High-silicon steel and preparation method thereof

A high-silicon steel and billet technology, which is applied in the field of high-silicon soft magnetic material preparation, can solve the problems of restricting industrial production and large-scale application, difficult processing and molding, and deterioration of magnetic properties, so as to avoid strain hardening, improve elongation, The effect of improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

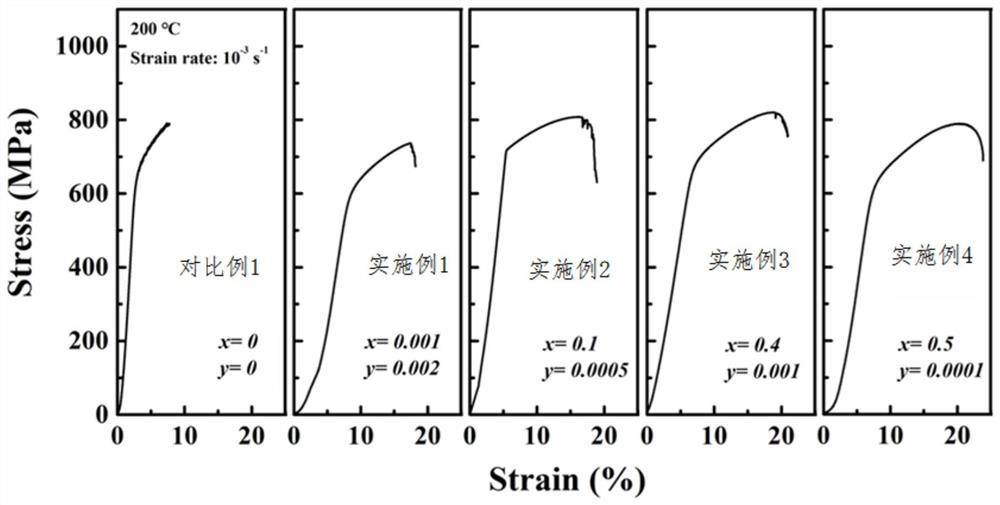

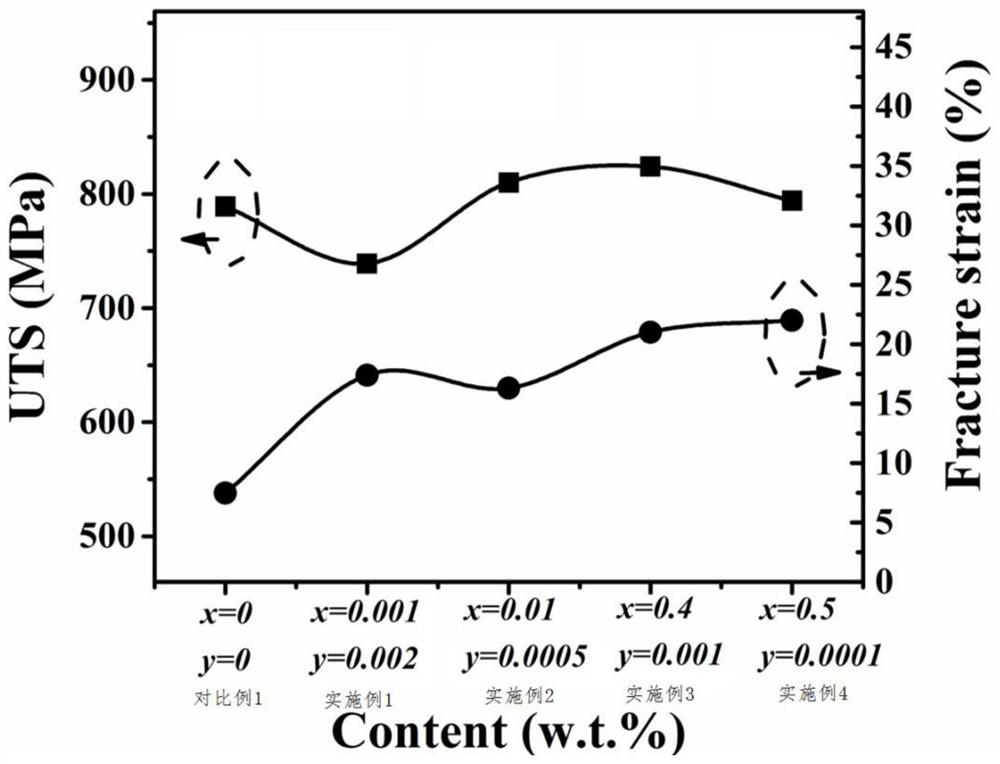

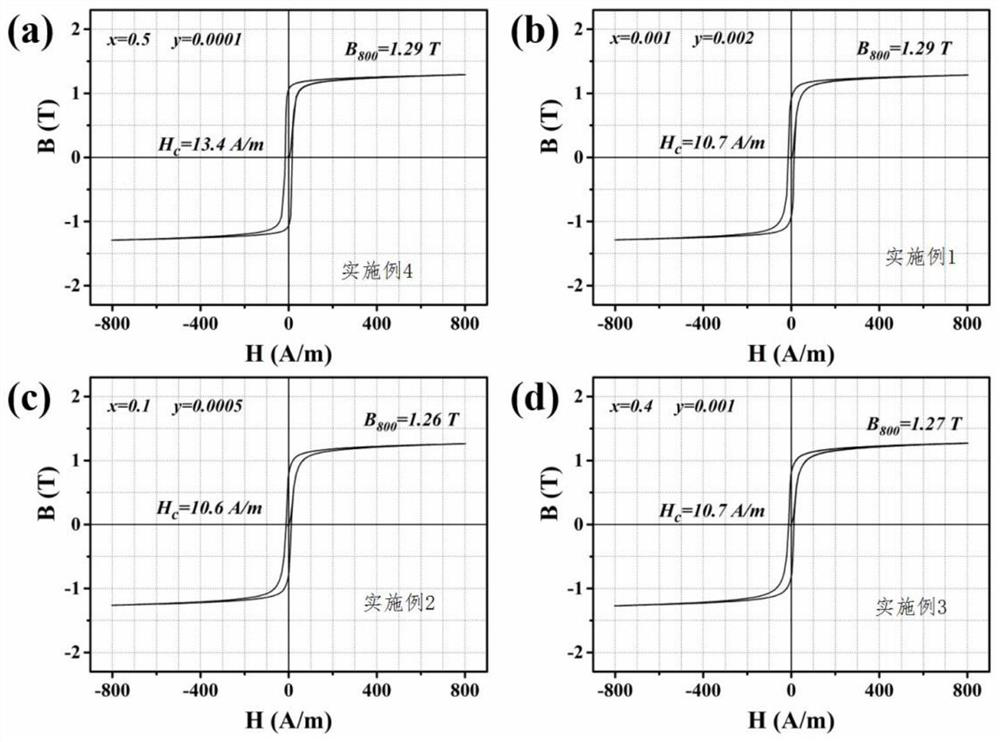

[0042] As an implementation manner of the examples of the present invention, the metallographic structure of the high silicon steel is α-BCC (ferrite)

[0043] On the other hand, the embodiment of the present invention also provides a method for preparing the above-mentioned high silicon steel, the method comprising:

[0044]S1, obtaining a steel slab; the steel slab is composed of the following chemical components in mass fractions: Si: 5.0-7.0%, Ni: 0.001-0.05%, Ce: 0.0001-0.0002%, and the rest is Fe and unavoidable impurities;

[0045] S2, heating the billet to a temperature of 1180-1200° C., holding the temperature for 3-4 hours, and then forging to obtain an intermediate billet;

[0046] S3, rolling the intermediate billet once at a temperature of 950-1100° C. to obtain a thick steel strip;

[0047] S4, heating the thick steel strip to a temperature of 160-400° C., keeping it warm for 8-12 minutes, and then performing secondary rolling to obtain a thin steel strip;

[0...

Embodiment 1

[0063] This embodiment 1 provides a magnetically compatible Fe-6.5Si-0.001Ni-0.002Ce high silicon steel and its preparation method, the preparation method comprising the following steps:

