Patents

Literature

51results about How to "Good self-lubricating properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

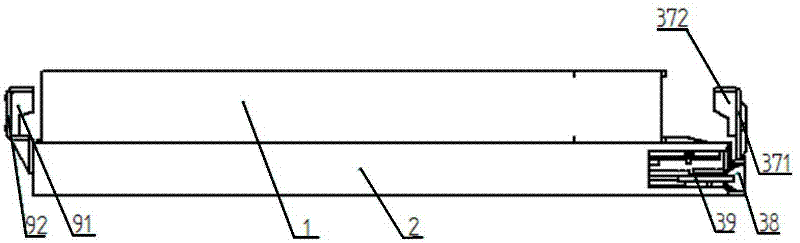

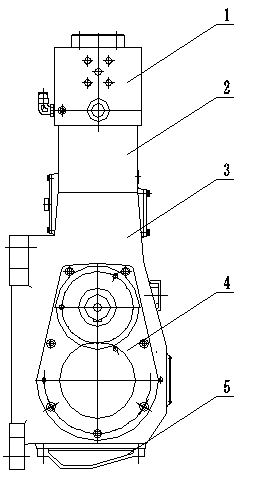

Bottom power taking self-locking electric bus battery box system capable of quickly changing battery

ActiveCN102303589AEasy to installPositioning constraints resolvedElectric propulsion mountingElectric vehicle charging technologyElectricityPower battery

