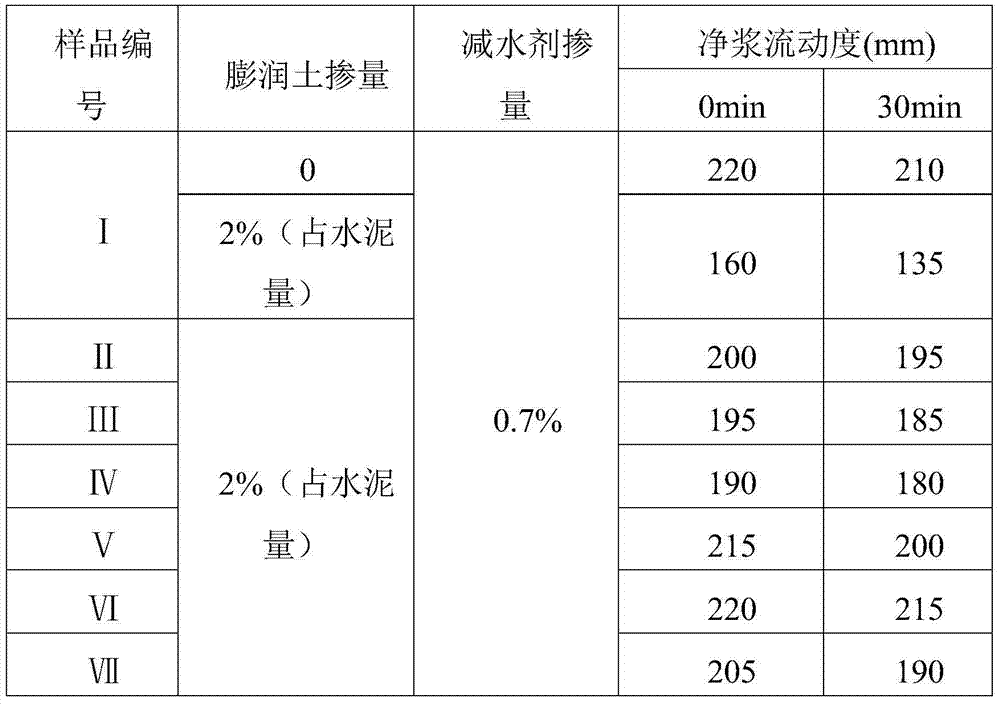

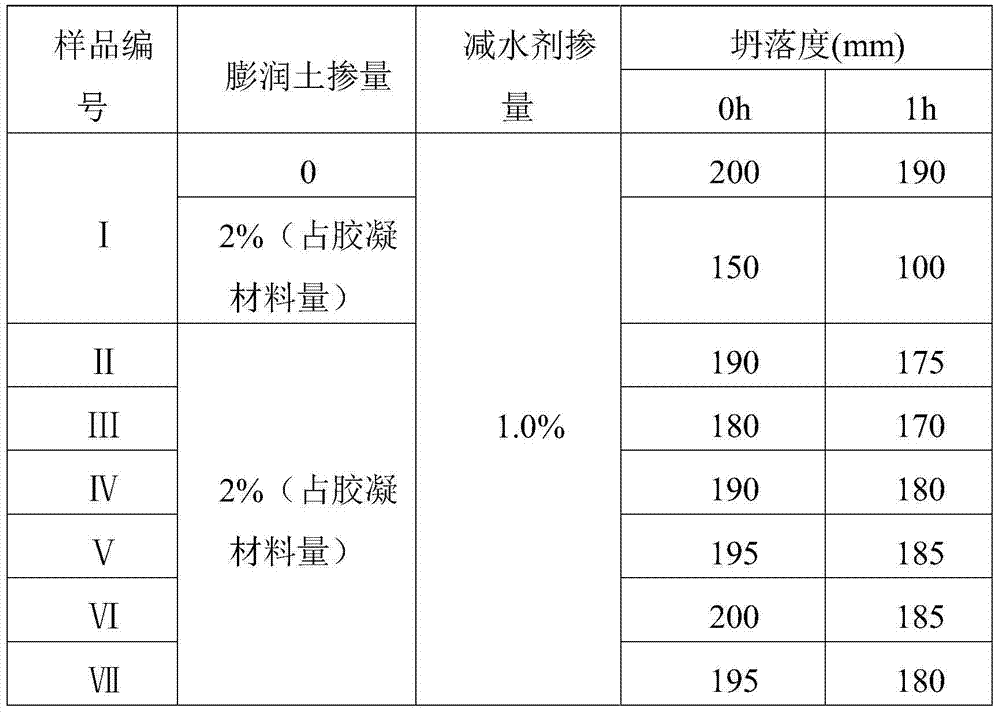

Treating agent for inhibition of harm of montmorillonite clay to concrete and using method thereof

The invention discloses a treating agent for inhibition of harm of montmorillonite clay to concrete and a using method thereof, and the treating agent belongs to the technical field of concrete additives, is used for inhibition of harm of the montmorillonite clay to concrete with a poly carboxylic acid doped water reducing agent, and solves the problem of complex technology, high cost, and bad effect of technological means in the prior art. The treating agent for inhibition of harm of montmorillonite clay to concrete comprises the following components by mass: 25%-35% of an intercalation adsorbent, 45%-55% of a dispersing agent and 10%-25% of a stabilizer. When in use, the dosage of the treating agent for inhibition of harm of montmorillonite clay to concrete is 0.01% to 0.03% of the dosage of a cementitious material in the concrete. The treating agent can effectively reduce the poly carboxylic acid doped water reducing agent adsorption of the montmorillonite clay, improves concrete performance, and has the advantages of simple preparation process, small dosage, and low cost of production and use.

Owner:SHANGHAI CONSTRUCTION GROUP

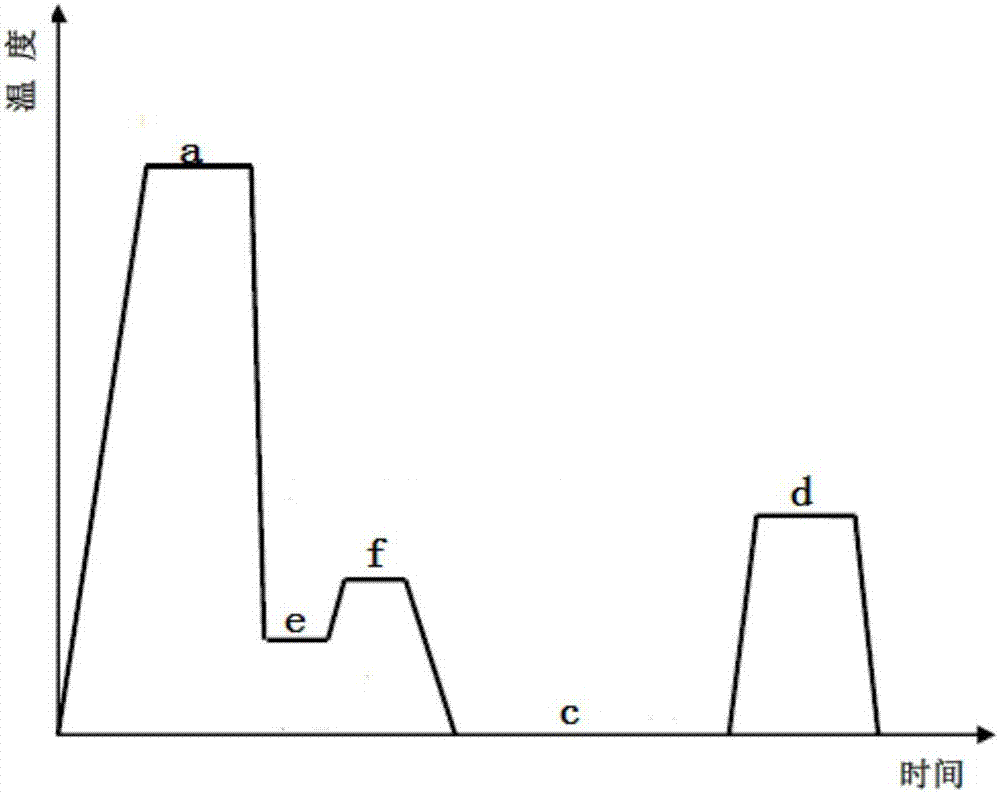

Heat treatment method capable of improving natural aging stability of 6000-series aluminum alloy and aluminum alloy plate

The invention discloses a heat treatment method capable of improving natural aging stability of 6000-series aluminum alloy and an aluminum alloy plate, and relates to the technical field of aluminum alloy heat treatment. The heat treatment method comprises the following steps that a 6000-series aluminum alloy plate is subjected to solid solution treatment and quenched to 40-60 DEG C, heat is preserved for 5-20 min, then the temperature is quickly increased to 100-120 DEG C, heat is preserved for 2-5 min, and then the plate is cooled to the room temperature. By means of the method, the problems that a traditional solid solution pre-aging treatment method is poor in natural aging stability and short in bake hardening performance maintaining time are relieved. By adoption of the heat treatment method, the stability in the room temperature stagnating process can be better regulated and controlled, and thus adverse influences of natural aging are restrained; and not only can the aluminum alloy keep a good forming property for a long time, but also the paint-bake hardenability of the aluminum alloy is obviously improved, after paint baking, the strength and hardness of the obtained aluminum alloy plate are obviously improved, the yield strength is greater than 200 MPa, and the hardness is greater than 95 HB.

Owner:SHANDONG NANSHAN ALUMINUM +1

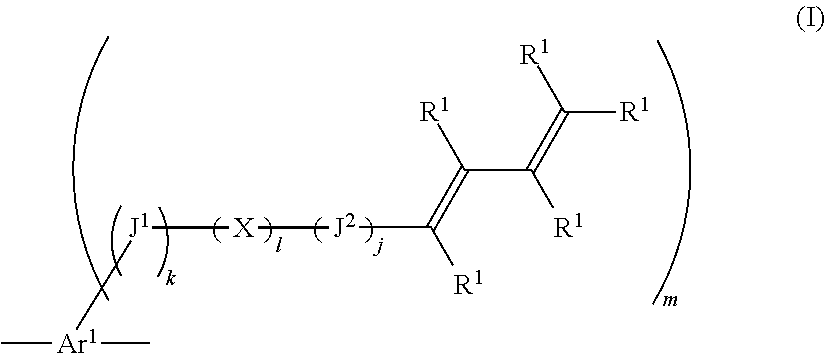

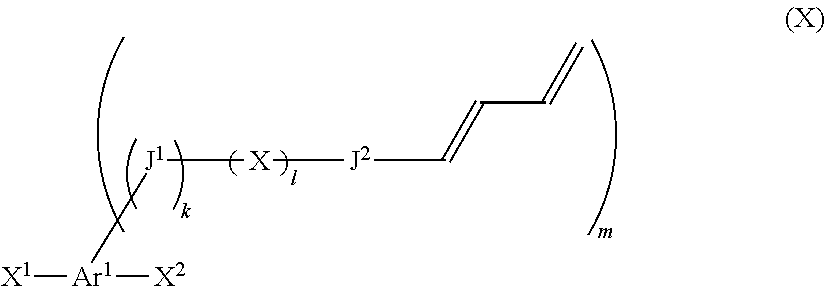

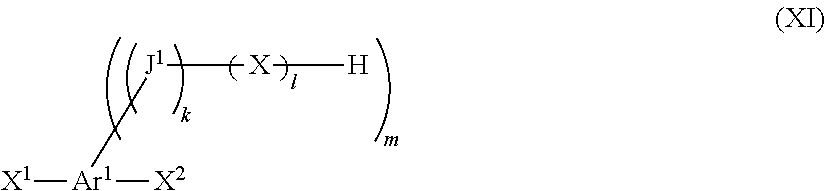

Compound containing 1,3-diene structure and method for producing same

InactiveUS20110127517A1Good hardening effectOrganic compound preparationElectroluminescent light sourcesSilyleneAcyl group

