Multi-blank-holder radial blocking-blank pressing method applied to nonaxisymmetrical piece

A non-axisymmetric, blank holder ring technology, applied in the blank holder field, can solve the problem of separate blank holder, reduce the total blank holder force, improve the forming quality and forming limit, and optimize the blank holder effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings by taking the box-shaped part as an example:

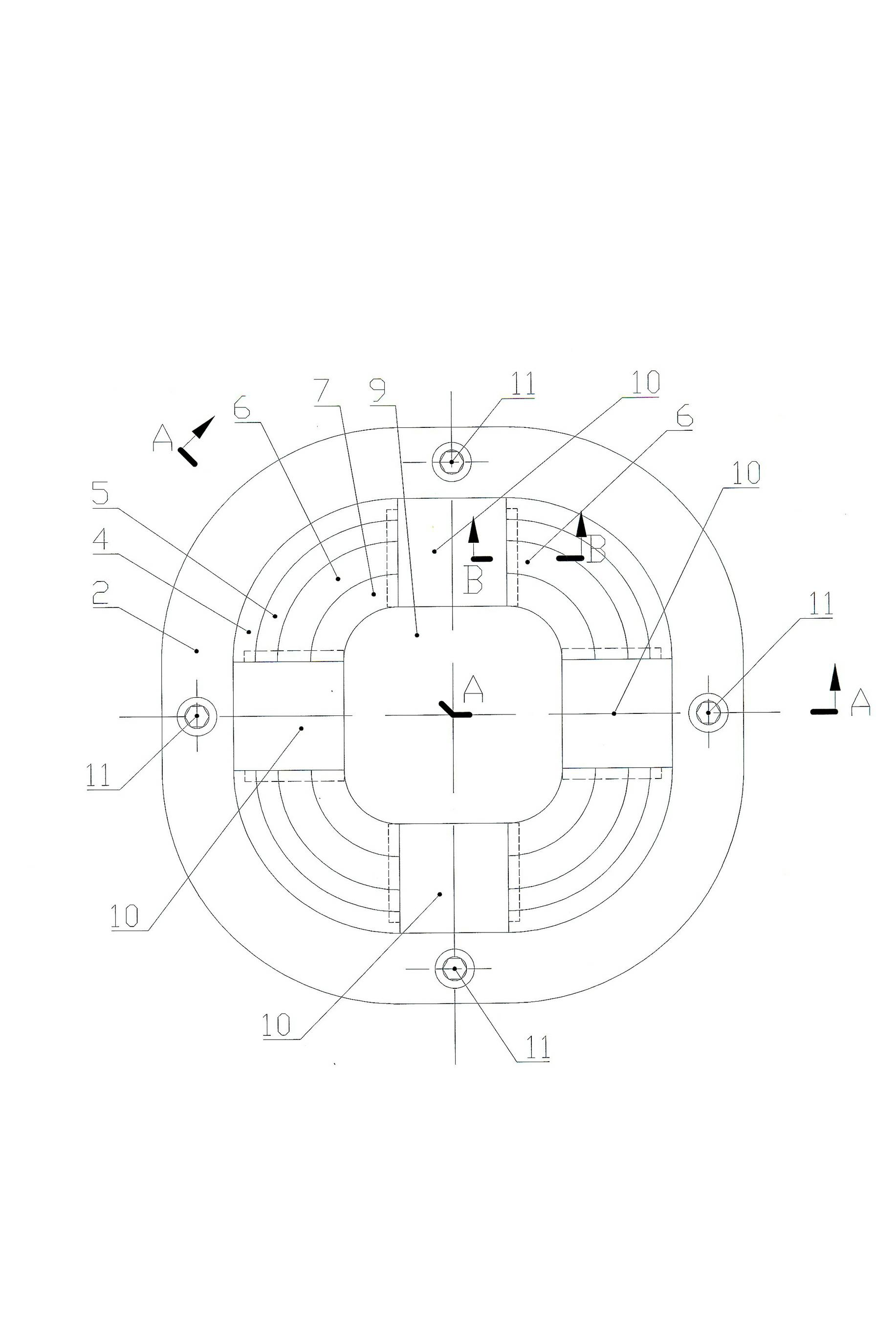