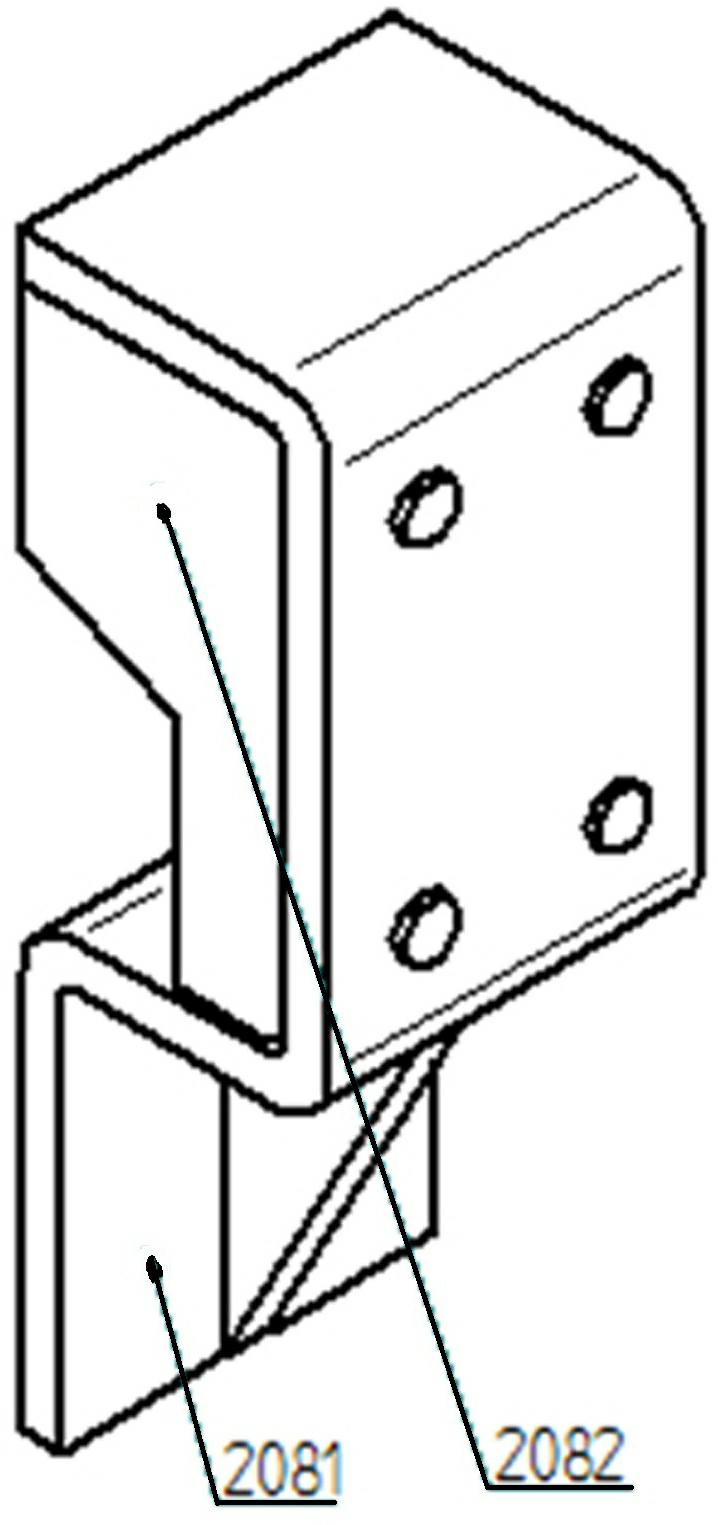

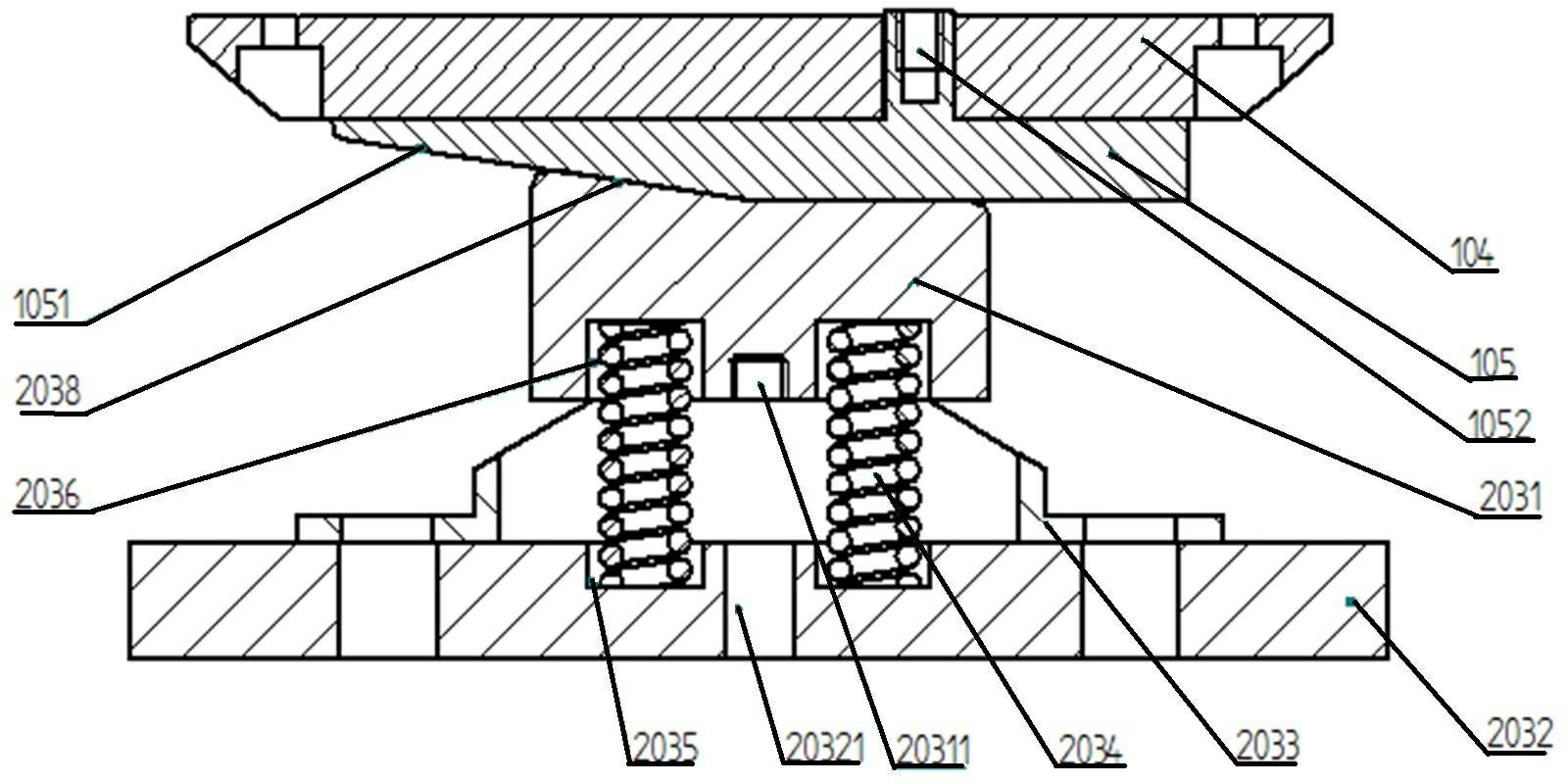

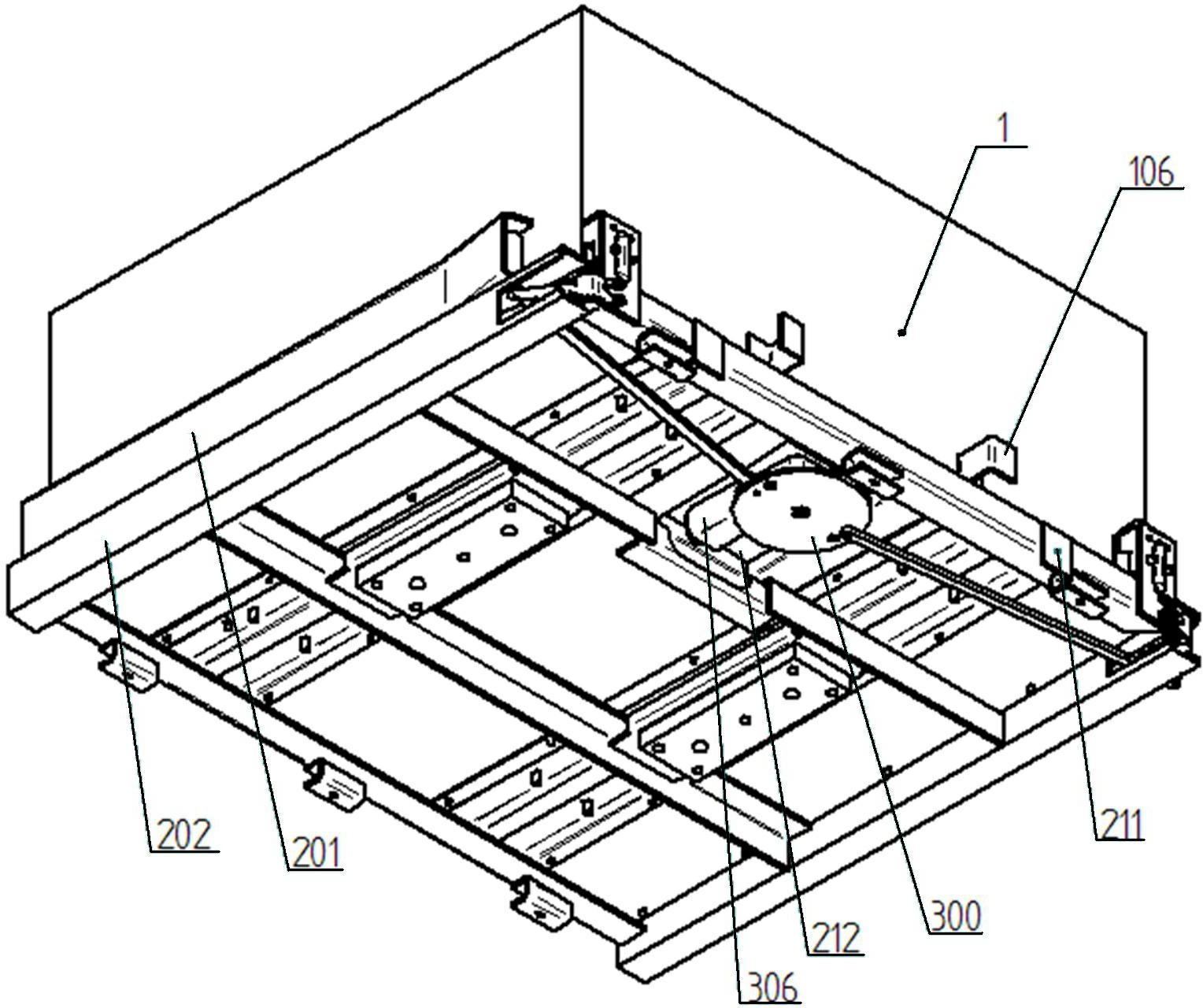

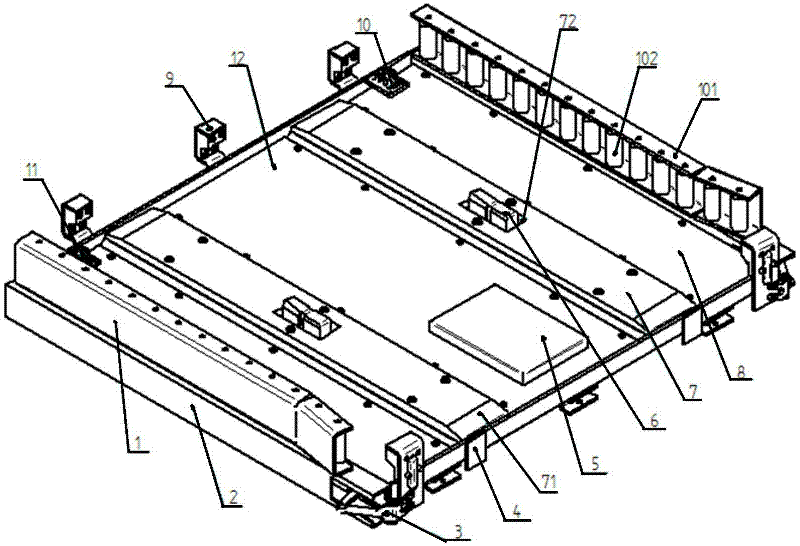

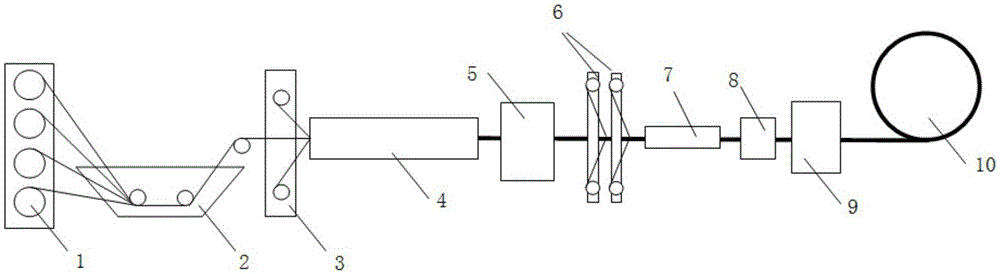

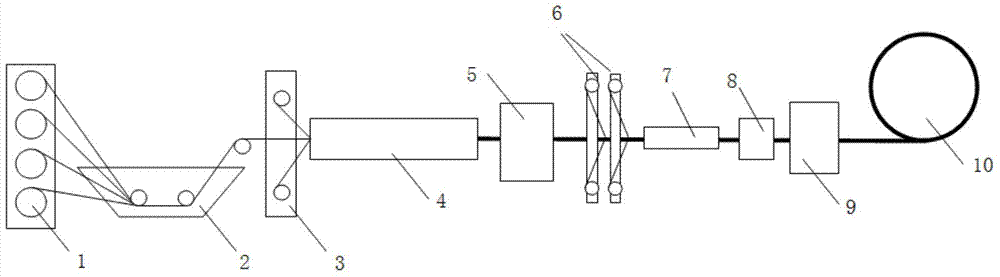

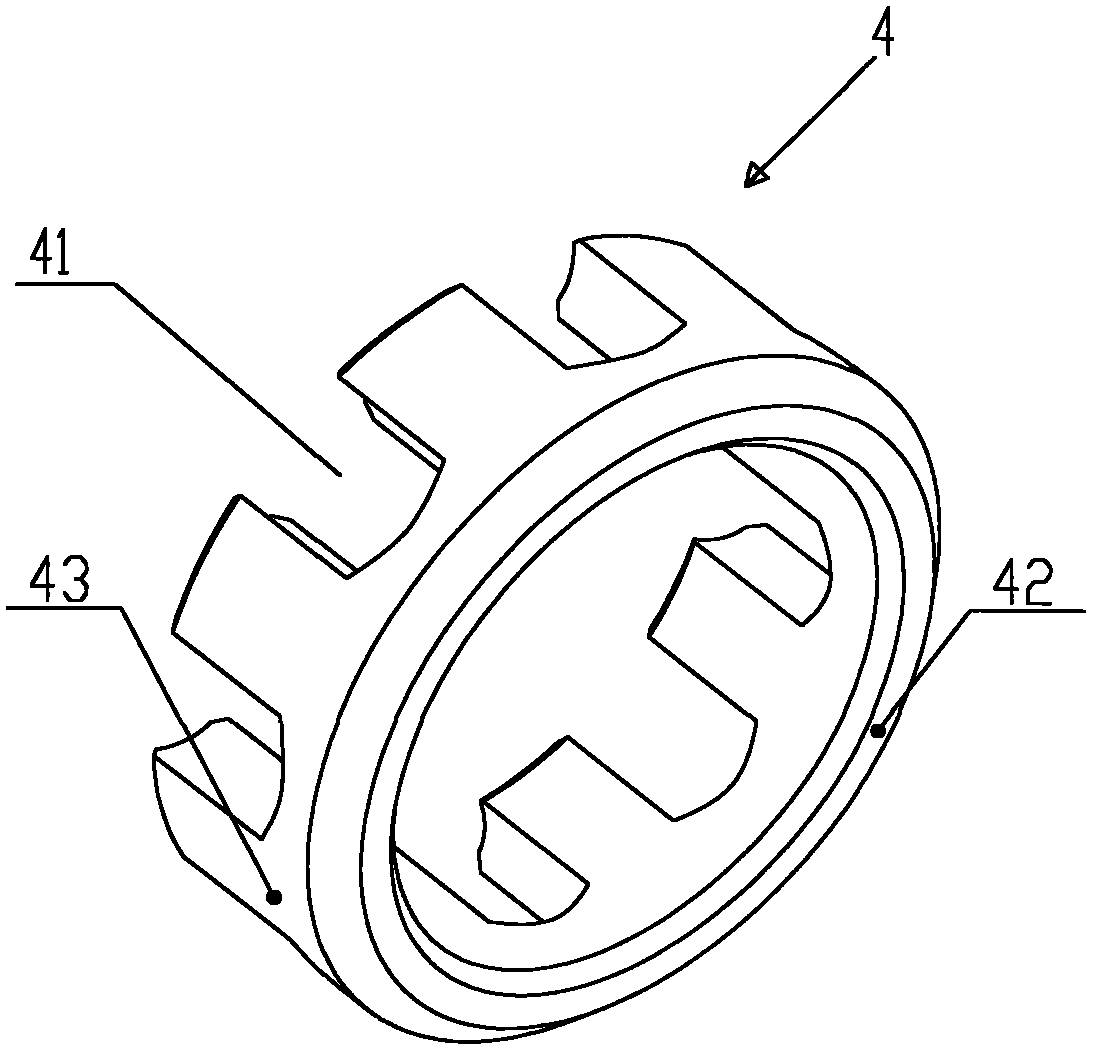

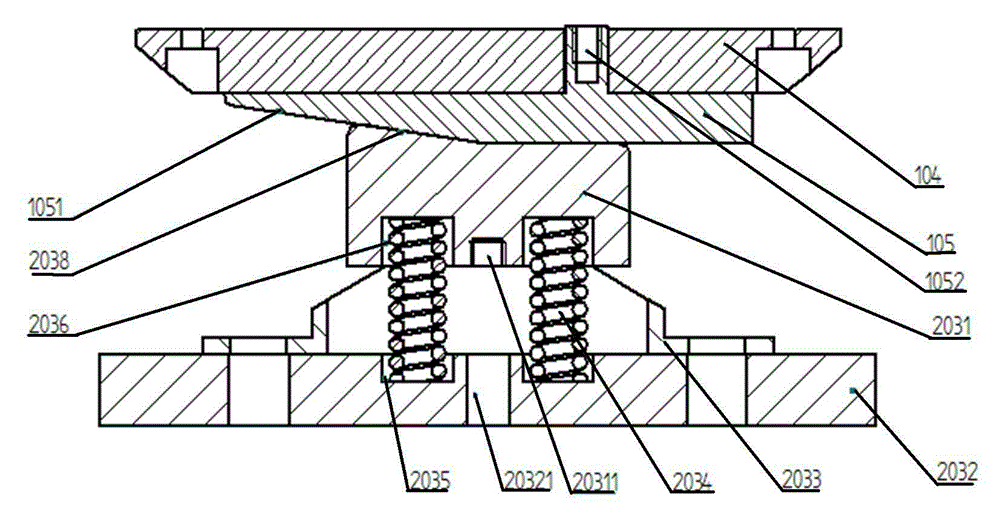

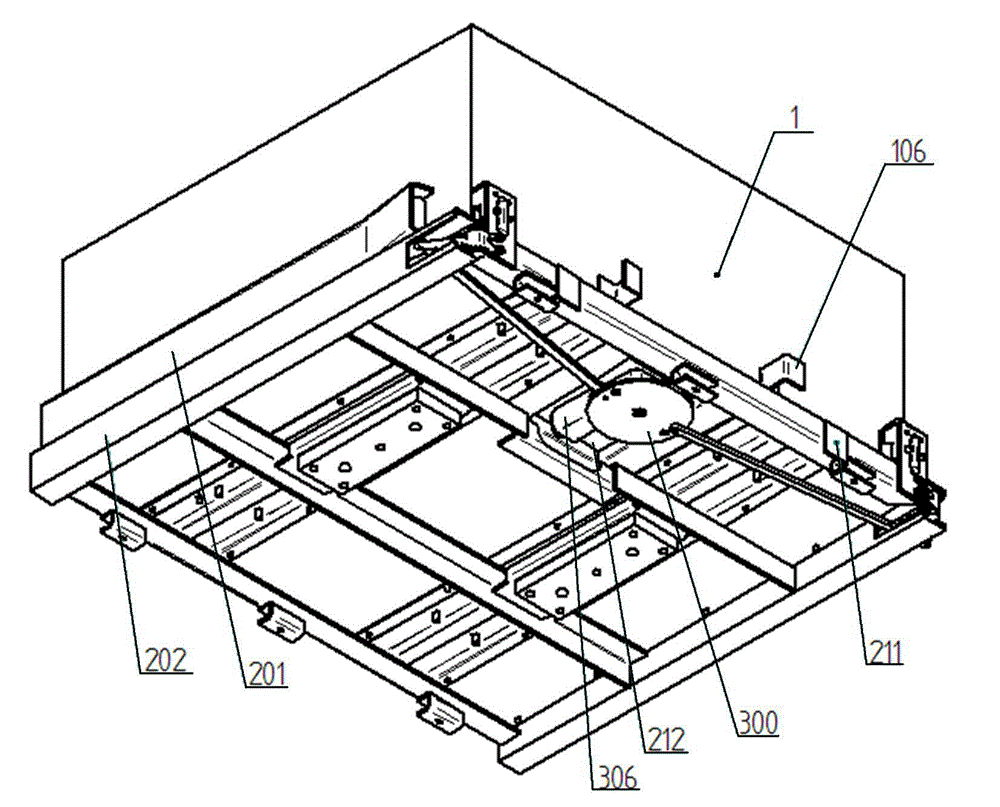

The invention discloses a bottom power taking self-locking electric bus battery box system capable of quickly changing a battery. The system comprises a battery box (1), a tray (2) used for bearing the battery box and arranged on an electric bus, mobile equipment (4) for conveying the battery box, and a grabbing device (5) arranged on the mobile equipment; and a battery box locking and unlocking device (3) is arranged on the tray. Through the system, automatic assembly of the battery box in the electric bus battery box system is realized, and the problems of over positioning, deformation of power wire connection pegs, breakage, arc discharge, welding, difficulty in automatically realizing unlocking due to impact of the battery box to a bolt of a locking mechanism in jolt and deformation of the battery box due to impact in jolt. The system is reasonable, reliable, simple and compact in structure, and can full-automatically, quickly and conveniently realize quick change of the power battery.

Owner:KUNMING SHIPBUILDING EQUIP

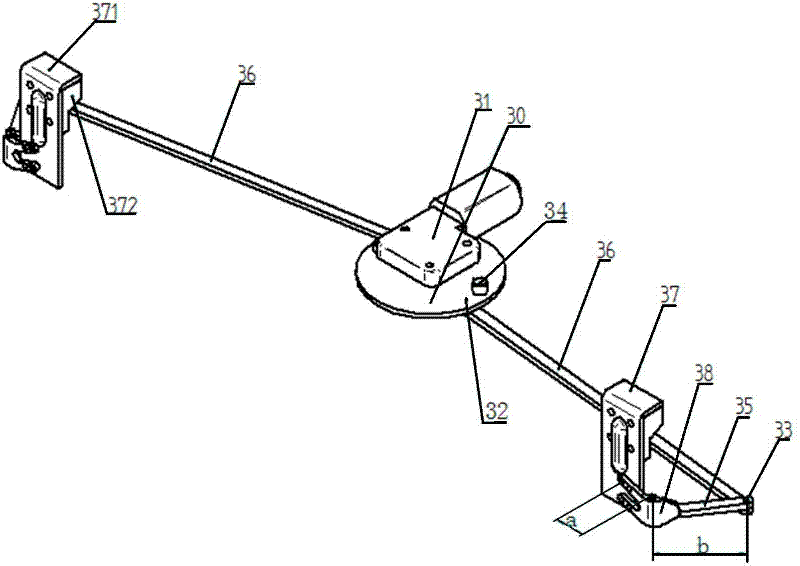

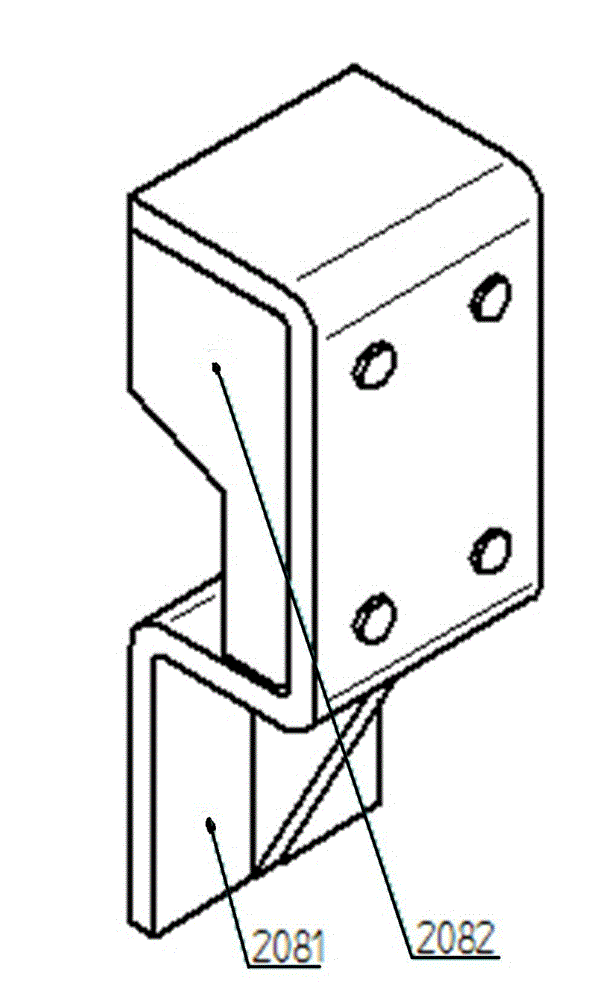

Sliding bottom electricity-taking and self-locking electric bus battery quick-change pellet device

ActiveCN102343894APositioning constraints resolvedAvoid the problem of severe squeezing that cannot be unlockedCharging stationsElectric propulsion mountingElectricityEngineering

The invention provides a sliding bottom electricity-taking and self-locking electric bus battery quick-change pellet device. The electric bus battery quick-change tray device comprises a pellet and a locking and unlocking mechanism (3) mounted on the pellet. According to the invention, the battery box can be correctly positioned and reliably locked reasonably; the force is reasonably applied to the battery box; simple structure and simple and reasonable power wire splicing mode are obtained; and the arc discharge phenomenon can be effectively prevented.

Owner:KUNMING SHIPBUILDING EQUIP

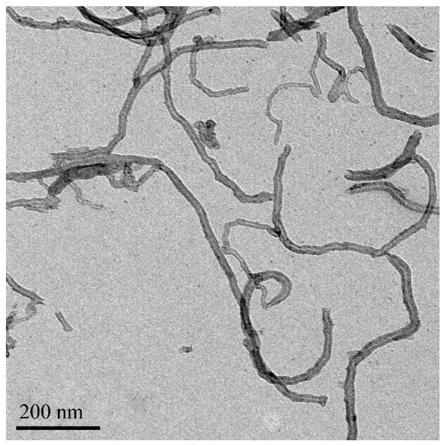

Solid lubricating composite material and manufacturing method thereof

InactiveCN101717682AReduce lubricationLow self-lubricating propertiesBase-materialsElectricityCarbon nanotube

The invention discloses a solid lubricating composite material and a manufacturing method thereof. Raw materials for the solid lubricating composite material comprise carbon nano tube, boron oxide and polytetrafluoroethylene. The manufacturing method comprises the following steps: grinding the carbon nano tube in a ball mill to form sectional structures, adding ethanol and surface dispersant into the carbon nano substances of the sectional structures, and treating the mixture by ultrasonic wave to obtain carbon nano liquid; taking boron oxide powder, polytetrafluoroethylene powder and the carbon nano liquid in percentage by weight, and mixing the three substances and stirring the mixture at a high speed to disperse the carbon nano liquid into the boron oxide and polytetrafluoroethylene powder so as to obtain a mixture; and die-pressing and molding the mixture, and demoulding the mixture to obtain the finished product solid lubricating composite material. The solid lubricating composite material prepared from the combination of the carbon nano tube and the polytetrafluoroethylene with self-lubricating property greatly improves the technical indexes such as low friction coefficient, self-lubricating property, abrasion resistance and the like, can conduct heat and electricity and eliminate static electricity produced by friction, and can be continuously produced in batch with lower cost.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