Disclosed is a compound containing a divalent group represented by formula (I). (In formula (I), Ar1 represents an arylene group, a divalent heterocyclic group or a divalent aromatic amine group; J1 represents a phenylene group; J2 represents an alkylene group; X represents an oxygen atom or a sulfur atom; j represents 0 or 1, k represents an integer of 0-3, and l represents 0 or 1, while satisfying 1≦j+k+l≦5; m represents 1 or 2; R1 represents a hydrogen atom, an alkyl group, an alkoxy group, an alkylthio group, an aryl group, an aryloxy group, an arylthio group, an arylalkyl group, an arylalkoxy group, an arylalkylthio group, an arylalkenyl group, an arylalkynyl group, an amino group, a substituted amino group, a silyl group, a substituted silyl group, a halogen atom, an acyl group, an acyloxy group, an imine residue, a carbamoyl group, an acid imide group, a monovalent heterocyclic group, a carboxyl group, a substituted carboxyl group, a cyano group or a nitro group; the plurality of R1's may be the same as or different from each other; and when there are a plurality of J1's, J2's, X's, j's, k's or l's, the J1's, J2's, X's, j's, k's or l's may be the same as or different from each other, respectively.)

Owner:SUMITOMO CHEM CO LTD

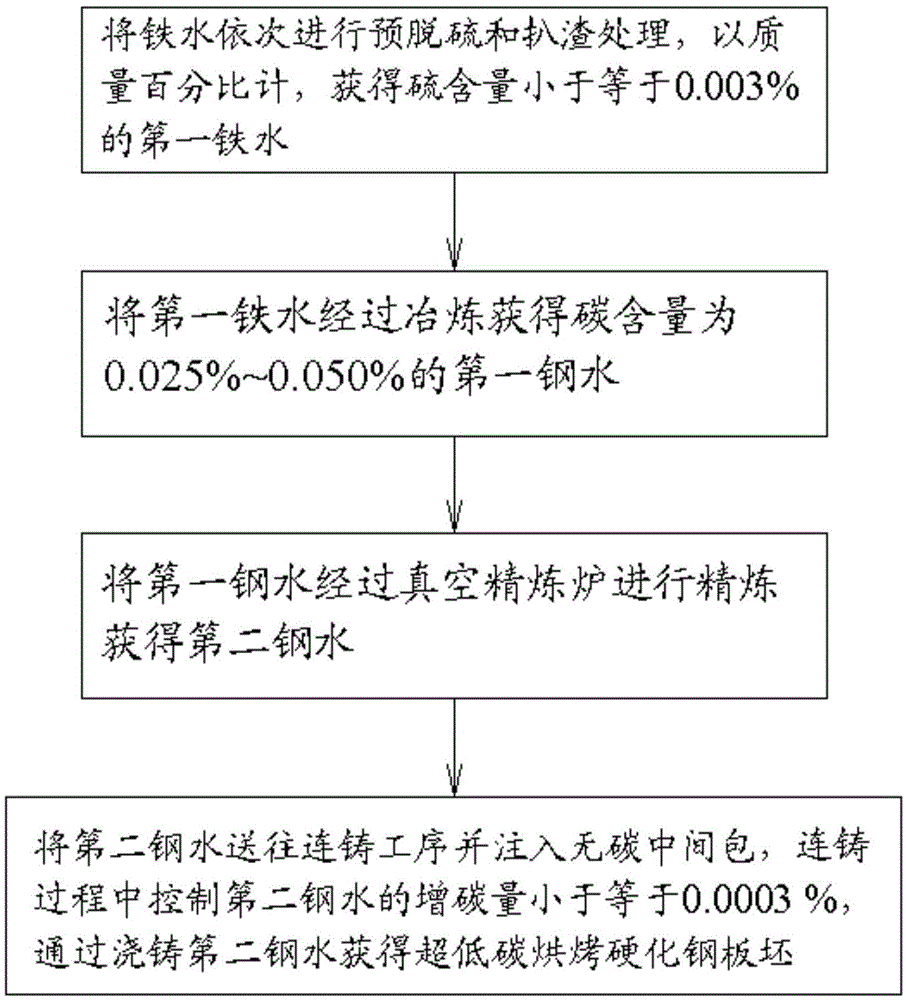

Ultralow-carbon bake-hardened steel plate blank and control method of solid solution carbon content thereof

ActiveCN104946974AHigh control precisionImprove smelting hit rateManufacturing convertersSlagHardened steel

The invention relates to an ultralow-carbon bake-hardened steel plate blank which comprises the following chemical components in percentage by weight: 0.0015-0.0030% of C, at most 0.03% of Si, 0.30-0.60% of Mn, 0.030-0.050% of P, at most 0.015% of S, 0.015-0.060% of Alt, 0.005-0.025% of Nb, at most 0.0050% of N, 0.0005-0.0020% of B and the balance of Fe. The invention also relates to of a control method of the solid solution carbon content of the ultralow-carbon bake-hardened steel, which comprises the following steps: sequentially carrying out pre-desulfurization and slag removal treatment on molten iron to obtain first molten iron with the sulfur content of at most 0.003%; smelting the first molten iron to obtain first molten steel with the carbon content of 0.025-0.050%; refining the first molten steel by a vacuum refining furnace to obtain second molten steel; sending the second molten steel into a continuous casting procedure, injecting into a carbon-free tundish, and casting the molten steel to obtain the ultralow-carbon bake-hardened steel plate blank, wherein the carbon increase amount of the second molten steel in the continuous casting process is at most 0.0003%. The control method shortens the smelting time in the vacuum refining furnace, enhances the production efficiency, and enhances the primary smelting hit rate of the plate blank composition.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