[0064] In the first step, Fe-6.5Si-0.001Ni-0.002Ce is smelted by vacuum induction melting method, and the unit is w.t.%, that is, the mass percentage content. And at 1200 ℃ for 4h homogenization heat treatment.

[0065] In the second step, the alloy ingot is forged into a square alloy block with a thickness of 20mm at 1200°C in an atmospheric environment.

[0066] The third step is to carry out multi-pass rolling on the alloy block at 1100° C. to obtain an alloy sheet with a thickness of 2 mm.

[0067] The fourth step is to perform surface grinding on the rolled alloy plate to remove scale.

[0068] The fifth step is to carry out multi-pass rolling on the alloy ingot at 300° C., the reduction rate in the first pass is 12%, and the average reduction rate is 6%. The diameter of the roll is 8...

Embodiment 2

[0071] This embodiment 2 provides a magnetically compatible Fe-6.5Si-0.1Ni-0.0005Ce high-silicon steel and a preparation method thereof, the preparation method comprising the following steps:

[0072] In the first step, Fe-6.5Si-0.1Ni-0.0005Ce is smelted by vacuum induction melting method, and the unit is w.t.%, that is, the mass percentage content. And at 1200 ℃ for 4h homogenization heat treatment.

[0073] In the second step, the alloy ingot is forged into a square alloy block with a thickness of 20mm at 1200°C in an atmospheric environment.

[0074] The third step is to carry out multi-pass rolling on the alloy block at 1000° C. to obtain an alloy sheet with a thickness of 2 mm.

[0075] The fourth step is to perform surface grinding on the rolled alloy plate to remove scale.

[0076] The fifth step is to carry out multi-pass rolling on the alloy ingot at 300° C., the reduction rate of the first pass is 10%, and the average reduction rate is 8%. The diameter of the roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com