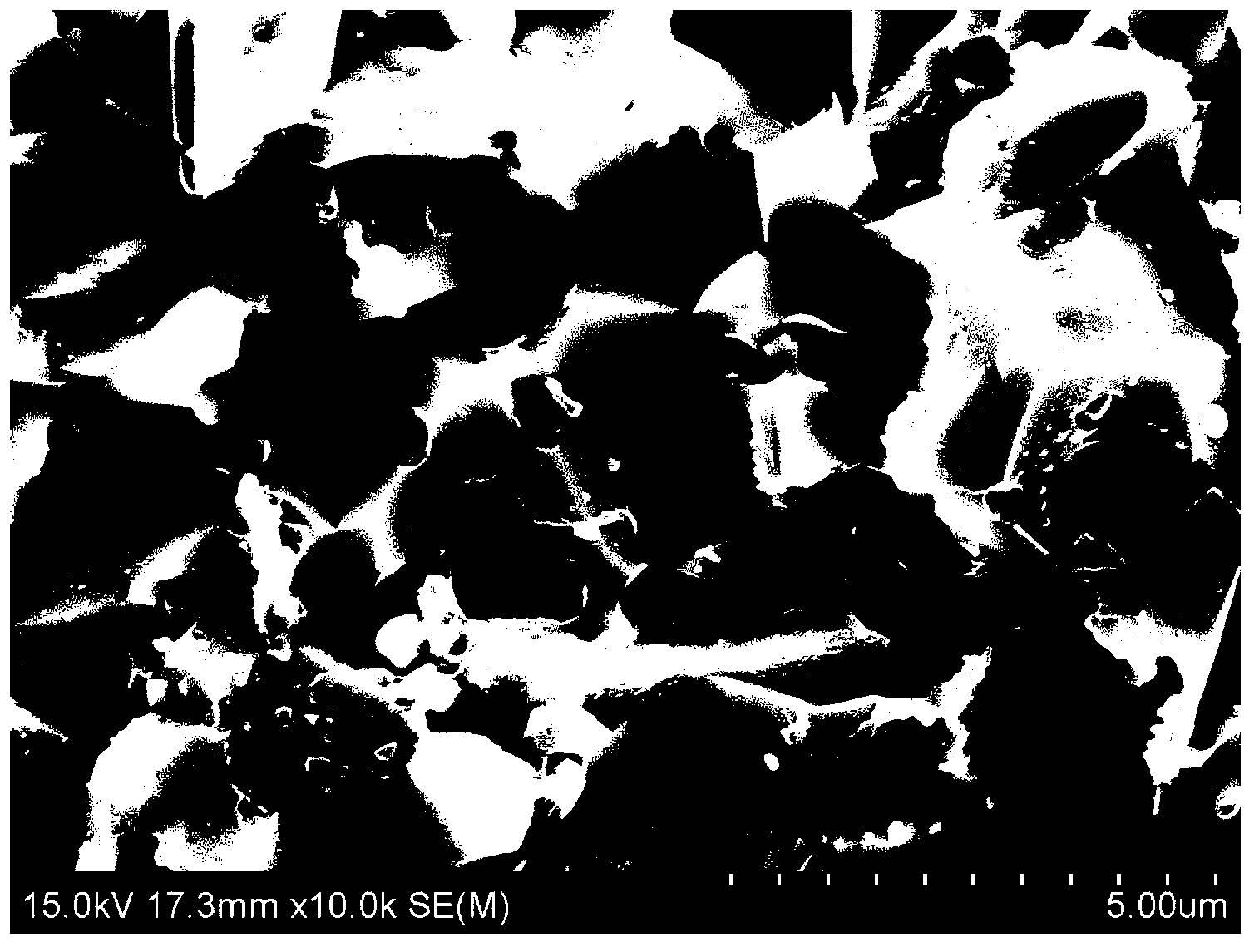

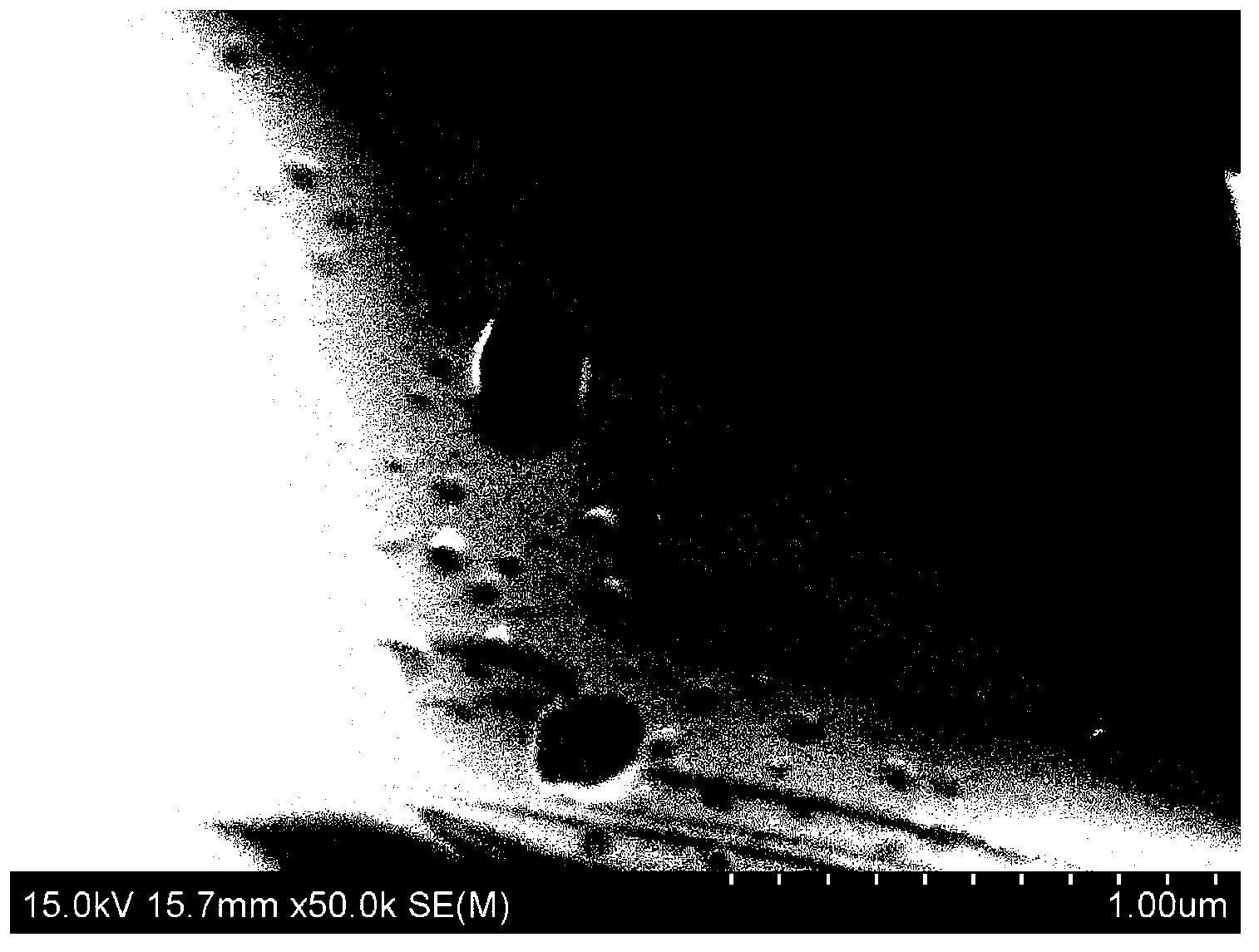

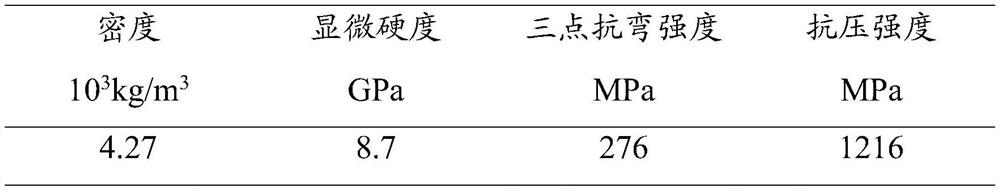

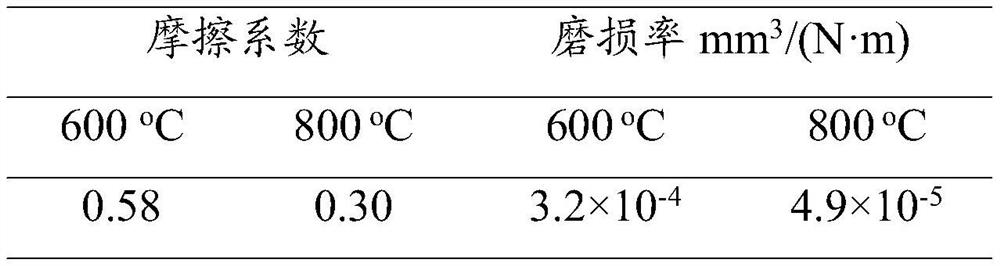

Nano solid lubricant and nano ceramic grain composite modified cutter material and preparation method thereof

InactiveCN103058667AImprove mechanical propertiesGood self-lubricating propertiesNanoceramicNano al2o3

The invention relates to a nano solid lubricant and nano ceramic grain composite modified cutter material and a preparation method thereof. The cutter material comprises the following ingredients in percentage by volume: 20-50% of micron titanium carbide, 5-15% of nano calcium fluoride, 3-6% of nano aluminum oxide ceramic grains, 0.5-1.5% of magnesium oxide and the balance of micron aluminum oxide. The preparation method comprises the following steps of firstly, preparing dispersion liquids of the nano calcium fluoride and the nano aluminum oxide, mixing and adding the magnesium oxide, the micron aluminum oxide and the micron titanium carbide, mixing, dispersing, carrying out ball-milling and drying to obtain powder, and sintering by using a hot-press method. According to the cutter material, the nano ceramic grains Al2O3 and a nano solid lubricant CaF2 are successfully introduced into a ceramic matrix, so that the mechanical property and the tribological property are both considered, and the cutter material which is good in mechanical property and good in self-lubrication property is obtained. The cutter material is low in material cost and simple in process, and industrial production is easy to carry out.

Owner:QILU UNIV OF TECH

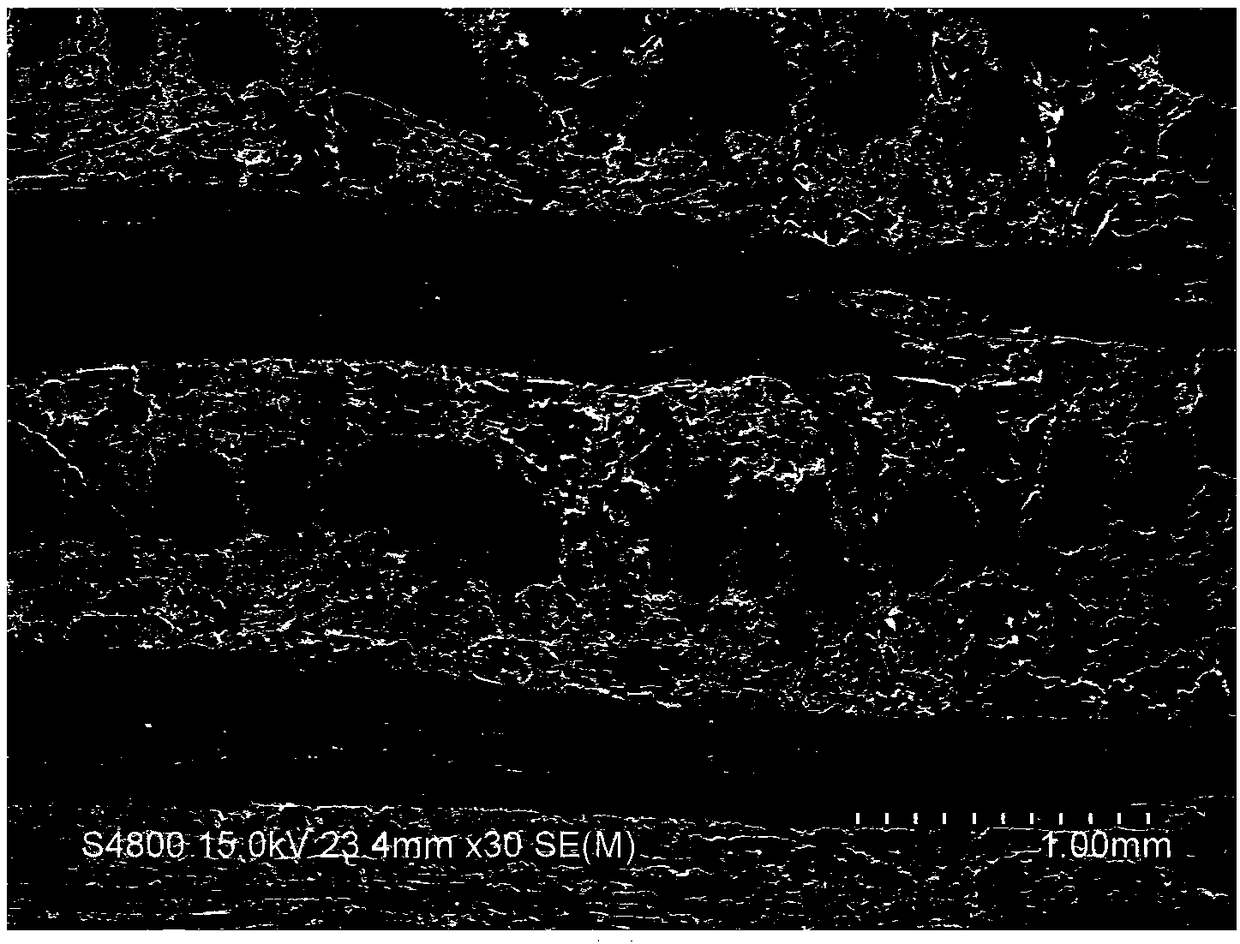

Continuous carbon fiber sucker rod with wear-resistant protective layer and preparation method thereof

ActiveCN105298403AImprove anti-eccentric wear characteristicsLong application lifeDrilling rodsDrilling casingsWear resistantHardness

The invention discloses a continuous carbon fiber sucker rod with a wear-resistant protective layer and a preparation method thereof. The continuous carbon fiber sucker rod comprises a sucker rod body, a glass fiber layer coated on the surface of the sucker rod body, and a wear-resistant layer coated at the outer side of the glass fiber layer, wherein the wear-resistant layer comprises a fiber-reinforced fabric and a thermoplastic resin layer coated on the surface of the fiber-reinforced fabric, and hard wear-resistant particles are uniformly mixed in the thermoplastic resin layer, so that the hard wear-resistant particles are uniformly distributed on the surface of the wear-resistant layer. The hard wear-resistant particles are uniformly distributed on the surface of the sucker rod, and by virtue of the high hardness and high wear resistance of inorganic hard particles and the ball form formed with the mesh fabric structure, the eccentric wear resistance of the wear-resistant layer on the surface of the composite sucker rod is strengthened. Meanwhile, the part where the hard wear-resistant particles are in contact with the interface of the sucker rod body plays a role of interface mechanical meshing, thereby preventing the wear-resistant protective layer from slipping and layering from the surface of the sucker rod.

Owner:SHANDONG UNIV

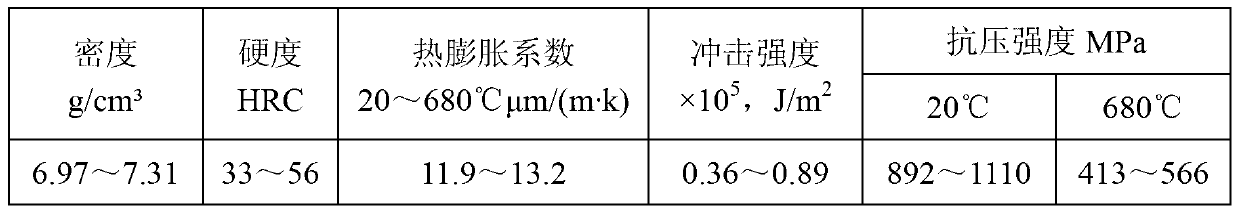

MoS2-group self-lubricating wear-resistant corrosion-resistant alloy and preparation method thereof

ActiveCN103343263AHigh mechanical strengthImprove corrosion resistanceCorrosion resistant alloyWear resistant

The invention relates to a MoS2-group self-lubricating wear-resistant corrosion-resistant alloy and a preparation method thereof. The MoS2-group self-lubricating wear-resistant corrosion-resistant alloy comprises the following components by weight percent; 0.3-0.4% of C, 0.03-0.08% of N, 2-5% of Cu, 8-16% of Ni, 2-25% of MoS and the balance of aluminum base. The MoS2-group self-lubricating wear-resistant corrosion-resistant alloy has favorable self-lubricating properties of low friction and wear resistance, has high mechanical strength and corrosion resistance, is suitable for producing dry friction parts such as bearing retainers, shaft sleeves, sliding plates, sealing elements and control valves operating in a self-lubricating, dry-friction and helium-atmosphere environment and at a high temperature in the industrial production field of metallurgy, energy and nuclear power, and has special application requirements. By the preparation method, alloy can be prepared conveniently and rapidly, and the preparation method has the characteristics that the burning loss of alloy components is small and the components can be easily controlled.

Owner:CHENGDU TAIHUA ZHONGCHENG TECH GRP CO LTD

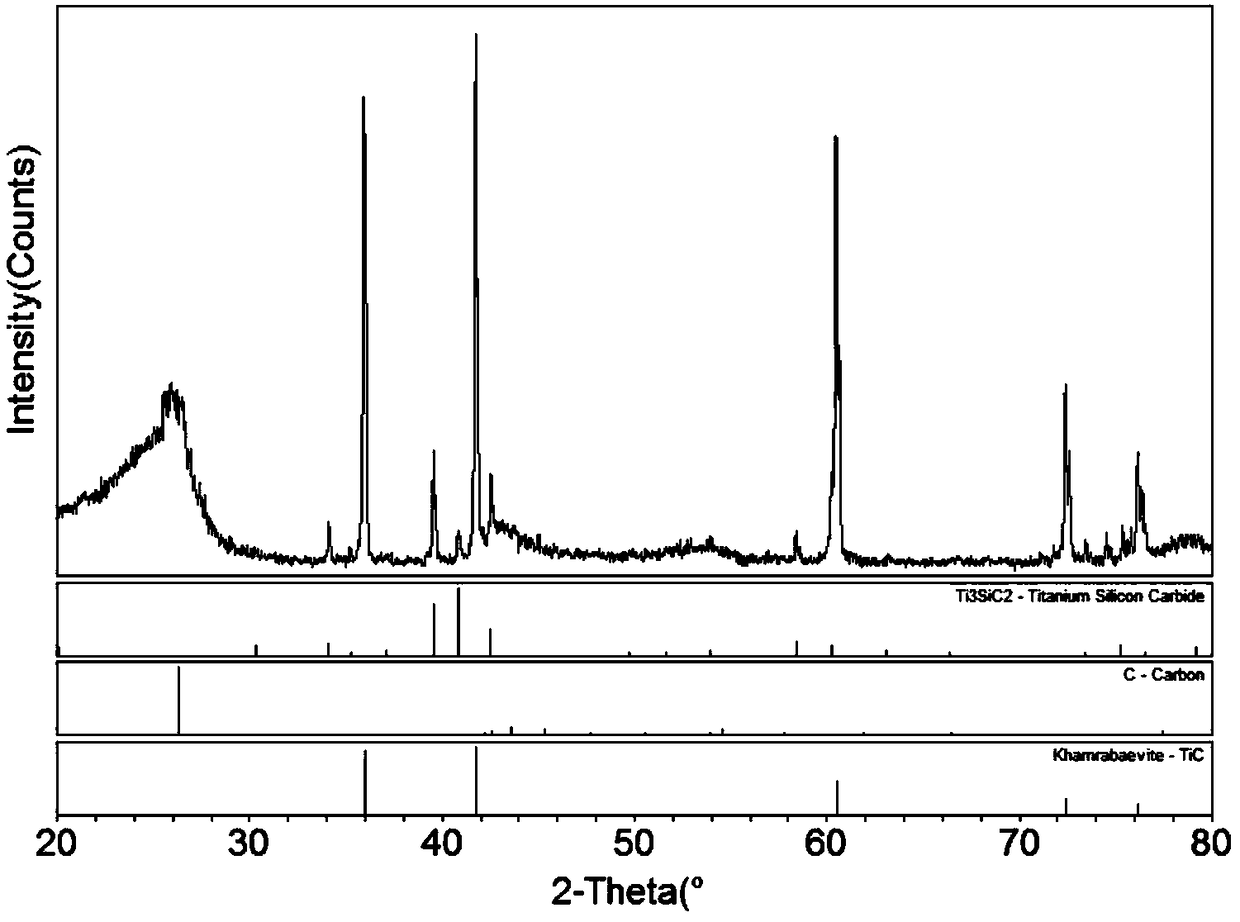

Carbon-ceramic composite material with self-lubricating and anti-oxidation functions and preparation method of composite material

ActiveCN108264368AImprove antioxidant capacityImprove wear resistanceFriction liningActuatorsFiberCarbon fibers

The invention relates to a carbon-ceramic composite material with self-lubricating and anti-oxidation functions and a preparation method of the composite material. The carbon-ceramic composite material is C / C-TiC-Ti3SiC2; and the preparation method of the composite material comprises the following steps: (1) preparing a carbon fiber pre-prepared body and performing pretreatment; (2) preparing a protective coating layer on the surface of carbon fibers of the carbon fiber pre-prepared body; (3) performing densification on the carbon fiber pre-prepared body with the protective coating layer to obtain a porous C / C pre-prepared body; (4) performing high-temperature heat treatment on the porous C / C pre-prepared body; and (5) performing high-temperature heat treatment on a Ti / Si alloy or mixed powder of Ti and Si and the porous C / C pre-prepared body to prepare the C / C-TiC-Ti3SiC2 carbon-ceramic composite material. The preparation method provided by the invention has simple operation, low costs and a short process period, and the prepared C / C-TiC-Ti3SiC2 carbon-ceramic composite material has self-lubricating and anti-oxidation functions, and is wear-resistant, environmentally friendly andpollution-free.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

