Nano solid lubricant and nano ceramic grain composite modified cutter material and preparation method thereof

A compound modification and tool material technology, applied in the field of ceramic tool materials, can solve the problems of difficult balance between mechanical properties and friction and wear properties, achieve uniform and refined microstructure, improve bending strength and fracture toughness, and have good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

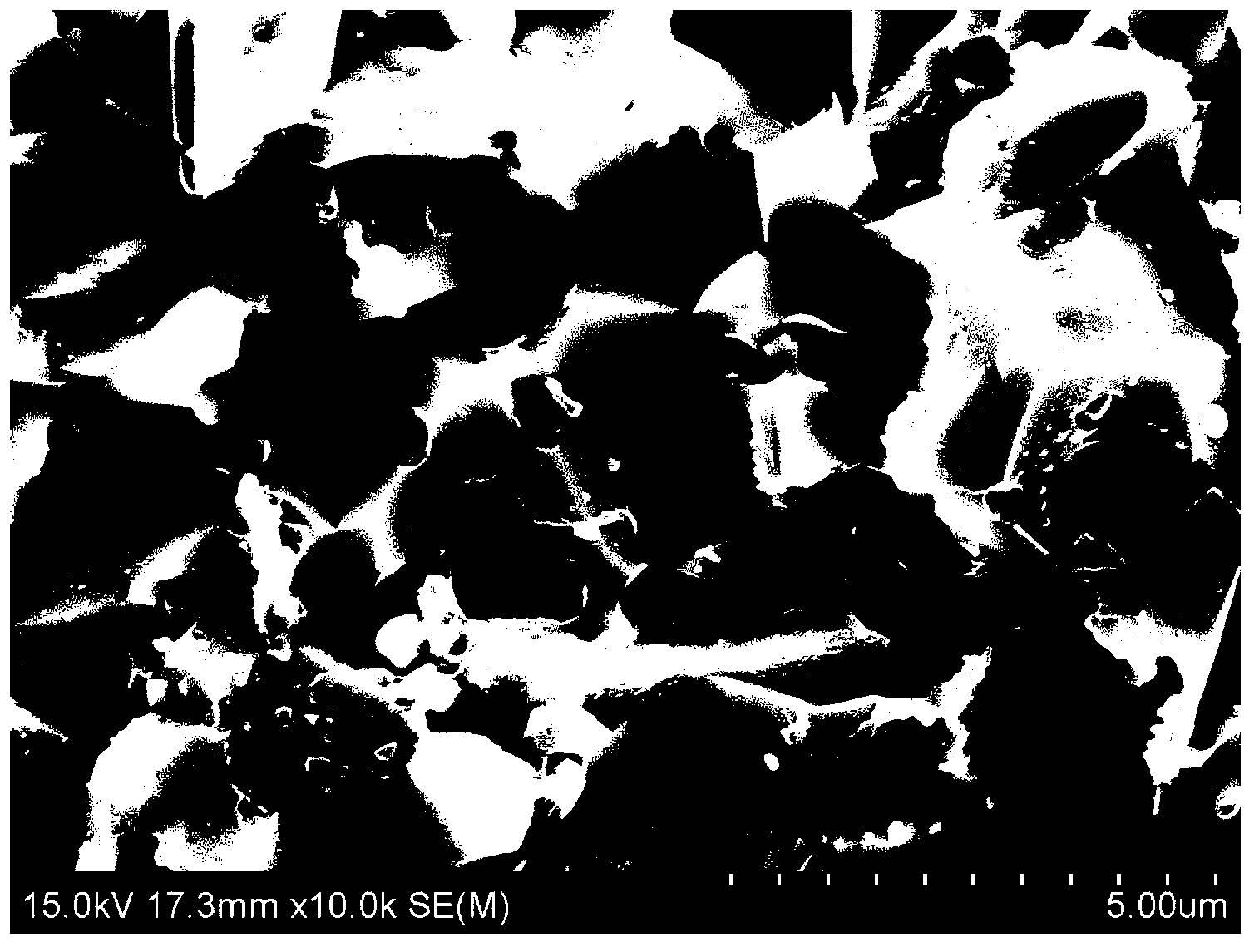

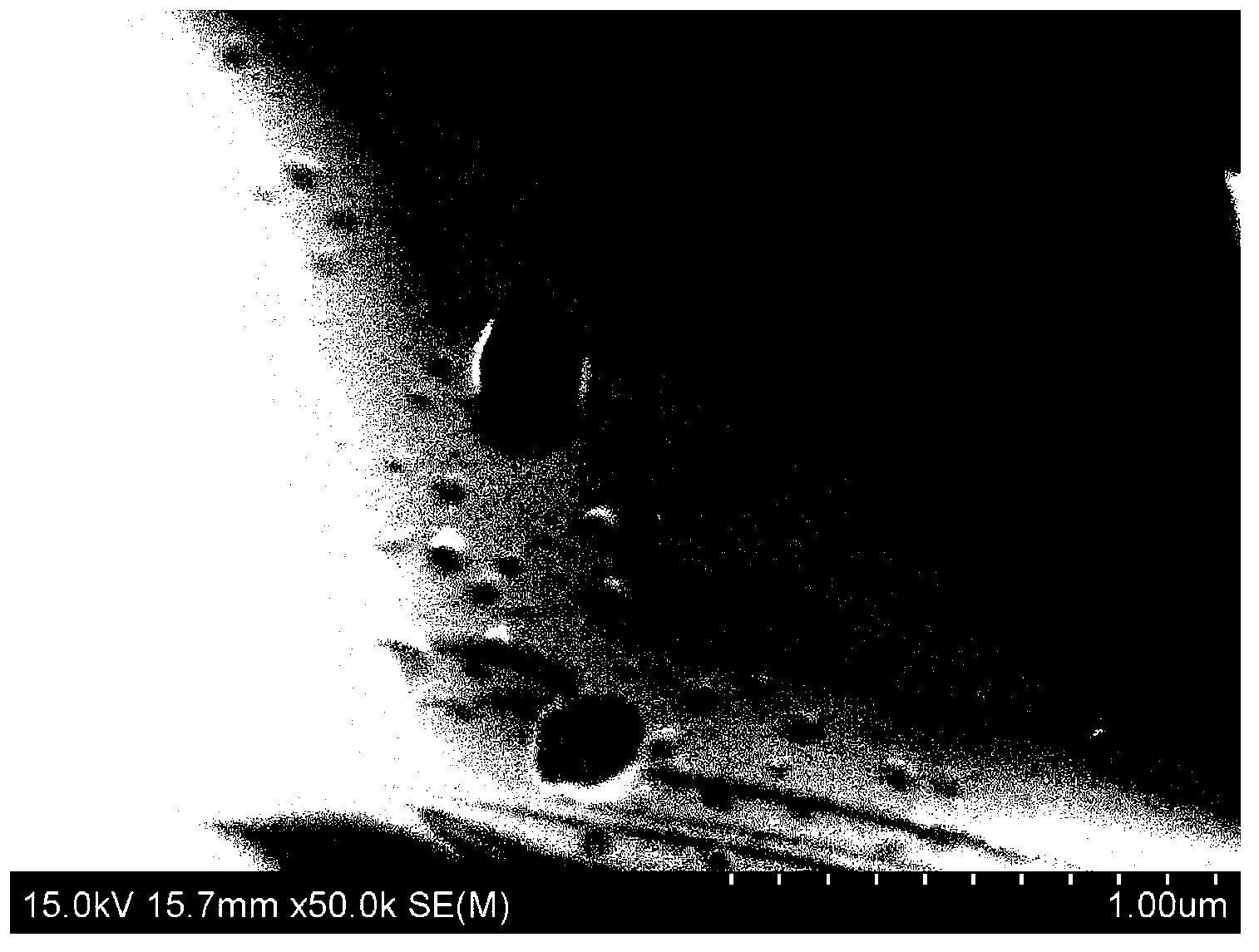

Image

Examples

Embodiment 1

[0031] Nano solid lubricant and nano ceramic particle composite modified tool material, the volume percentage of the raw material component is: 40% micron Al 2 o 3 , 45.5% micron TiC, 10% nano CaF 2 , 4% nano Al 2 o 3 Ceramic particles, 0.5% MgO.

[0032] The preparation method is as follows:

[0033] (1) Weigh polyethylene glycol 4000 (PEG4000) as a dispersant, dissolve it in absolute ethanol, and prepare two 100mL PEG4000 dispersions with a concentration of 3g / L; weigh nano-alumina and nano-calcium fluoride in Under the conditions of ultrasonic and mechanical stirring, respectively add to two prepared dispersion liquids to obtain nano-alumina dispersion liquid and nano-calcium fluoride dispersion liquid respectively, and ultrasonically stir for 30 minutes;

[0034] (2) Then, mix two nano-alumina dispersions and nano-calcium fluoride dispersions together, and add micron alumina, micron titanium carbide and sintering aid magnesium oxide into the mixed solution according t...

Embodiment 2

[0039] Nano solid lubricant and nano ceramic particle composite modified tool material, the volume percentage of the raw material component is: 55% micron Al 2 o 3 , 34% micro TiC, 5% nano CaF 2 , 5.5% nano Al 2 o 3 Ceramic particles, 0.5% MgO.