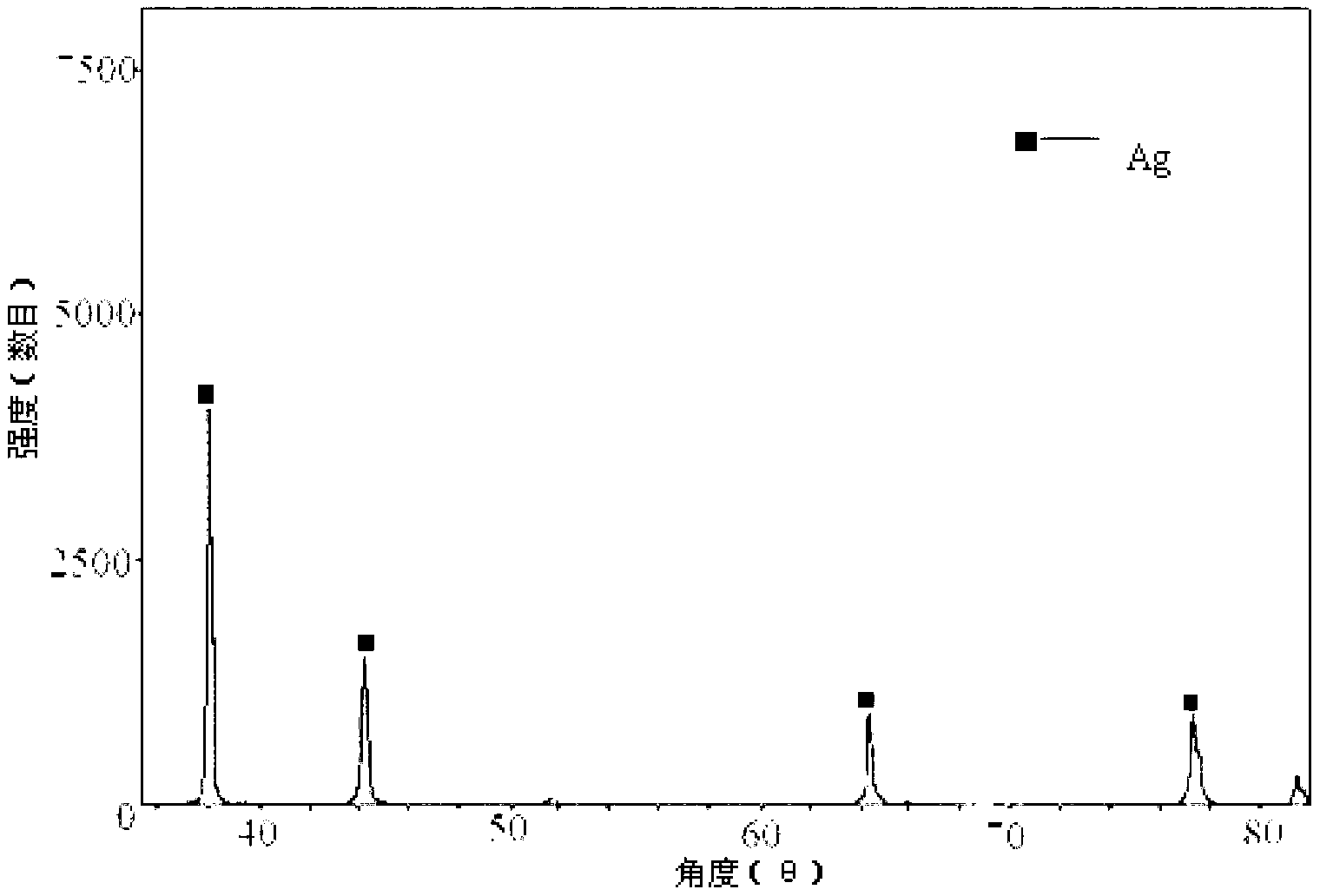

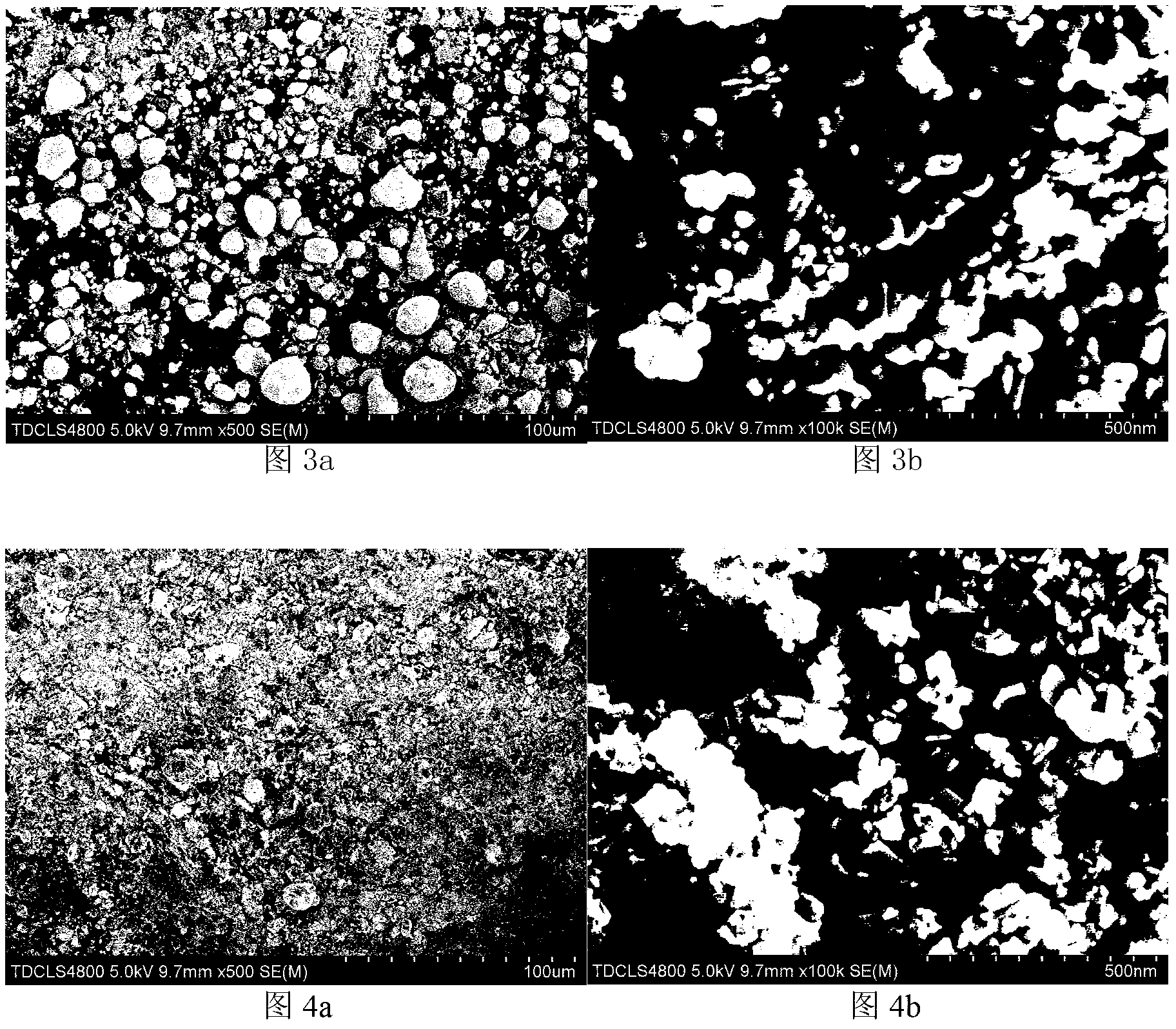

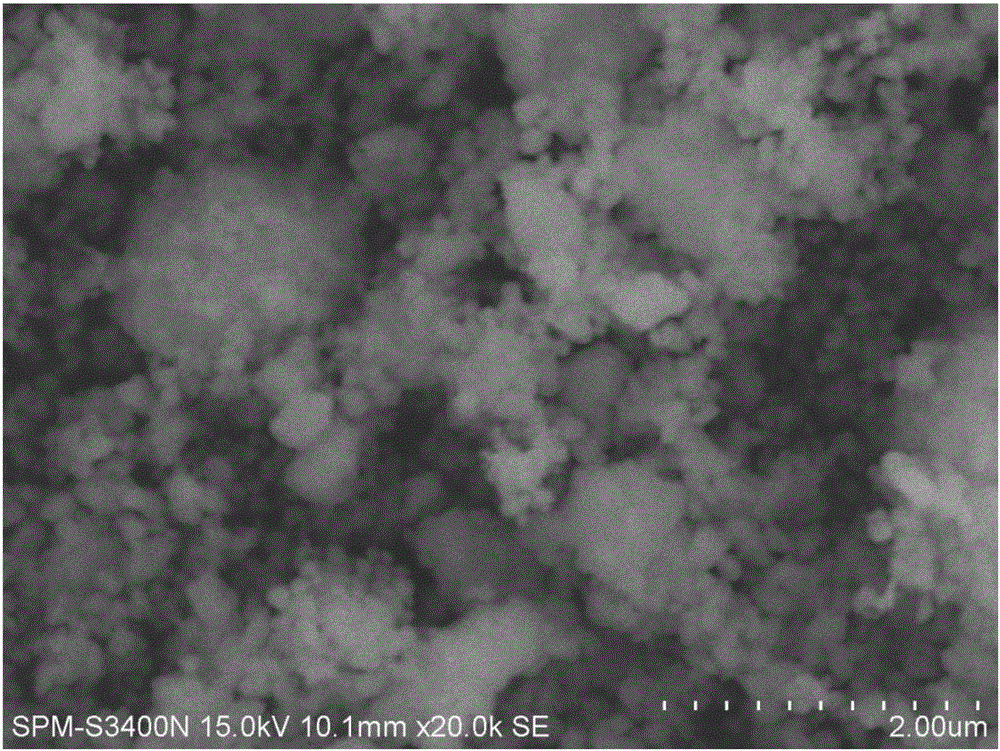

Technology for preparing silver rare earth oxide electric contact material for low voltage electric apparatus with liquid phase method

InactiveCN103233136ARaw materials are easy to getLow costRare earth metal compoundsContactsPowder metallurgyOxide

The invention relates to a technology for preparing a silver rare earth oxide electric contact material for a low voltage electric apparatus with a liquid phase method. According to the method, a chemical reduction method is combined with a homogeneous precipitation method to prepare nano-silver and rare earth oxide powder, and the silver rare earth oxide electric contact material is prepared by adopting a powder metallurgy technology, so that the contact material has high hardness, density and electric conductivity. The material used in the technology is easily available and little, and the cost is low; the chemical reduction method is combined with homogeneous precipitation method to prepare nano-silver and rare earth oxide powder, so that the technology is simple, the nano-silver and rare earth oxide powder are easy for industrial production, and the technology is environment-friendly and meets the currently recommended requirement of low-carbon production; and the contact material has good electrical property, 10%-30% of silver can be saved, and the contact material is a novel silver-saving electrical contact material.

Owner:HEBEI UNIV OF TECH

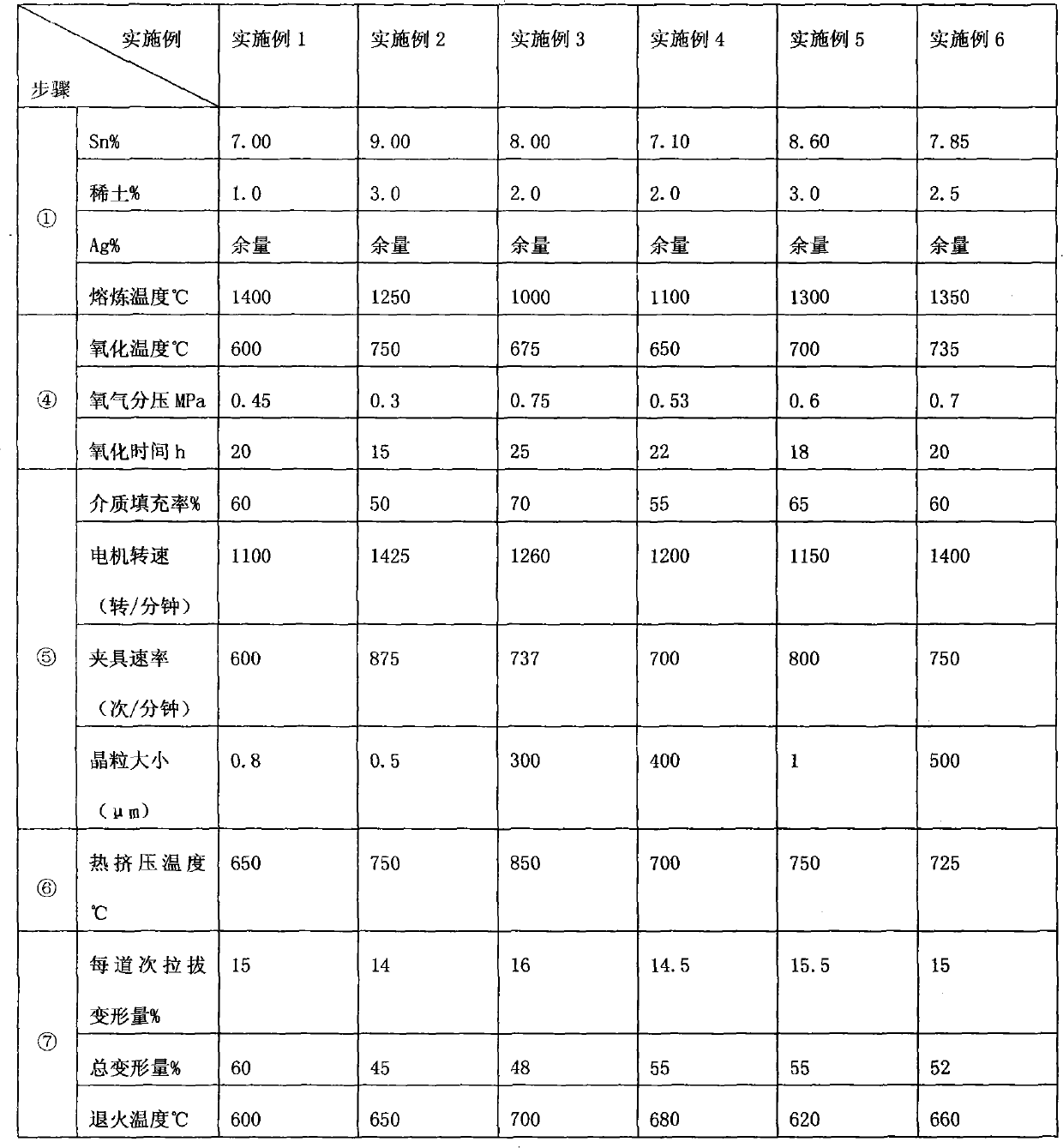

Manufacturing method of silver tin oxide contact alloy material and manufactured alloy thereof

The invention discloses a manufacturing method of a silver tin oxide contact alloy material and a manufactured alloy thereof. The method comprises the following steps: 1.smelting: smelting the ingredients at the preset temperature and continuing to stir in the process of smelting; 2. casting the ingredients into a round spindle and lathing the surface of the round spindle; 3. carrying out hot rolling and then cold rolling on the round spindle and then rolling the round spindle into sheets; 4. carrying out oxygenation processing on the sheets in an internal oxidation furnace; 5. crushing the sheets and then carrying out high energy crushing processing on the crushed sheets; 6. carrying out hot extrusion to obtain a wire stock blank; 7. carrying out drawing processing and annealing treatment; and 8. taking the obtained material as the finished product. The alloy comprises the following components in percentage by weight: 7%-9% of Sn, 1.0%-3.0% of rare earth additive and the balance of Ag. The invention has the advantages of more simplified technique, easy implementation and excellent product performance.