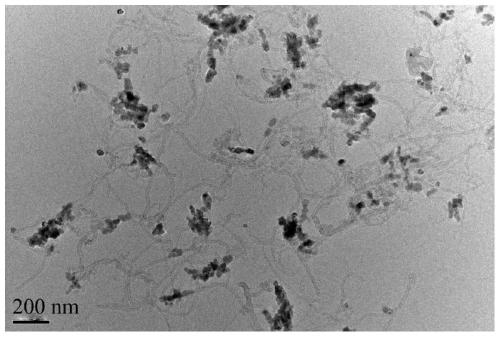

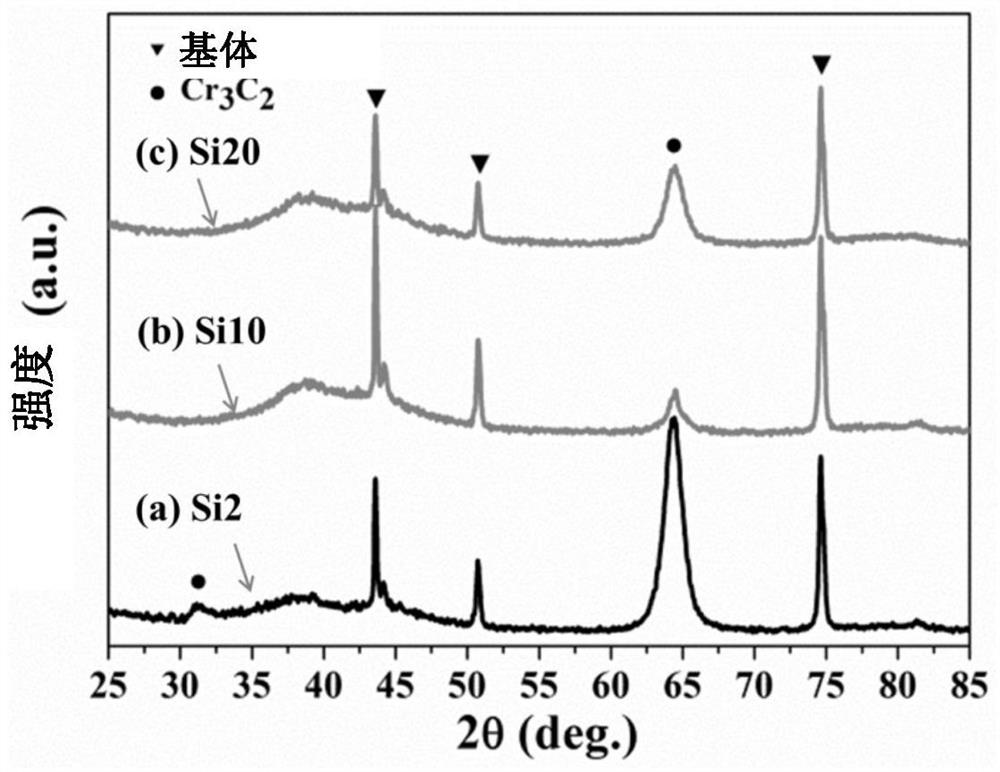

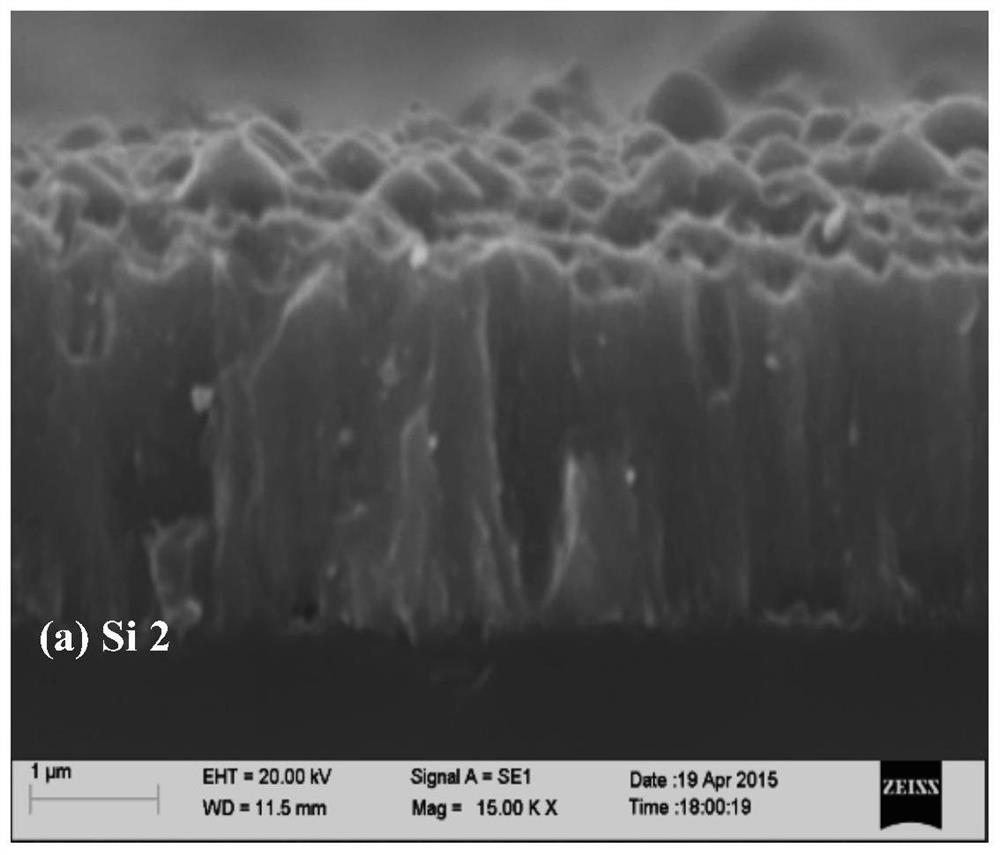

Hybrid carbon nanotube reinforced wear-resistant anti-friction ceramic coating and preparation method thereof

The invention discloses a hybrid carbon nanotube reinforced wear-resistant anti-friction ceramic coating and a preparation method thereof, and belongs to the technical field of cermet coatings. The preparation method includes preparing micron zinc oxide sol according to a sol-gel method, reacting the micron zinc oxide sol with a hybrid carbon nanotube, treated by a mixed-acid oxidation method, togenerate a zinc oxide / carbon nanotube composite, adding the zinc oxide / carbon nanotube composite as a nano additive to an adhesive ceramic coating, and solidifying the adhesive ceramic coating to obtain the wear-resistant anti-friction ceramic coating. Compared with non-hybridized carbon nanotube reinforced ceramic coatings, the hybrid carbon nanotube reinforced wear-resistant anti-friction ceramic coating has the advantages that the bonding strength to a coating ceramic phase is high, and the friction coefficient and wear rate can be remarkably reduced in a room-temperature or high-temperature environment, so that the ceramic coating can be applied to surfaces of parts bearing collision and abrasion and has a broad application prospect.

Owner:JIANGNAN UNIV

Copper-based dispersive bimetallic self-lubricating material and method for preparing self-lubricating base material

ActiveCN102039414AGood self-lubricating performanceReduce coefficient of frictionWork in processAlloy

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

CuNiSn alloy-based self-lubricating composite material used at room temperature to 500 DEG C and preparation method thereof

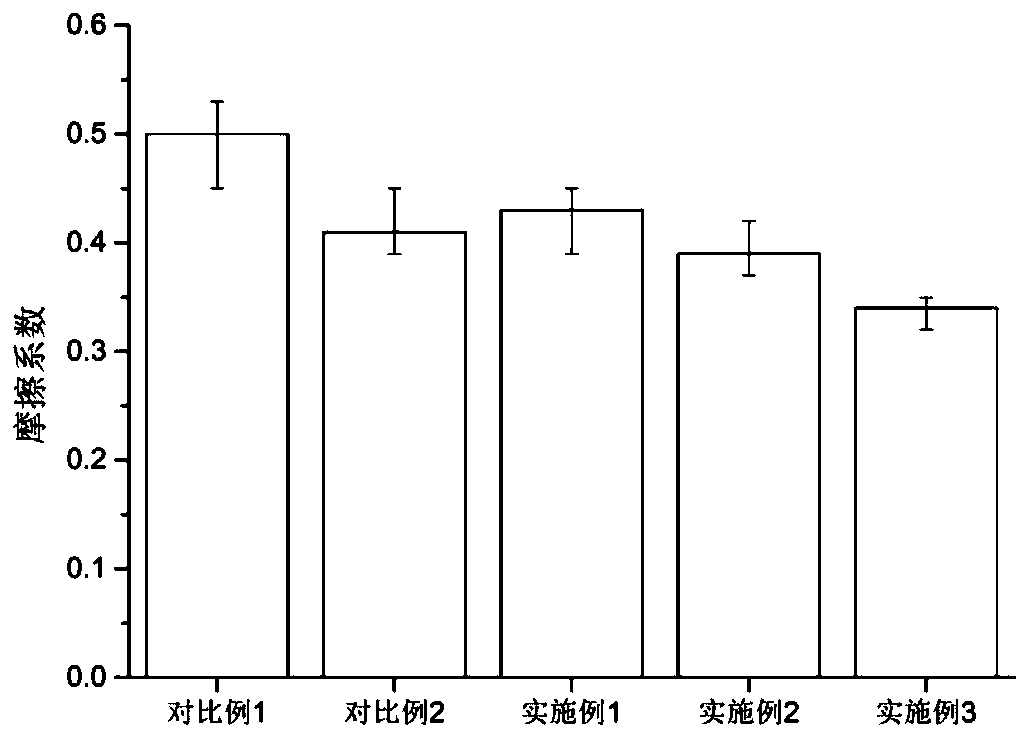

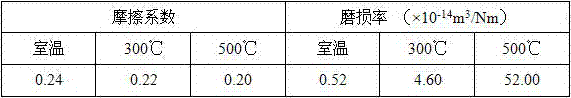

The invention discloses a CuNiSn alloy-based self-lubricating composite material used at the room temperature to 500 DEG C and a preparation method thereof. The material is composed of, by mass, 1-12% of Ni, 3-6% of Sn, 0.5-3% of Fe, 0.01-0.08% of Al, 0.01-0.08% of Ti, 1.0-4.0% of graphite, 1.0-6.0% of PbO, 0.1-1.0% of CeF3 and the balance Cu. The material has high-hardness, high-strength, low-friction, abrasion-resistant and self-lubricating characteristics at the room temperature to 500 DEG C and is suitable for manufacturing sliding bearings, sliding plates, rolling bearing holding frames or other parts for equipment within the temperature range.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

