Novel silver rare earth oxide alloy and preparing method thereof

A technology of rare earth oxides and oxide electrodes, applied in metal processing equipment, coatings, contacts, etc., can solve the problems of difficult control of rare earth oxide powder particle size, cumbersome preparation process, and grain growth, and achieve hardening The effect is obvious, the process is simple, and the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

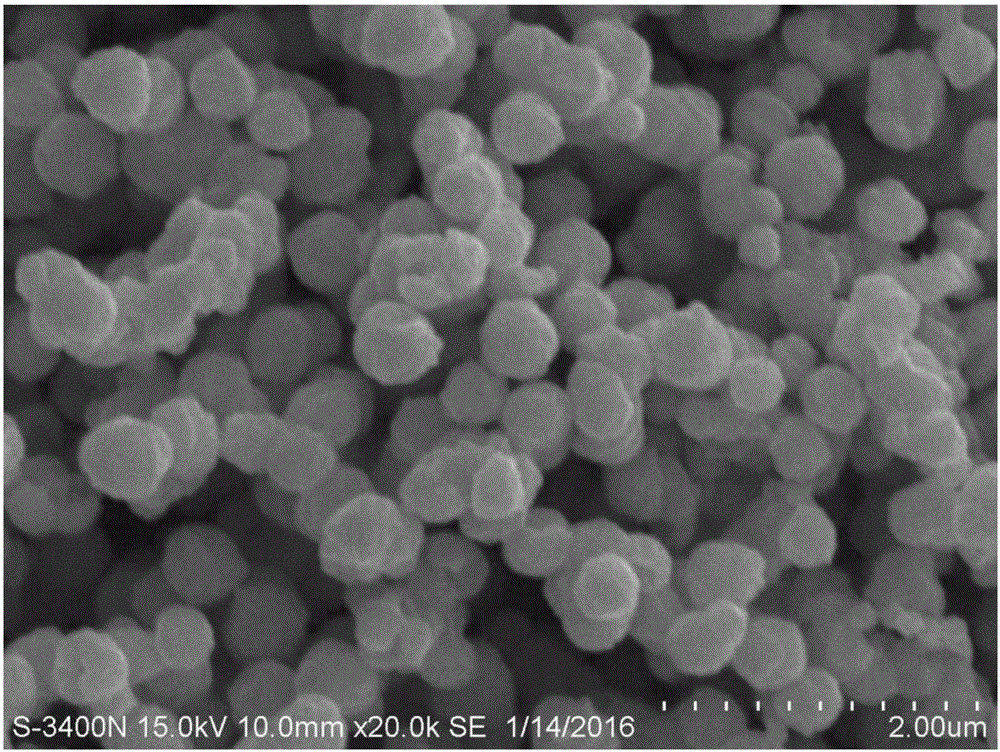

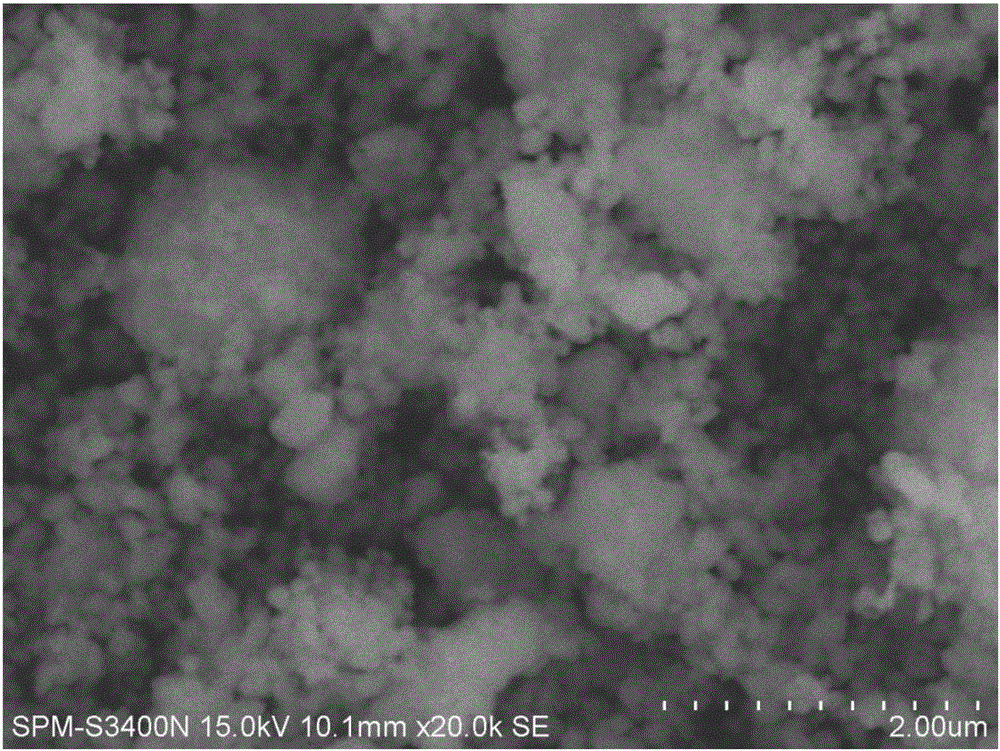

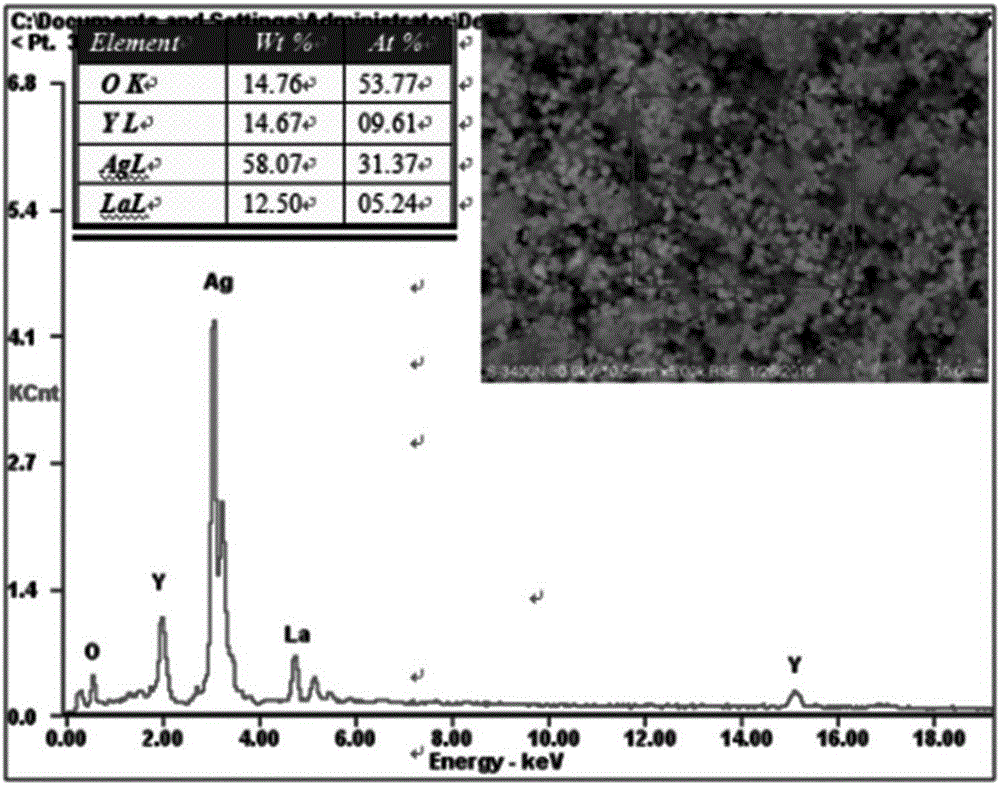

Image

Examples

Embodiment 1

[0027] (1) Take by weighing respectively 20 g of yttrium oxide and lanthanum oxide with a particle size of 3-5 μm, and 200 g of stainless steel balls, and put them into a ball mill cylinder for ball milling for 15 hours to obtain a mixed powder of yttrium oxide and lanthanum oxide with a particle size of about 500 nm;

[0028] (2) take by weighing silver nitrate 15g, be dissolved in deionized water 500ml, be made into the silver nitrate solution that concentration is 0.2mol / L, then add the ammoniacal solution that concentration is 10-12% in the silver nitrate solution prepared, After the brown precipitate is produced, continue to add ammonia water dropwise and stir until the precipitate disappears, then add 2-4 drops of ammonia solution after the precipitate disappears, and stir evenly to obtain a silver ammonia solution; weigh 18g of ascorbic acid and add it to another container, add 500ml of deionized water to dissolve, and prepare Ascorbic acid solution.

[0029] (3) Weigh ...