Owner:浙江乐银合金有限公司

High manganese steel containing tungsten

The invention discloses a high manganese steel which contains tungsten, and the high manganese steel contains chemical constituents in the following mass percent: C: 1.05%-1.35%, Si: 0.3%-0.9%, Mn: 11%-19%, W: 0.5%-1.5%, P<=0.070% and S<=0.045%, and the rest is Fe, furthermore, the high manganese steel also can contain a rare earth element RE, and the content of the RE is 0.01%-0.3%. The high manganese steel also can contain Cr and the content of the Cr is 1.2-2.5%. The high manganese steel which contains the tungsten of the invention is added with the elements of tungsten, rare earth element RE and chrome in particular when the content of the Mn is 16%-19%, which enables the whole high manganese steel to have the advantages of good toughness, high yield strength, high work hardening degree, better abrasive resistance and the like compared with the existing steel, and thereby the application range of the high manganese steel is enlarged. The high manganese steel of the invention is suitable for preparing fitting parts which are used in the working condition of abrasion and in particular to impact abrasion.

Owner:JINAN UNIVERSITY

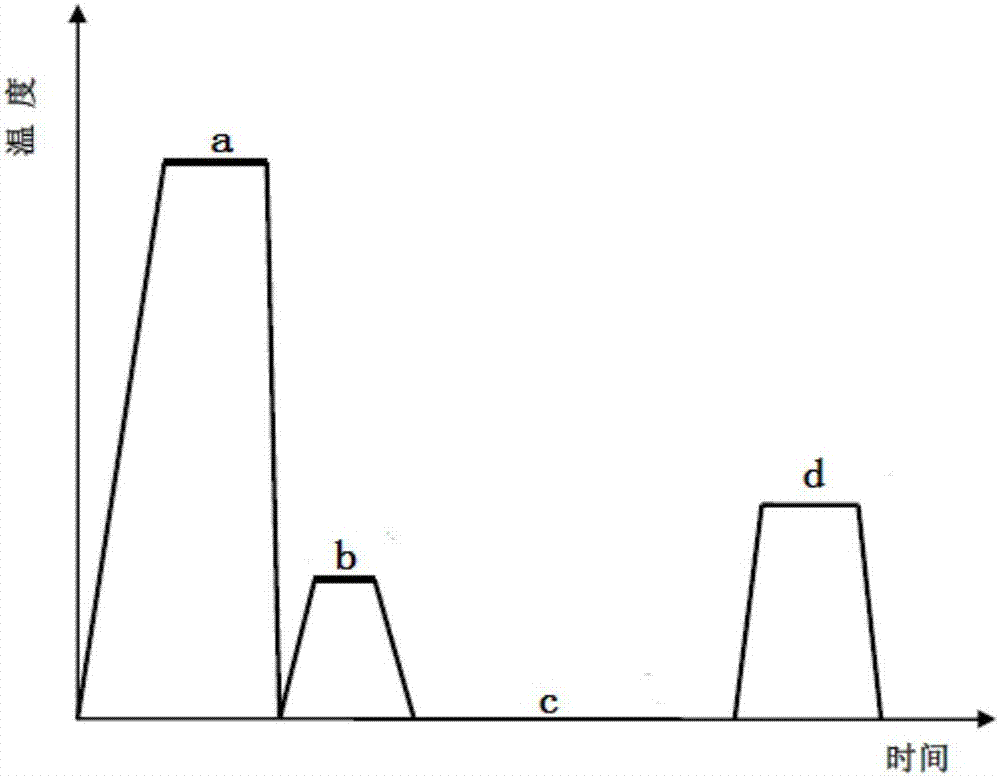

Heat treatment technology for increasing strength of aluminum alloy profile

The invention discloses a heat treatment technology for increasing strength of an aluminum alloy profile, and belongs to the technical field of aluminum profile processing. According to the heat treatment technology disclosed by the invention, secondary solid-solution treatment and tertiary aging treatment are combined; the secondary solid-solution treatment is in favor of uniform combination of vacancies and a solid solution, and thus, a foundation is laid for solute to diffuse, cluster and form precipitated phase precipitation through a vacancy mechanism during ageing treatment, and thereby,uniformity of heat treatment is increased, and material property deficiencies brought by single-stage solid-solution treatment and ageing treatment in the prior art are overcome.

Owner:ANHUI CHUANGHONG PRECISION MACHINERY

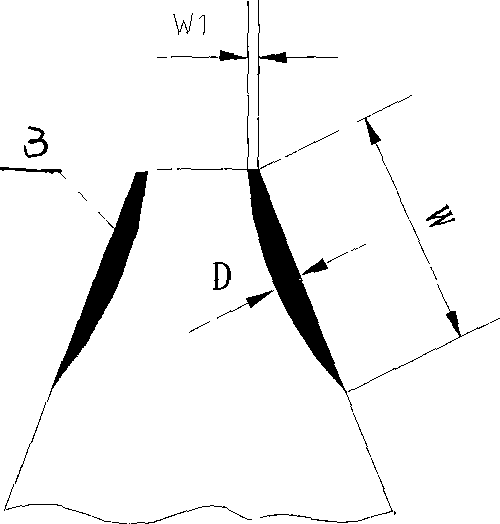

Tooth ring tooth surface laser induration processing method

ActiveCN101368226ASmall quenching deformationMeet hardening technical requirementsLaser quenchingLight guide

The invention relates to a laser hardening treatment method for a gear surface of a gear ring, which is characterized the in that: laser hardening treatment methods for the two side surfaces of each gear of the gear ring (1) and the top of the gear thereof are the same; the processing method thereof is described as follows: 1) the gear ring is arranged in the clamp of a rotary working platform; the direction of the length of the gear is vertical to the surface of the rotary working platform; 2) the upper end of the gear ring is provided with a light shielding ring; 3) the laser hardening treatment parameters, such as a laser power, a laser beam scanning speed, the focus of a focus lamp, are reasonably matched; 4) the center of a light guide cylinder deviates from the center of the gear ring; 5) the layer beam enters into the processing surface of the gear side of the gear ring; 6) a guide head moves up and down to match the periodic rotating of the rotary platform with small angle and scale division; or the light guide head moves up and down and rotates to form a laser hardening zone at the processing surface; 7) a primary switch is blocked by light to finish laser hardening treatment on all the gear surface of the gear ring (1). The rigidity and the wear-resistance when the two side gear surfaces of each gear of the gear ring are engaged with the gear surface of a planet gear are improved; simultaneously, as the self-owned characteristics of laser quenching, the quenching deformation of the gear ring is very small which completely meets the technical demands for design and production.

Owner:CHINA FIRST AUTOMOBILE

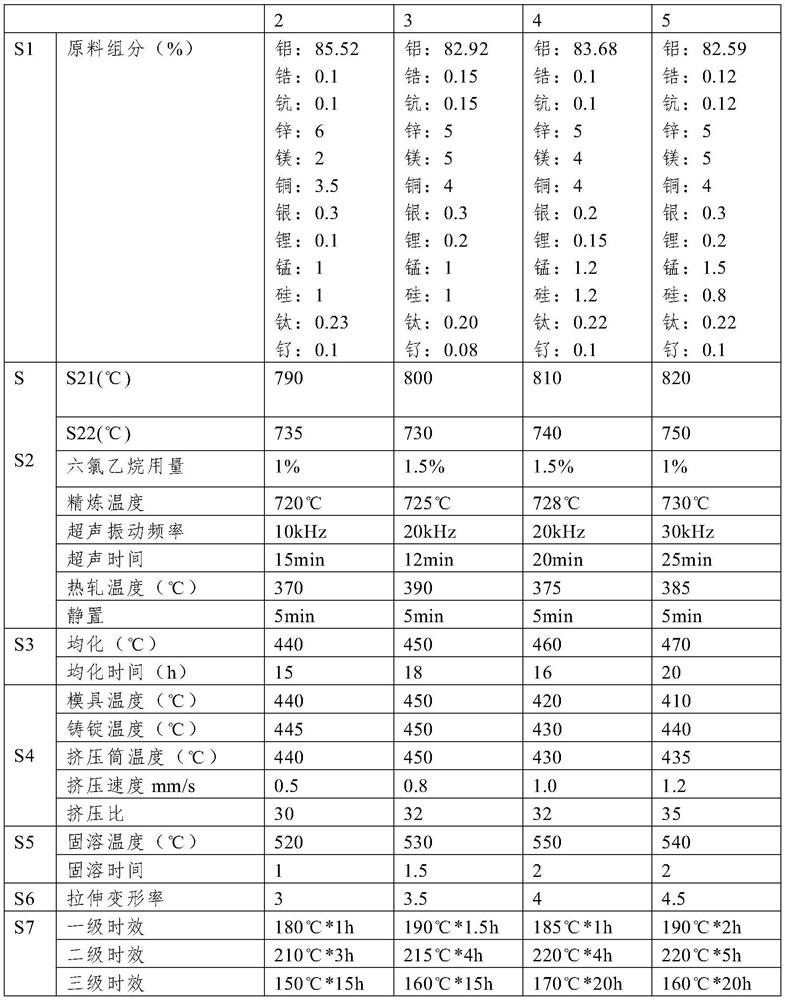

Corrosion resistance aluminum alloy plate for aviation and preparation method of corrosion resistance aluminum alloy plate

InactiveCN111926225AImproves corrosion performance and toughnessGood overall performanceCorrosionAluminium alloy

The invention relates to the technical field of aluminum alloy processing, in particular to a preparation method of an aluminum alloy plate for aviation. The aluminum alloy comprises the following chemical components of, in percentage by mass, 0.05%-0.2% of zirconium, 0.05%-0.2% of scandium, 3.0%-6.0% of zinc, 3.0%-6.0% of magnesium, 3.0%-4.0% of copper, 0.2%-0.4% of silver, 0.05%-0.2% of lithium,1.0%-1.5% of manganese, 0.8%-1.5% of silicon, 0.20%-0.40% of titanium, 0.05%-0.1% of ruthenium, and the balance aluminum and inevitable impurities, and the content of the impurities is controlled tobe 0.15% or below; and an aluminum alloy melt is prepared according to pre-prepared materials, ultrasonic vibration is adopted in a refining process to refine grains, and then the aluminum alloy platefor the aviation is obtained through pouring, homogenization, extrusion, solid solution treatment, pre-stretching and three-stage aging treatment. According to the corrosion resistance aluminum alloyplate for the aviation and the preparation method of the corrosion resistance aluminum alloy plate, the Vickers hardness of the prepared aluminum alloy plate ranges from 175 Hv to 190 Hv, the yield strength ranges from 520 MPa to 562 MPa, the tensile strength ranges from 605 MPa to 656 MPa, the elongation ranges from 9.4% to 12%, the overall performance is excellent, and the aluminum alloy plateis particularly suitable for being used in the aerospace field.