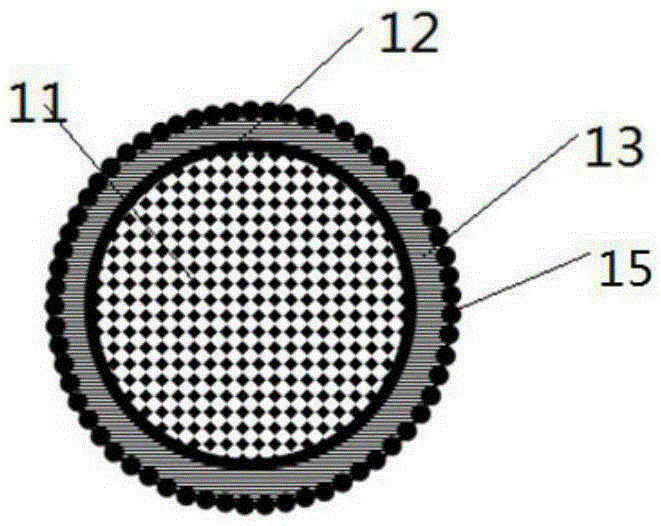

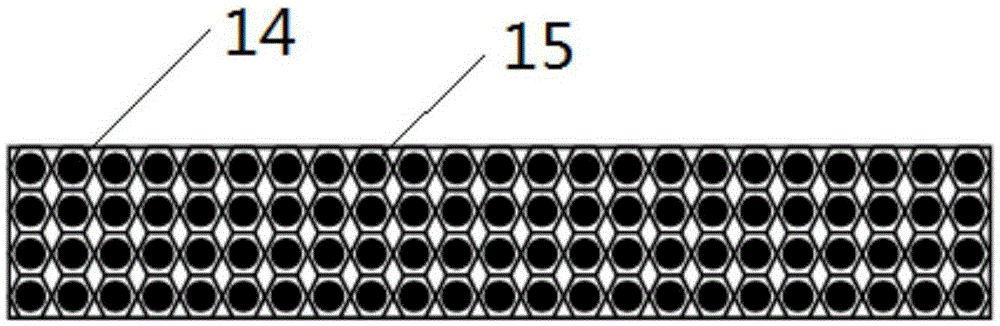

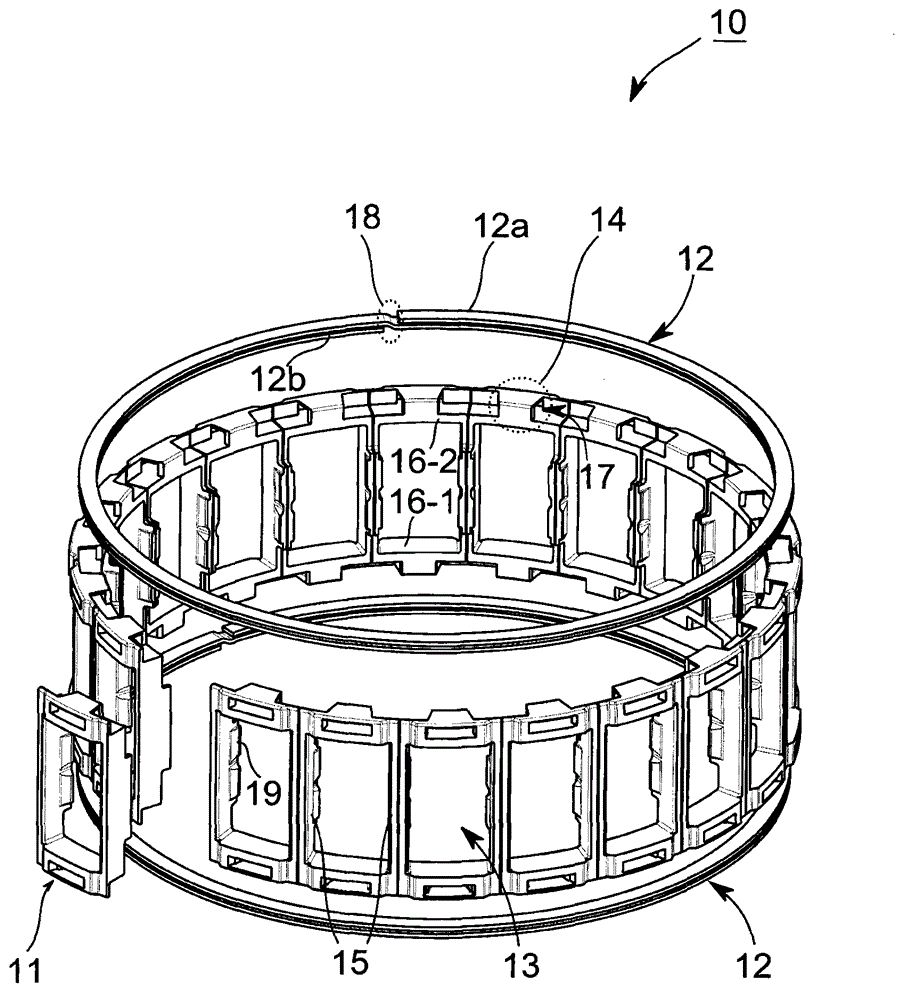

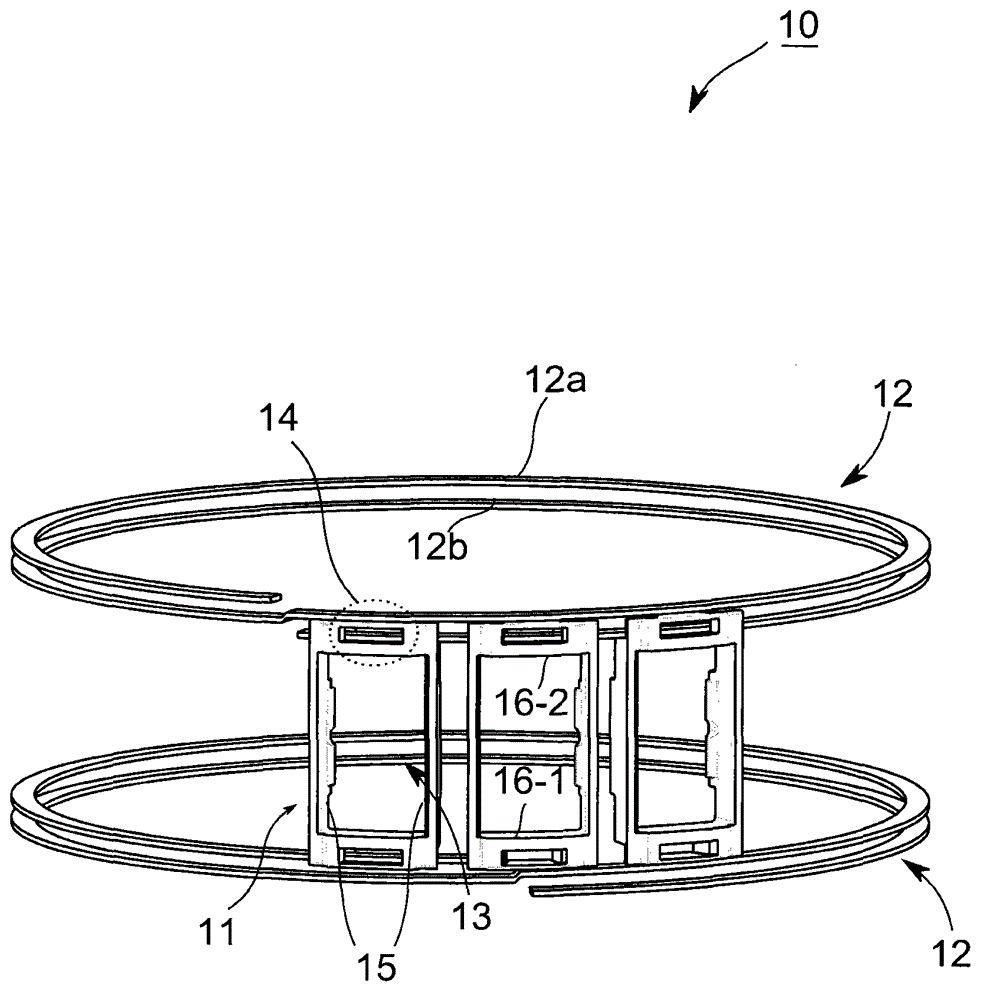

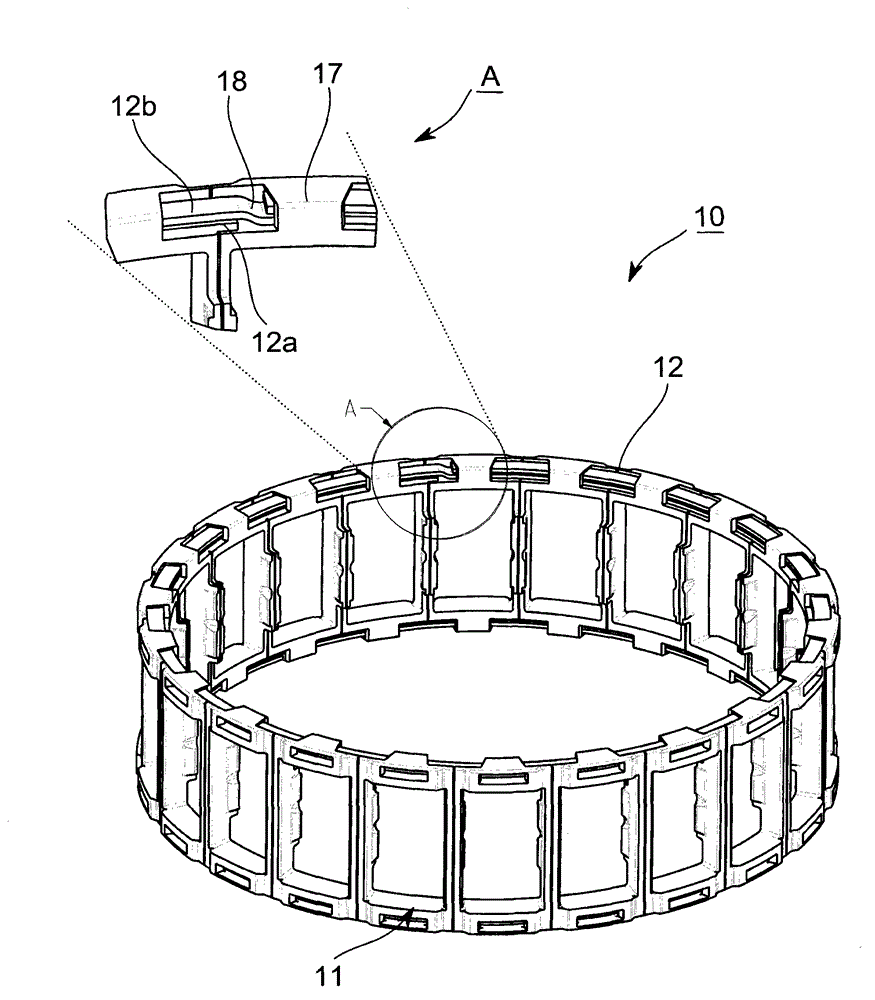

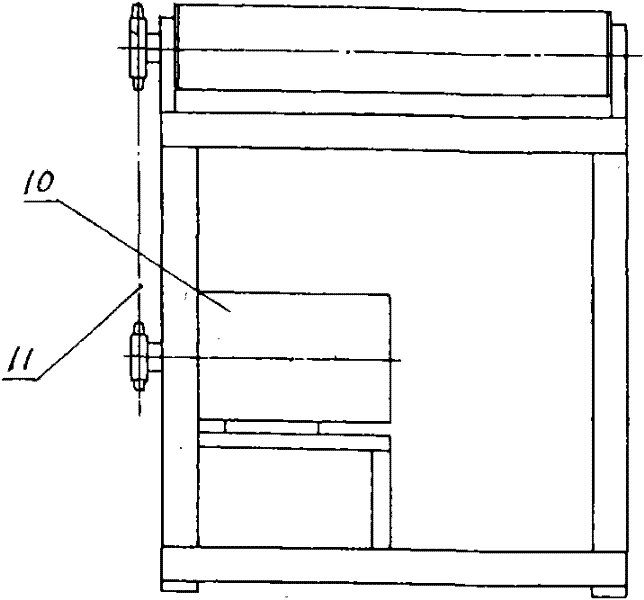

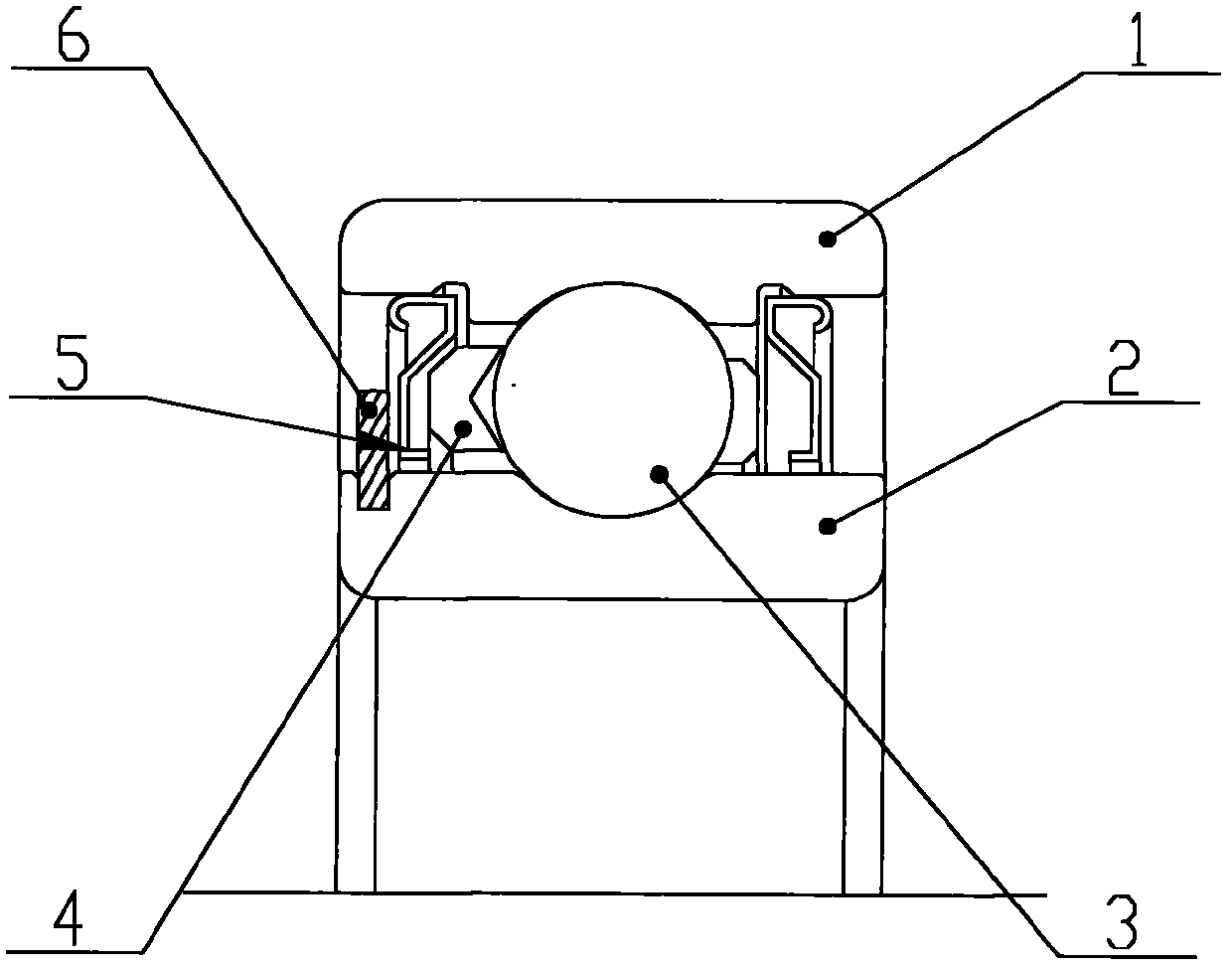

Bearing cage segment, bearing cage and method for manufacturing the same

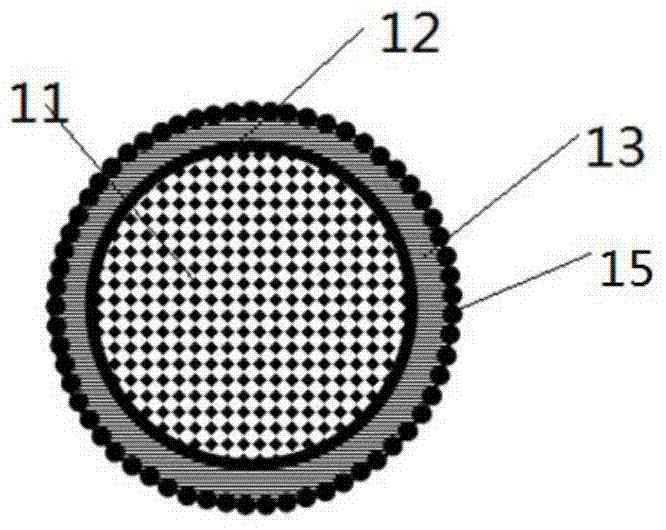

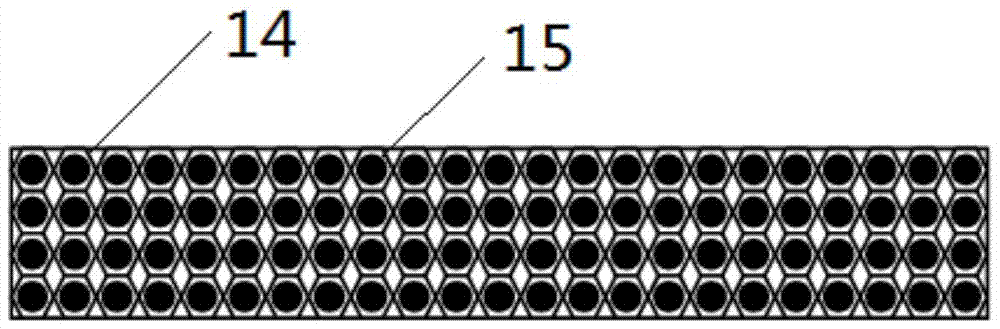

ActiveCN102913556AReduce weightReduce running noiseRoller bearingsShaftsEngineeringRolling-element bearing

The embodiment of the invention relates to a bearing cage used for rolling bearings. The bearing cage (10) has a plurality of bearing cage segments (11) for accommodating rolling bodies in rolling body pockets (13) formed through the bearing cage segments (11). Each bearing cage segment comprises a coupling arrangement (14), which is formed to arrange the segments on a carrier ring (12) that is formed as a lamellar ring. The bearing cage (10) has at least one carrier ring (12) that is formed as a lamellar ring, the carrier ring (12) brings the segments on the carrier ring by the coupling arrangement (14), so that at least one rolling body pocket (13) is formed by two bearing cage segments (11) arranged in a circumferential direction adjacent to the carrier ring.

Owner:AB SKF

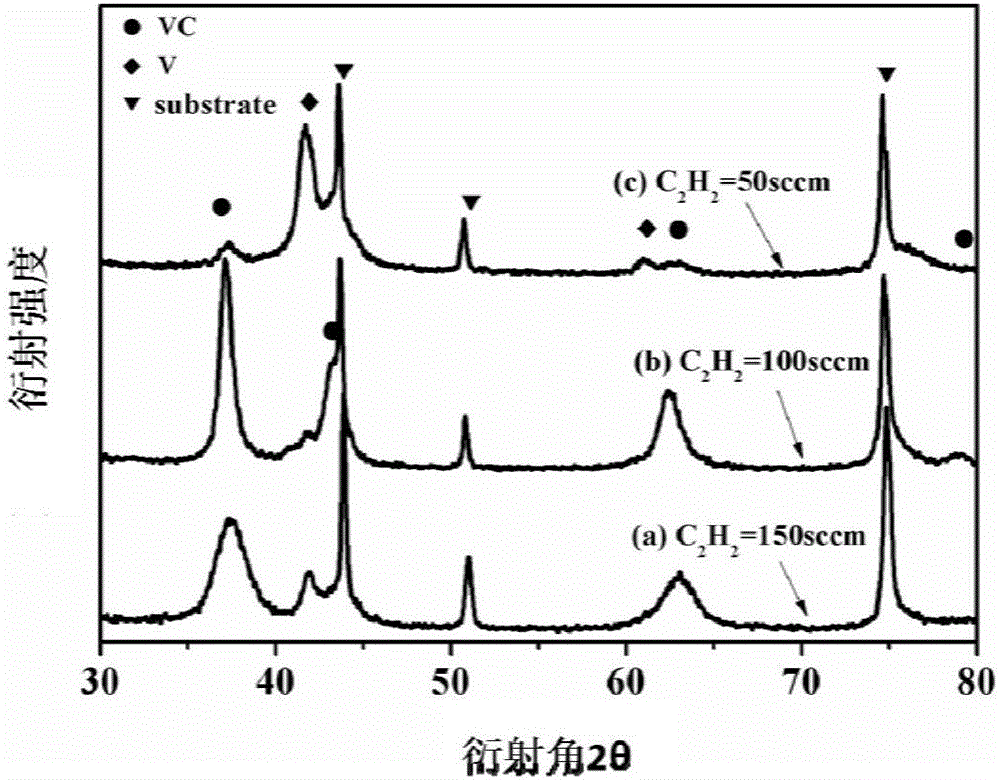

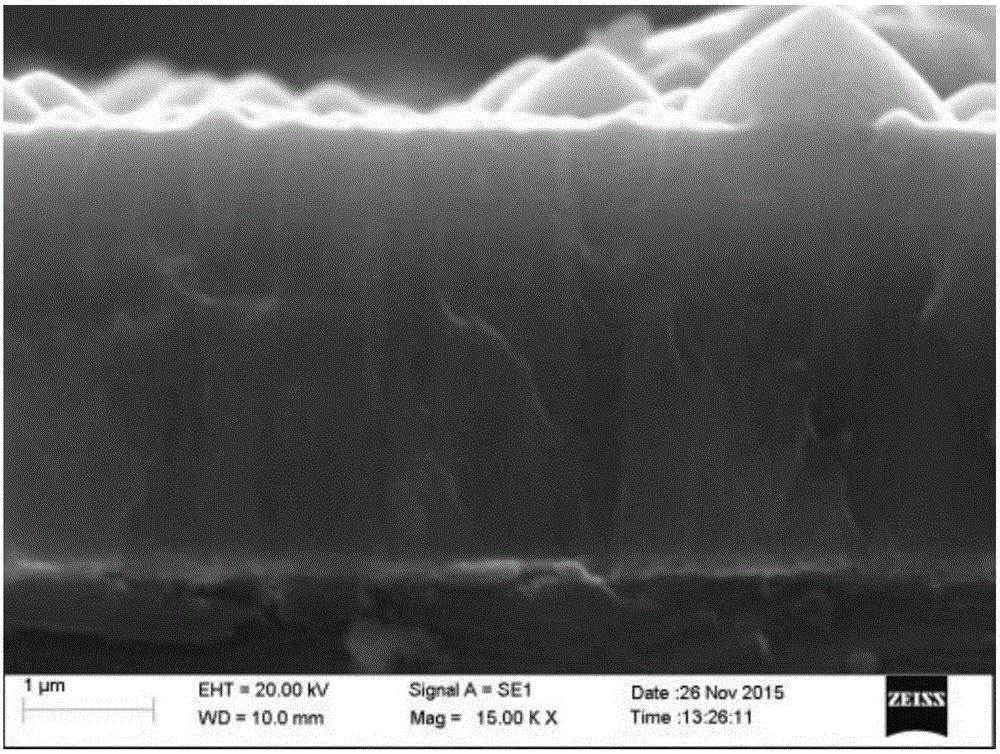

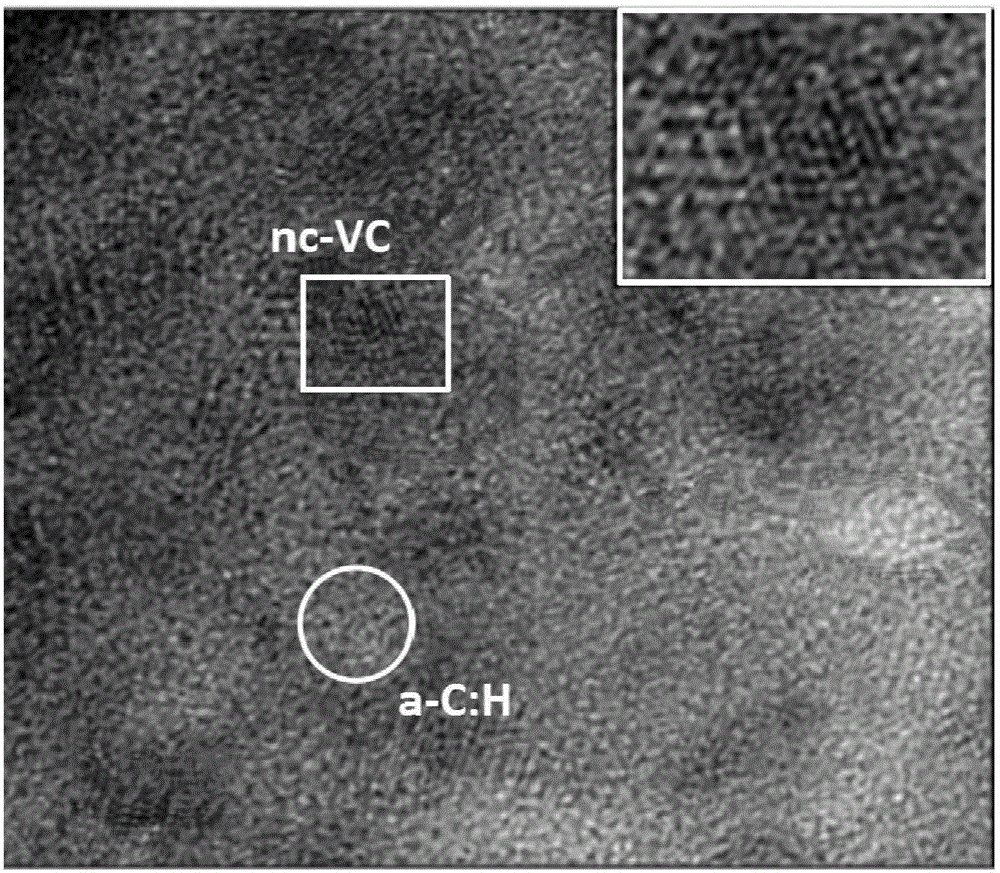

VC/a-C:H nano-composite coating on substrate surface and preparation method of VC/a-C:H nano-composite coating

