A device and method for sheet metal multi-point punch liquid-filled deep drawing

A technology of liquid-filled deep drawing and punching, which is applied to the forming device of deep-cavity plate parts, complex curved surfaces, and thin-walled fields. Problems such as uneven distribution of billet wall thickness achieve the effect of less quantity, improved forming limit and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

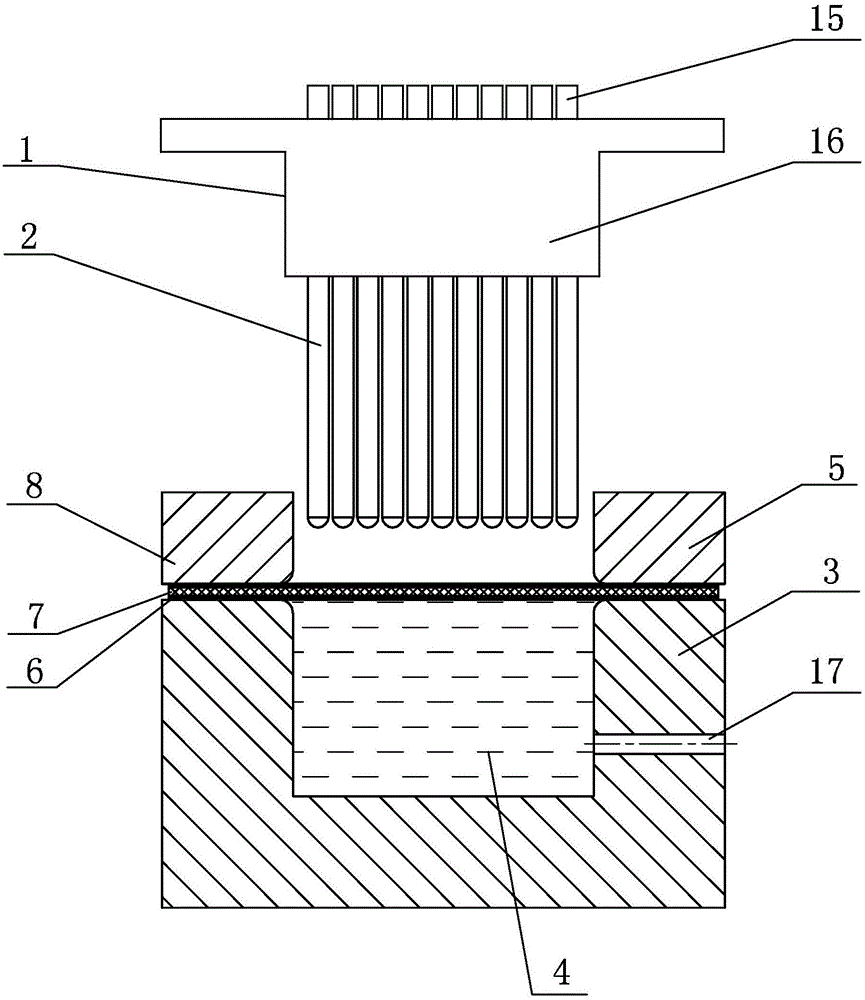

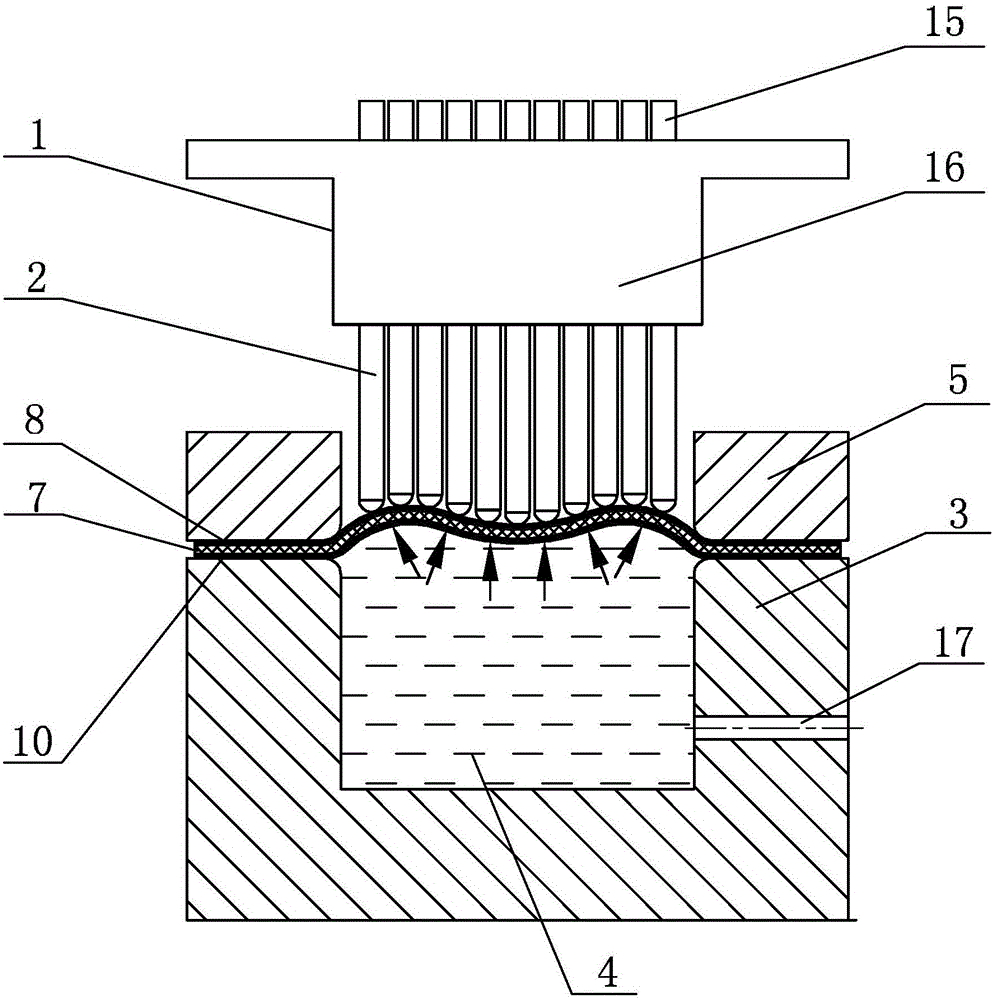

[0042] Specific implementation mode one: as Figure 1 to Figure 7 As shown, a sheet material multi-point punch liquid-filled deep drawing device in this embodiment includes a die 3, a blank holder 5, an elastic backing plate 7 and a metal guard plate 8, and the device also includes a multi-point punch Die 1 and a plurality of linear drive devices 15; the multi-point punch 1 and blankholder 5 are all arranged directly above the die 3, the multi-point punch 1 includes a punch body 16 and a plurality of small punches 2, A plurality of small punches 2 are vertically arranged independently of each other and form a punch module. The punch body 16 is positioned directly above the plurality of small punches 2. The corresponding position of the punch body 16 is provided with Multiple through holes, the quantity of the through holes is consistent with the quantity of the small punches 2, the upper ends of the multiple small punches 2 correspond to the multiple through holes of the punch...

specific Embodiment approach 2

[0044] Specific implementation mode two: combination Figure 1 to Figure 7 Note that the elastic backing plate 7 in this embodiment is a polyurethane plate or a rubber plate; the metal guard plate 8 is a low carbon steel plate, a stainless steel plate or an aluminum alloy plate. The thickness of the metal guard plate 8 and the elastic backing plate 7 can be selected according to the forming needs. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

