CuNiSn alloy-based self-lubricating composite material used at room temperature to 500 DEG C and preparation method thereof

A composite material and room temperature technology, which is applied in the field of metal-based high-temperature self-lubricating composite materials and their preparation, can solve the problems of strength, oxidation resistance and wear resistance, and restricted high-temperature resistance, and achieve smooth friction-temperature characteristics, Effects of wear-resistant self-lubricating properties and self-lubricating friction-temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

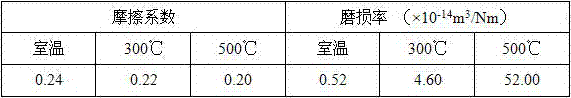

Embodiment 1

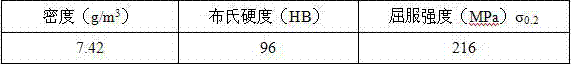

[0013] Weigh the materials according to the ratio of No. 1 in Table 5, put them into a double-cone mixer and mix them evenly, and the mixing time is 8 to 10 hours. Weigh the mixture as required and put it into a steel mold, place the steel mold with the mixture on a 60-ton hydraulic press, press it under a pressure of 300 MPa, and demould after holding the pressure for 3 minutes, and then form a cold-pressed product blank. Place the cold-pressed product blank in a box-type free sintering furnace, raise the temperature at 3-5°C / min in a hydrogen protective atmosphere, and raise the temperature to 890°C for 70 minutes. After the heat preservation is over, freely cool to room temperature and take it out. Then the product blank is subjected to amplitude modulation treatment, that is, it is placed in a box-type free sintering furnace, and in a hydrogen protective atmosphere, the temperature is raised at 3-5°C / min, and the temperature rises to 350°C, and the temperature is kept for ...

Embodiment 2

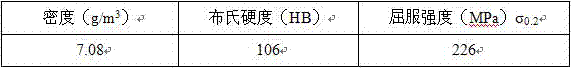

[0020] Weigh the materials according to the ratio of No. 2 in Table 5, and mix them in a double-cone mixer for 8 to 10 hours. Weigh the mixture as required and put it into a steel mold, place the steel mold with the mixture on a 60-ton hydraulic press, press it under a pressure of 350 MPa, and demould after holding the pressure for 3 minutes to form a cold-pressed product blank. Place the cold-pressed product blank in a box-type free sintering furnace, raise the temperature at a rate of 3-5°C / min in a hydrogen protective atmosphere, and raise the temperature to 950°C for 90 minutes. After the heat preservation is over, freely cool to room temperature and take it out. Then the product blank is subjected to amplitude modulation treatment, that is, it is placed in a box-type free sintering furnace, and in a hydrogen protective atmosphere, the temperature is raised at 3-5°C / min, and the temperature is raised to 400°C, and the temperature is kept for 240 minutes. After the heat pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com