ActiveCN106756816AHigh hardnessGood self-lubricating performanceVacuum evaporation coatingSputtering coatingHardnessNanometre

The invention provides a VC / a-C:H nano-composite coating, which is prepared from hard-phase nanocrystal VC and lubricating-phase amorphous a-C:H, wherein the a-C:H is taken as a matrix and the nanocrystal VC is dispersed into the matrix, so that the characteristics of high hardness and low abrasion of a traditional VC hard coating are kept, meanwhile, the VC / a-C:H nano-composite coating has excellent self-lubricating characteristics of the a-C:H material, can play a good protecting role on a substrate operating in high-abrasion and high-friction environments and has good application value. The invention further provides a preparation method. A multi-arc ion plating technology is adopted, a metal V is taken as a target material, C2H2 is taken as a reaction gas, the content of a V element and a C element in the coating can be regulated and controlled through controlling the gas flow of V target current and / or a carbon source C2H2, so that the contents of a VC phase and an a-C:H phase in the coating are regulated and controlled.

Owner:宁波奥深科技有限公司

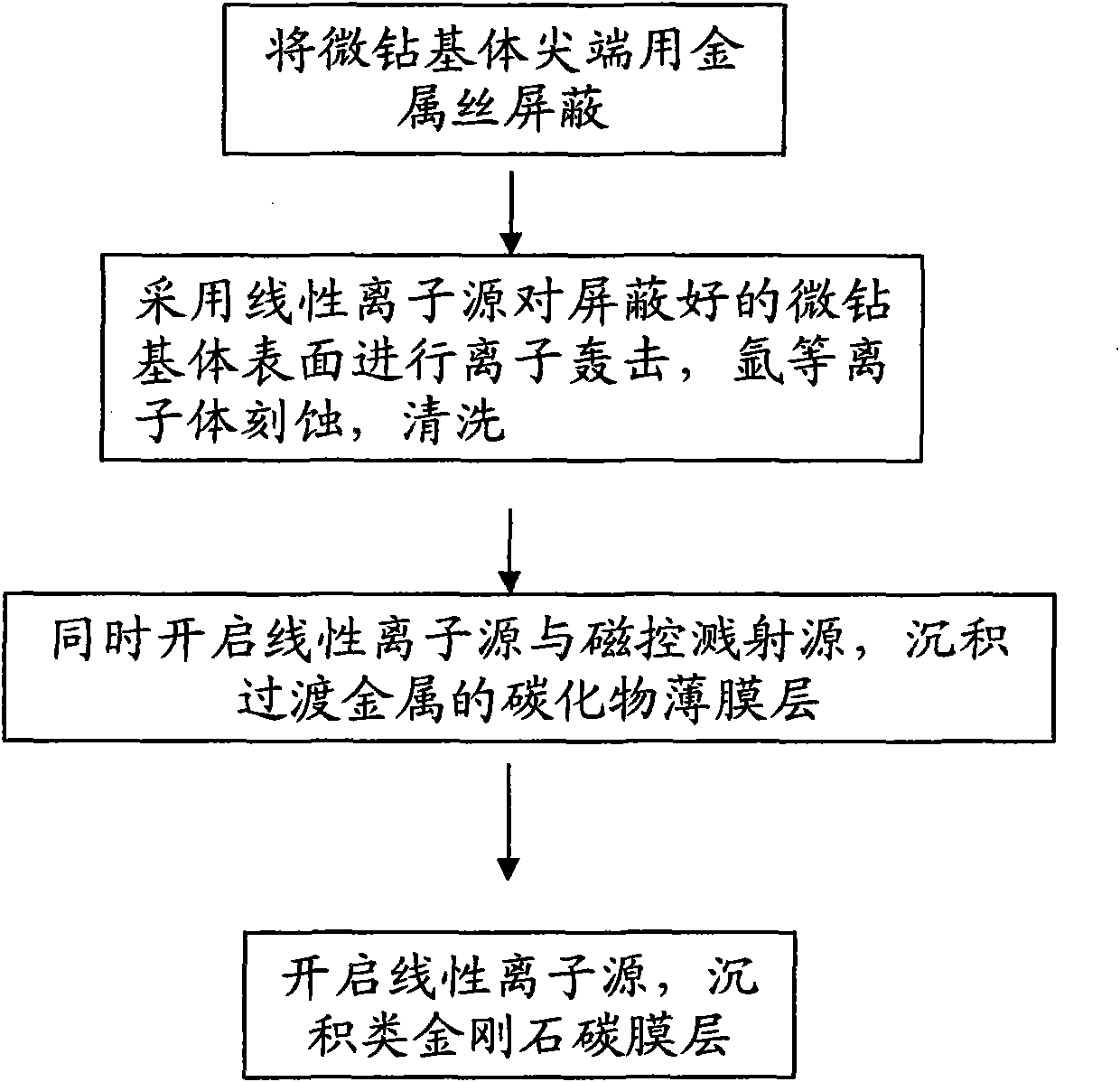

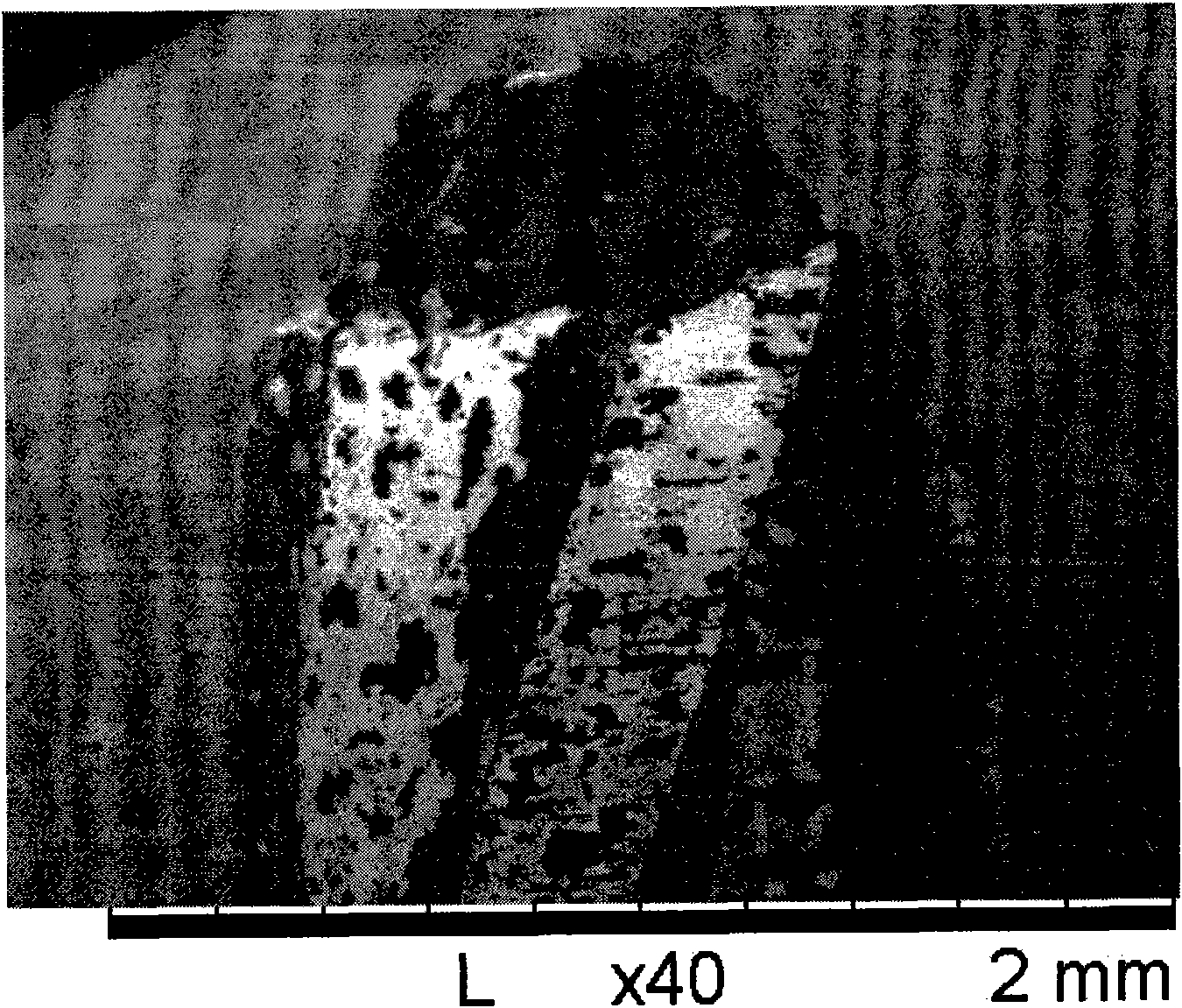

Micro-drill for copper alloy processing and preparation method thereof

ActiveCN101775587AImprove protectionExtended service lifeLayered productsVacuum evaporation coatingCarbon filmDiamond-like carbon

The invention discloses a micro-drill for copper alloy processing and a preparation method thereof. The micro-drill comprises a micro-drill base body and a thin film deposited on the surface of the micro-drill base body; and the thin layer consists of three film layers; a transitional metal element film layer, a transitional metal carbide film layer and a diamond-like carbon film layer are arranged on the surface of the micro-drill base body in sequence from inside to outside. The preparation method comprises the step that: after the tip of the micro-drill base body is shielded by metal wires, the deposition of three film layers is carried out on the micro-drill base body by a linear ion source or / and a magnetic control sputtering source. The invention takes the shielding measures with metal wires on the tip of the high-speed steel micro-drill, and then carries out deposition of a plurality of layers of films, thus greatly improving the wear resistance and anti-adhesion performance, service life and processing quality of the micro-drill for copper alloy processing.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Composite lubricating grease for heavy load bearing and preparation method thereof

PendingCN107502405AUniform sizeImproves strength and hardnessCarbon preparation/purificationAdditivesLithiumEvaporation

The invention relates to the field of lubricating grease, in particular to composite lubricating grease for a heavy load bearing and a preparation method thereof. The composite lubricating grease is prepared from the following ingredients in percentage by weight: 99.2 to 99.8 percent of lithium-based lubricating grease and 0.2 to 0.8 percent of micro carbon spheres and nanometer particles. The micro carbon spheres and nanometer particles are uniformly distributed in the lithium-based lubricating grease by using ethanol as carriers. Compared with the existing ordinary lithium-based lubricating grease, the composite lubricating grease prepared after the ethanol evaporation has the advantage that the improvement is realized in aspects of friction heating, friction mark area and the like.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of titanium alloy grading powder laser cladding layer and titanium alloy with same cladding layer

InactiveCN107761093AMeet specification requirementsHigh hardnessMetallic material coating processesHardnessPre treatment

The invention discloses a preparation method of a titanium alloy grading powder laser cladding layer. The method comprises the following steps: 1) preprocessing a base titanium alloy material; and removing oxide skin, greasy dirt and rust on the surface; 2) sieving to grade 70 Ni cladded B4C powder being 5-140 microns in particle size; 3) mixing the graded powder at different particle size grade to prepare 70 Ni cladded B4C grading powder; 4) uniformly mixing the 70 Ni cladded B4C grading powder and TC4 powder based on ratio so as to obtain cladding mixing coating grading powder; and 5) prearranging the cladding mixing coating grading powde4 on the surface of the base titanium alloy material; and performing laser cladding on a test block with the cladding mixing coating grading powder through 3*12mm, 3*24mm, 6*12mm or 6*24mm rectangular wide spots under the conditions that the power is 2-8kw, the scanning speed is 5-20mm / s and the argon protection environment is provided, thus obtaining the titanium alloy grading powder laser cladding layer. The cladding layer prepared through the method is high in hardness, high in durability and high in self-lubricating performance.

Owner:TIANJIN POLYTECHNIC UNIV

A load-bearing plane conveying device

InactiveCN102259747AAchieve self-lubricating effectWill not increase the loadConveyorsGraphiteEngineering

The invention discloses a load-bearing plane conveying device, which is composed of driving rollers, bearing seats, conveyor belts, graphite gaskets, pallets, brackets, brackets, racks, driven rollers, reduction motors and transmission chains , the driving roller is installed on the left side of the frame, the driven roller is installed on the right side of the frame, the geared motor installed in the middle of the left side of the frame drives the driving roller and the conveyor belt forward through the transmission chain, and the graphite gasket under the conveyor belt , the supporting plate and the bracket are connected together, the graphite gasket is supported by the supporting plate, and the bracket is installed on the frame through the bracket. The present invention designs the load-bearing structure according to the lubricating characteristics, horizontal heat conduction characteristics and transfer characteristics of graphite. The graphite gasket supports the conveyor belt for load-bearing and plays a lubricating role in the relative friction movement. Due to the transfer characteristics of graphite, the graphite will move from The graphite gasket is transferred to the conveyor belt to achieve self-lubrication and reduce the friction coefficient.

Owner:郝钰 +1

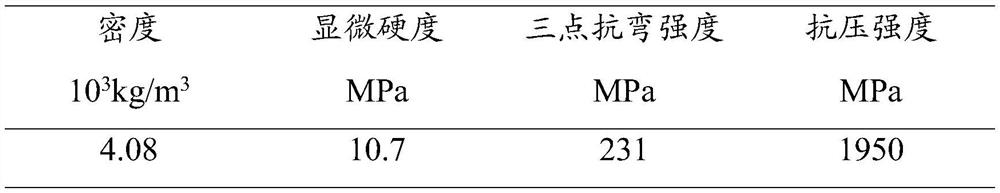

High-temperature self-lubricating composite material as well as preparation method and application thereof

The invention discloses a high-temperature self-lubricating composite material as well as a preparation method and application thereof, and relates to the technical field of wear-resistant materials. The preparation method comprises the following steps that after Ti3SiC2 powder and Cu powder are evenly mixed, under the vacuum condition, a spark plasma sintering process is adopted, the temperature is increased to 850-1350 DEG C, sintering is conducted for 5-10 min, then the temperature is decreased to 650-1100 DEG C, heat preservation is conducted for 10-20 min, and the Ti3SiC2 / Cu high-temperature self-lubricating composite material is obtained. According to the invention, a spark plasma sintering (SPS) technology is adopted, the preparation of the block material is completed at a relatively low temperature within a relatively short time, and the problem of high-temperature decomposition of Ti3SiC2 can be solved.

Owner:CHENGDU UNIV

A continuous carbon fiber sucker rod with wear-resistant protective layer and its preparation method

ActiveCN105298403BHigh friction durabilityGood self-lubricating propertiesDrilling rodsDrilling casingsGlass fiberPolymer science

The invention discloses a continuous carbon fiber sucker rod with a wear-resistant protective layer and a preparation method thereof, comprising a sucker rod body, a glass fiber layer coated on the surface of the sucker rod body, and a glass fiber layer coated outside A wear-resistant layer, the wear-resistant layer includes a fiber reinforced fabric and a thermoplastic resin layer coated on the surface of the fiber-reinforced fabric, the thermoplastic resin layer is evenly mixed with hard wear-resistant particles, so that the surface of the wear-resistant layer is evenly distributed with the Hard wear-resistant particles. Hard wear-resistant particles are evenly distributed on the surface of the sucker rod. Through the high hardness and wear resistance of the inorganic hard particles and the spherical ball form formed with the mesh fabric structure, the wear resistance of the wear-resistant layer on the surface of the composite sucker rod is strengthened. Partial wear characteristics. At the same time, the hard wear-resistant particles also play the role of interface mechanical engagement at the part in contact with the sucker rod body interface, preventing the slipping and delamination of the wear-resistant protective layer from the sucker rod surface.