Owner:湖南恒佳新材料科技有限公司

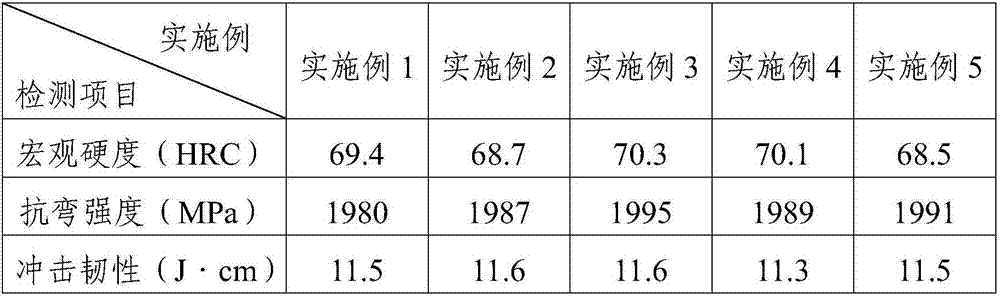

Abrasion resistant and high-hardness high chromium cast iron and production process thereof

The invention provides a wear-resistant high-hardness high-chromium cast iron and a production process thereof, which relate to the field of metal casting and contain the following components in weight percentage: C 2.52-4.87%, Cr 25.5-35%, Si 1.5-2.5% , Mn 0.2‑0.8%, Mo 0.3‑0.8%, Cu 0.8‑1.5%, Ni 0.25‑0.48%, V 0.13‑0.28%, Al 0.4‑1.2%, Nb 0.28‑0.46%, Bi 0.08‑0.14%, and others For iron and other unavoidable impurities, the high-chromium cast iron can be obtained after the raw materials are melted, deoxidized three times, modified by a Re-Al-Bi-Mg compound modifier, inoculated with a rare earth inoculant, cast, quenched and tempered, The high chromium cast iron produced by the invention has the advantages of good wear resistance, high hardness, macroscopic hardness, high bending strength and impact toughness, and easy processing.

Owner:安徽巨泰机械制造有限公司

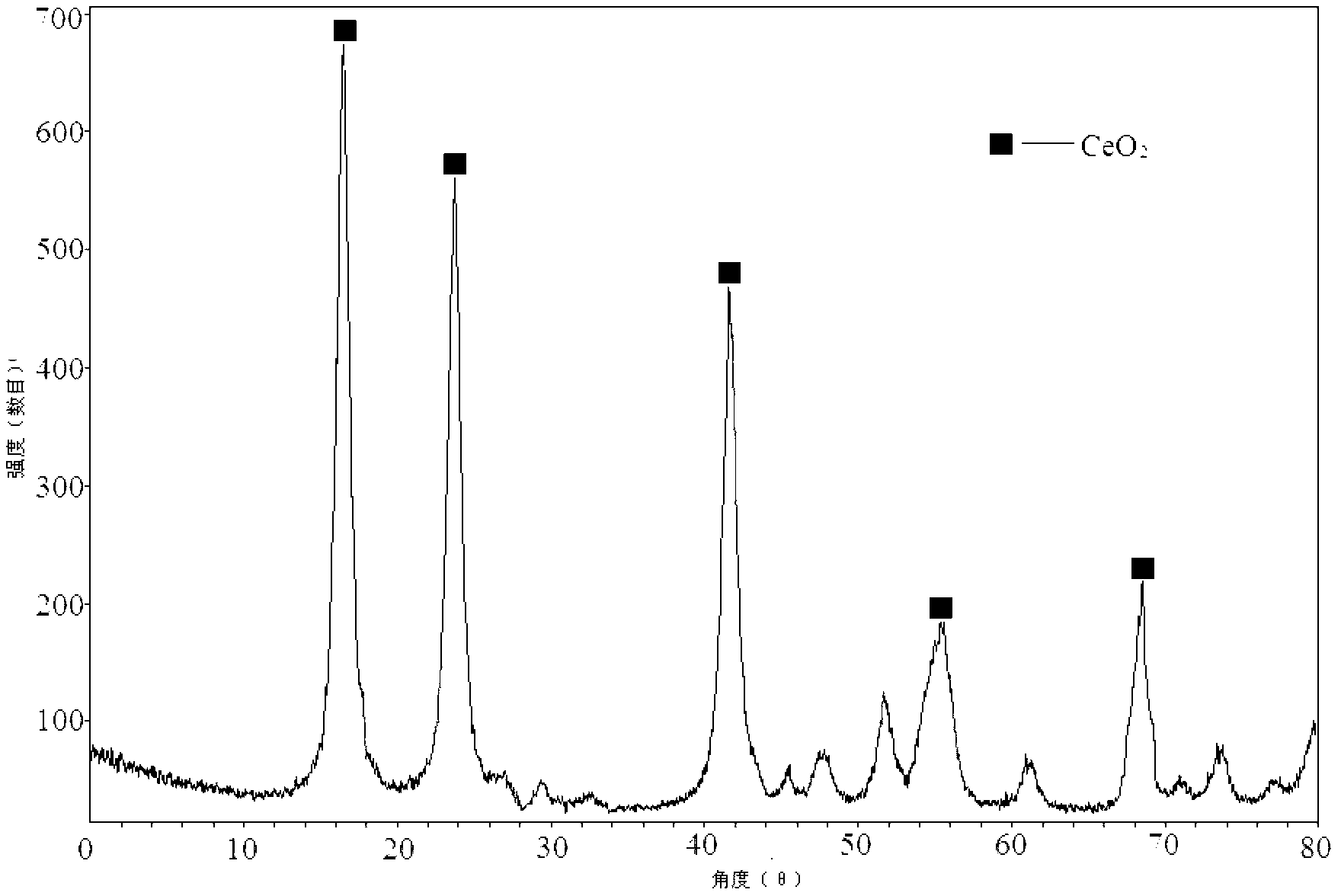

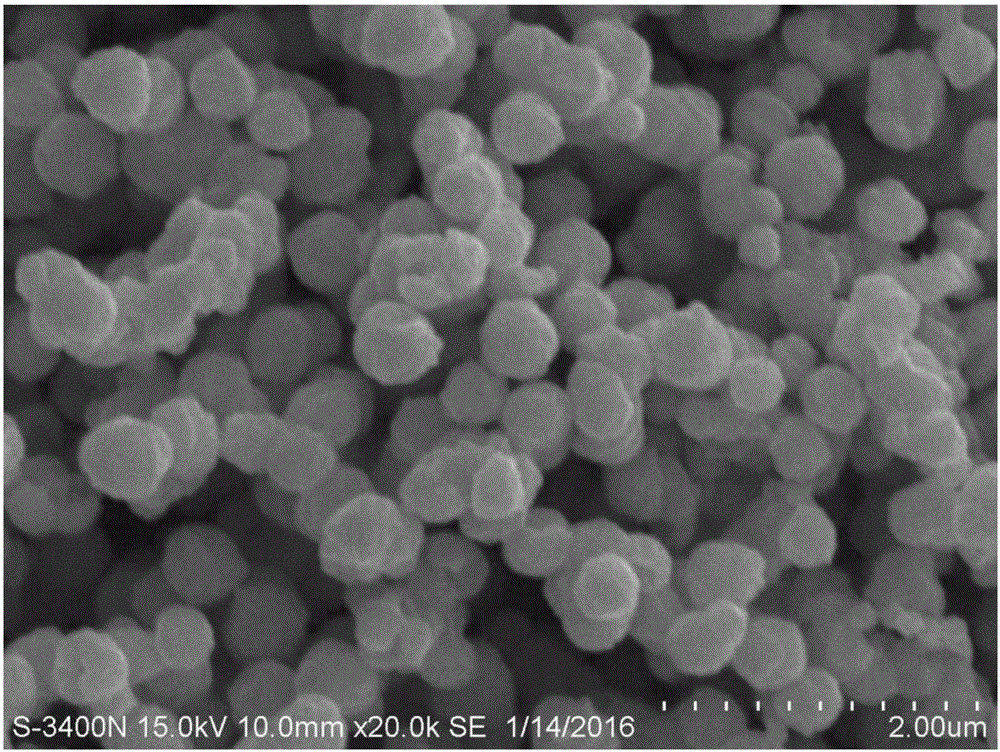

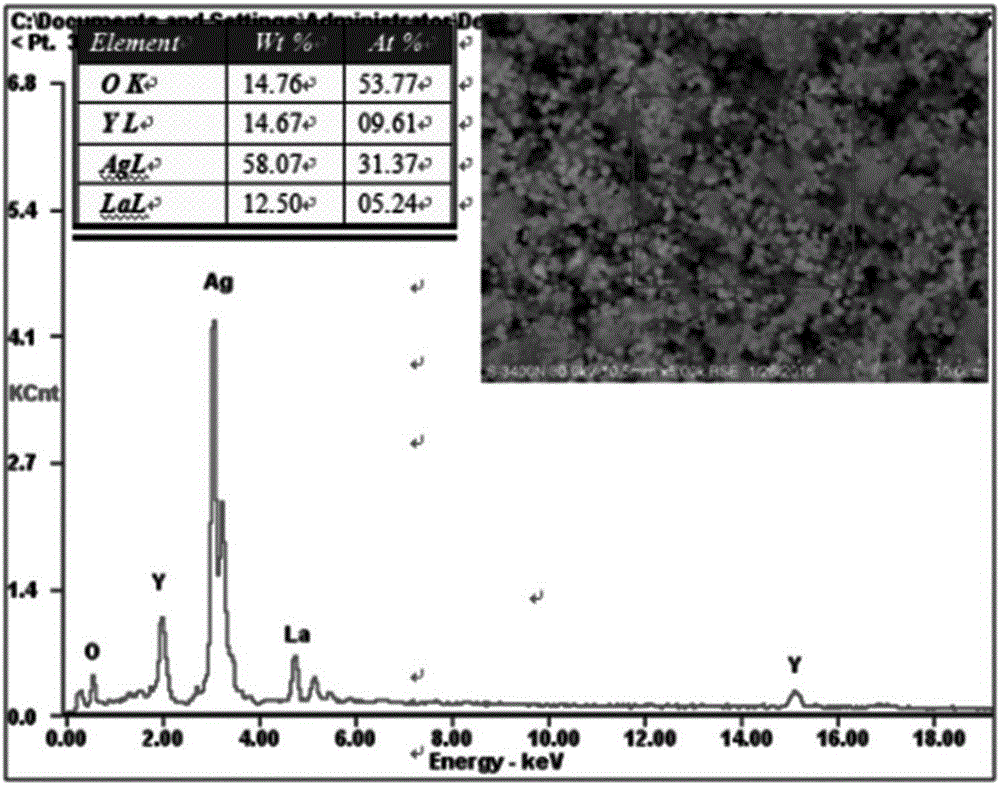

Novel silver rare earth oxide alloy and preparing method thereof

InactiveCN105695791AEase of industrial productionLow costTransportation and packagingMetal-working apparatusAlloyElectric properties

The invention discloses a novel silver rare earth oxide alloy and a preparing method thereof. According to the method, a chemical reduction method and a high-energy ball milling method are combined to prepare nano silver and rare earth oxide powder, and a powder metallurgy technology is used for preparing a novel silver rare earth oxide electric contact material; and the contact material has the higher hardness, density and specific conductance. The silver rare earth oxide electric contact material comprises, by weight percent, 3.0% to 8.0% of Y2O3, 2.0% to 8.0% of La2O3 and the balance Ag. Raw materials used in the method are easily obtained and few, and the cost is low; the technology for combining the chemical reduction method and the high-energy ball milling method to prepare the nano silver and rare earth oxide powder is simple, industrialized production is easily achieved, the method is environment-friendly, the service life of a contact is long, and the higher hardness and density are achieved; and the contact material has the excellent electric performance, meanwhile, the electric contact properties of wear resisting, corrosion resisting, electric arc burning loss resistance, fusion welding resistance and the like are achieved, and therefore the contact performance and the reliability of an electric appliance are improved.

