Patents

Literature

299results about How to "Meet specification requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

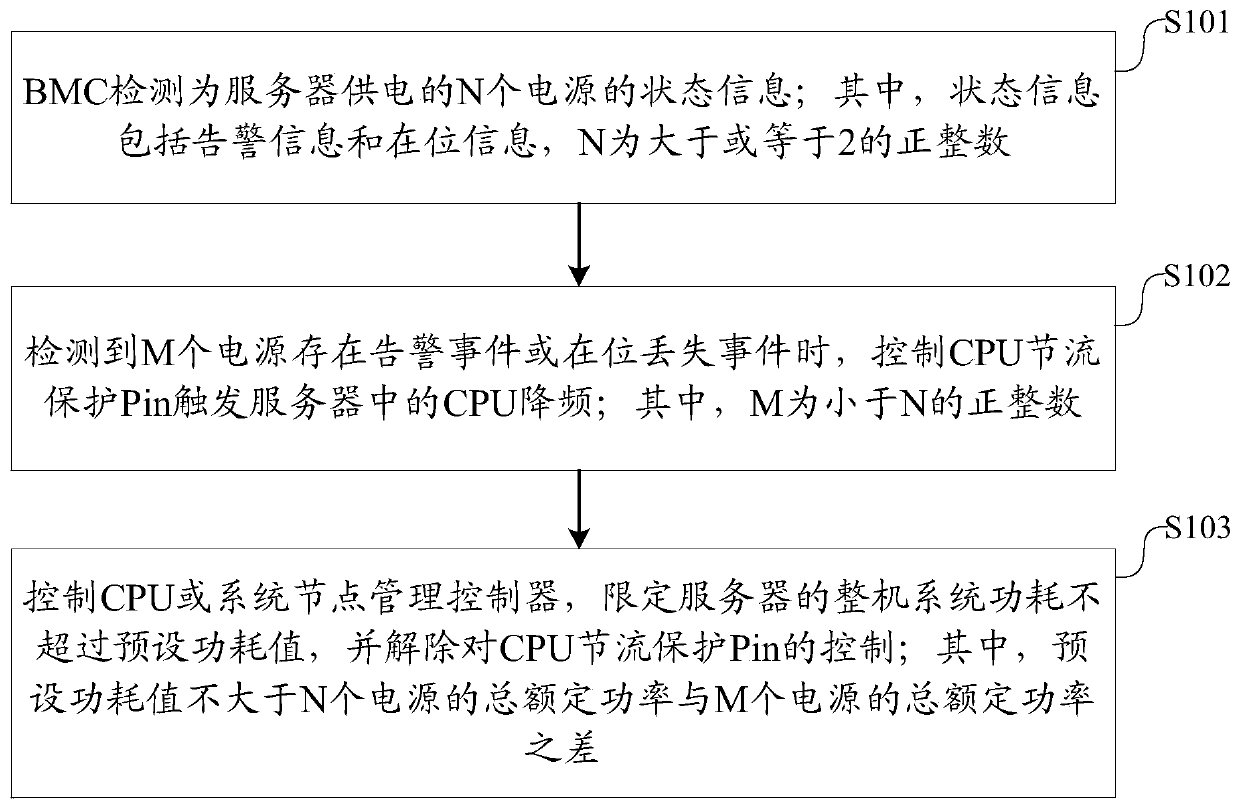

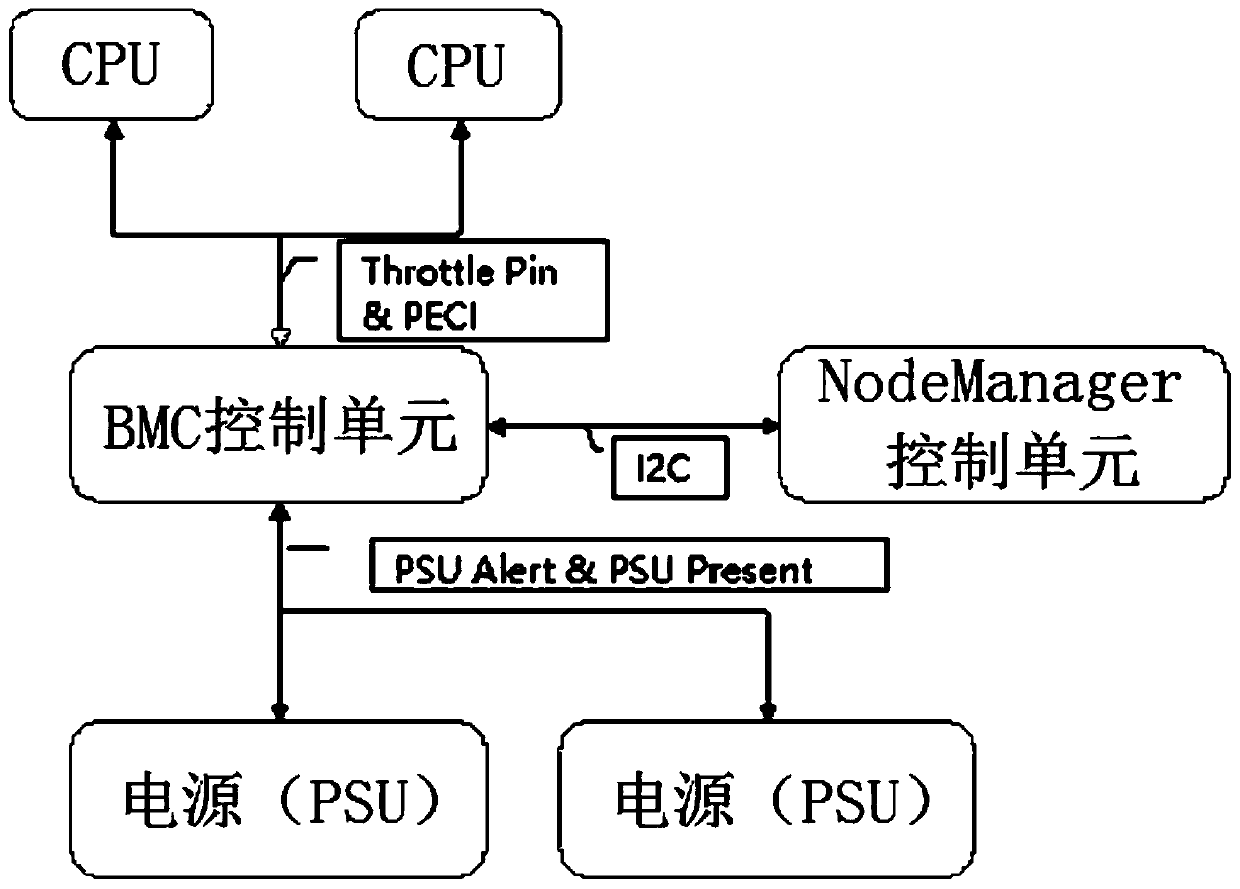

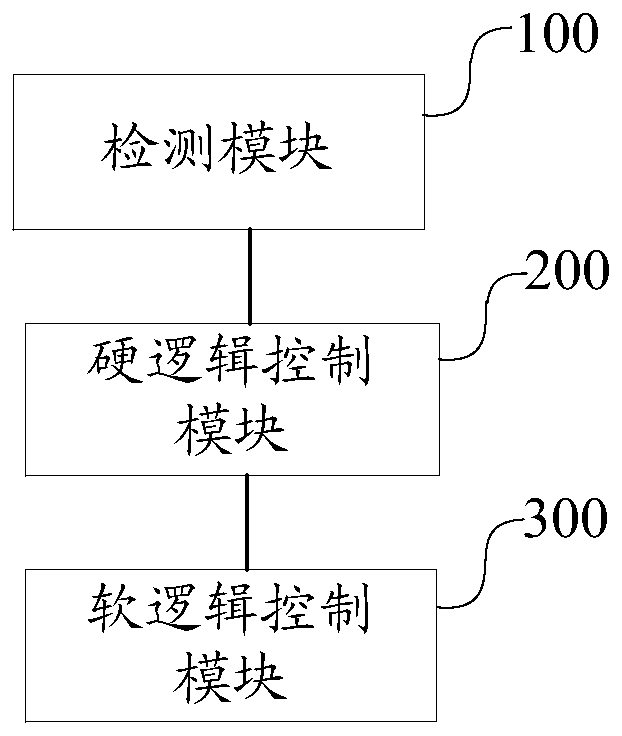

Server power supply cold redundancy control method and device based on BMC and BMC

InactiveCN110147155ARelease of controlLimited Power ConsumptionVolume/mass flow measurementPower supply for data processingMachining systemEmbedded system

The invention discloses a server power supply cold redundancy control method and device based on a BMC, the BMC and a server. The method comprises the steps that the BMC detects state information of Npower supplies for supplying power to the server; when it is detected that an alarm event or an in-place loss event exists in the M power supplies, a CPU throttling protection Pin is controlled to trigger a CPU in the server to reduce the frequency; the CPU or the system node management controller is controlled to limit the whole machine system power consumption of the server not to exceed a preset power consumption value; in the invention, the BMC controls the CPU throttling protection Pin to trigger the CPU to reduce the frequency and rapidly reduce the power consumption of the whole machine system, thereby avoiding the overload of the power consumption of the system caused by abnormal output of a redundant power supply; and the power consumption of the whole system is limited not to exceed the preset power consumption value through the control CPU or the system node management controller, so that the control of the cold redundancy of the server power supply is realized, the specification requirement of a client on the cold redundancy of the power supply in the high-configuration server application is met, and the power supply design complexity and the power supply cost are reduced.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