Owner:SHANDONG UNIV

Iron-based self-lubricating wear-resistant alloy

InactiveCN1276116CGood friction compatibilityReduce coefficient of frictionWear resistantPetrochemical

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

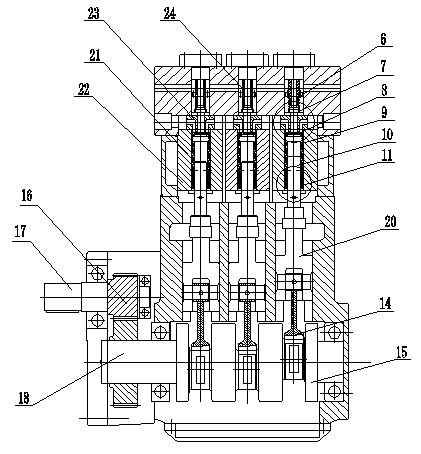

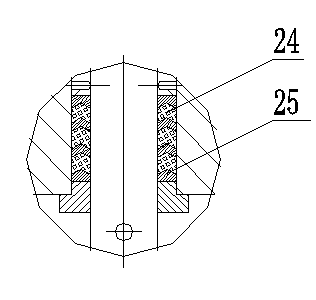

Ultrahigh pressure three-plunger water pump

InactiveCN103321866ASmall pulsation of high pressure water outputStable water pressurePositive-displacement liquid enginesMulti-cylinder pumpsPore water pressureHigh pressure water

An ultrahigh pressure three-plunger water pump includes a plunger seal, a suction valve and a drain valve, wherein the plunger seal adopts the alternated combined seal of a supra polymer PE seal body and a sponge body ceramic cushion block structure; the combined seal consists of four ceramic cushion blocks and three seal bodies; the suction valve includes a suction valve body and a suction valve block; the drain valve includes a drain valve body and a drain valve block; the suction valve block and the drain valve block adopt the structure that the surface of a heat-resistance stainless base body is coated with a ceramic layer; the thickness of the ceramic layer is 0.6 mm. Compared with the prior art, the ultrahigh pressure three-plunger water pump provided by the invention has the advantages of smaller high-pressure water ripple in output, more stable water pressure, higher volume efficiency, longer service life and lower running noise; the combined seal has the characteristics of high temperature resistance, frication resistance, high mechanical strength and excellent self-lubricating performance; compared with other water pumps of the same kind, the ultrahigh pressure three-plunger water pump has the benefits that the pressure grade is improved by 50 MPa, the service life is improved by 1.3 times, the volume efficiency is improved by 5%, and the running noise is reduced by 5 db.

Owner:SHANXI FANGSHENG HYDRAULIC MECHANICAL & ELECTRICAL EQUIP

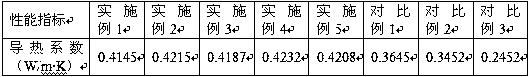

Graphene heat conduction master batch for elastomer material and preparation method

The invention relates to the field of heat conduction master batch preparation and discloses a graphene heat conduction master batch for an elastomer material and a preparation method. The preparationmethod comprises the following steps: (1) dispersing expanded graphite into a polyethylene solution with a perfluoroalkyl ethyl methyl methacrylate monomer, and carrying out ultraviolet radiation soas to obtain PE-g-PFAMAE / expanded graphite; (2) carrying out peeling and extrusion so as to obtain a mixed material with dispersed graphene; (3) mixing and kneading the mixed material with porous elastomer microspheres and silicone, and carrying out extrusion pelletizing, thereby obtaining the graphene heat conduction master batch. According to the graphene heat conduction master batch disclosed by the invention, a solid lubricant is generated among expanded graphite layers, effective peeling and dispersion of graphene are achieved, the graphene is further adhered to and packaged inside the porous elastomer microspheres through the silicone to prepare the master batch, the problem of graphene clustering is effectively solved, and heat conduction properties of the graphene can be relativelywell brought into play.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Ternary composite self-repairing unfired sliding plate brick and preparation method thereof

The invention discloses a ternary composite self-repairing unfired sliding plate brick and a preparation method thereof. The ternary composite self-repairing unfired sliding plate brick is prepared from the following components in percentage by mass: 5 to 10 parts of macrocrystalline fused magnesite with the particle size of 3 to 1mm, 15 to 25 parts of macrocrystalline fused magnesite with the particle size of 2 to 1mm, 5 to 15 parts of macrocrystalline fused magnesite with the particle size of 1 to 0.5 mm, 5 to 10 parts of macrocrystalline fused magnesite with the particle size of 0.5 to 0mm, 12 to 20 parts of 200-mesh macrocrystalline fused magnesite, 1 to 4 parts of -197 graphite, 0.5 to 3 parts of Al4SiC4 micro powder, 0.5 to 2 parts of nano SiC micro powder, 3 to 8 parts of 325-mesh metal Al powder, 0.5 to 3 parts of 200-mesh metal Si powder, 0.5 to 2 parts of boron carbide, 0.5 to 1 part of silicon boride, 2 to 4 parts of thermosetting phenolic resin and 2 to 4 parts of organic silicon resin. The ternary composite self-repairing sliding plate brick has a self-repairing function when being used at high temperature, and the oxidation resistance and high-temperature stability of a sliding plate are remarkably improved.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

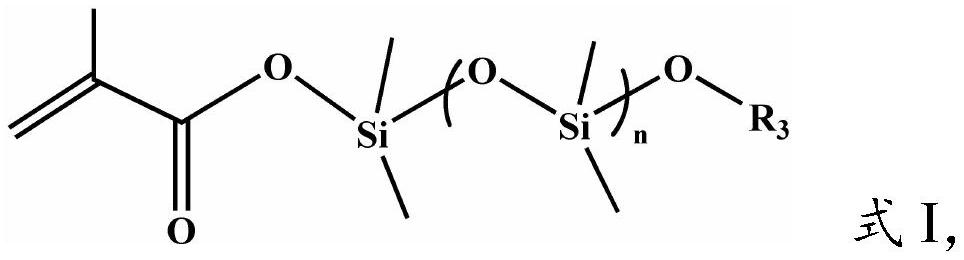

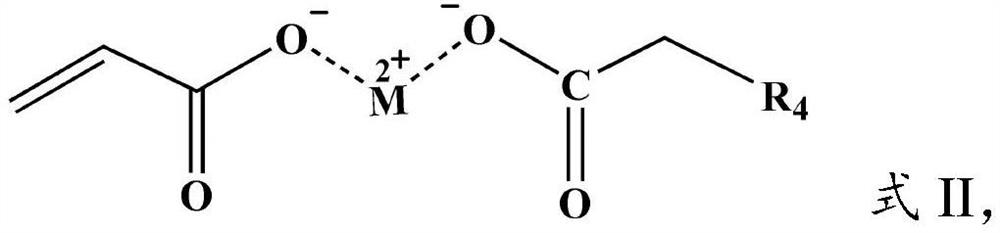

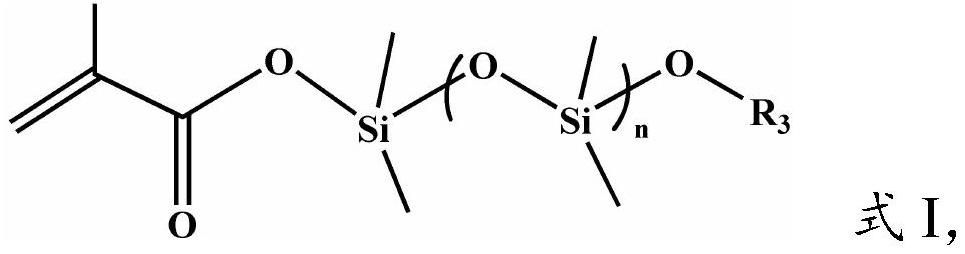

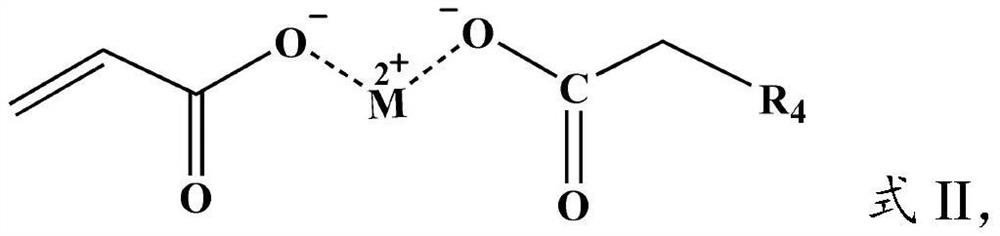

A kind of low-friction self-lubricating acrylic resin and its preparation method and application, low-friction self-lubricating marine antifouling coating

ActiveCN112480336BImprove adhesionExtend the antifouling periodAntifouling/underwater paintsPaints with biocidesOrganic acidPolymer science

The invention belongs to the technical field of lubricating functional materials, in particular to a low-friction self-lubricating acrylic resin, a preparation method and application thereof, and a low-friction self-lubricating marine antifouling coating. The structure of the low-friction self-lubricating acrylic resin provided by the present invention is grafted and introduced with silicone oil groups to construct a low-friction self-lubricating interface, which significantly improves the mechanical properties of the low-friction self-lubricating acrylic resin and is beneficial to improving the stability of the self-lubricating interface; Grafting introduces unsaturated organic acid divalent metal ion salt structure and sulfonic acid inner salt, which is beneficial to enhance the static antifouling performance of low-friction self-lubricating acrylic resin and prolong the antifouling effect; fluorine-containing acrylate structure and silicone oil structure are introduced together The main chain of the low-friction self-lubricating acrylic resin is beneficial to reduce the surface energy of the paint coating containing the low-friction self-lubricating acrylic resin and enhance the drag reduction performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Low-friction self-lubricating acrylic resin, preparation method and application thereof, and low-friction self-lubricating marine antifouling paint

ActiveCN112480336AEasy to disengageImprove bindingAntifouling/underwater paintsPaints with biocidesOrganic acidPolymer science

The invention belongs to the technical field of lubricating functional materials, and particularly relates to low-friction self-lubricating acrylic resin, a preparation method and application thereofand low-friction self-lubricating marine antifouling paint. According to the structure of the low-friction self-lubricating acrylic resin provided by the invention, a silicone oil group is grafted andintroduced to construct a low-friction self-lubricating interface, so that the stability of the self-lubricating interface is improved while the mechanical property of the low-friction self-lubricating acrylic resin is remarkably improved; besides, an unsaturated organic acid divalent metal ion salt structure and sulfonic acid inner salt are introduced through grafting, so that the static antifouling property of the low-friction self-lubricating acrylic resin is enhanced, and the antifouling period is prolonged; in addition, a fluorine-containing acrylate structure and a silicone oil structure are introduced into a low-friction self-lubricating acrylic resin main chain, so that the surface energy of a coating containing the low-friction self-lubricating acrylic resin is favorably reduced,and the drag reduction performance is enhanced.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

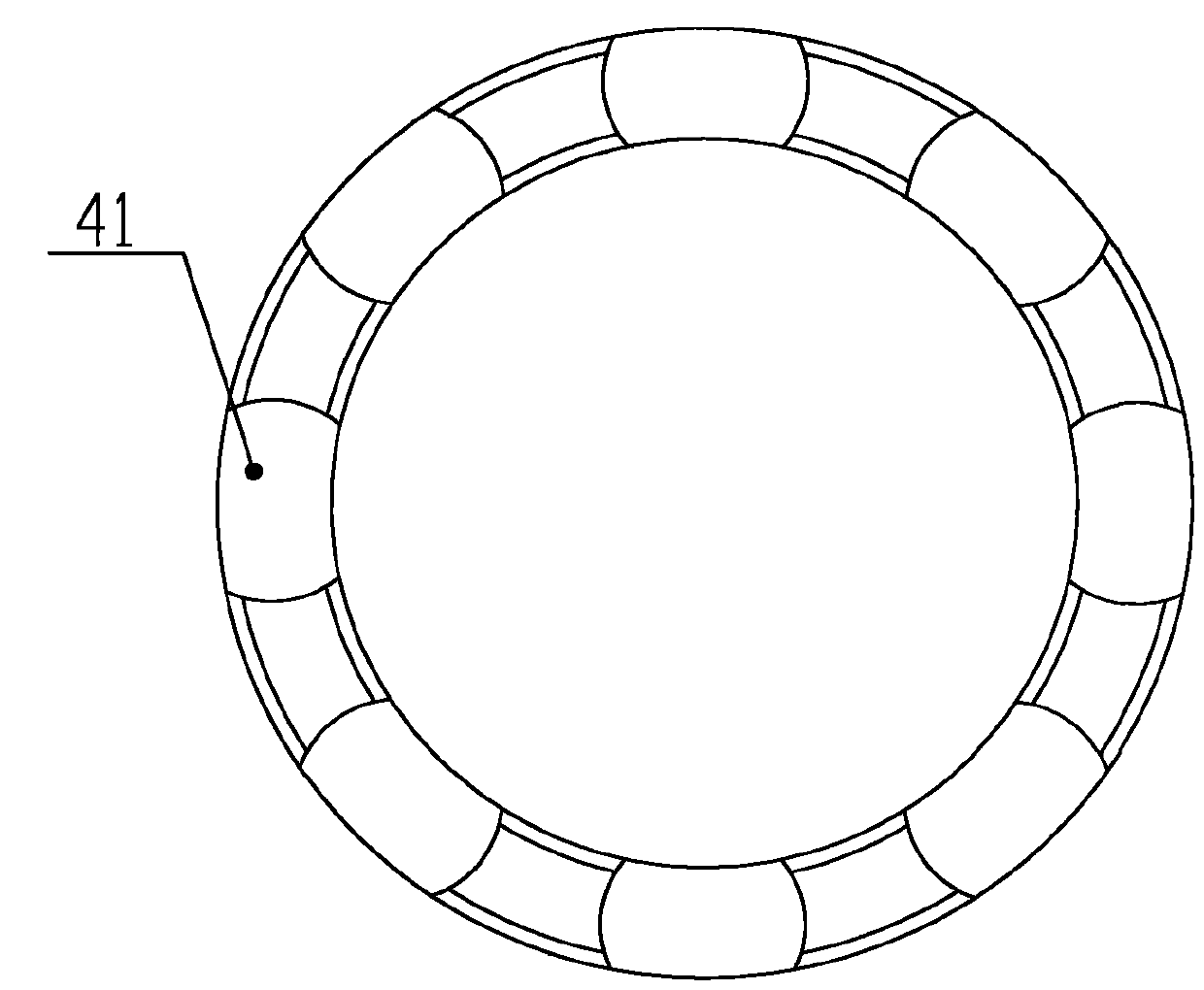

Rolling bearing taking carbon graphite or electrographite as integral holder and manufacturing method thereof

ActiveCN102052395BGood self-lubricating propertiesStable jobRolling contact bearingsBearing componentsLower limitStrong acids

The invention discloses a rolling bearing taking carbon graphite or electrographite as an integral holder, which comprises a bearing outer ring, an inner ring, a rolling body embedded between an outer ring roller path and an inner ring roller path, and a holder which uniformly separates the rolling body along a circumferential direction and is integrally formed by machining the carbon graphite or an electrographite pipe or an electrographite ring. The integral holder is made of the carbon graphite or the electrographite which has the advantages of high temperature resistance, low temperature resistance, corrosion resistance, and high strength, self-lubricating performance and machining performance, so that the holder is not a short slab which constrains the upper limit and the lower limit of the using temperature and the corrosion resistance of the bearing any longer. In an ultrahigh temperature, ultralow temperature or strong acid, alkali and salt medium invaded environment in which lubricating oil or lubricating grease cannot work, by using the carbon graphite or electrographite integral holder, the lubricating oil or the lubricating grease is not filled into the bearing, so that the invention has very high engineering application value.