Embodiment 2

[0037] The difference is that by Ag:La 2 o 3 / Y 2 o 3=85:15 (mass ratio) ratio of silver and rare earth oxide mixed powder through 22 tons of cold pressing, holding pressure for 1 hour; sintering at 650 ° C, holding for 2 hours; 40 tons of re-pressing, holding for 1 hour; 900 Refire at ℃, keep warm for 4 hours; hot extrusion at 900℃, and finally cold drawn into Φ1.36mm wire, and punched into rivets.

[0038] Alloy performance indicators:

[0039] Resistivity 2.23μΩ.cm

[0040] Tensile strength 287.6MPa

[0041] The hardness is 1058MPa

Embodiment 3

[0043] The difference is that by Ag:La 2 o 3 / Y 2 o 3 =95:5 (mass ratio) The mixed powder of silver and rare earth oxide is subjected to 18 tons of cold pressing, holding pressure for 1 hour; 550 ℃ sintering, holding for 1 hour; Refire at ℃, heat preservation for 3 hours; hot extrusion at 900℃, and finally cold drawing into Φ1.36mm wire, and rivets.

[0044] Alloy performance indicators:

[0045] Resistivity 2.42μΩ.cm

[0046] Tensile strength 399.3MPa

[0047] The hardness is 759MPa

[0048] Through the research of process parameters such as initial pressure, sintering temperature, time and recompression pressure in the preparation process of the new silver rare earth oxide composite material in Examples 1-3, the optimal process parameter of the process has been determined to be the initial pressure. 20t, sintering temperature 600°C, recompression pressure 36t, refiring temperature 900°C. The contact material provided by the invention has excellent mechanical properti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com