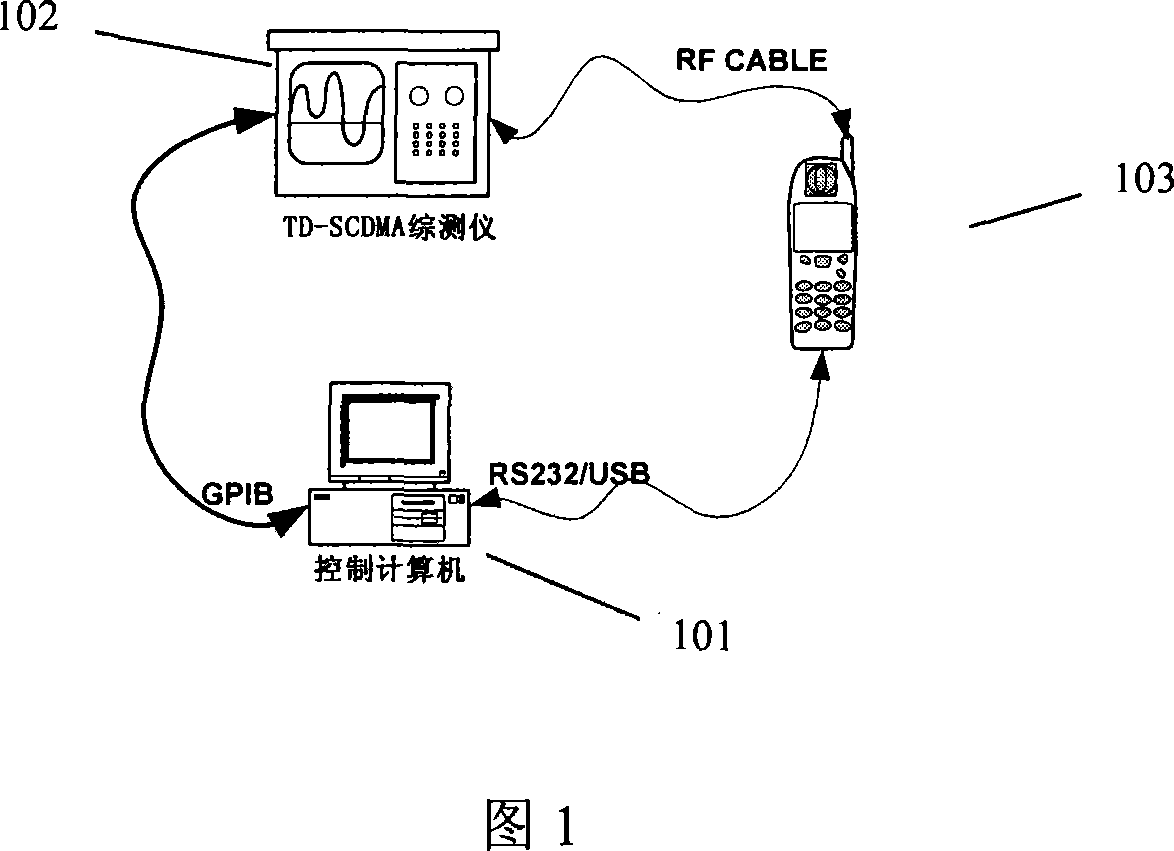

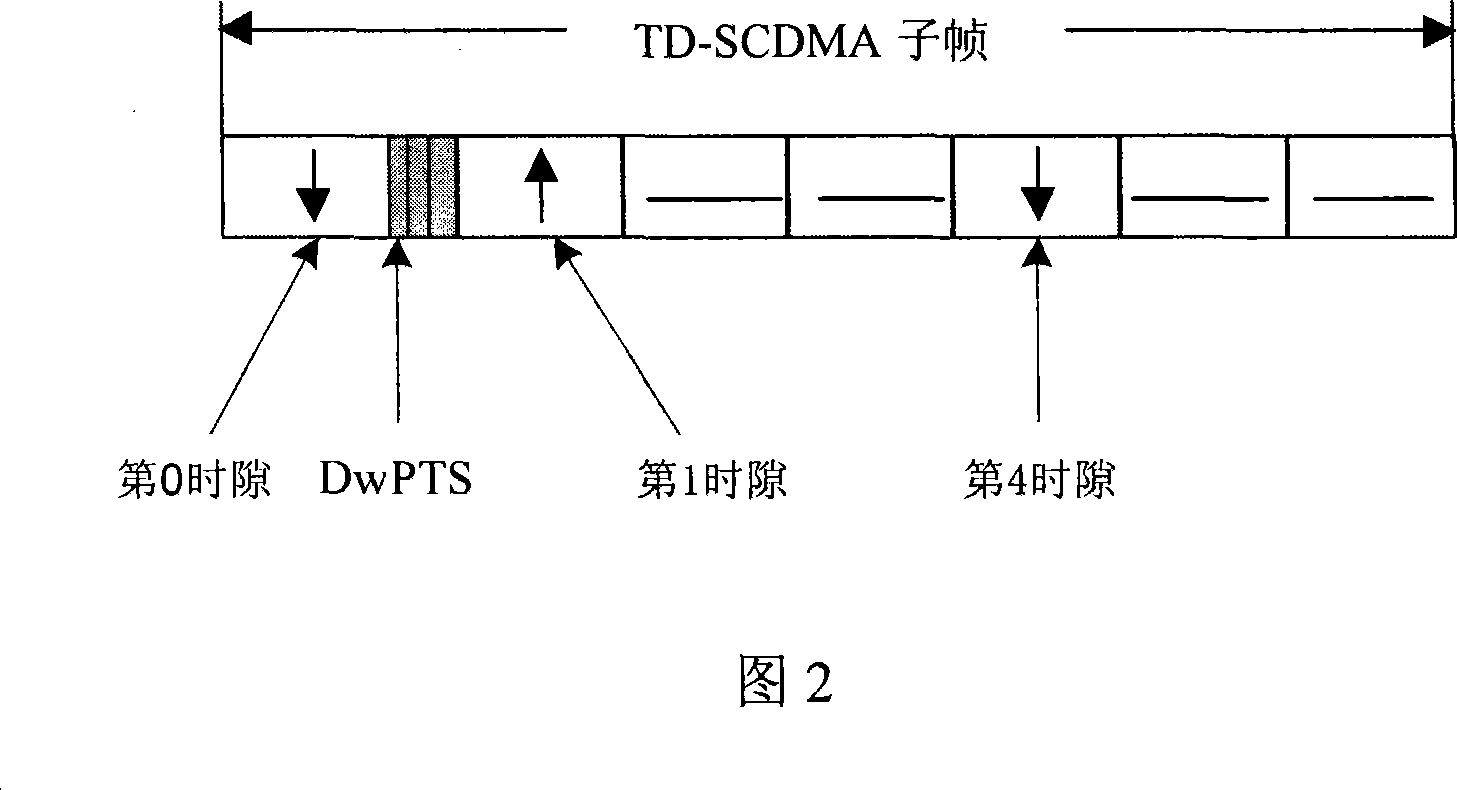

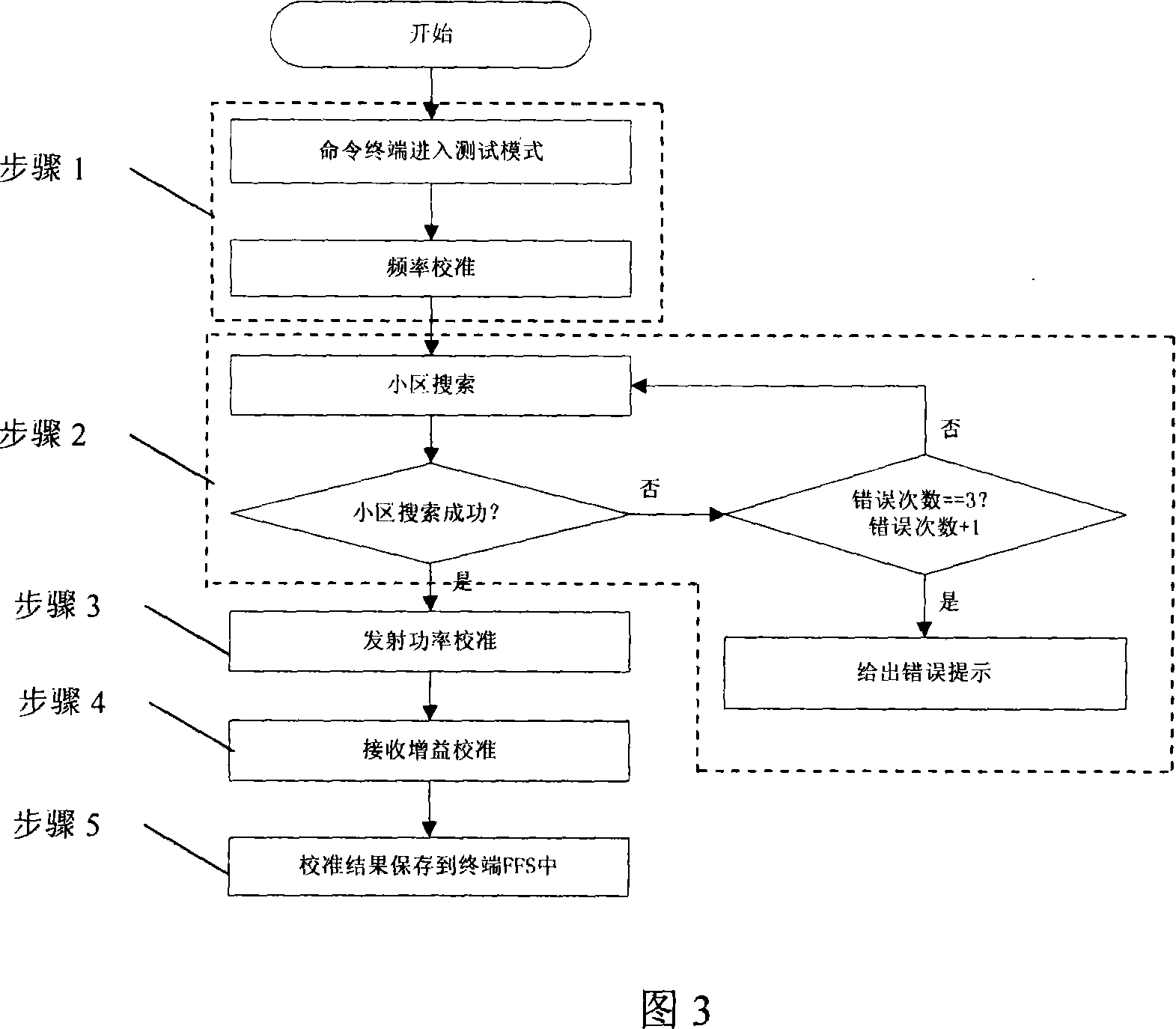

Method and device for automatic calibration of third-generation TD-SCDMA mobile terminal

InactiveCN101047915ARealize automatic calibrationImprove calibration accuracyTransmission control/equalisingCode division multiplexRadio frequencyEmission power

This invention relates to an automatic calibration method and a device for radio frequencies of TD-SCDMA / 3G mobile terminals, which can calibrate RF, emission power and received gain of mobile terminals automatically and store the calibrated results in NVRAM in the way of files with FFS. This invention can adjust the RF performance of terminals effectively mainly to current TD-SCDMA mobile terminals that their chips do not have the same control attribute.

Owner:XUANPU INDUSTRY CO LTD

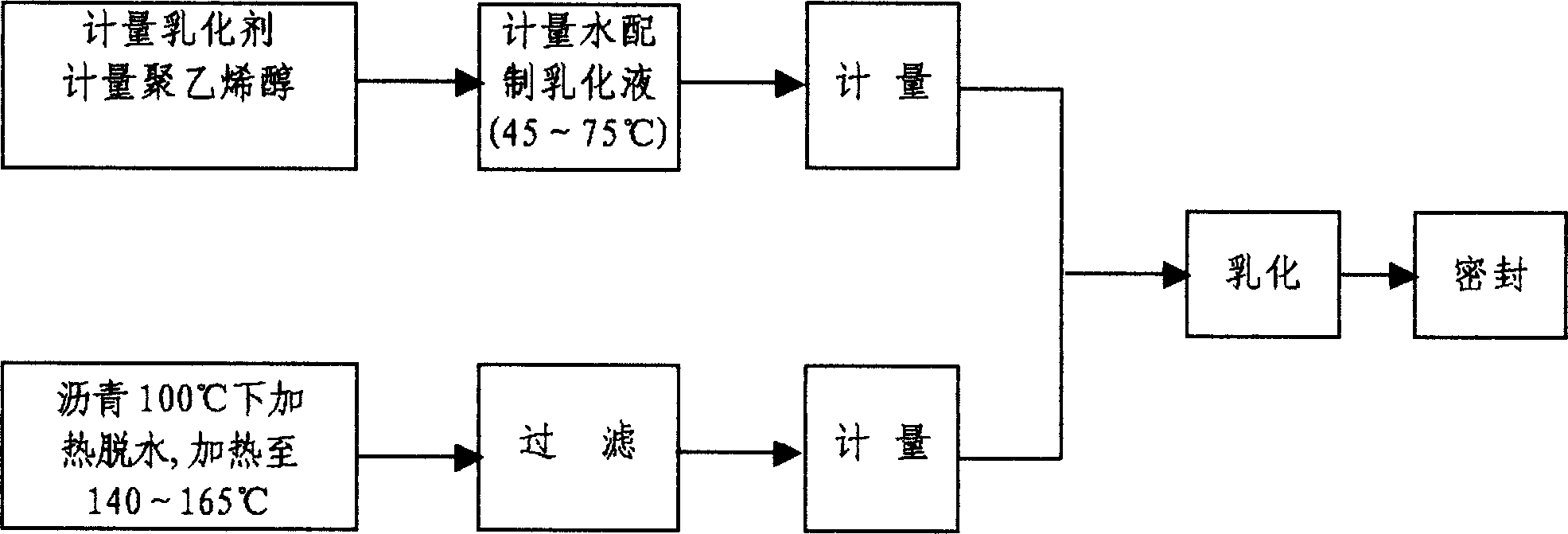

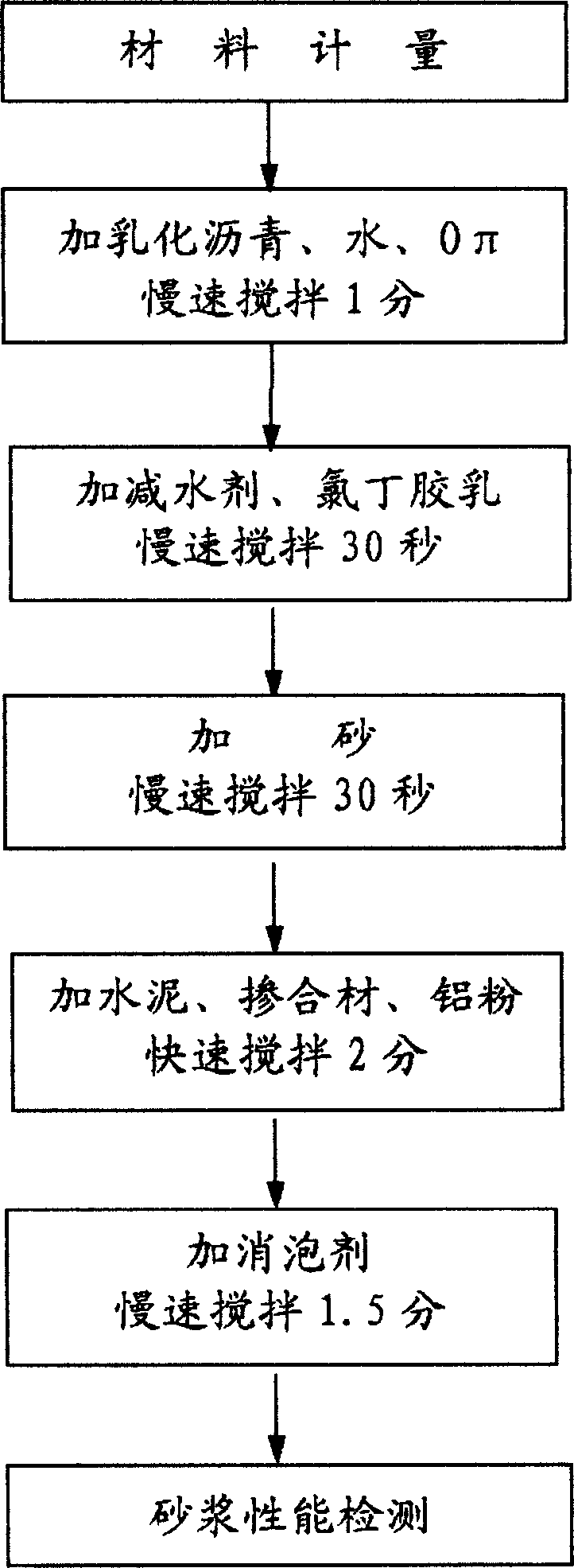

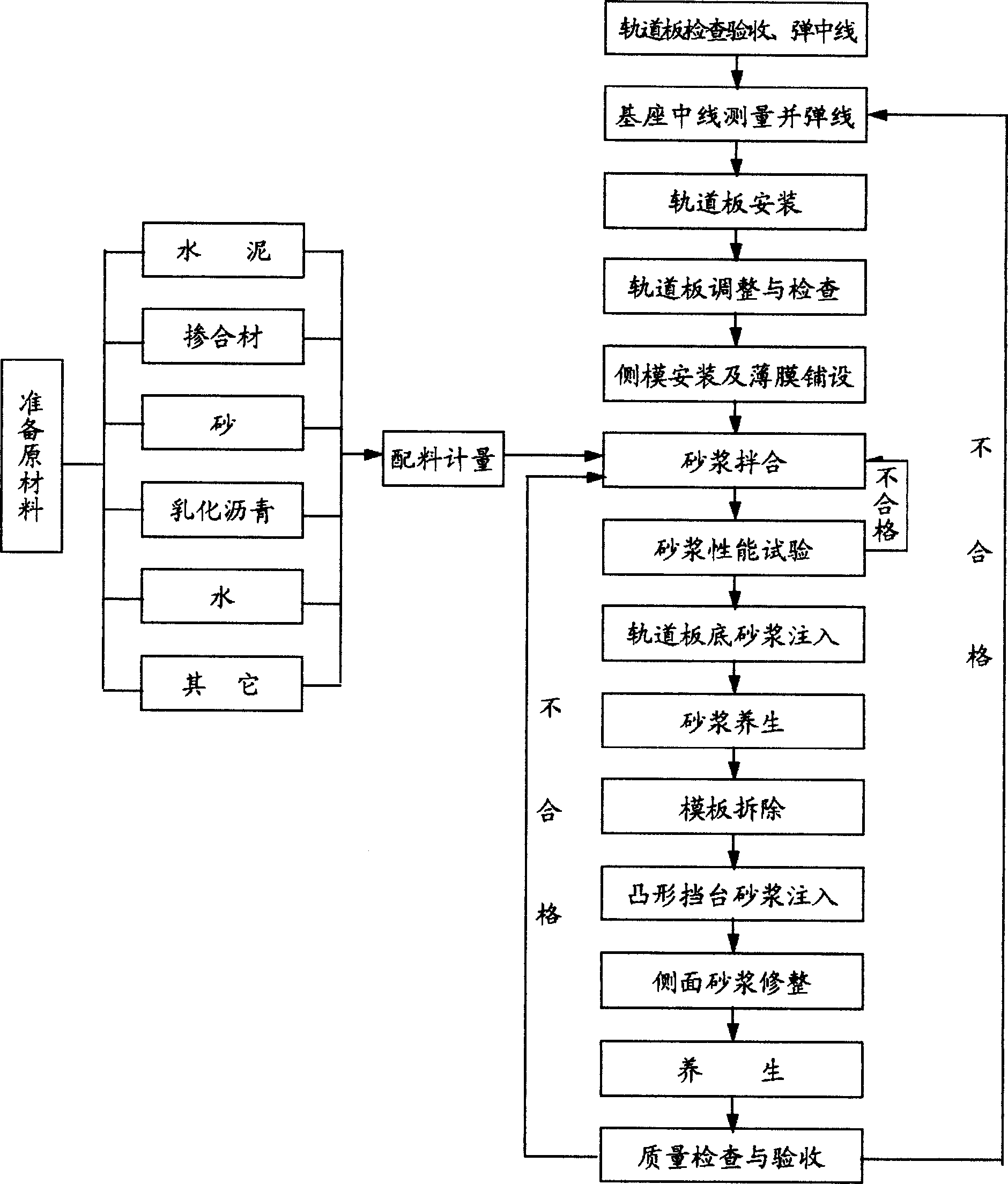

Cement emulsion asphalt mortar and its preparing method as well as application in rilroad and in ballastless track of city light rail

A cement-emulsified asphalt mortar used for railway and overhead railway in urban area contains cement and its additive, emulsified asphalt, sand, water, water-reducing agent, aluminium powder, surfactant, defoaming agent, polyacrylic fibres and chlorobutadiene latex. Its preparing process is also disclosed. Its advantages are high flowability, high strength and freeze-thawing resistance, and no environmental pollution.

