Graphene heat conduction master batch for elastomer material and preparation method

An elastomer material, graphene technology, applied in the field of preparation of thermally conductive masterbatches, can solve problems such as the inability to fully utilize the thermal conductivity of graphene, and the difficulty of dispersing graphene, achieve excellent self-lubricating properties, solve agglomeration, good fluidity and Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

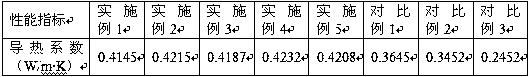

Examples

Embodiment 1

[0026] (1) First disperse the expanded graphite in the polyethylene solution containing perfluoroalkyl ethyl methacrylate monomer, irradiate with ultraviolet light, and generate a self-lubricating graft product PE-g- between the expanded graphite layers PFAMAE, PE-g-PFAMAE / expanded graphite is prepared; the ultraviolet wavelength of ultraviolet radiation is 220nm, and the irradiation distance is 16cm; the irradiation is 30min.

[0027] In the preparation process of PE-g-PFAMAE / expanded graphite, in parts by weight, wherein: 64 parts by weight of expanded graphite, 13 parts by weight of perfluoroalkyl ethyl methacrylate monomer, 23 parts by weight of polyethylene solution; , The polyethylene solution is a solution obtained by dissolving polyethylene in benzene with a mass concentration of 20%.

[0028] (2) Add the PE-g-PFAMAE / expanded graphite prepared in step (1) into a co-rotating intermeshing twin-screw extruder for peeling and extruding, and extrude into a mixed material wi...

Embodiment 2

[0032] (1) First disperse the expanded graphite in the polyethylene solution containing perfluoroalkyl ethyl methacrylate monomer, irradiate with ultraviolet light, and generate a self-lubricating graft product PE-g- between the expanded graphite layers PFAMAE, to prepare PE-g-PFAMAE / expanded graphite; the ultraviolet wavelength of ultraviolet radiation is 100nm, the irradiation distance is 10cm; the irradiation time is 45min.

[0033] In the preparation process of PE-g-PFAMAE / expanded graphite, in parts by weight, wherein: 70 parts by weight of expanded graphite, 10 parts by weight of perfluoroalkyl ethyl methacrylate monomer, 20 parts by weight of polyethylene solution; , The polyethylene solution is a solution obtained by dissolving polyethylene in benzene with a mass concentration of 20%.

[0034](2) Add the PE-g-PFAMAE / expanded graphite prepared in step (1) into a co-rotating intermeshing twin-screw extruder for peeling and extruding, and extrude into a mixed material wit...

Embodiment 3

[0038] (1) First disperse the expanded graphite in the polyethylene solution containing perfluoroalkyl ethyl methacrylate monomer, irradiate with ultraviolet light, and generate a self-lubricating graft product PE-g- between the expanded graphite layers PFAMAE is prepared from PE-g-PFAMAE / expanded graphite; the ultraviolet wavelength of ultraviolet radiation is 300nm, and the irradiation distance is 20cm; the irradiation time is 50min.

[0039] In the preparation process of PE-g-PFAMAE / expanded graphite, in parts by weight, wherein: 60 parts by weight of expanded graphite, 15 parts by weight of perfluoroalkyl ethyl methacrylate monomer, 25 parts by weight of polyethylene solution; , The polyethylene solution is a solution obtained by dissolving polyethylene in benzene with a mass concentration of 20%.

[0040] (2) Add the PE-g-PFAMAE / expanded graphite prepared in step (1) into a co-rotating intermeshing twin-screw extruder for peeling and extruding, and extrude into a mixed ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com