Owner:KUNMING INST OF PRECIOUS METALS

Generating unit comprising a combustion engine and a generator

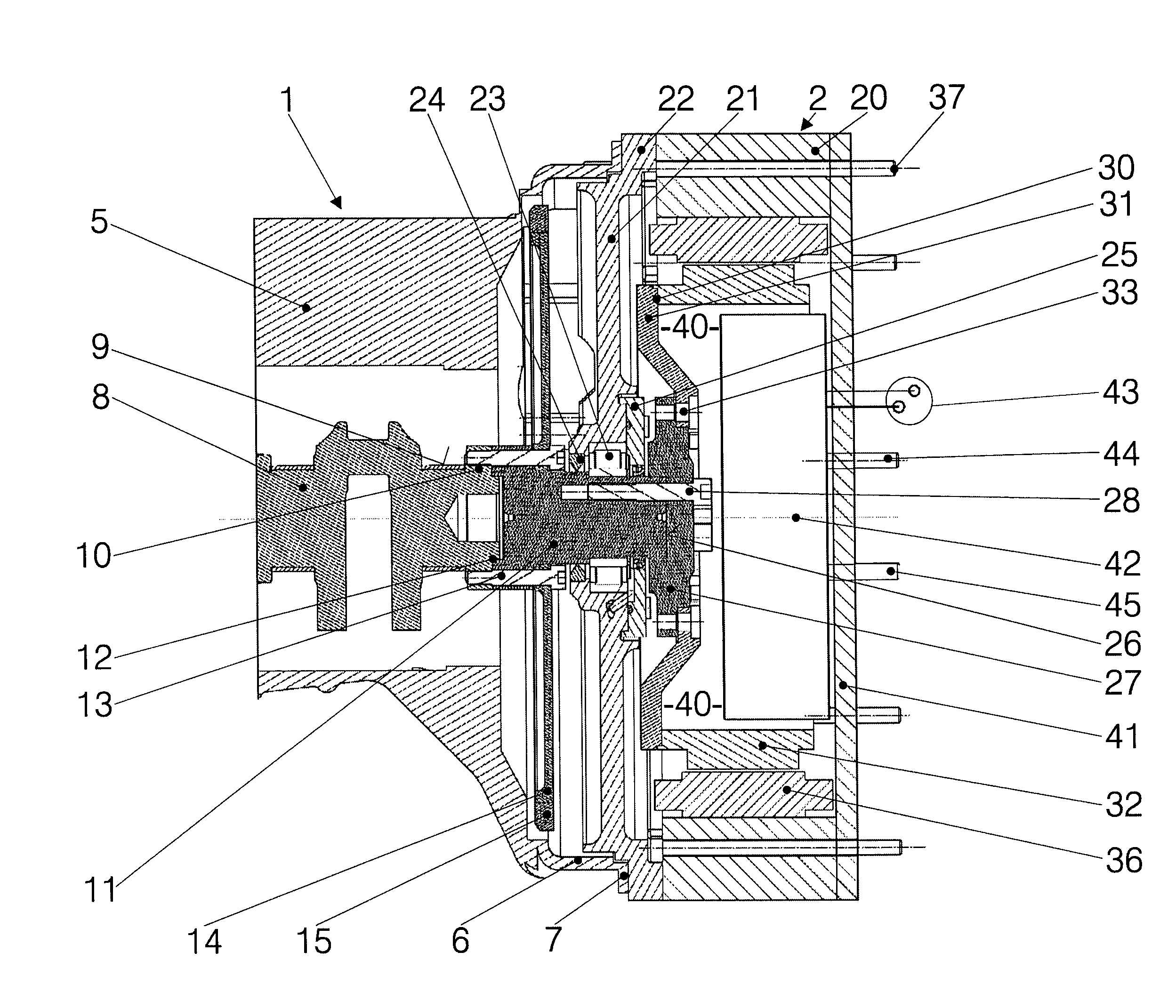

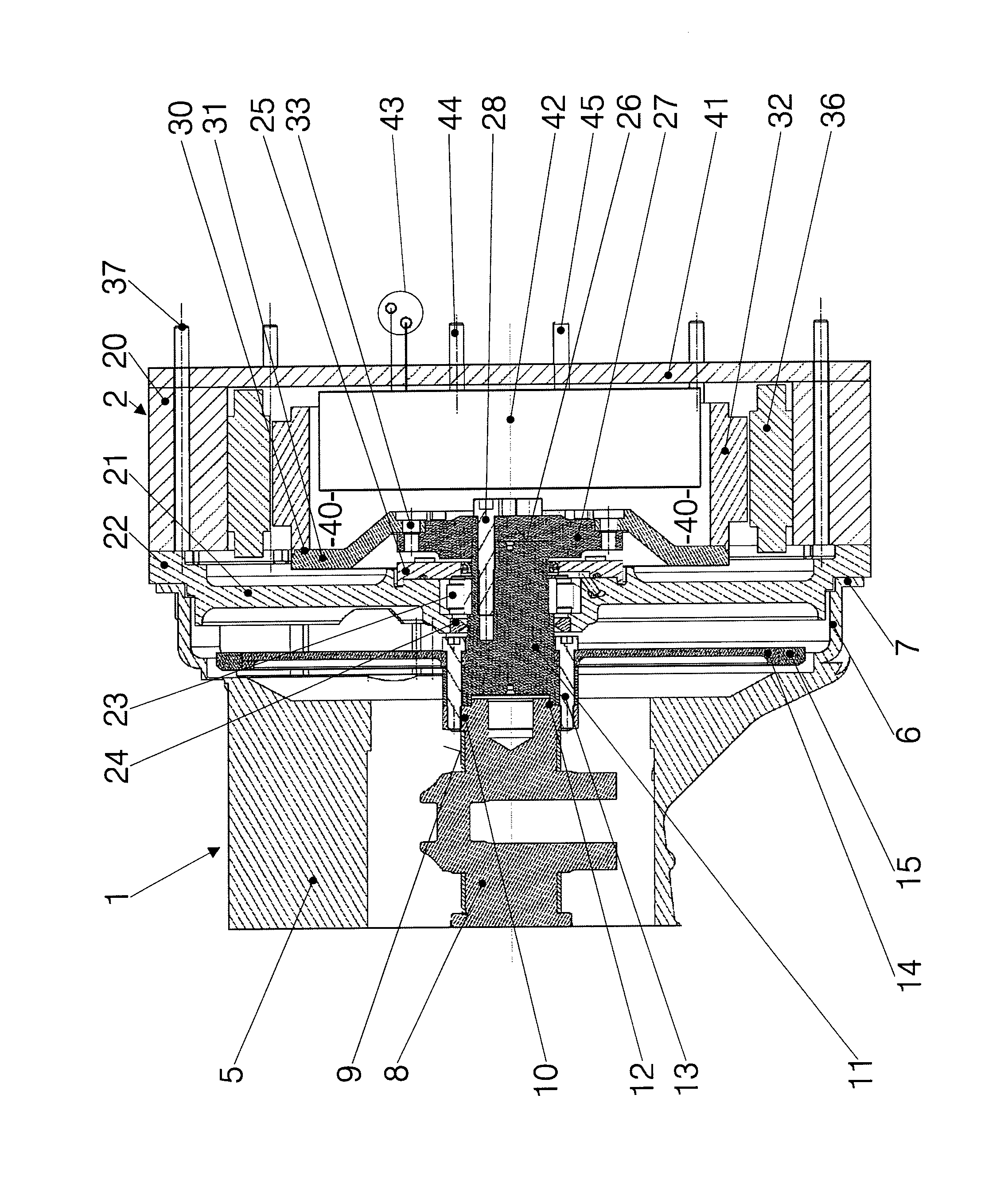

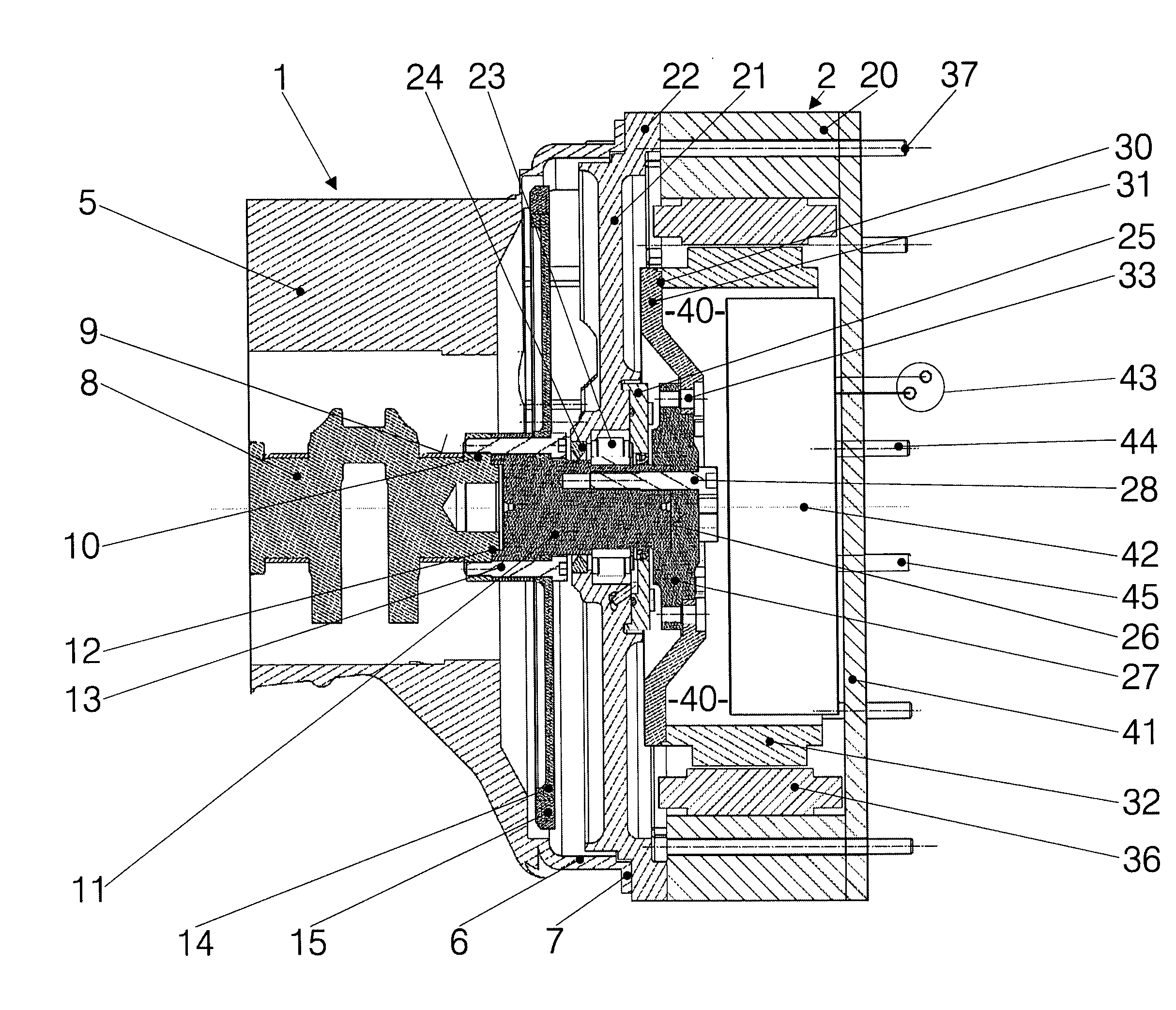

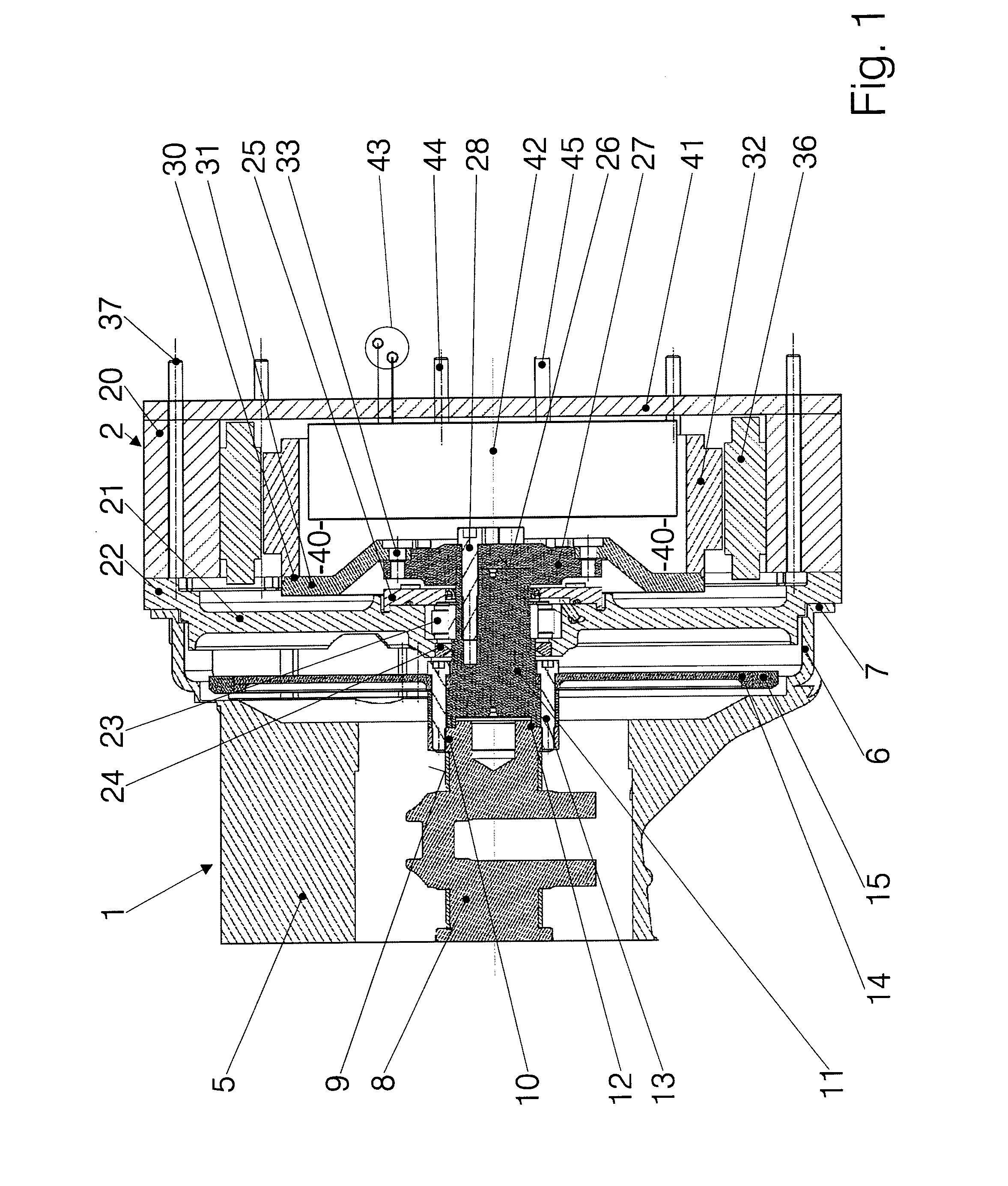

ActiveUS8227931B2Increase stiffnessEasy accessElectric machinesPropulsion using engine-driven generatorsCombustionCrankcase

A power generating unit consists of an internal combustion engine (1) and a generator (2), the former comprising a crankshaft (8) received in a crankcase (5) and the generator comprising a generator housing (20) connected to the crankcase (5), a stator (36) and a rotor (30) that is connected so as to rotate with the crankshaft (8). The aim is to provide a power generation unit that requires little space and that allows a precise guidance of a rotor designed for the overall unit power. A concentric stub shaft (11) is fixedly connected at the one end to the crankshaft (8) and at the other end to the rotor (30). The generator housing (20), on its side facing the internal combustion engine (1), has a front plate (21) that accommodates a bearing (23) for the sub shaft (11). The rotor (30) is otherwise overhung.

Owner:STEYR MOTORS BETRIEBS GMBH

Generating unit comprising a combustion engine and a generator

ActiveUS20100127508A1Increase stiffnessEasy accessPropulsion using engine-driven generatorsElectric machinesCombustionEngineering

