Hydraulic pressure molding device and hydraulic pressure molding method

A technology for hydroforming and forming bodies, applied in presses, forming tools, metal processing equipment, etc., can solve the problems of small fracture limit strain of aluminum alloys, difficult to obtain formed bodies, and limited shape types, so as to improve strength and prevent fractures. , the effect of improving the resistance to stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

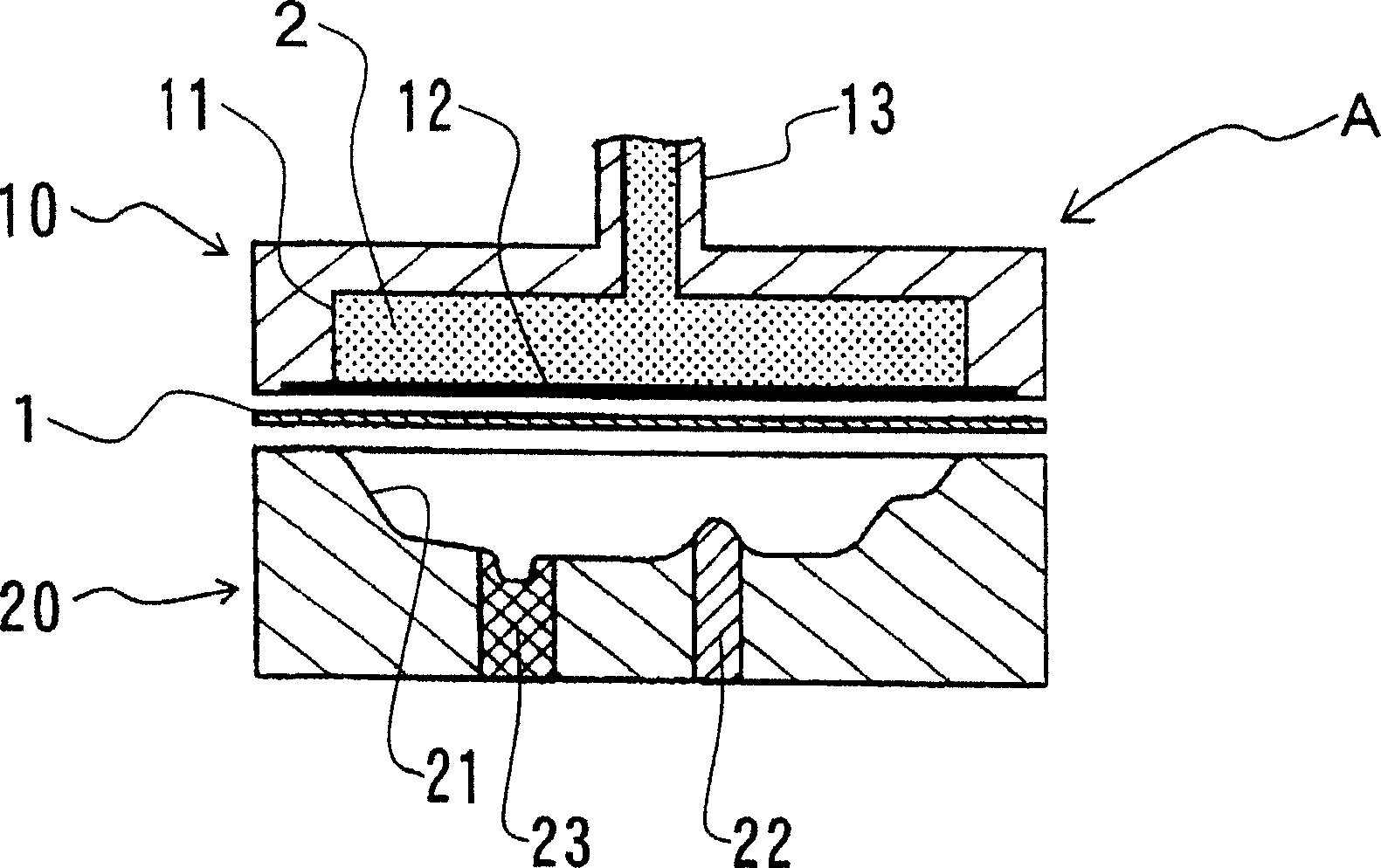

[0036] In the hydroforming device and hydroforming method of the present invention, the blank plate is clamped by the first mold and the second mold to form a desired shape, and the second mold is provided with a concave surface for forming with a predetermined shape for forming the desired shape. , and a liquid medium is accommodated in the first die, and by pressurizing the liquid medium, the blank sheet is pressed toward the concave surface for molding by the liquid medium, and the blank sheet is brought into contact with the concave surface for molding to form a predetermined shape shaped body.

[0037] In particular, the second mold is provided with a deformation resistance adjustment device that locally changes the deformation resistance of the blank plate. Through the first mold and the second mold, the blank plate is stretched using a liquid medium. On the other hand, the deformation resistance is adjusted. The device locally adjusts the blank sheet of the stretched pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com