[0040] The preparation method is as follows:

[0041] (1) Weigh polyethylene glycol 4000 as a dispersant, dissolve it in absolute ethanol, and prepare two 100mL PEG4000 dispersions with a concentration of 4g / L; Under the condition of mechanical stirring, add the two prepared dispersions respectively to obtain the nano-alumina dispersion and the nano-calcium fluoride dispersion respectively, and stir ultrasonically for 25 minutes;

[0042] (2) Then, mix two nano-alumina dispersions and nano-calcium fluoride dispersions together, and add micron alumina, micron titanium carbide and sintering aid magnesium oxide into the mixed solution according to the proportion, and ultrasonically disperse for 25 minutes;

[0043] (3) Add the disp...

Embodiment 3

[0047] Nano solid lubricant and nano ceramic particle composite modified tool material, the volume percentage of the raw material component is: 45% micron Al 2 o 3 , 34.5% micron TiC, 15% nano CaF 2 , 4.5% nano-Al 2 o 3 Ceramic particles, 1% MgO.

[0048] The preparation method is as follows:

[0049] (1) Weigh polyethylene glycol 4000 as a dispersant, dissolve it in absolute ethanol, and prepare two 100mL PEG4000 dispersions with a concentration of 2g / L; weigh nano-alumina and nano-calcium fluoride in the ultrasonic and Under the condition of mechanical stirring, add to two prepared dispersions respectively to obtain nano-alumina dispersion and nano-calcium fluoride dispersion respectively, and ultrasonically stir for 30 minutes;

[0050] (2) Then, mix two nano-alumina dispersions and nano-calcium fluoride dispersions together, and add micron alumina, micron titanium carbide and sintering aid magnesium oxide into the mixed solution according to the proportion, and ultras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com