A power generating unit consists of an internal combustion engine (1) and a generator (2), the former comprising a crankshaft (8) received in a crankcase (5) and the generator comprising a generator housing (20) connected to the crankcase (5), a stator (36) and a rotor (30) that is connected so as to rotate with the crankshaft (8). The aim is to provide a power generation unit that requires little space and that allows a precise guidance of a rotor designed for the overall unit power. A concentric stub shaft (11) is fixedly connected at the one end to the crankshaft (8) and at the other end to the rotor (30). The generator housing (20), on its side facing the internal combustion engine (1), has a front plate (21) that accomodates a bearing (23) fort he sub shaft (11). The rotor (30) is otherwise overhung.

Owner:STEYR MOTORS BETRIEBS GMBH

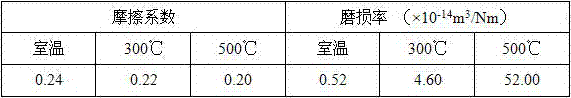

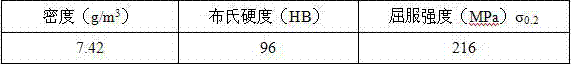

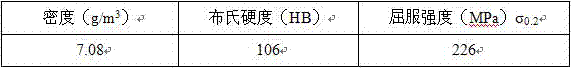

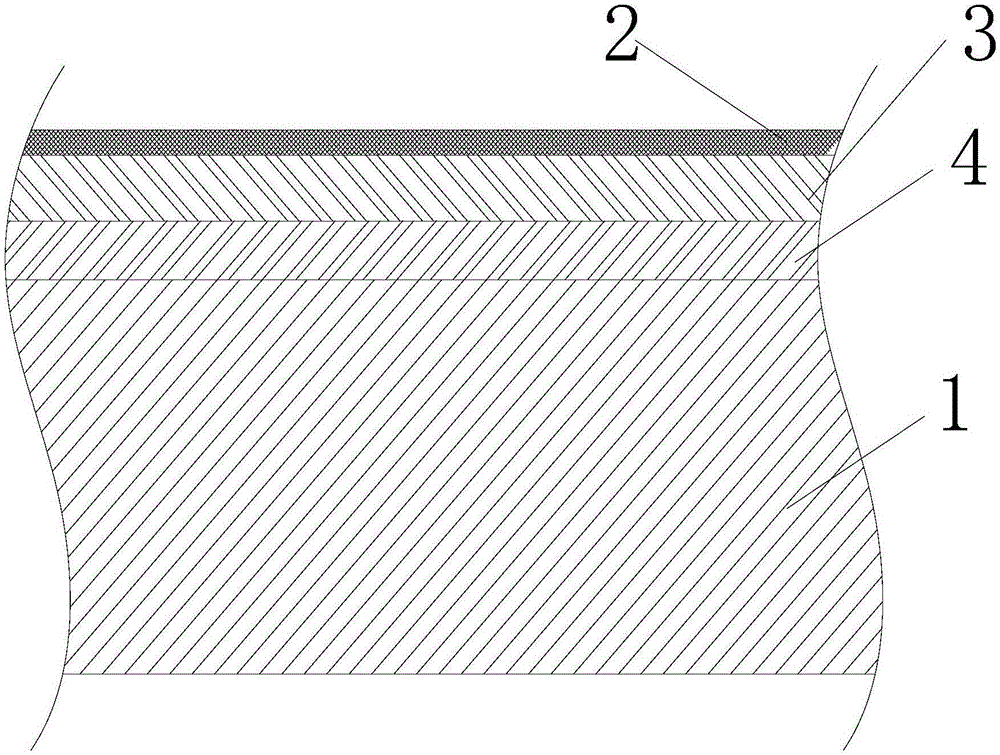

CuNiSn alloy-based self-lubricating composite material used at room temperature to 500 DEG C and preparation method thereof

The invention discloses a CuNiSn alloy-based self-lubricating composite material used at the room temperature to 500 DEG C and a preparation method thereof. The material is composed of, by mass, 1-12% of Ni, 3-6% of Sn, 0.5-3% of Fe, 0.01-0.08% of Al, 0.01-0.08% of Ti, 1.0-4.0% of graphite, 1.0-6.0% of PbO, 0.1-1.0% of CeF3 and the balance Cu. The material has high-hardness, high-strength, low-friction, abrasion-resistant and self-lubricating characteristics at the room temperature to 500 DEG C and is suitable for manufacturing sliding bearings, sliding plates, rolling bearing holding frames or other parts for equipment within the temperature range.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