Owner:CHINA RAILWAY 11TH BUREAU GRP

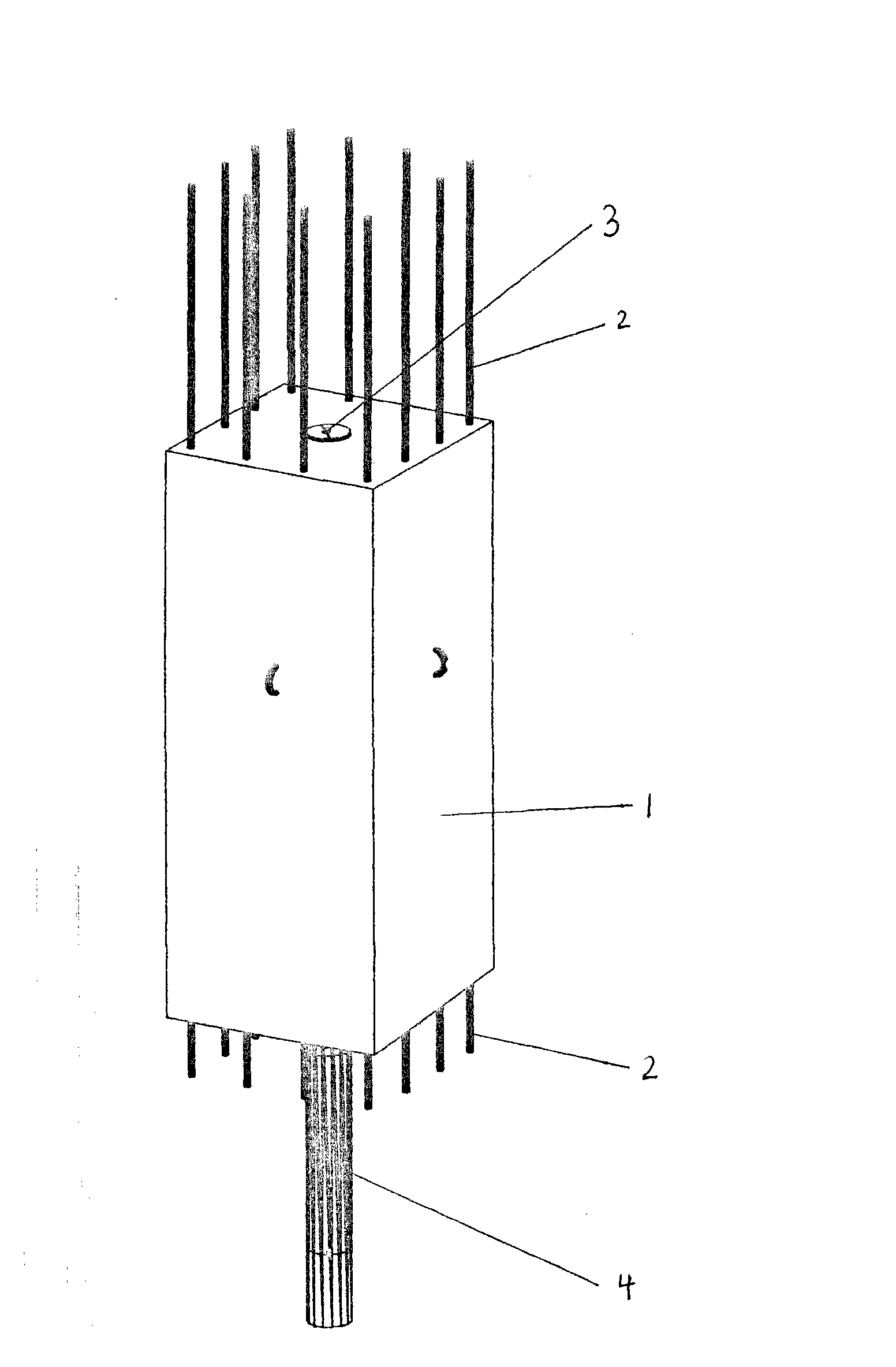

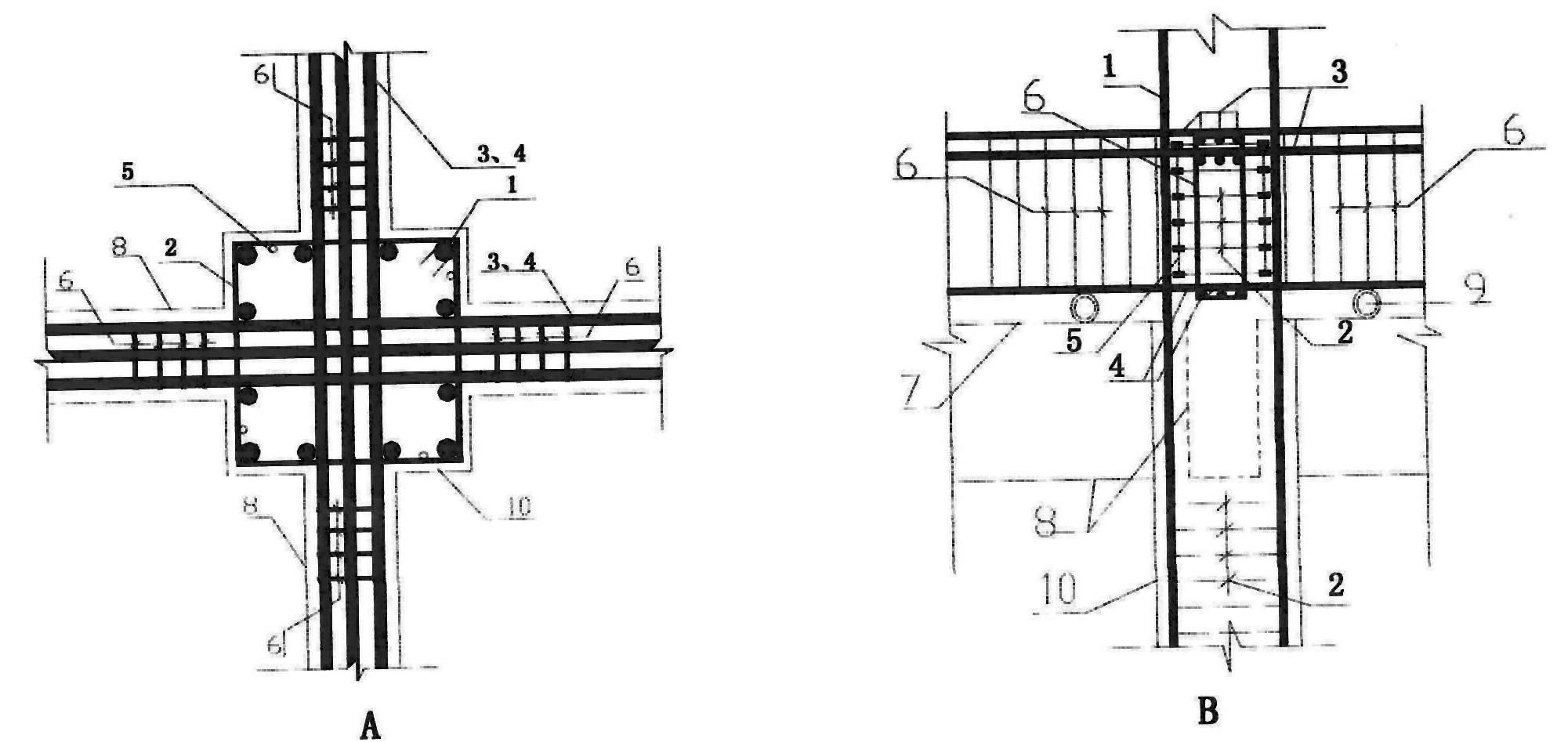

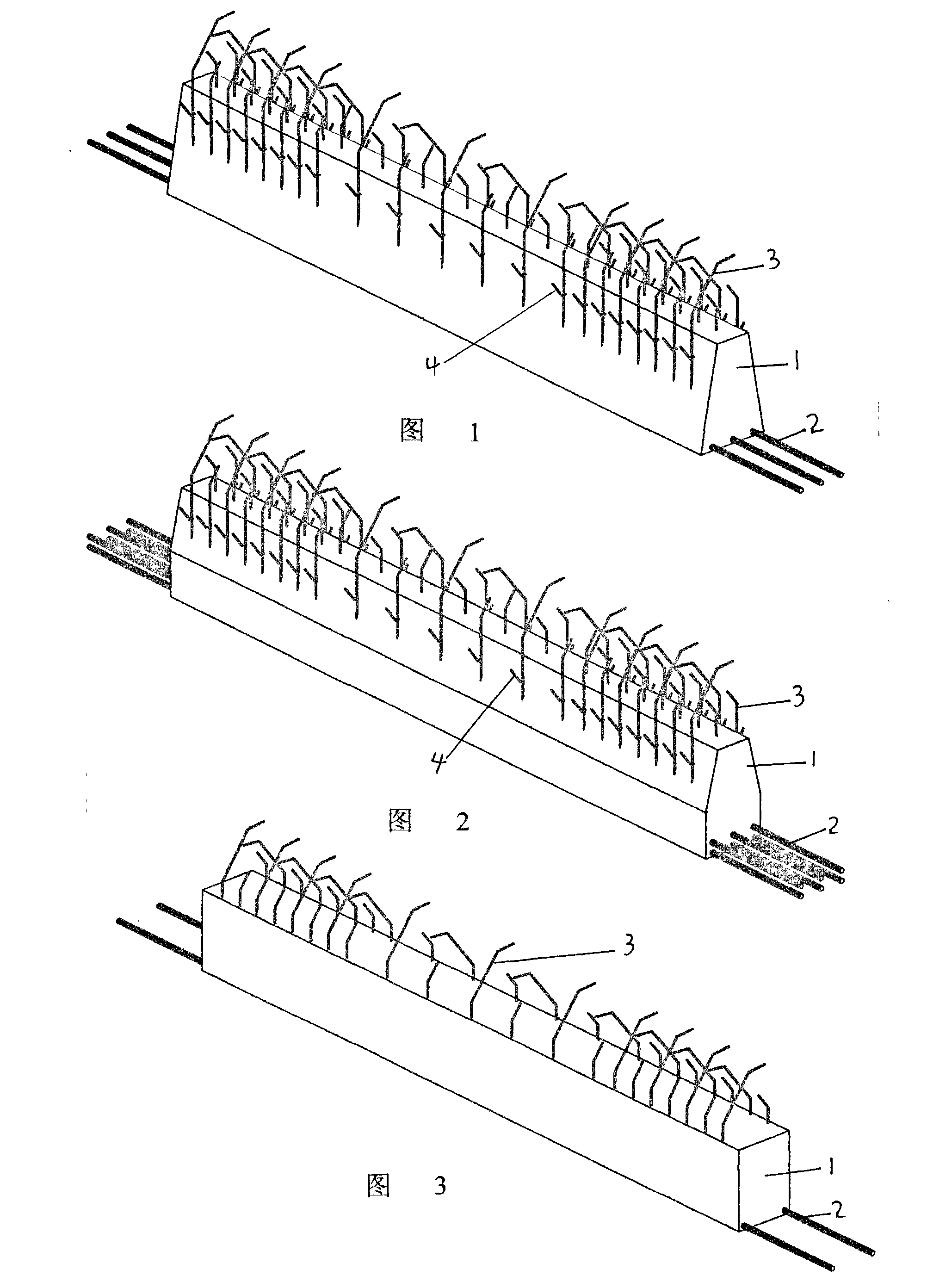

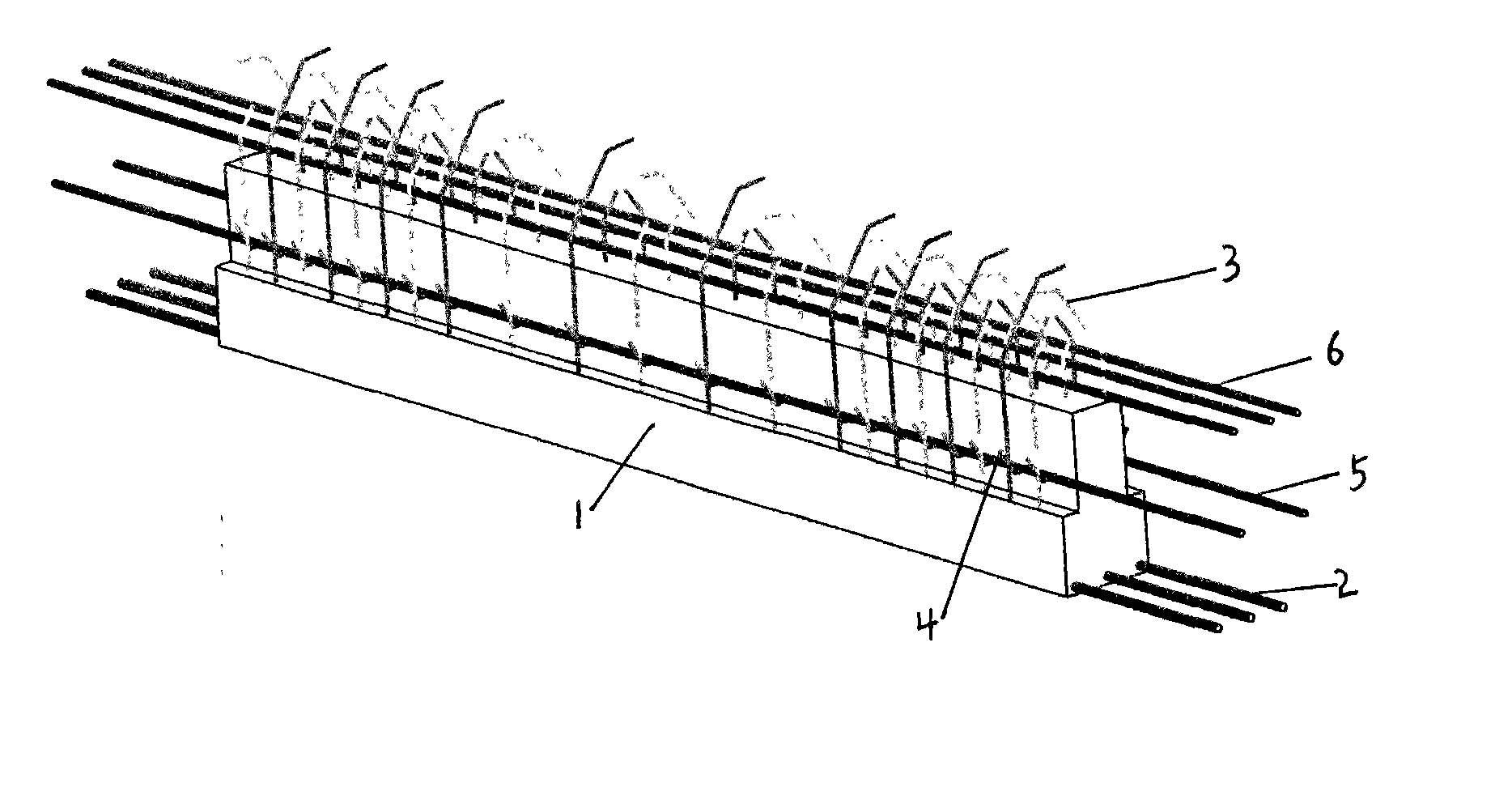

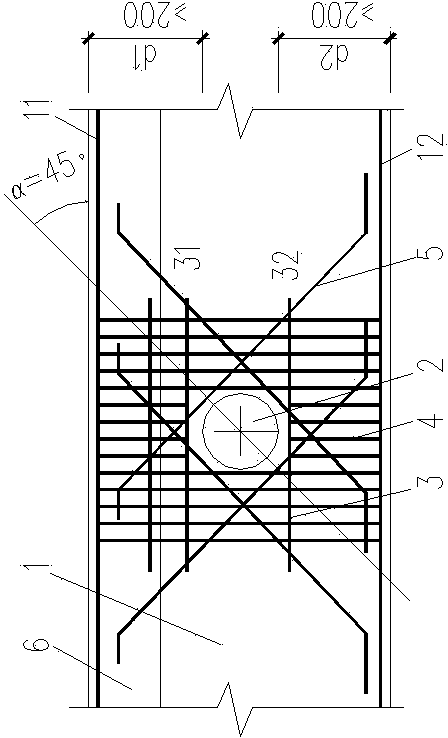

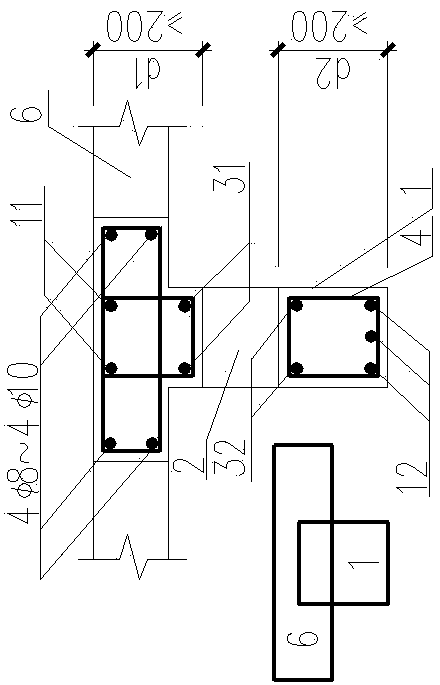

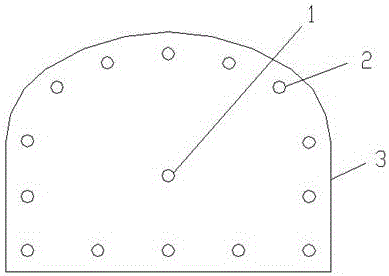

Prefabricated vertical member

The invention provides a prefabricated vertical member (including a pillar and a wall), which mainly comprises a member body and a prefabricated reinforcing bar (the reinforcing bar is the joint name of a principle bar longitudinally arranged along the member body, a vertically-distributed reinforcing bar, a hooping and a tie bar), and the principle bar or the principle bar and the vertically-distributed reinforcing bar stretch out of the upper end surface and the lower end surface of the member body. The prefabricated vertical member is characterized in that a core column is arranged in the middle of the lower end surface of the member body. The invention has the advantages that the installation of the prefabricated vertical member has no conflict with the anchoring of beam steel at a support, so as to meet the code requirement of the structure of cast-in-situ reinforced concrete; the core column is adopted for bearing load, the upper-layer construction operation can be carried out when in the joint concreting; no special design is needed; the connection of the reinforcing bar and the binding of a template are carried out at a floor slab, thereby not only ensuring the safety of workers, but also obviously improving the construction efficiency and the construction quality; the quantity of overhead work can be greatly decreased; the quantity of cast-in-situ concrete can be greatly decreased; and the operation is carried out at the floor slab, therefore, the construction speed is greatly improved.

Owner:管乃彦

Nano ceramic particle reinforced nickel-based superalloy composite material and laser 3D printing forming method thereof

InactiveCN104745887AGood high temperature corrosion resistanceImprove wear resistanceAlloy compositeHigh energy laser

The invention discloses a nano ceramic particle reinforced nickel-based superalloy composite material and a laser 3D printing forming method thereof. A nickel-based superalloy with the particle size of 15-45mu m is taken as a matrix, CrC with the particle size of 40-100nm is taken as a reinforced phase, and the addition amount of CrC is 2.0-8.0% by weight of the composite material matrix; a nano CrC particle hybrid reinforced nickel-based superalloy composite material part has the advantages of good high-temperature anti-corrosion property, abrasion resistance, high temperature creep and the like and can meet special performance requirements of an aero-engine hot end component at high temperature; a high-energy laser forming method is applicable to preparation of a difficult-to-process material and forming of a complex part; and a forming die is not needed, so that a manufacturing cycle is shortened, and the cost is reduced.

