Process method for improving high pressure forming limit in tube

A technology of internal high pressure forming and process method, which is applied in the field of improving the limit of internal high pressure forming of pipes, can solve problems such as cracking, difficulty in axial feeding, instability and wrinkling, etc., achieves small equipment tonnage, improves uniform deformation capacity, and delays rupture. destabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

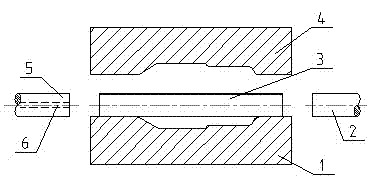

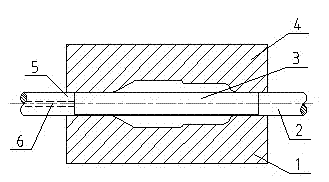

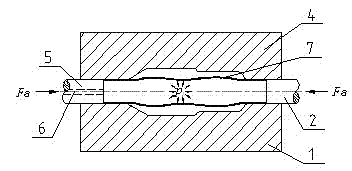

[0030] combined with Figure 1-6 , further describe the present invention:

[0031] 1. Mold operation preparation,

[0032] a, make mold, mold is made up of upper mold 4, lower mold 1 and right punch 2 and left punch 5 at the end, mold cavity is divided into feeding area, bulging area, above-mentioned is the same as prior art, this is not repeat,

[0033] b. Put the initial tube blank 3 into the die 1, the upper die 4 moves down and closes the lower die 1 to complete the mold clamping, and applies the corresponding mold clamping force. , The lower mold will not be separated due to the increase of internal pressure,

[0034] 2. Forming,

[0035] a. The right punch 2 and the left punch 5 at the end are fed axially until the two ends of the tube blank are sealed,

[0036] b. Fill the tube blank with forming medium from the medium filling channel 6 of the end punch until the cavity of the tube blank is completely filled, and keep the internal pressure at p 0 , the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com