Owner:SHANGHAI F&S BEARING TECH

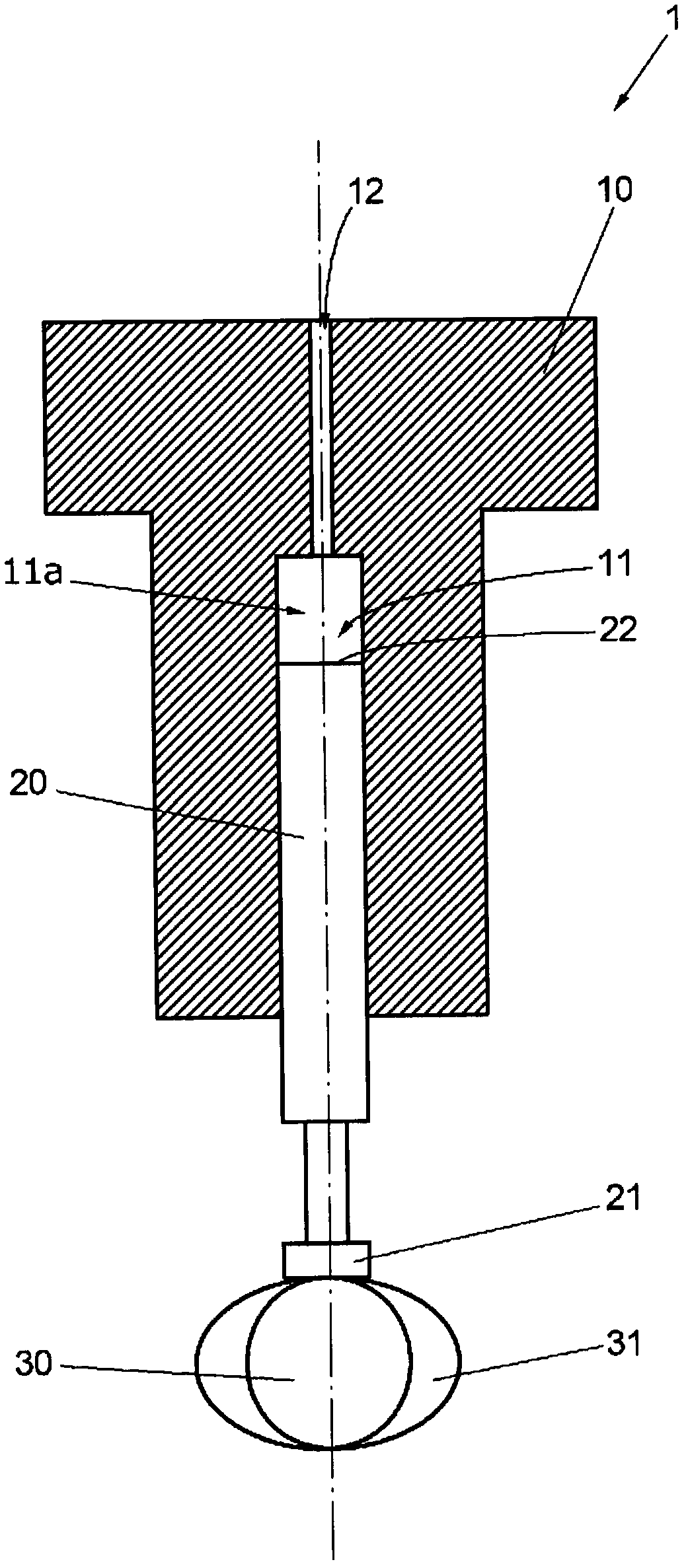

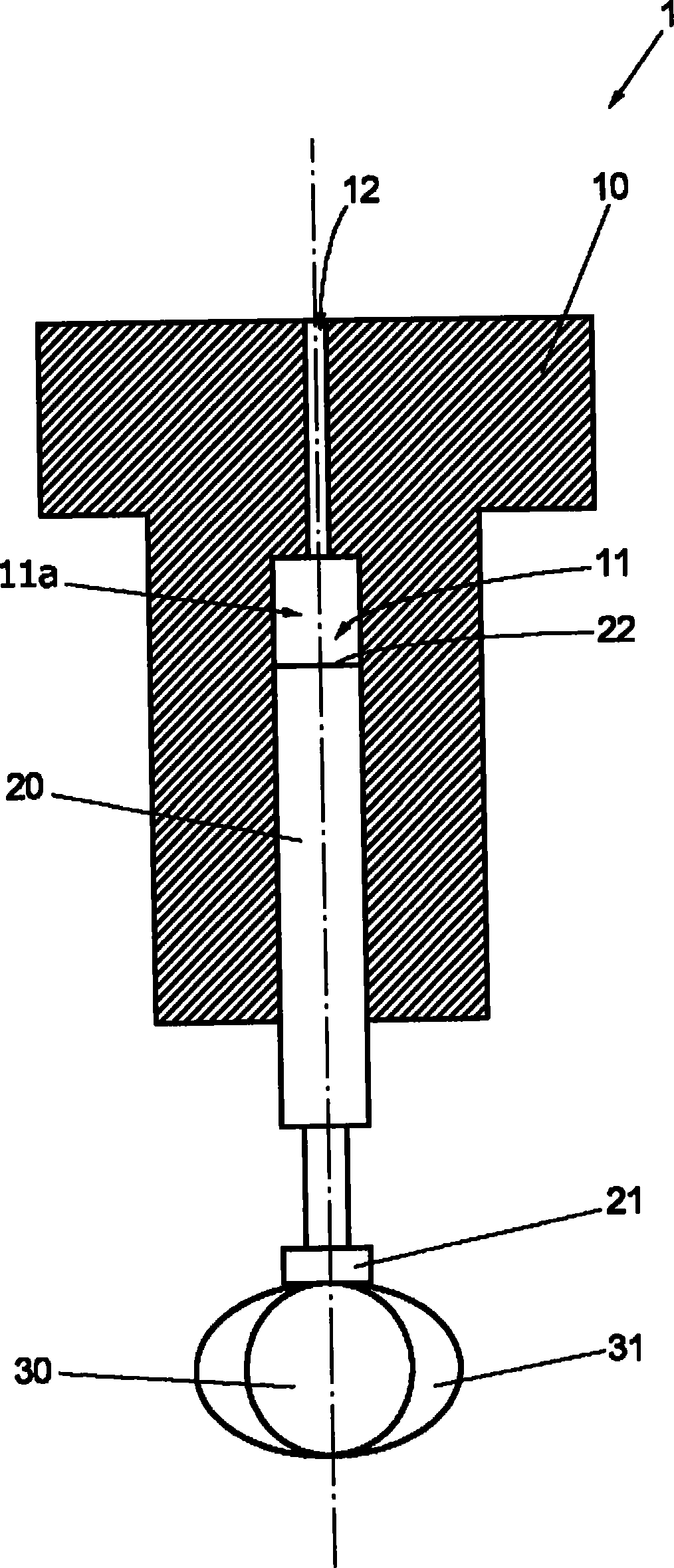

Fuel pump

InactiveCN102678416ALow manufacturing process costAvoid crackingPositive displacement pump componentsFuel injecting pumpsManufacturing technologyCommon rail

The invention provides a fuel pump (1), especially a high-pressure fuel pump of a common rail fuel system. The fuel pump comprises a metal pump cylinder (10) and a metal pump piston (20) movably guided therein. The fuel pump is manufactured by a manufacture technology with lower cost. Moreover, the pump piston (20) is made of a support material without heat treatment and coatings, wherein the support material is formed by a plastic alloy or a copper alloy.

Owner:MAN DIESEL & TURBO SE

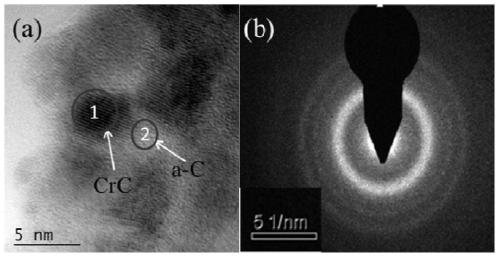

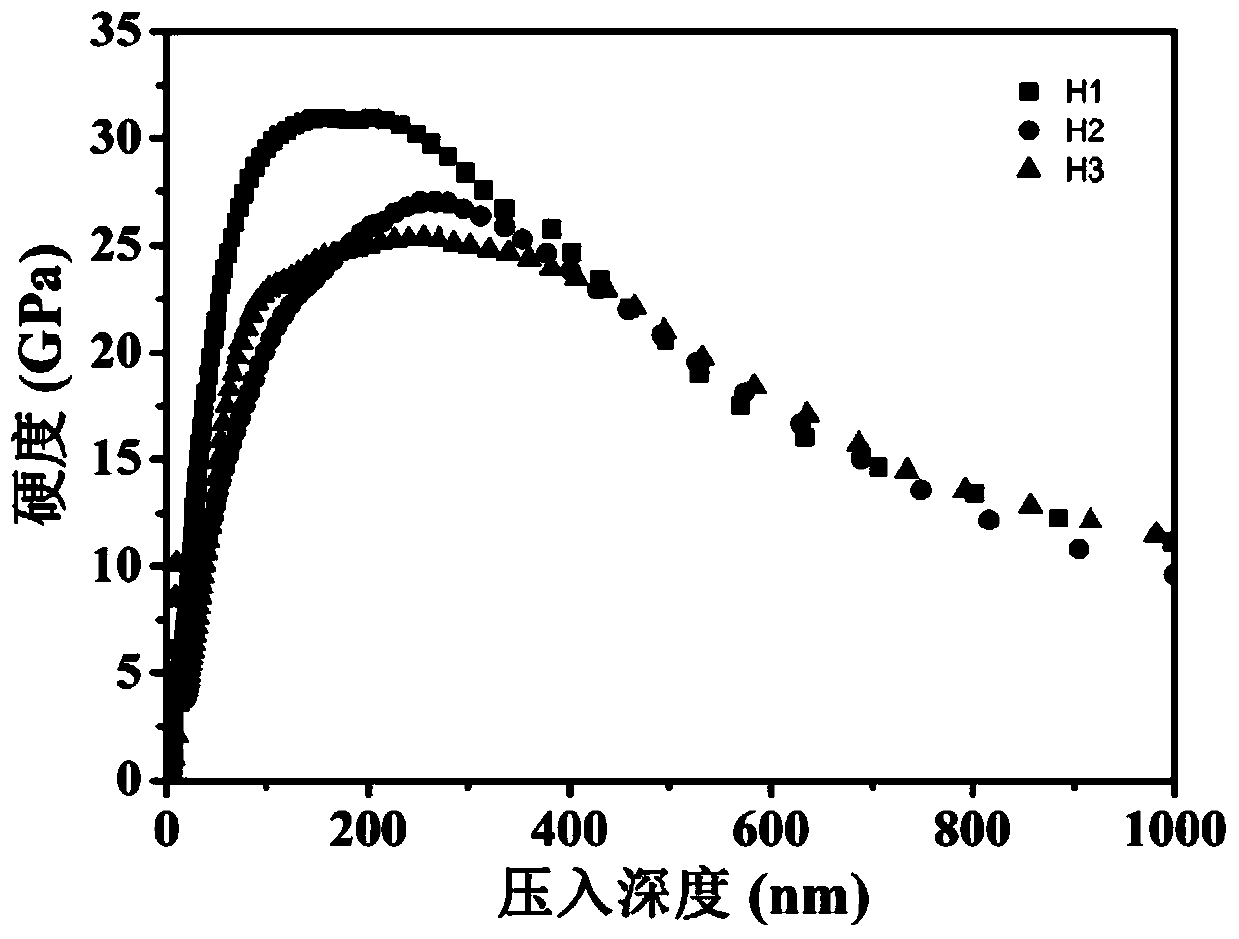

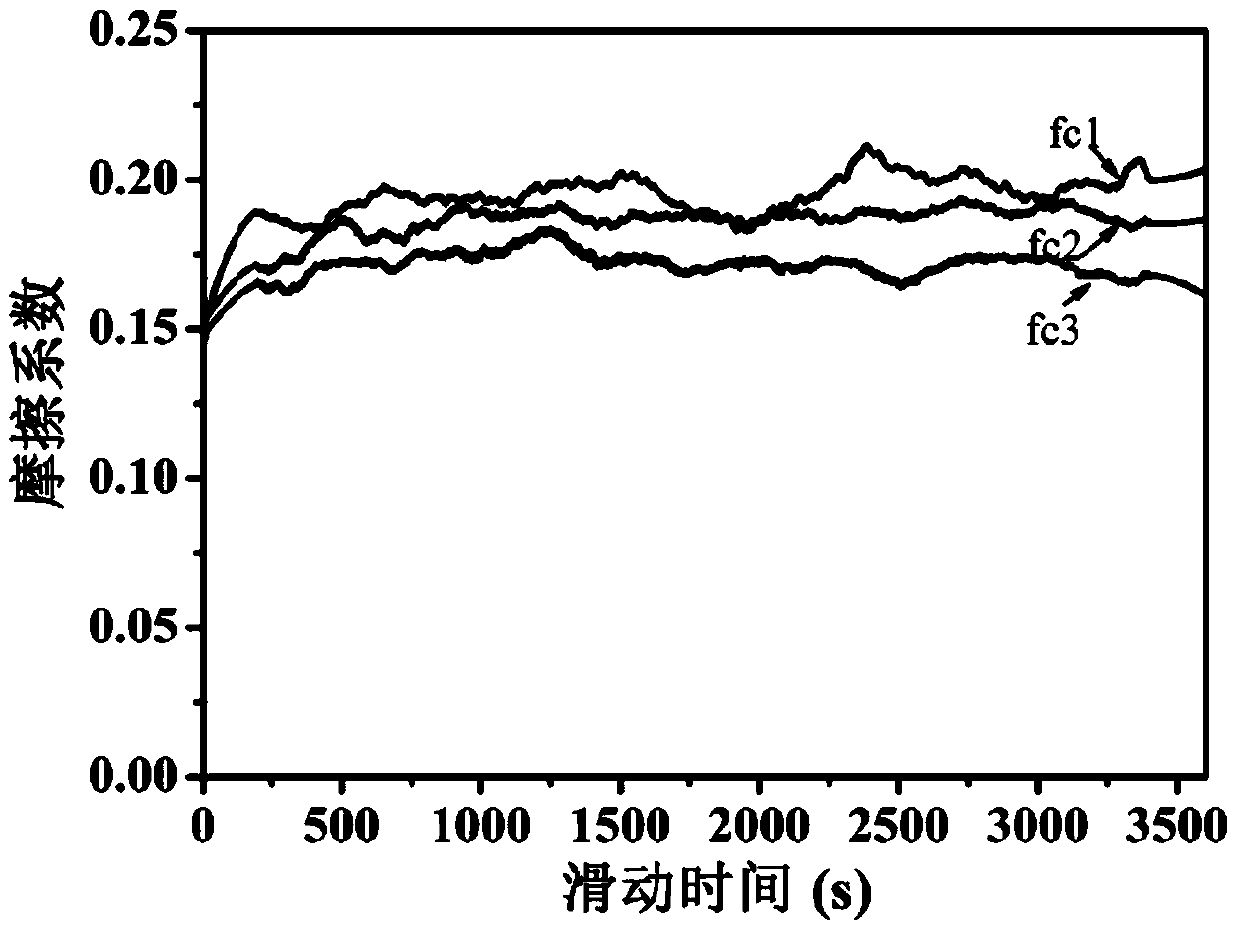

A solid lubricating composite coating on the surface of a substrate and its preparation method

ActiveCN106467959BReduce densityReduce coefficient of frictionVacuum evaporation coatingSputtering coatingPower flowHardness

The invention provides a solid lubrication composite coating on the surface of a base body. The composite coating is composed of hard phase nanocrystalline CrC and a lubricating phase a-C, a CrC / a-C composite coating is formed, the characteristics that the CrC hard coating is high in hardness and low in abrasion are kept, and meanwhile the excellent self-lubricating property of the a-C material is achieved. The multi-arc ion plating technology is adopted, metal Cr serves as a target material, high-purity Ar serves as working gas, C2H2 serves as reaction gas, the CrC / a-C composite coating is deposited on the surface of the base body, and the content of the CrC phase and the a-C phase in the composite coating can be regulated and controlled by controlling the flow of the Cr target current and the reaction gas C2H2. The hardness of the composite coating reaches up to 31 GPa, the abrasion rate reaches the magnitude of 10<-16> m<3> / N.m, the friction coefficient in the atmospheric environment is lower than 0.2, the base body working in the high-abrasion and high-friction environment can be well protected, and very high application value is achieved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Bottom power taking self-locking electric bus battery box system capable of quickly changing battery

ActiveCN102303589BEasy to installPositioning constraints resolvedElectric propulsion mountingElectric vehicle charging technologyElectricityPower battery

The invention discloses a bottom power taking self-locking electric bus battery box system capable of quickly changing a battery. The system comprises a battery box (1), a tray (2) used for bearing the battery box and arranged on an electric bus, mobile equipment (4) for conveying the battery box, and a grabbing device (5) arranged on the mobile equipment; and a battery box locking and unlocking device (3) is arranged on the tray. Through the system, automatic assembly of the battery box in the electric bus battery box system is realized, and the problems of over positioning, deformation of power wire connection pegs, breakage, arc discharge, welding, difficulty in automatically realizing unlocking due to impact of the battery box to a bolt of a locking mechanism in jolt and deformation of the battery box due to impact in jolt. The system is reasonable, reliable, simple and compact in structure, and can full-automatically, quickly and conveniently realize quick change of the power battery.

Owner:KUNMING SHIPBUILDING EQUIP

Lubricating oil modifying aid and preparation method and application thereof

ActiveCN111808652AIncrease coefficient of frictionReduce coefficient of frictionAdditivesRolling resistance optimizationGraphiteMaterials science

The invention provides a lubricating oil modifying aid. The lubricating oil modifying aid comprises fluorinated expanded graphite as a supporter and permanent magnet material particles adsorbed on thesurface of the supporter, and the lubricating oil modifying aid is worm-shaped. The lubricating oil modifying aid is low in friction coefficient, good in lubricating effect and high in adsorption capacity, modification treatment of lubricating oil is facilitated, the lubricating performance of lubricating oil under the low-temperature condition is improved, and therefore the problem of resonancesqueal caused by starting impact at the low temperature and the normal temperature is completely eradicated.

Owner:CHIAPHUA COMPONENTS SHENZHEN +1

crsic composite coating for water-based liquid environment and its preparation method and application

ActiveCN109957764BReduce coefficient of frictionReduce shear stressVacuum evaporation coatingSputtering coatingHigh densityAlloy

The invention discloses a CrSiC composite coating for a water-based liquid environment as well as a preparation method and application of the CrSiC composite coating. The CrSiC composite coating comprises a composite structure of hard-phase nanocrystalline CrC and lubricating-phase amorphous carbon a-C: H / Si.. The lubricating phase is a matrix, and the hard phase is dispersed and distributed in the matrix. The preparation method comprises the following steps: by adopting a multi-arc ion plating technology, by taking CrSi alloy as a target material, the protective gas as the working gas and C2H2 as the reaction gas, the negative bias is applied to the matrix, the target current is applied to the CrSi alloy target, and deposition is carried out on the surface of the matrix to form the CrSiCcomposite coating. The CrSiC composite coating has the advantages of low internal stress, high density, low friction, low wear and the like in a water environment, is suitable for matrix protection under high-wear and high-corrosion working conditions in a water-based liquid environment, and can improve the comprehensive performance of the matrix and prolong the service life of the matrix.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com