Owner:JIANGSU SILAIMU INTELLIGENT TECH CO LTD

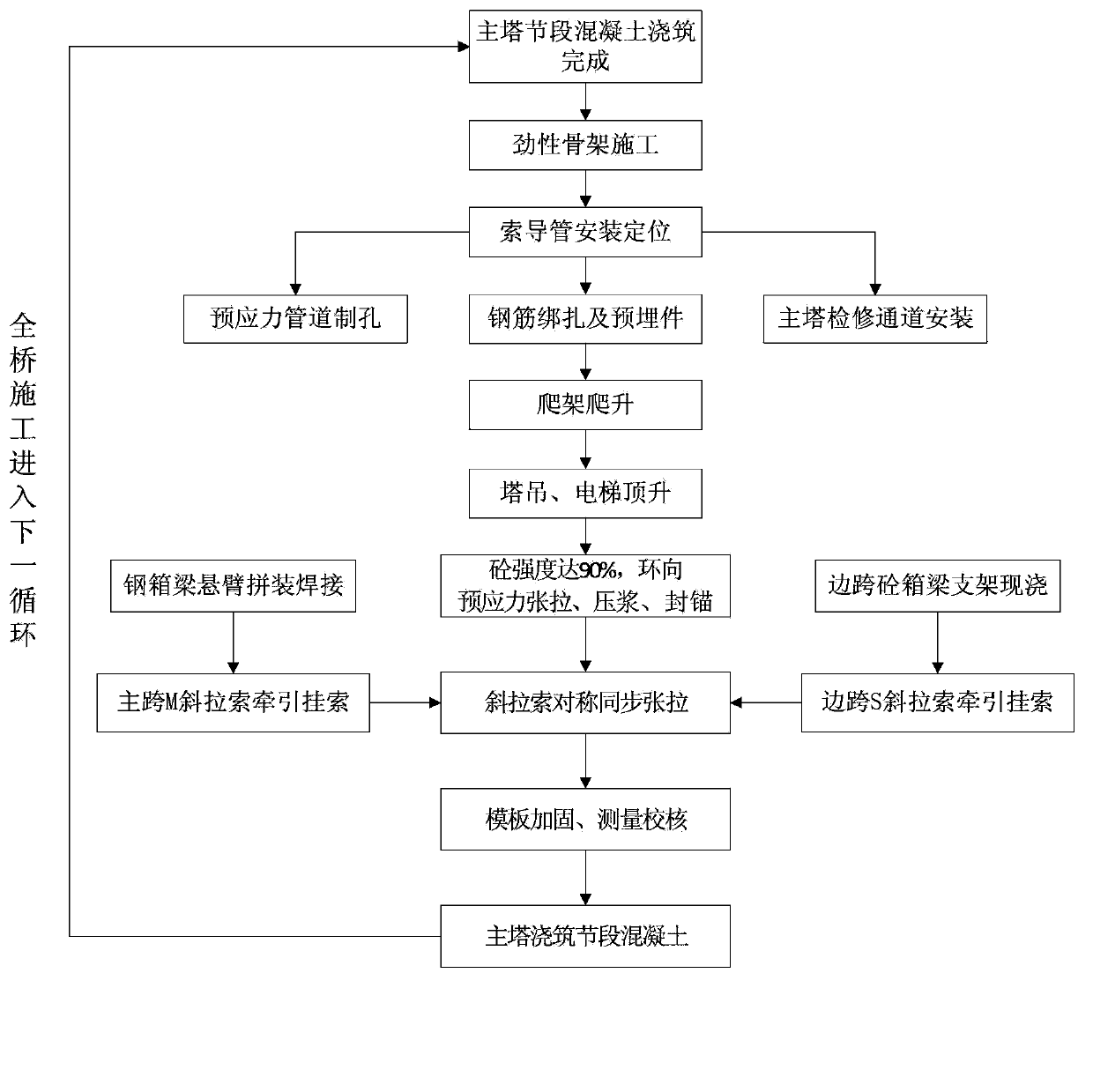

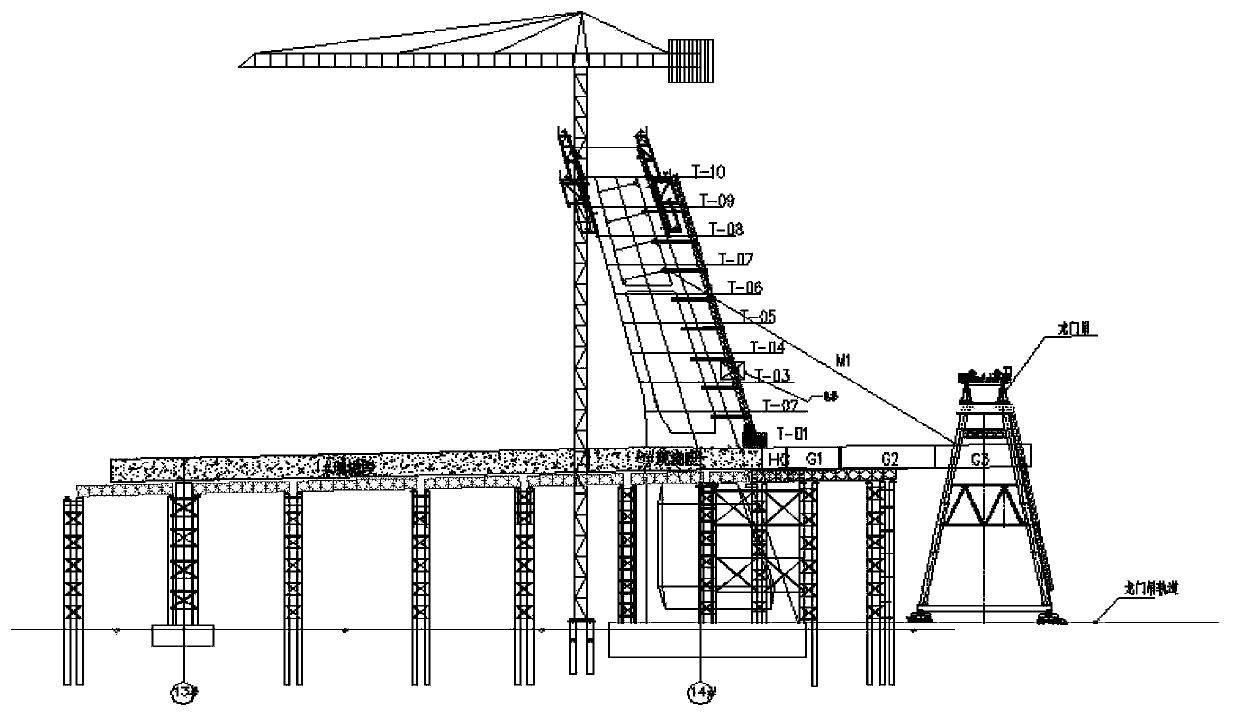

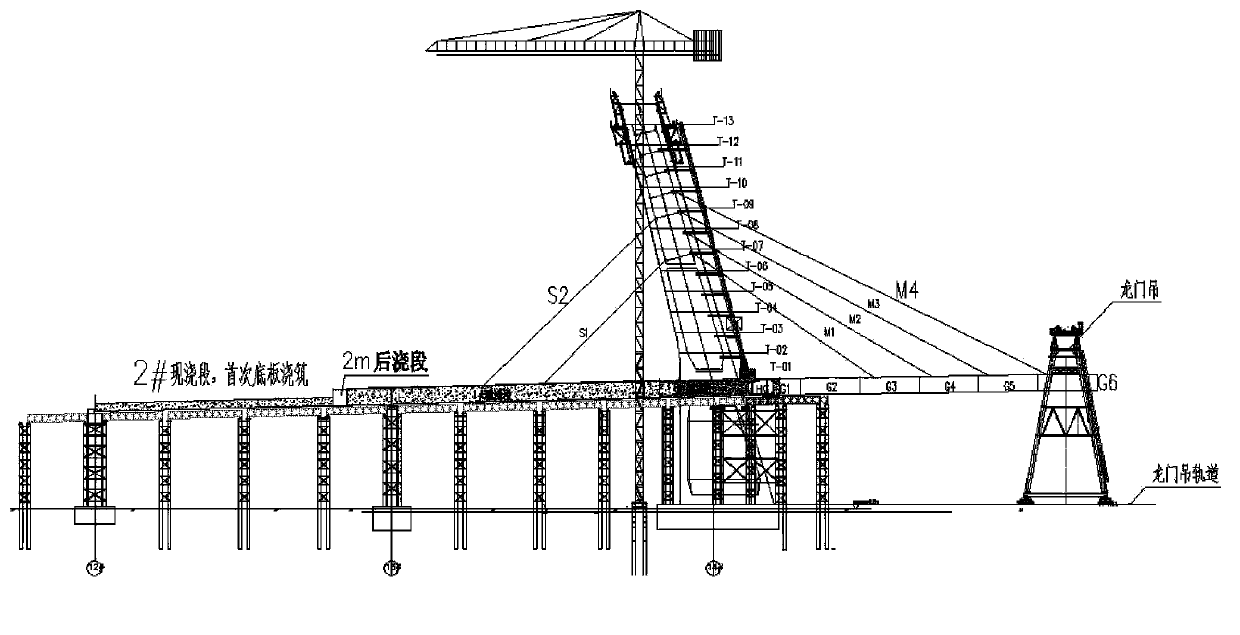

Tower, beam and cable synchronous bridge forming technology

ActiveCN103741601ASatisfied with the resultsMeet the design requirementsBridge erection/assemblyFull bridgeTower

The invention discloses a tower, beam and cable synchronous bridge forming technology. According to the technology, main tower creeping formwork construction, steel box beam cantilever assembly, side span concrete box beam cast-in-place support construction and stay cable and hung cable stretch-draw construction are conducted alternately and synchronously. The tower, beam and cable synchronous bridge forming technology achieves safe and reliable full-bridge construction.