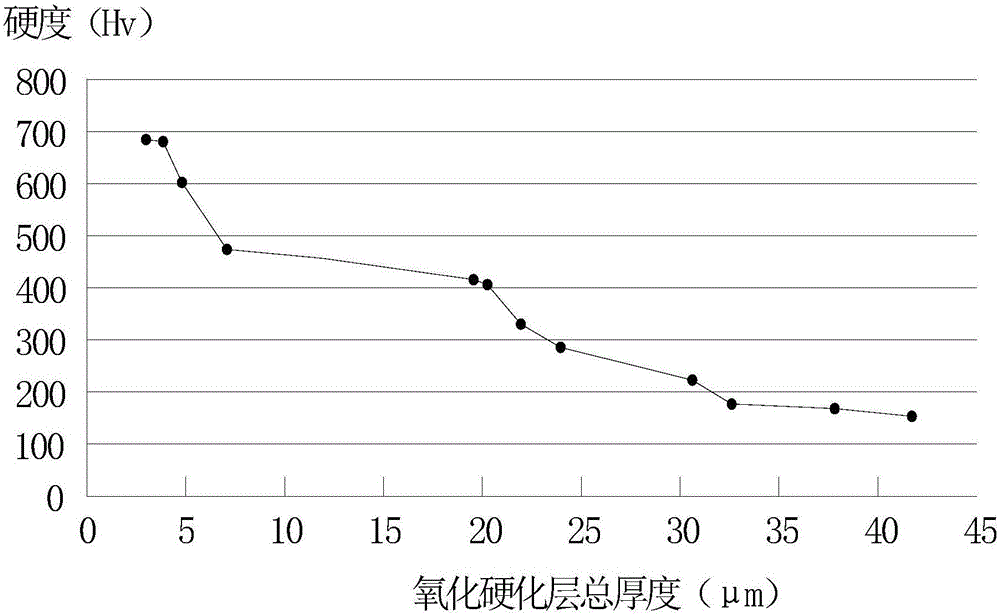

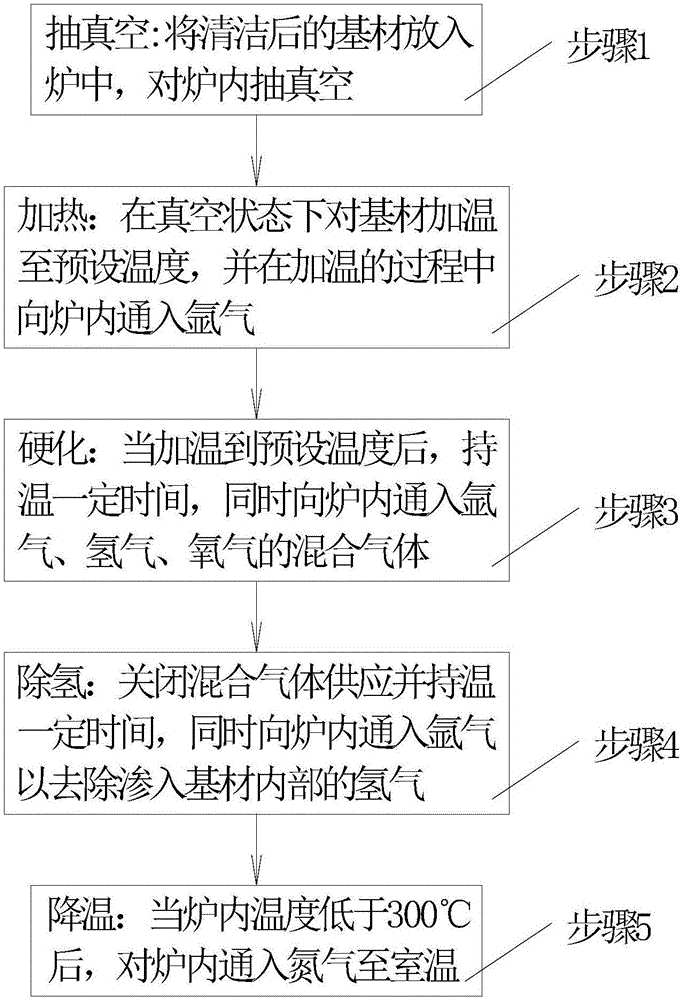

Pure titanium or titanium alloy and surface hardening method thereof

InactiveCN106637049AImprove protectionHigh surface hardnessSolid state diffusion coatingHydrogenCase hardening

Owner:中山源谥真空科技有限公司

Silver alloy compositions

Fire-scale resistant, work-hardenable-jewelry, silver-alloy compositions having desirable properties of reduced fire scale, reduced porosity, oxide formation and reduced grain size relative to traditional sterling silver alloys while providing improved work hardening performance. These compositions contain at least 86% by weight silver, 0-5-7.5% by weight copper, 0.07-6% by weight of a mixture of zinc an silicon with silicon being present in an amount from about 0.02 to about 2.0% by weight, and from about 0.01 to no more than 2.0% by weight germanium.

Owner:ECCLES ANTHONY

A device and method for sheet metal multi-point punch liquid-filled deep drawing

The invention discloses a multi-point male die liquid-filling drawing forming device and a multi-point male die liquid-filling drawing forming method for a plate, relates to a device and a method for forming thin-walled curved plate parts, and aims to solve the problem of difficulty in forming of thin-walled and deep-cavity parts with complicated curved surfaces. A plurality of small punches are independently arranged; the upper ends of the small punches penetrate into through holes in a male die body; the upper end of each small punch is connected with a linear driving device; a female die is a semi-closed cavity of which the upper end is opened and the lower end is closed; an elastic base plate and a metal protection plate are superposed on the upper end surface of the female die from bottom to top. The heights of the small punches are adjusted to realize the construction of an outer contour of a multi-point male die; a to-be-formed plate blank, the elastic base plate and the metal protection plate are sequentially arranged on the upper end surface of the female die; a blank holder moves down to be assembled with the female die, and the multi-point male die moves down and applies a drawing force to the to-be-formed plate blank; meanwhile, a liquid medium is filled into an inner cavity of the female by the aid of a pressurizing system until drawing is completed to obtain parts of a required shape. The device and the method are used for forming the plate, and the thin-walled and deep-cavity parts with the complicated curved surfaces can be formed.

Owner:HARBIN INST OF TECH

Submicron-scale and lower-micron graphitic fibrils as an anode active material for a lithium ion battery

ActiveUS8501348B2Good hardening effectImprove cooling effectElectrode thermal treatmentSecondary cellsFiberCarbon fibers

The present invention provides a lithium ion battery anode material comprising a submicron-scaled graphitic fibril having a diameter or thickness less than 1 μm but greater than 100 nm, wherein the fibril is obtained by splitting a micron-scaled carbon fiber or graphite fiber along the fiber axis direction. This type of graphitic fibril exhibits exceptionally high electrical conductivity, thermal conductivity, elastic modulus, and strength. The anode material exhibits a high reversible capacity and good charge / discharge cycling stability for both low and high charge rate conditions. Another preferred embodiment of the present invention is an anode active material containing a graphitic fibril with a diameter greater than 1 μm but less than 6 μm obtained by splitting a carbon fiber or graphite fiber of at least 6 μm in diameter.

Owner:GLOBAL GRAPHENE GRP INC

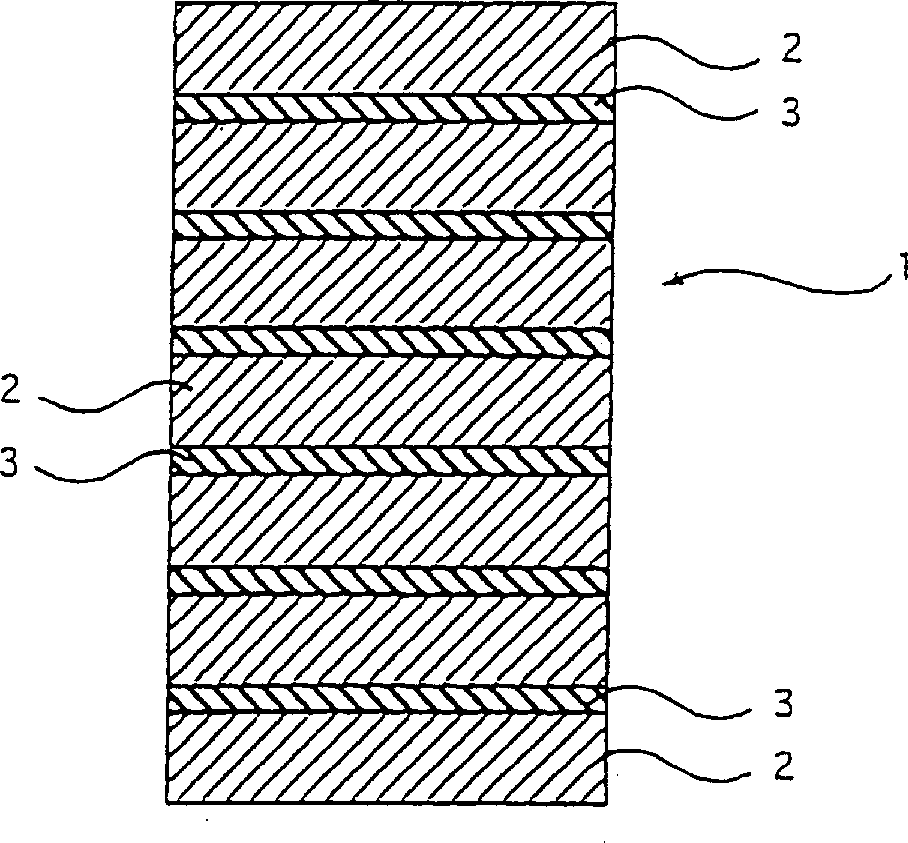

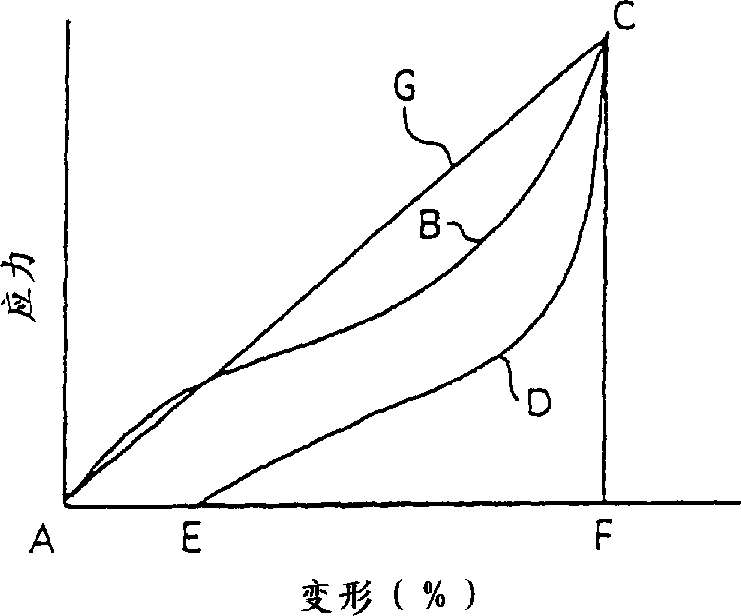

Rubber composition for seismic isolation laminates

InactiveCN1245512AIncrease dampingGood hardening effectFoundation engineeringRubber-like material springsIodineSeismic isolation

This invention relates to a rubber composition for seismic isolation laminate which exhibits excellent damping capacity as well as sufficient hardening properties. Such rubber composition for a seismic isolation laminate comprises at least a diene rubber; and 40 to 160 parts by weight of carbon black having a CTAB specific surface area of 120 to 370 (m / g) and a CTAB specific surface area (m<2> / g) / iodine adsorption (mg / g) of up to 1.0 per 100 parts by weight of the diene rubber.

Owner:YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com