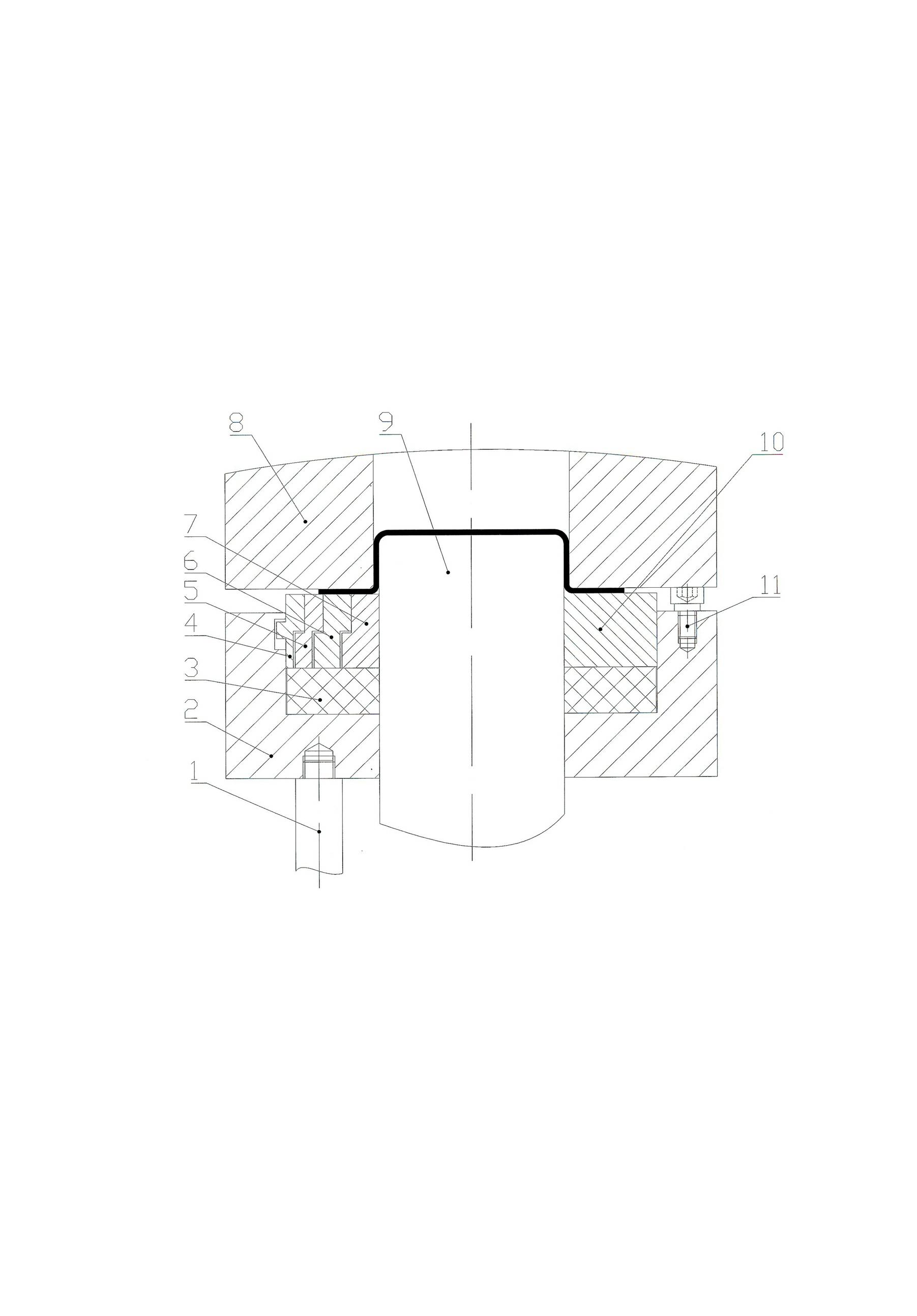

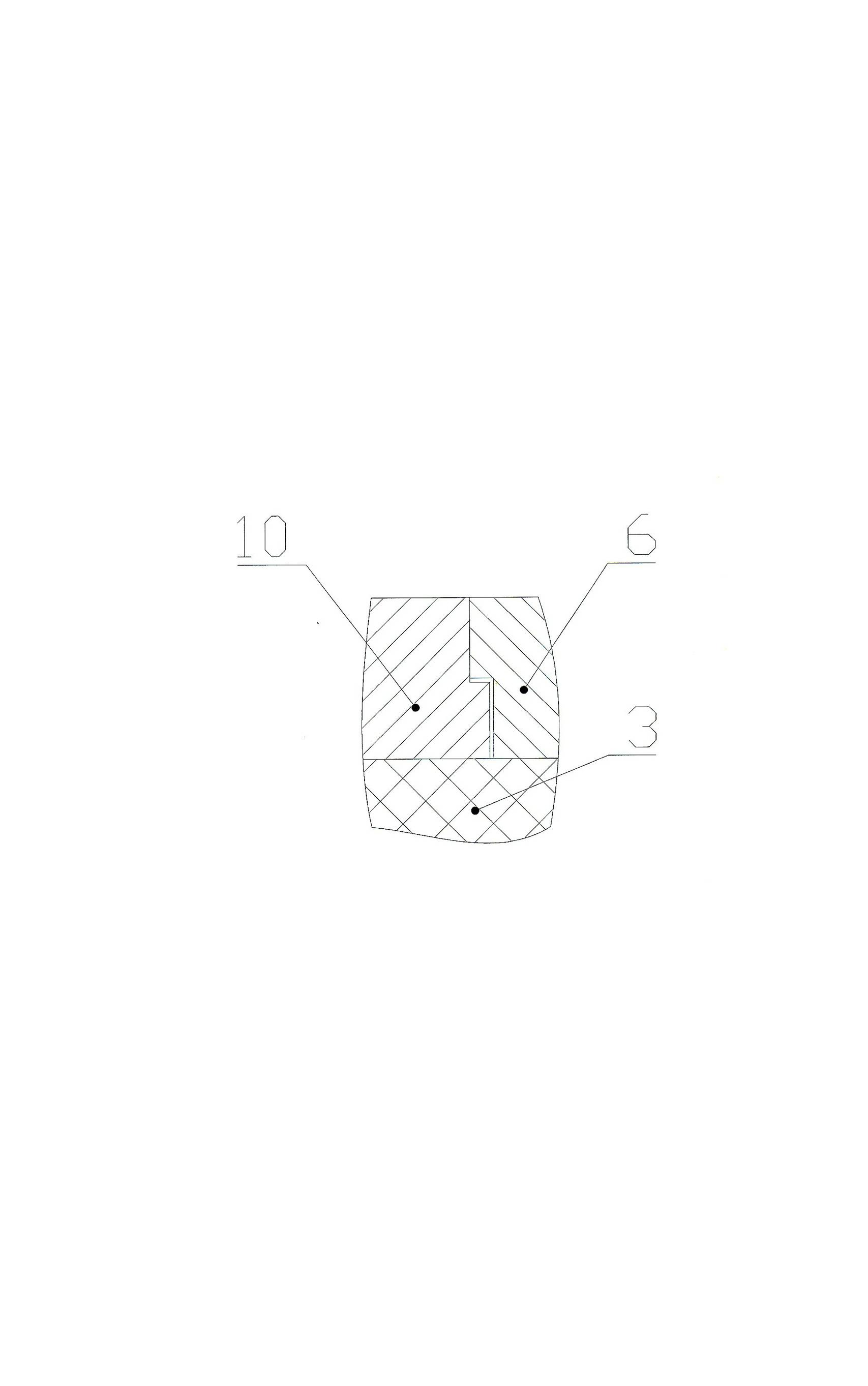

[0013] The structural forms and relative positions of each blank holder and force transmission plate are as follows: figure 1 , 2 , 3 shown.

[0014] As shown in the accompanying drawings, the blank holder area is divided into eight, four in the straight edge area and four in the rounded corner area, and each rounded corner area is divided into four small areas according to the radial position; the blank holder ring 10 It is mainly used for blanking of straight edges. The four blanking rings 4, 5, 6 and 7 in each fillet area are mainly used for blanking of rounded corners. Each blanking ring moves in the vertical direction without interfering with each other. , respectively provide blank-holding force.

[0015] In the actual drawing process, when the upper mold goes down, the die 8 first contacts the slab, and the blank ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com