Owner:CCCC THIRD HARBOR ENG +1

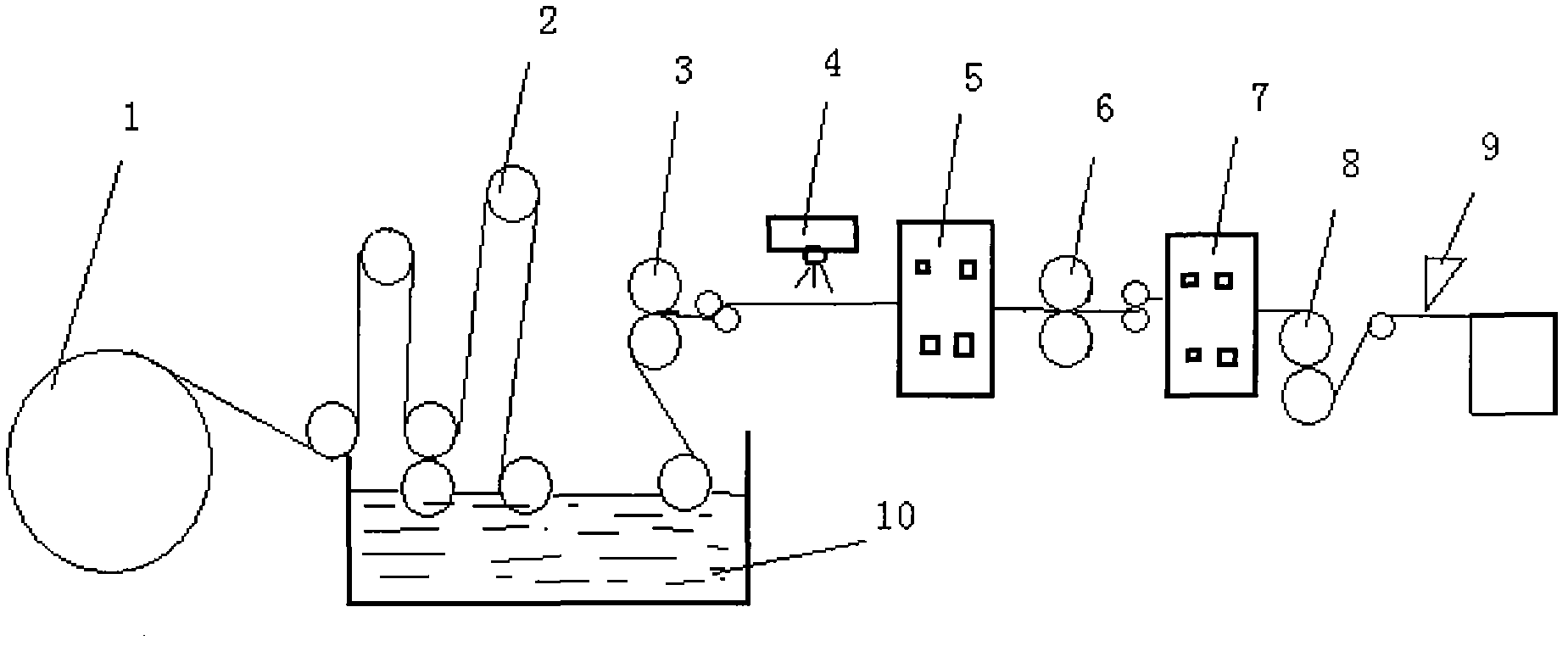

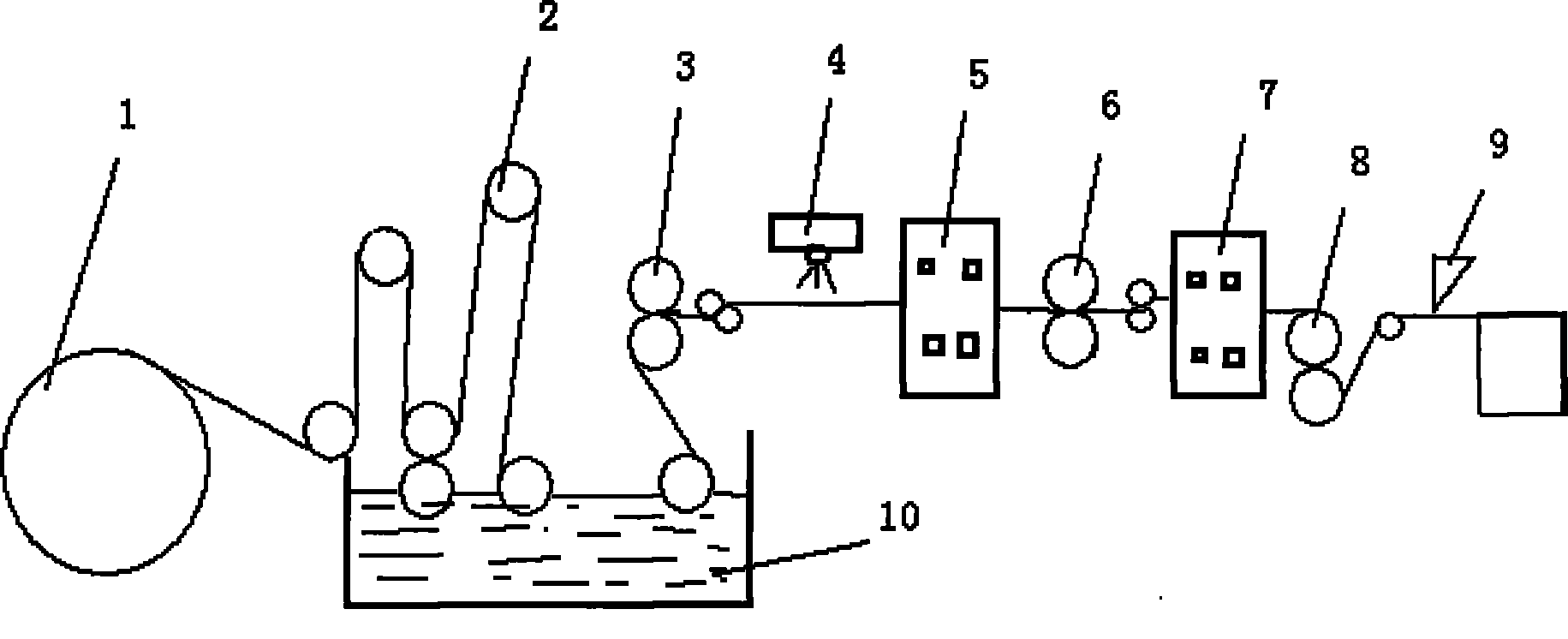

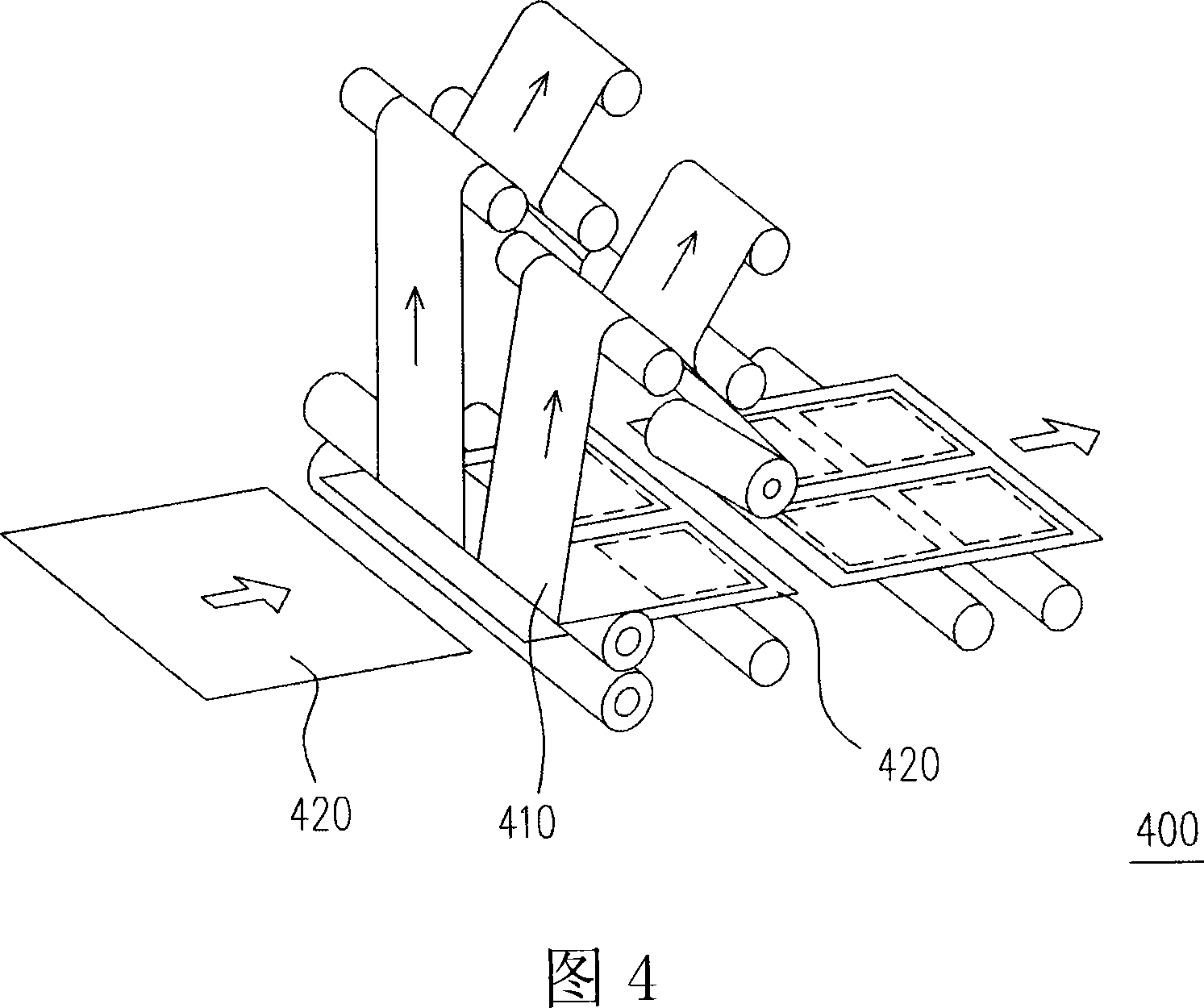

Method for manufacturing surface wear-resisting impregnated paper of laminate floor by dry-spraying Al2O3

ActiveCN102086616AImprove wettabilityImprove the wrapping effectNon-fibrous pulp additionPaper coatingRolling paperMelamine formaldehyde

The invention relates to a method for manufacturing surface wear-resisting impregnated paper of a laminate floor by dry-spraying Al2O3. The method comprises the following steps: impregnating pure wood pulp roll paper with a melamine-formaldehyde (MF) resin liquid; uniformly spraying the Al2O3 on the surface of the impregnated paper by utilizing a dry sprayer; allowing the impregnated and sprayed paper to enter a first oven for drying at the temperature of 100-150 DEG C; roll-coating 300-500% (relative to the weight of the paper) of the MF resin liquid on the paper surface after preliminary drying; and allowing the roll-coated paper to enter a second oven for drying at the temperature of 100-150 DEG C, controlling the whole-course running speed of the paper at 10-12m / minute, cooling, adjusting the temperature of the oven and machine speed so as to reach 6.0-7.5% of volatile matters and 40-60% of pre-curing degree, cutting and packaging. By means of the method, the defects of the prior art are overcome, and the spray quantity of the Al2O3 can be adjusted by controlling the dry sprayer so as to obtain the surface wear-resisting impregnated paper with reliable quality according to different wear-resisting requirements; and the method has the advantages of reasonable process and obvious effect, and is simple in operation, thus effectively improving the product quality.

Owner:天津市瑞鸿装饰材料销售有限公司

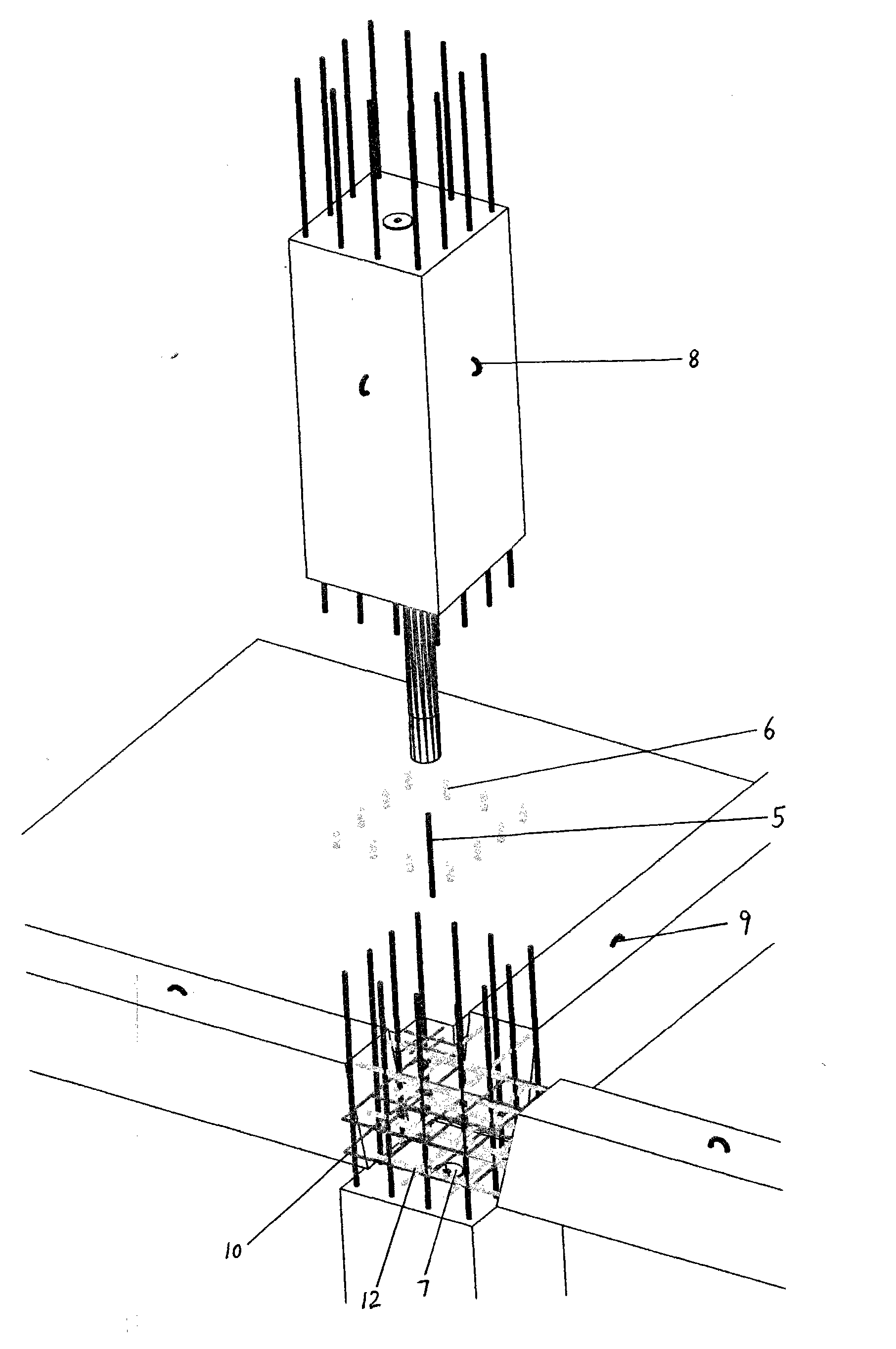

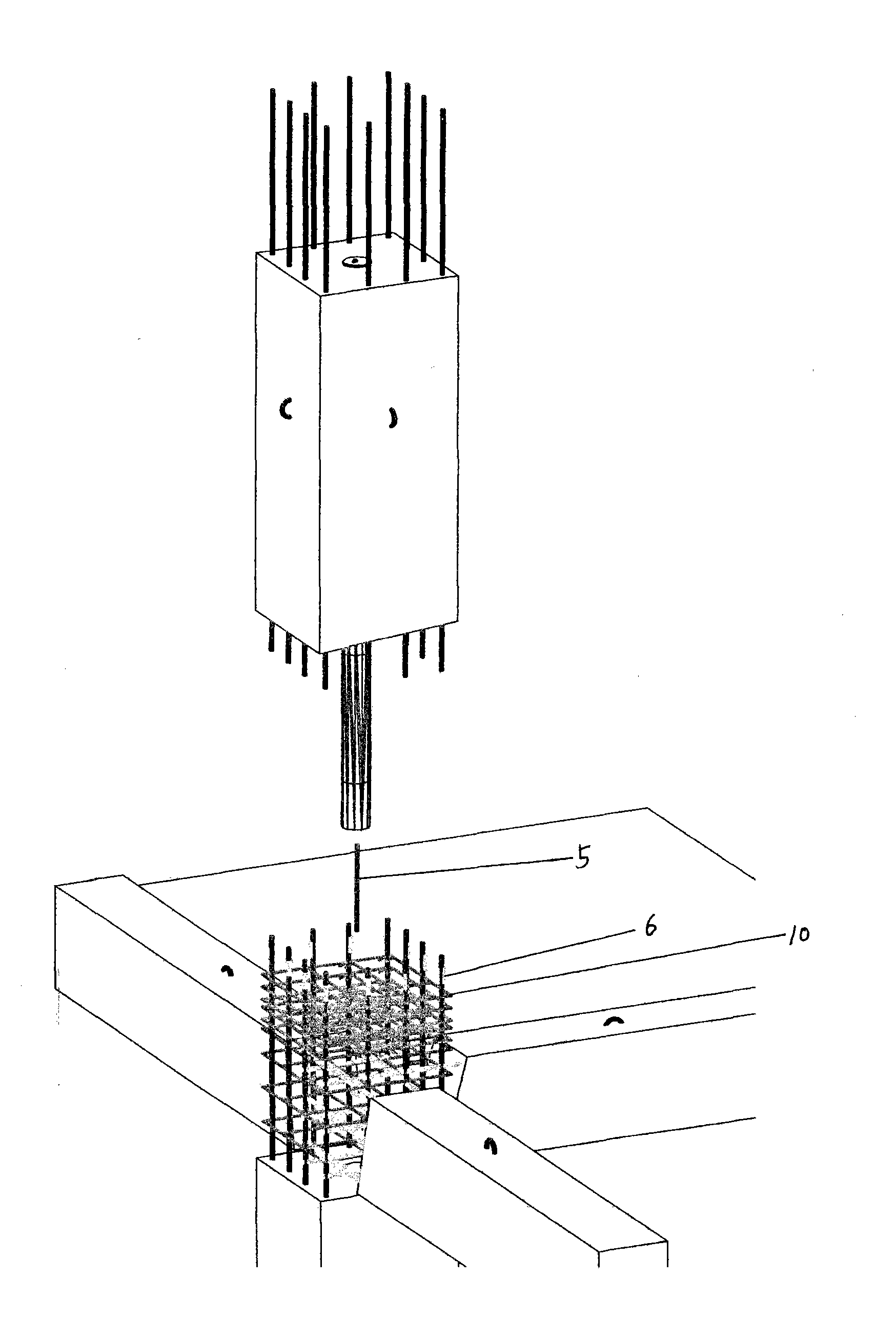

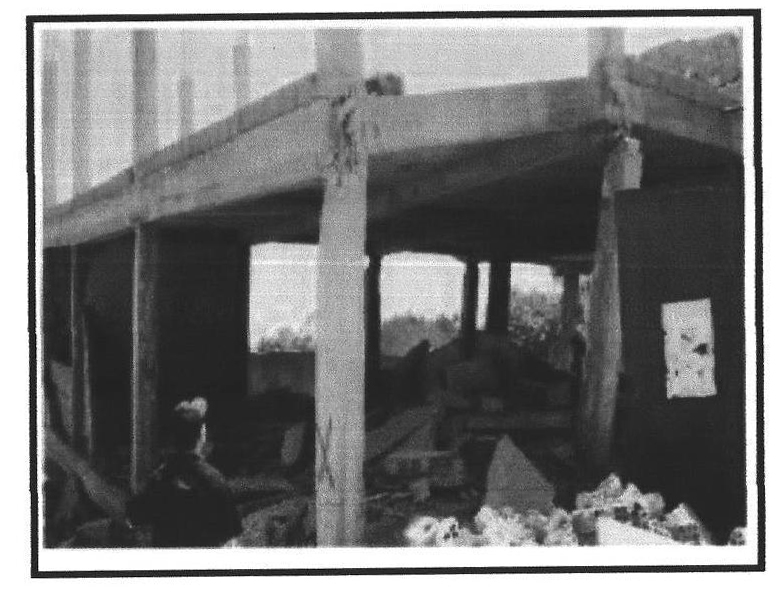

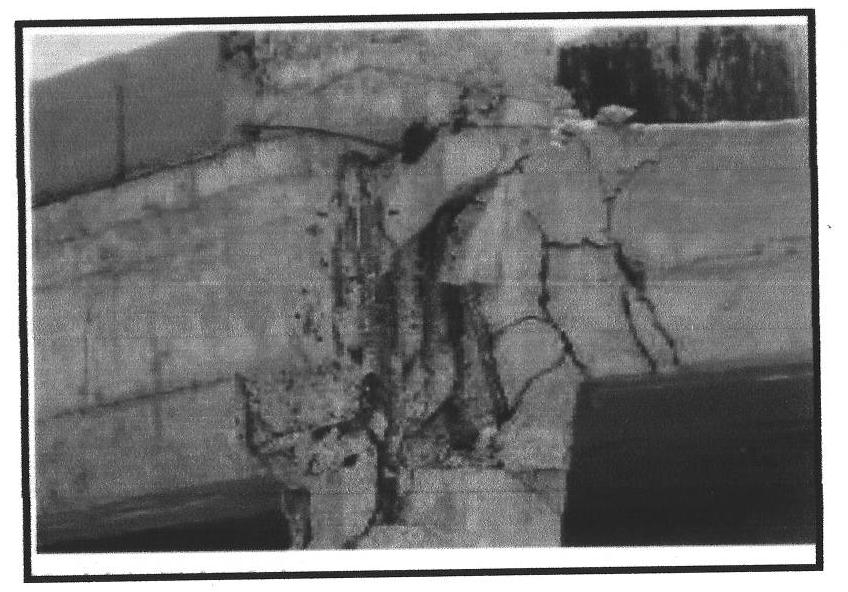

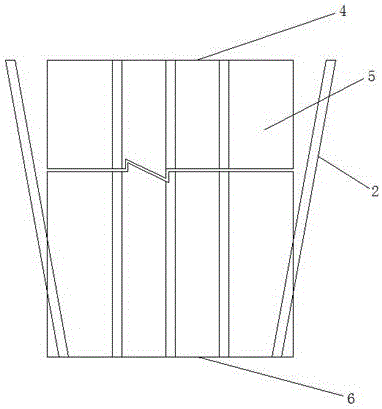

Improved method for installing reinforcement cage in beam column joint zone of reinforced concrete frame structure

ActiveCN102359279AGuaranteed installation qualityReduce labor intensityBuilding material handlingReinforced concreteEngineering

The invention discloses an improved method for installing a reinforcement cage in the beam column joint zone of a reinforced concrete frame structure, which belongs to the building and the structure of the reinforced concrete frame structure in the civil engineering field. The method aims to overcome the problems brought by the traditional installing method, can guarantee the installing quality of the reinforcement cage at the positions of the nodes of beams and columns and creates great convenience for operation. In the detail drawing 3, erecting a bracket above a beam template groove; the longitudinal reinforcements of the beams are interspersed in the longitudinal tendons of the columns and are arranged on the bracket; core zone column stirrups are arranged at the positions of the longitudinal tendons of the columns and between the upper longitudinal tendons and the lower longitudinal tendons of the beams; the longitudinal reinforcements of the beams are fixed by being bonded with the stirrups of the beams; the stirrups of the columns are fixed by bonded with stirrup spacing tringles (B in the drawing 4) to form a reinforcement cage in the beam column joint zone, which is temporarily arranged exactly above the beam column joint zone and the beam template groove and is not bonded with the longitudinal tendons of the columns; finally, the beam reinforcement cage and a column stirrup cage integrally slide into the beam template groove and the beam column joint core zone along the longitudinal tendons of the columns; and therefore, the final position of the reinforcement cage in the beam column joint zone is realized.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD