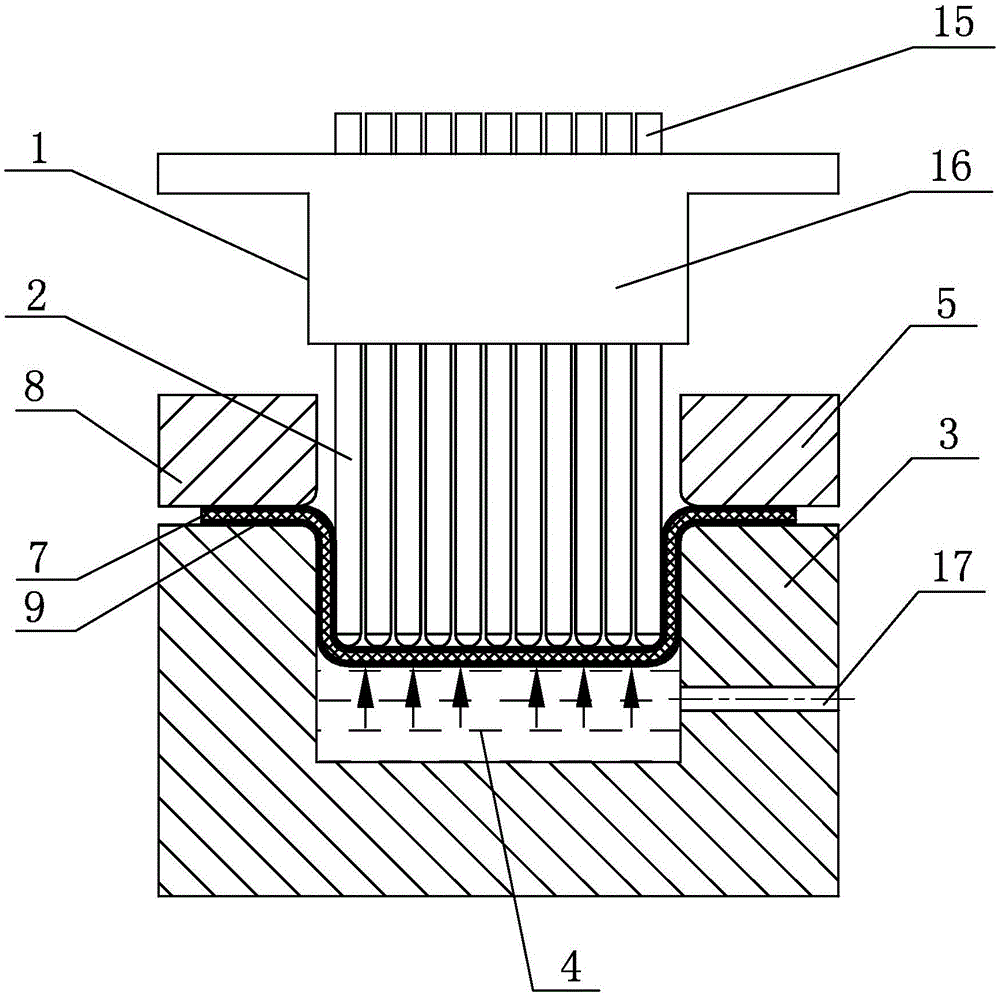

[0045] Specific implementation mode three: combination figure 1 , figure 2 To illustrate, in this embodiment, using the device described in Specific Embodiment 1 or 2 to realize the forming method of sheet multi-point punch liquid-filled deep drawing, the method includes the following steps (liquid-filled deep drawing)

[0046] Step 1: First, according to the shape of the part 9, adjust the heights of the plurality of small punches 2 respectively to realize the outer contour configuration of the multi-point punch 1, and then place the slabs 6 to be formed on the upper end surface of the die 3 in sequence , elastic backing plate 7 and metal guard plate 8;

[0047] Step 2: The blank holder 5 is driven downward by the blank holder slider of the press to close the mold with the die 3, and then the multi-point punch 1 is driven downward by the deep drawing slider of the press and applied to the slab 6 to be formed. 10-1000t drawing force; at the same time, through the pressuriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com