Magnetic pulse flanged hole method for shells

A technology of shell parts and magnetic pulses is applied in the field of plastic forming and manufacturing of metal sheets, which can solve the problems of complex process, long production cycle and low production efficiency, and achieve the effects of simplified process, short forming cycle and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

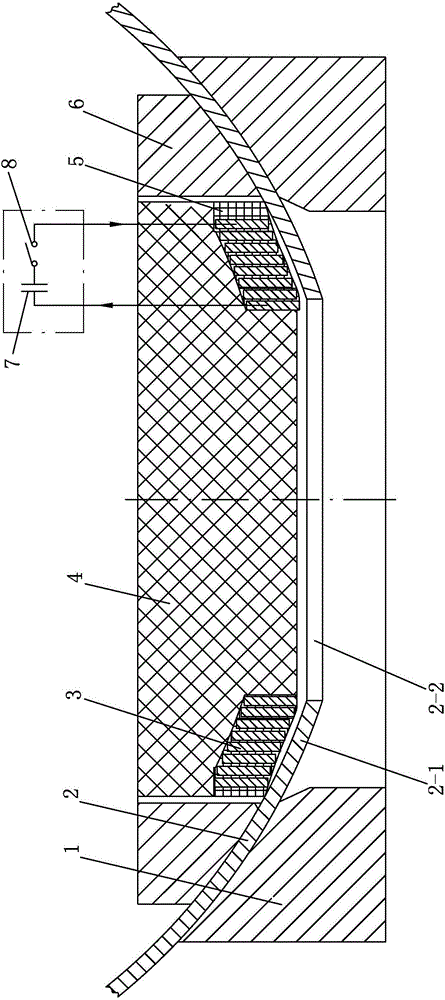

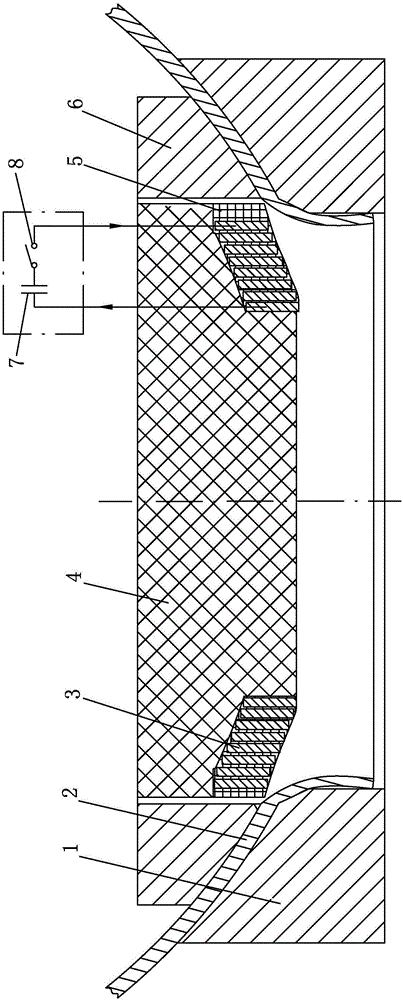

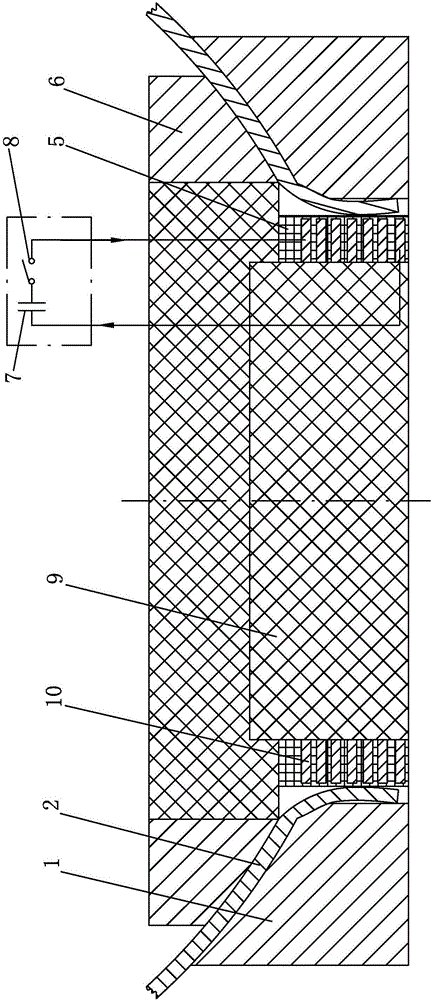

[0013] Specific implementation mode one: combine Figure 1-Figure 4 Explain, a kind of magnetic pulse hole turning forming method of shell parts, it comprises the following steps:

[0014] Step 1. Design the shape of the hole turning coil 3 according to the curved shell part 2 that has processed the prefabricated hole 2-2;

[0015] Step 2. Place the curved shell part 2 that has processed the prefabricated hole 2-2 on the hole forming die 1. The inner surface of the curved shell part 2 is provided with a blank holder 6 along the circumferential direction, and the hole forming die is 1 and the blank holder 6 clamp the curved shell part 2, and reserve the hole-turning deformation area 2-1. 2-1 Matching hole-turning coil 3, hole-turning coil 3 covers and sticks to the hole-turning deformation area 2-1, hole-turning coil 3 is coaxially arranged with prefabricated hole 2-2, and the hole-turning coil is made of rectangular cross-section copper turns Winding;

[0016] One end of th...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 2, the capacitor bank 7 is charged to 1kV-20kV. The induced current in the deformation zone will also generate an induced magnetic field. The coil current magnetic field and the induced current magnetic field are strengthened between the coil and the deformation area of the curved surface part, and through the interaction with the induced current, a normal strong pulse magnetic field force acting on the deformation area of the curved surface part is generated, which meets the design requirements and actual needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 4, the capacitor bank 7 is charged to 1kV-20kV. Such setting is conducive to the generation of large pulse current and the radial pulse load acting on the straight wall of the flanged hole, causing it to produce high-speed radial deformation, thereby reducing the inclination angle and eliminating the bulge, so as to realize the molding. Meet the design requirements and actual needs. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com