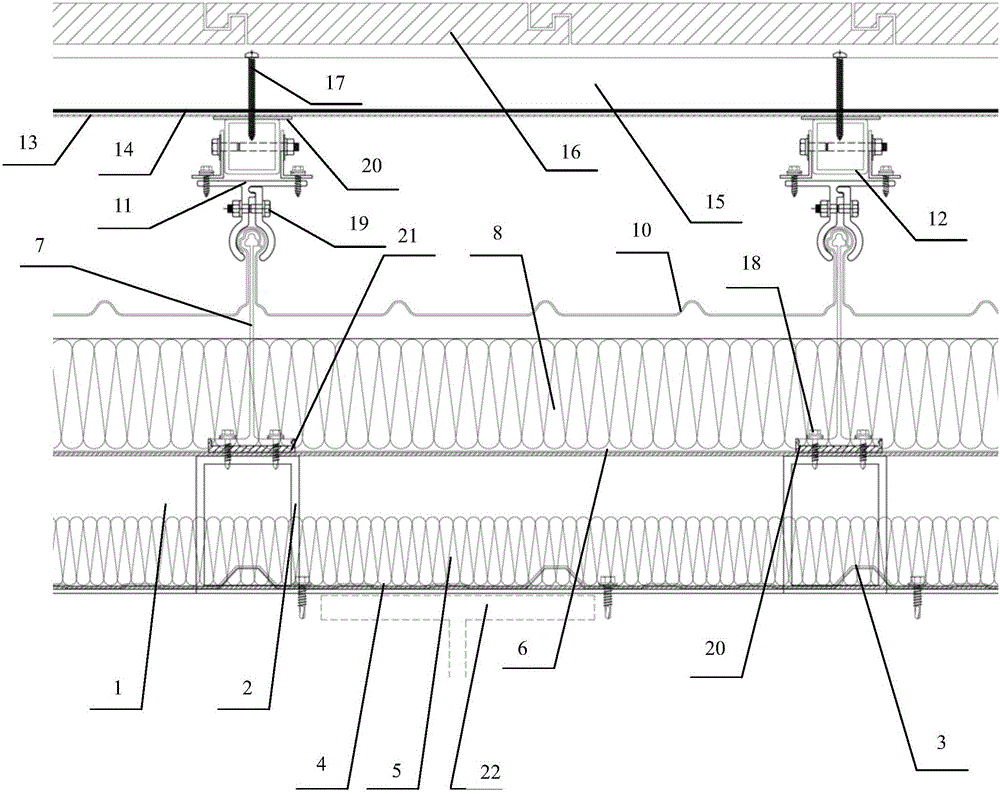

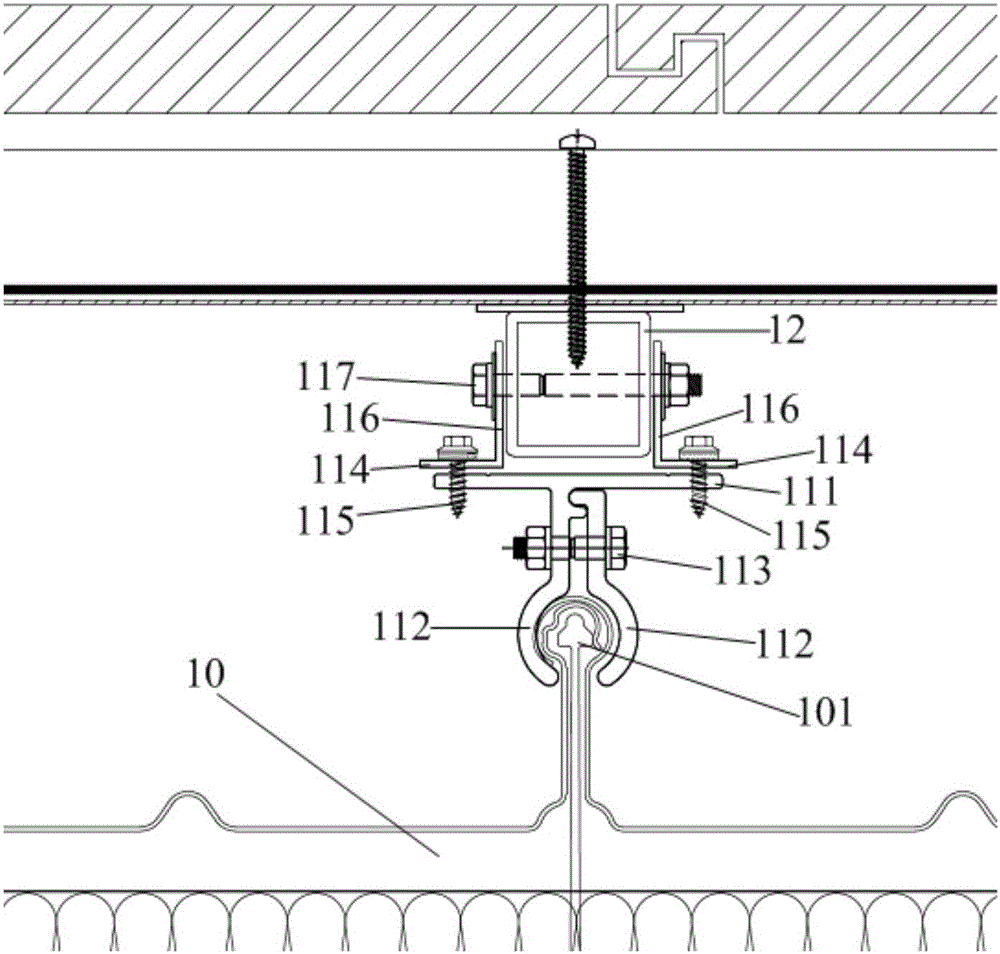

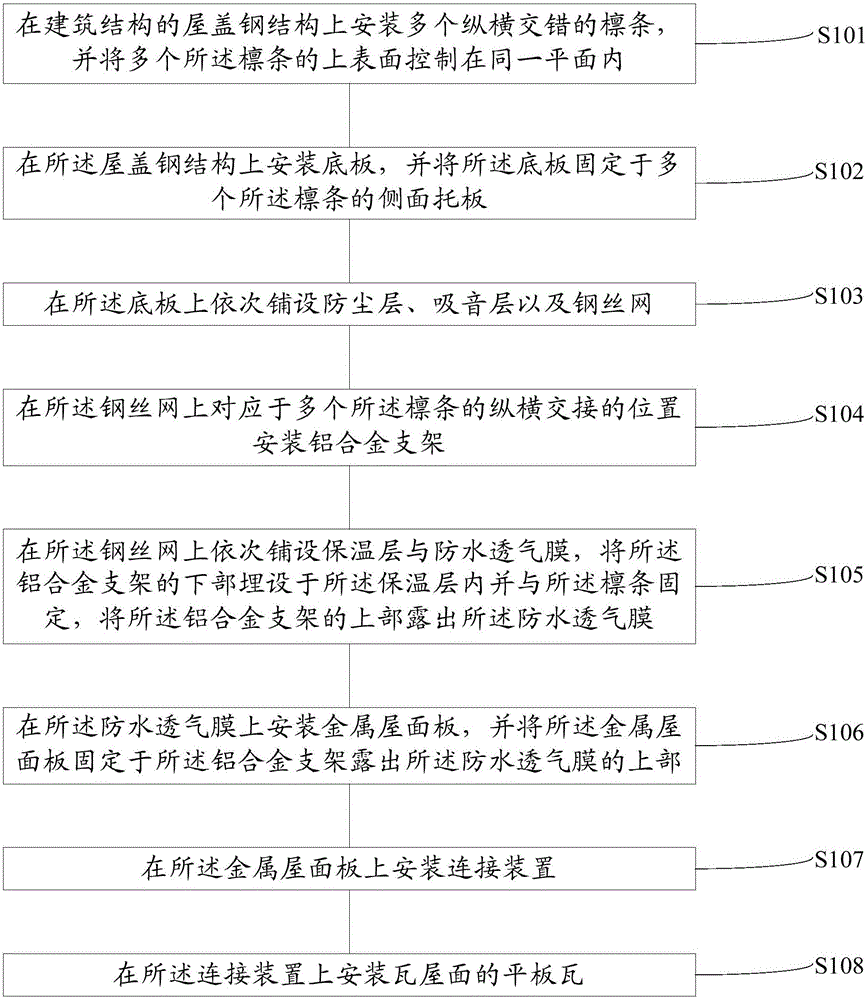

Metal roof plate and plane tile combined roof system and construction method thereof

ActiveCN105908910ASolve the problem of whether the connection is reliableSolve hidden dangers of waterproofingRoof covering insulationsInsulation layerAlloy

The invention discloses a metal roof plate and plane tile combined roof system and a construction method thereof. The method comprises the following steps that a plurality of longitudinally and transversely staggered purlines are arranged on a roof steel structure of a building structure, and the upper surfaces of the plurality of purlines are controlled in the same plane; a bottom plate is arranged on the roof steel structure, and is fixed on a side surface support plate of the plurality of purlines; a dustproof layer, a sound absorbing layer and a steel wire net are sequentially paved on the bottom plate; an aluminum alloy support frame is arranged in a position, corresponding to the longitudinally and transversely connected position, on the steel wire net; a heat insulation layer and a waterproof ventilated membrane are sequentially laid on the steel wire net; the lower part of the aluminum alloy support frame is embedded in the heat insulation layer and is fixed with the purlines; the upper part of the aluminum alloy support frame is exposed out of the waterproof ventilated membrane; a metal roof plate is arranged on the waterproof ventilated membrane, and is fixed at the upper part, exposed out of the waterproof ventilated membrane, of the aluminum alloy support frame; a connecting device is arranged on the metal roof plate; and plane tiles of a tiled roof are arranged on the connecting device.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

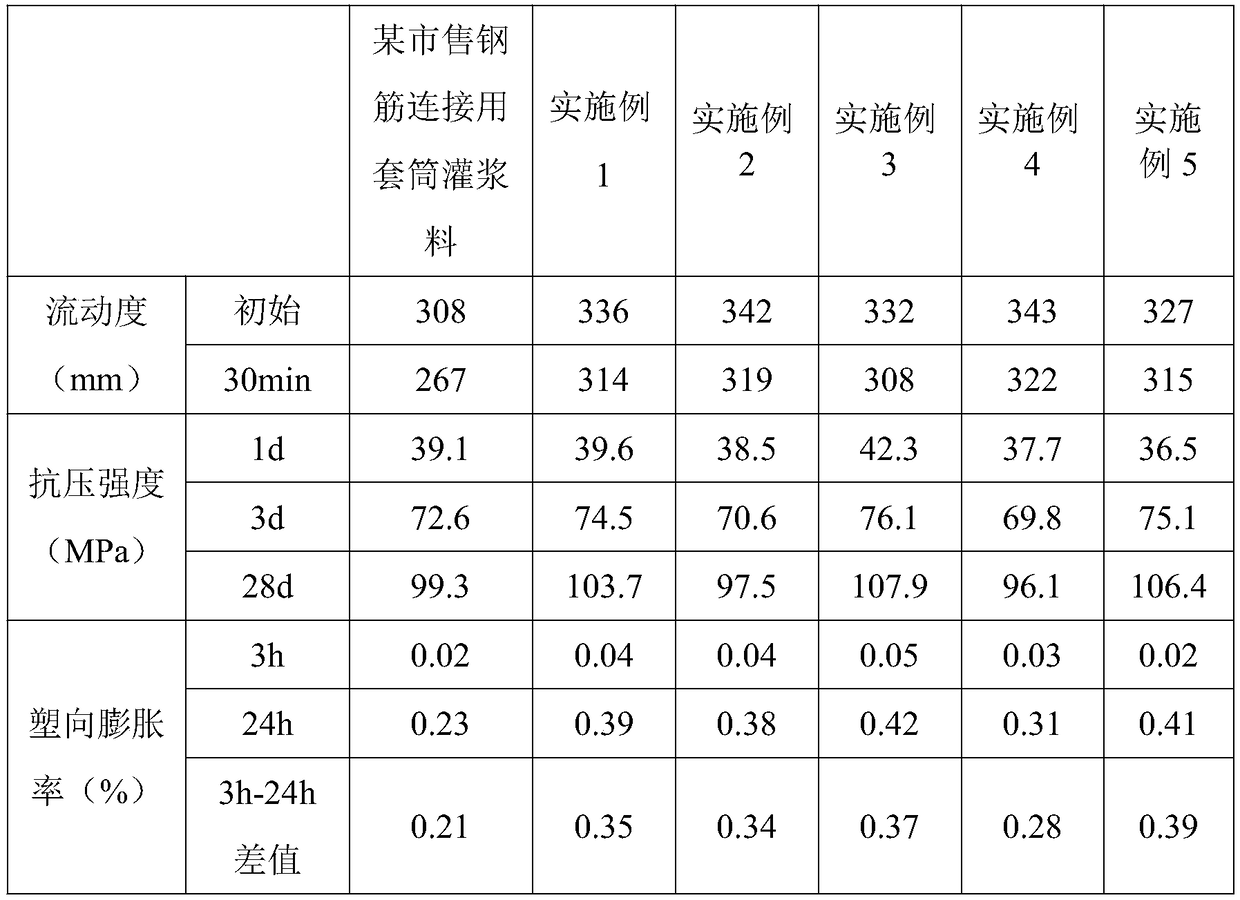

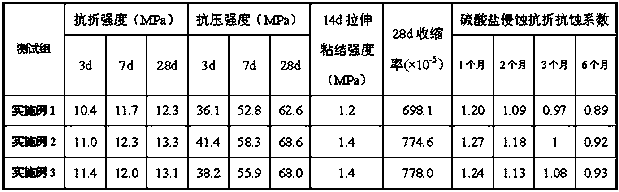

High-fluidity sleeve grouting slurry for rebar connection and preparation method thereof

The invention belongs to the field of building materials and particularly discloses a high-fluidity sleeve grouting slurry for rebar connection and a preparation method thereof. The grouting slurry isprepared from the following materials in parts by weight: 390-410 parts of cement, 90-110 parts of admixture, 460-500 parts of sand, 0.05-0.07 part of a water-retaining agent, 1.4-1.6 parts of a de-foaming agent, 6-8 parts of a compound water reducer, 40-50 parts of compound retarder, 35-40 parts of a compound expanding agent, 7-10 parts of a compound early strength agent and 135-145 parts of water. The preparation method for the grouting slurry comprises the steps of proportionally weighting the raw materials and uniformly stirring in a certain stirring manner. The sleeve grouting slurry forrebar connection prepared according to the invention is high in fluidity and can solve the problems of more insufficient initial fluidity or lower surplus initial fluidity and poorer fluidity holdingability than those of standard slurry of the present sleeve grouting slurry for rebar connection in practical engineering application.

Owner:成都宏基建材股份有限公司

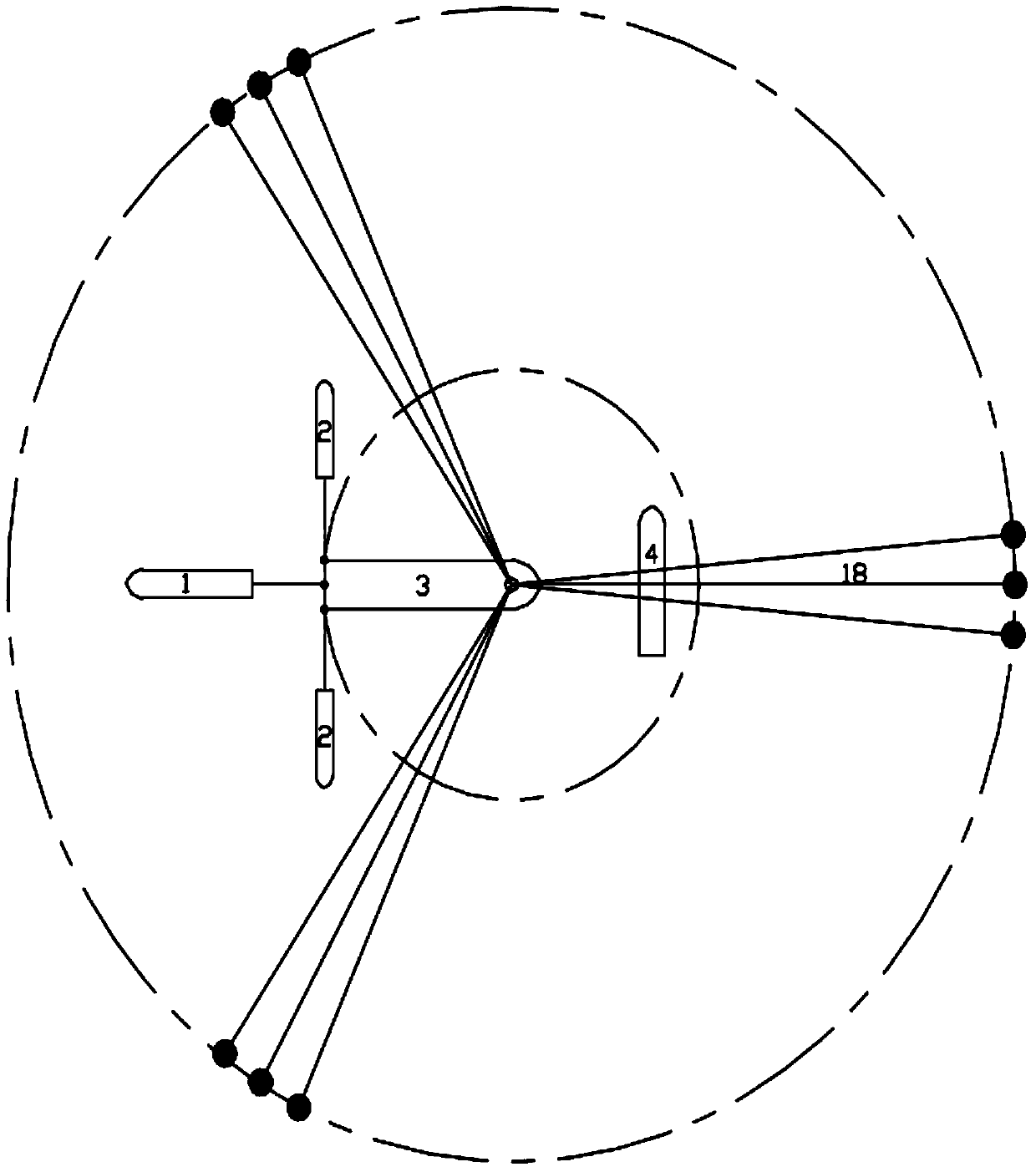

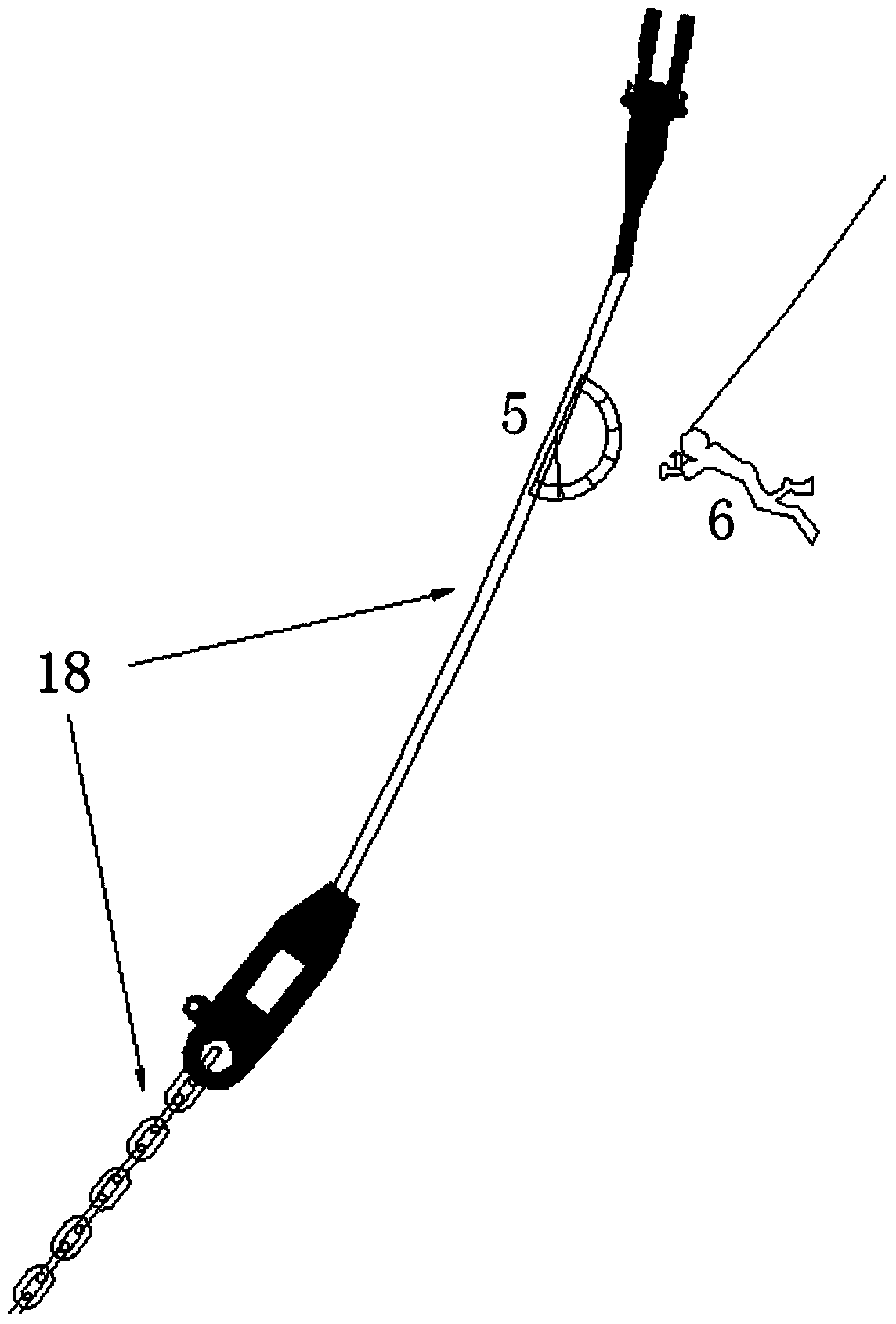

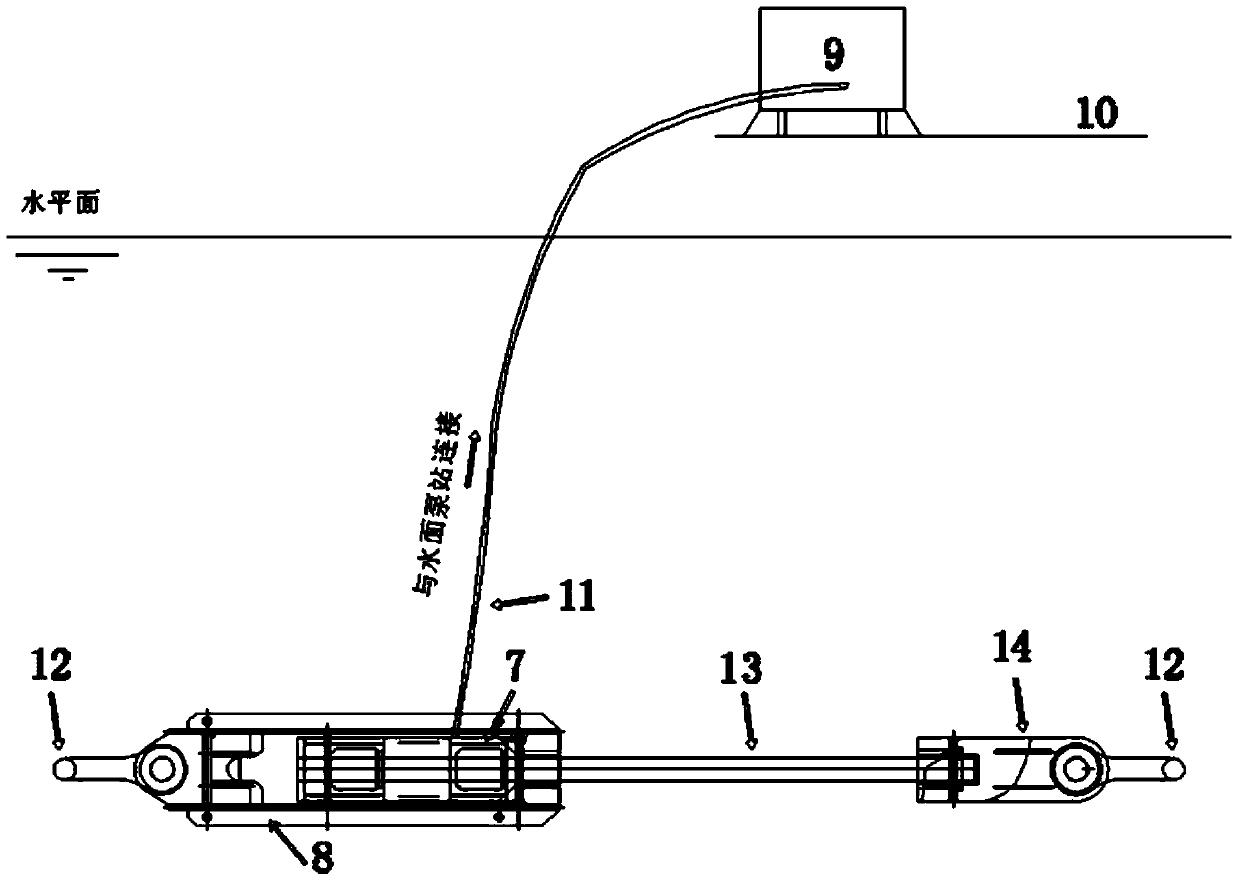

Method for replacing upper anchor cable of mooring anchor legs

ActiveCN103738477AReduce workloadReduce yield lossAnchoring arrangementsEnvironmental geologyStructural engineering

Disclosed is a method for replacing an upper anchor cable of mooring anchor legs. The method includes 1), arranging a plurality of limiting tugs on the stem of a floating production storage and offloading oil tanker; 2), mounting protractors on the mooring anchor legs; 3), descending a tensioner to the sea floor and then tightening an anchor chain; 4), cutting a loosened anchor chain ring; 5), demounting the tensioner; 6), regulating heading of the oil tanker to be perpendicular to the anchor legs; 7), uplifting the upper anchor cable; 8), demounting an old upper anchor cable section head; 9), pulling a new upper anchor cable section head to the bottom of a single point; 10), mounting the new upper anchor cable section head; 11), connecting the new upper anchor cable section head with one section of the anchor chain to form a complete anchor leg; 12), releasing an underwater hydraulic tensioner steel strand to a natural state and demounting the same; 13), remeasuring water entry angle of the anchor legs and water depth and position of an lower anchor cable section head of the anchor legs. By the application of the method, all construction work like recycling the old anchor cable and mounting the new anchor cable are realized under the condition of not releasing the floating production storage and offloading oil tanker; therefore, production efficiency and reliability are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +3

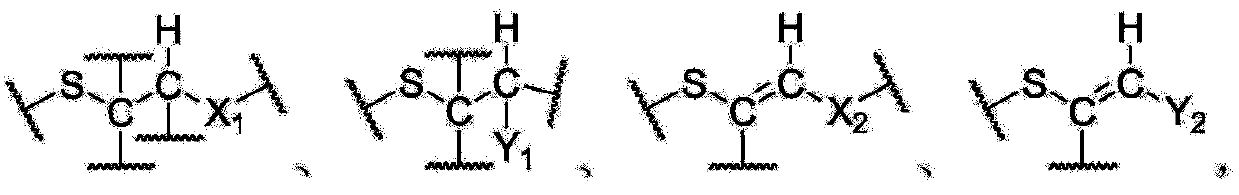

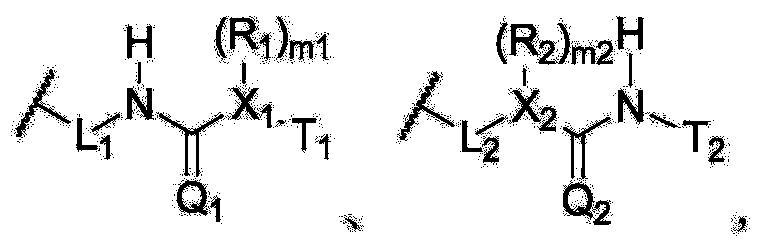

Self-repairing solid-state hybrid dynamic polymer and application thereof

PendingCN109666168ARich dynamic reversible characteristicsVarious forms of activationDevice materialBackbone chain

The invention discloses a self-repairing solid-state hybrid dynamic polymer. The self-repairing solid-state hybrid dynamic polymer contains sulfydryl-Michael addition bond dynamic covalent crosslinking and supermolecular hydrogen bond interaction, wherein the sulfydryl-Michael addition bond dynamic covalent crosslinking reaches above a gel point in at least one crosslinking network; sulfydryl-Michael addition bonds are obtained through sulfydryl-Michael addition reaction between sulfydryl groups and electron-deficient conjugate alkenes / enynes; the supermolecular hydrogen bond interaction contains hydrogen bond interaction involving at least one from side hydrogen bond groups, backbone hydrogen bond groups and other end hydrogen bond groups; with dynamic reversibility, the sulfydryl-Michaeladdition bonds and the supermolecular hydrogen bonds endow the self-repairing solid-state hybrid dynamic polymer with good plasticity, self-repairability, repeatability, reusability and recoverability and ensure that the self-repairing solid-state hybrid dynamic polymer can be widely applied to self-repairing materials, flexible materials, shape memory materials, energy storage device materials and the like.

Owner:厦门天策材料科技有限公司

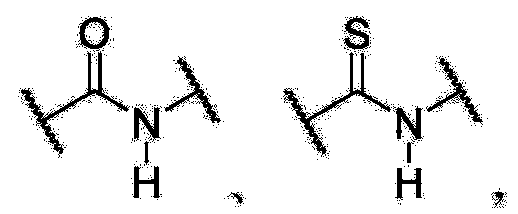

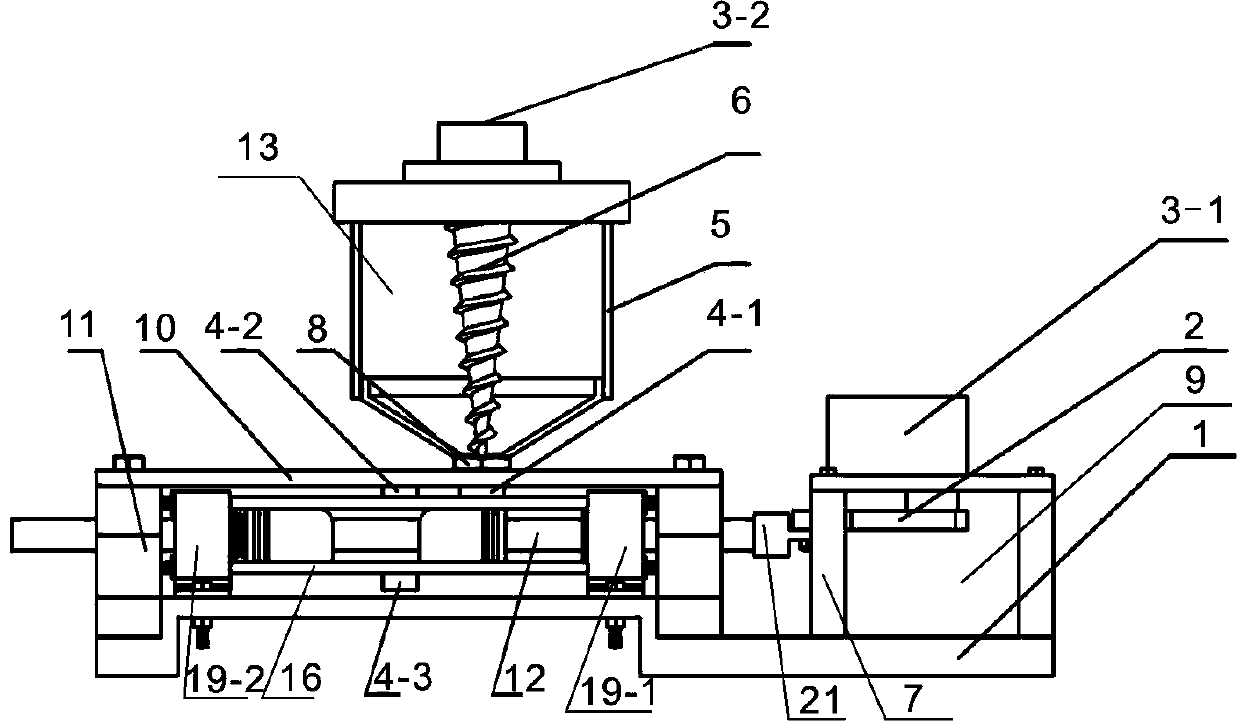

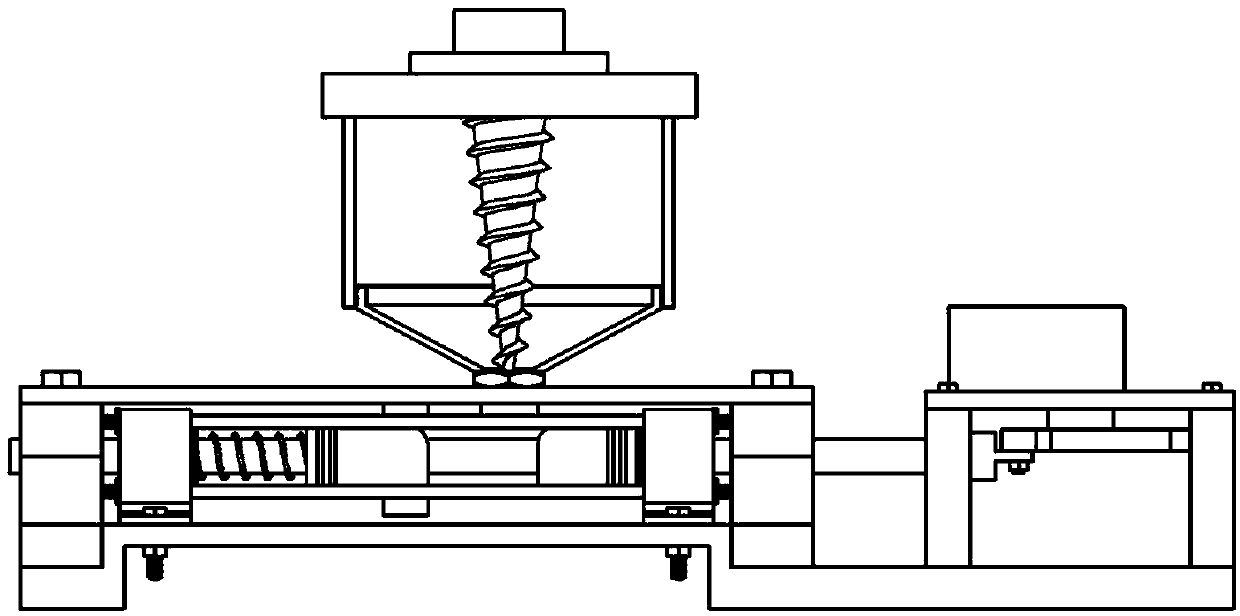

Powdered graphite quantitative conveying device

ActiveCN104192504AAdequately meet specific requirementsMeet specification requirementsPackagingConveyor partsCamFlake graphite

The invention provides a powdered graphite quantitative conveying device. The powdered graphite quantitative conveying device comprises a supporting frame with a protrusion, a reciprocating driving mechanism, a plunger type powdered graphite conveying mechanism and a spiral powdered graphite supplying mechanism, wherein the plunger type powdered graphite conveying mechanism is arranged on the protrusion part of the supporting frame, a supporting pad is arranged outside the plunger type powdered graphite conveying mechanism and is fixed to the spiral powdered graphite supplying mechanism through a supporting plate, plunger rods are arranged at the two ends of the plunger type powdered graphite conveying mechanism respectively, and the plunger rod at one end is connected with the reciprocating type driving mechanism through a cam roller. The powdered graphite quantitative conveying device is simple in structure, low in manufacturing cost, and suitable for accurate weighing and accurate conveying of flake graphite, nanometer graphite sheets and other light, low-mobility and fragile powder.

Owner:湖北天烽精密机械有限公司

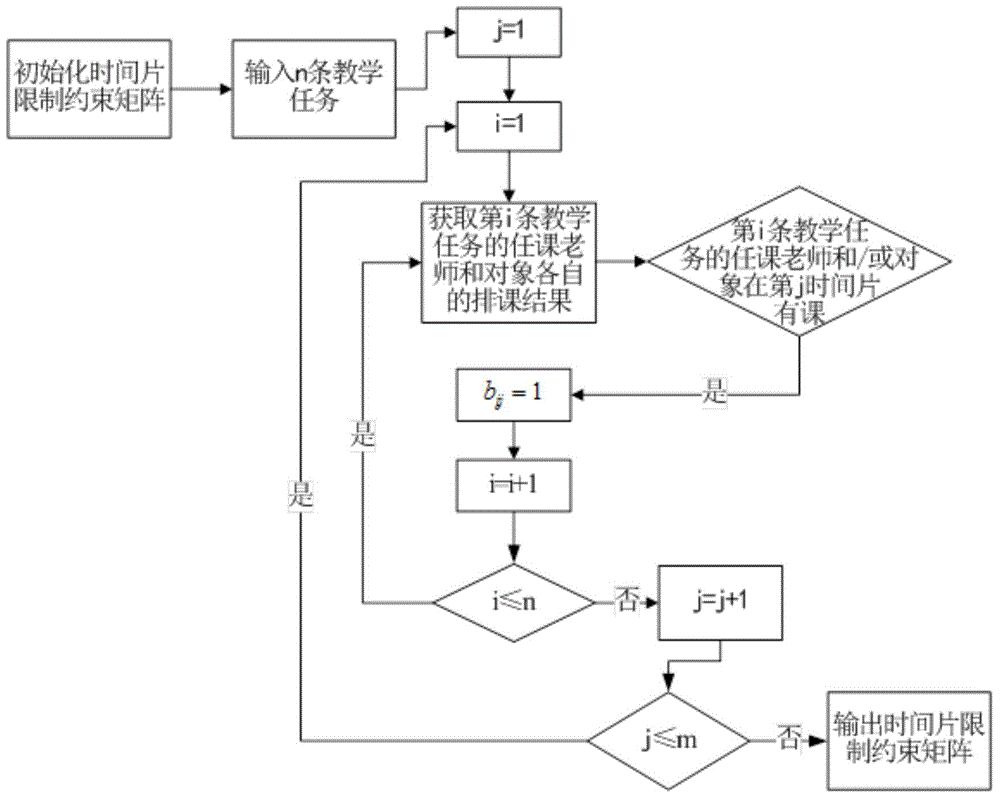

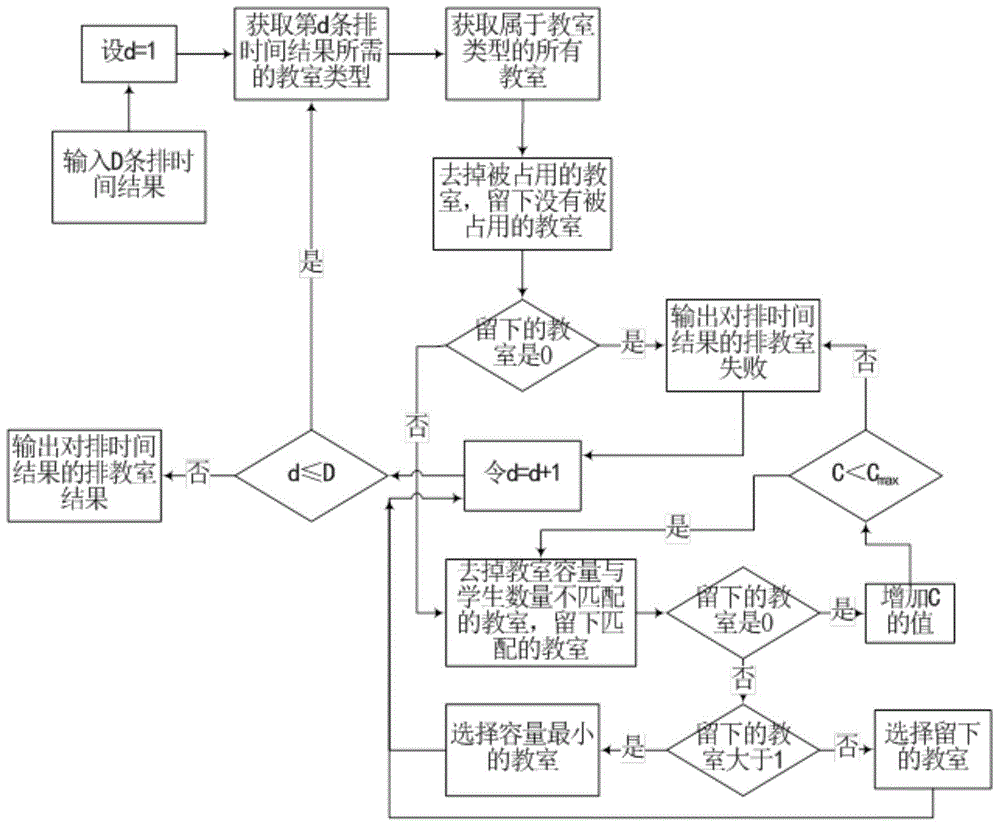

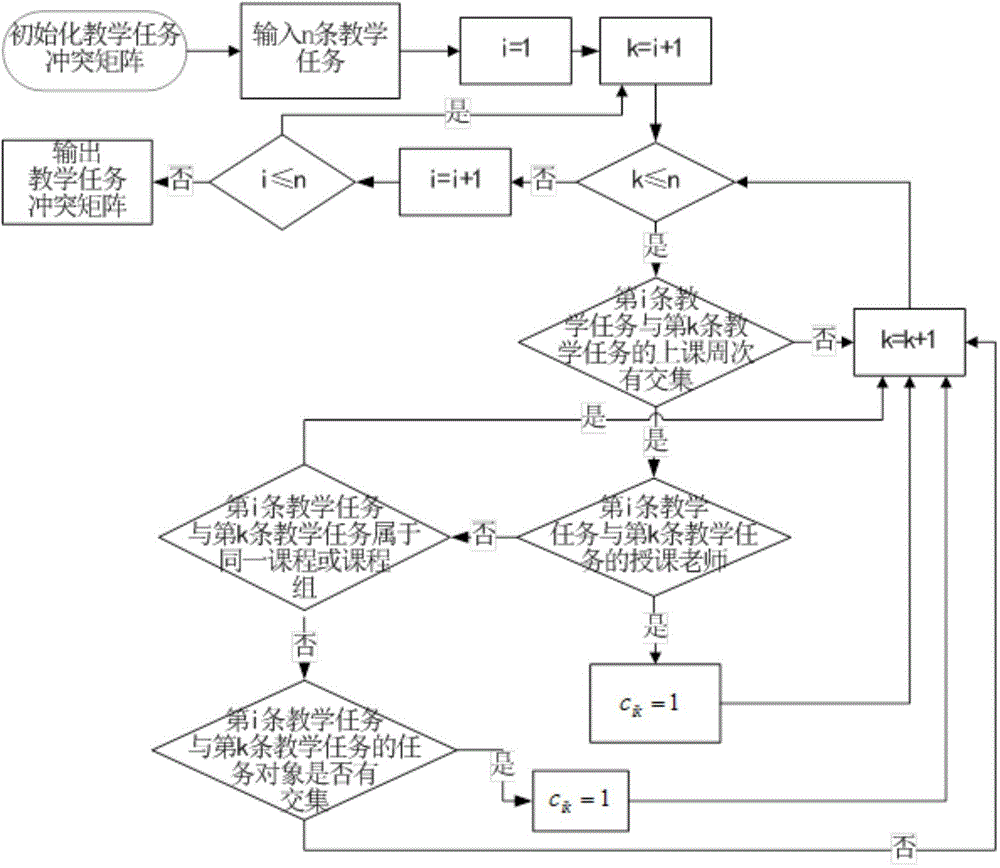

Courses arrangement algorithm

InactiveCN104794666AMeet specification requirementsScheduling process is simpleData processing applicationsSpecial data processing applicationsAlgorithmObject function

The invention relates to a courses arrangement algorithm. The algorithm includes establishing a time arranging model and a classrooms arranging algorithm. The time arranging model comprises constraint conditions and an objective function, and then branch-bound algorithm is adopted to solve the time arranging model to achieve a group of solutions, the group of solutions is D time arranging results; the classroom arranging algorithm is proceeded aiming at the D time arranging results, and finally output of the classroom arranging results related to the time arranging results is a courses timetable. By the application of the courses arrangement algorithm, time is arranged before classrooms are arranged, the courses arranging is not only simple, but also high effective, and thereby the courses arrangement algorithm is more widespread. What's more important is that the courses arrangement algorithm also defines a plurality of flexible regulations, by the setting of the flexible regulations, special requirements to the courses timetables of more colleges and universities are met, and the courses arrangement algorithm is more diverse and easy to popularize.

Owner:CHONGQING UNIV

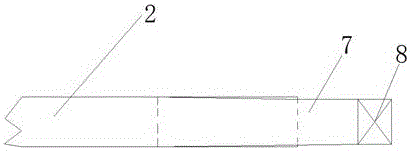

Improved semiautomatic flame cutting machine

InactiveCN101823175ALow equipment requirementsReduce equipment costsGas flame welding apparatusEngineeringAssurance quality

The invention discloses an improved semiautomatic flame cutting machine, which comprises a semiautomatic flame cutting machine (4), a liquid oxygen tank (8) and a gun head connected with one another through air belts, wherein the gun head is a prolonged gun head (2) for digital control cutting, the length of the gun head is 450 to 550 mm, and an inlet cutting nozzle (5) connected with the gun head is a divergent inlet cutting nozzle. The improved semiautomatic flame cutting machine is also provided with a rail (7) which is in slide connection with a base of the semiautomatic flame cutting machine (4). The improved semiautomatic flame cutting machine can process a steel box girder groove of the semiautomatic flame cutting machine through the steps of preparation before operation, normal operation and post-operation; besides, the improved semiautomatic flame cutting machine has the advantages of having simple and convenient operation, ensuring the quality, shortening the time limit, reducing the cost and the like, and can replace the conventional mode of processing the groove mechanically.

Owner:WUHAN YIYE STEEL STRUCTURE

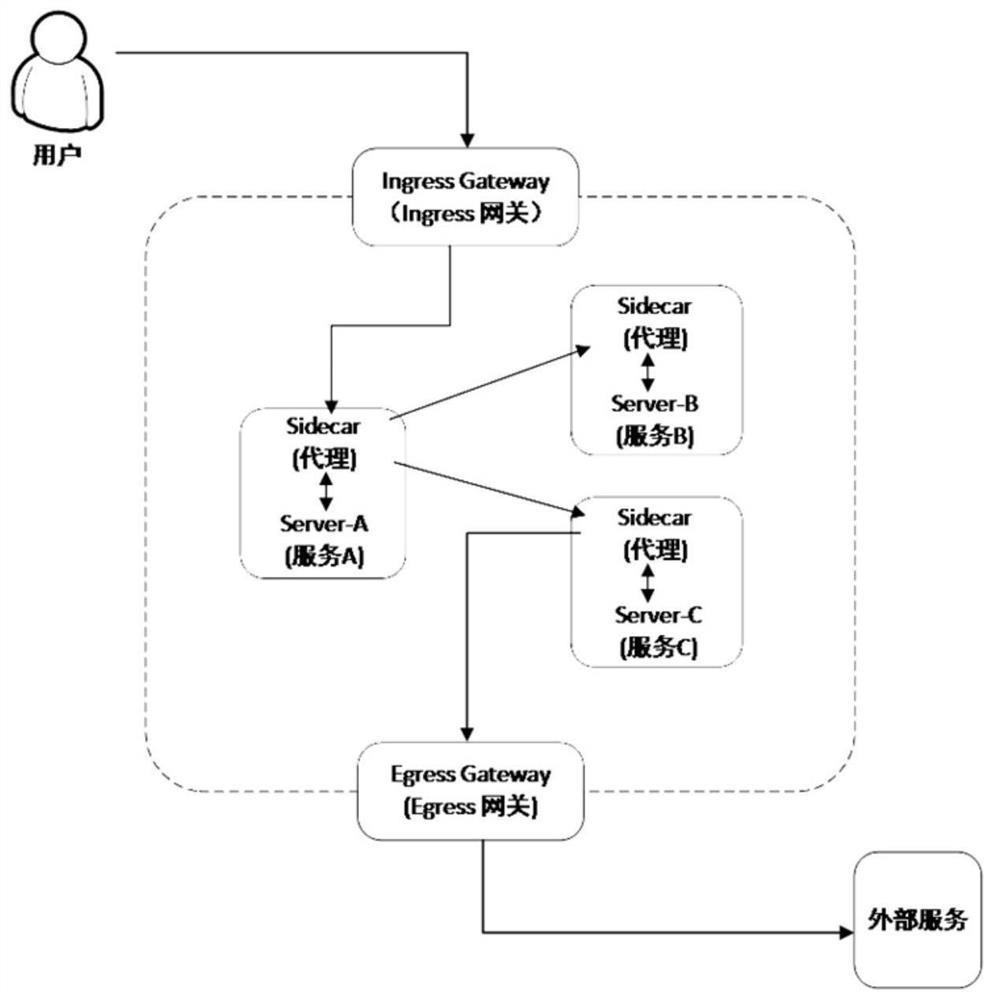

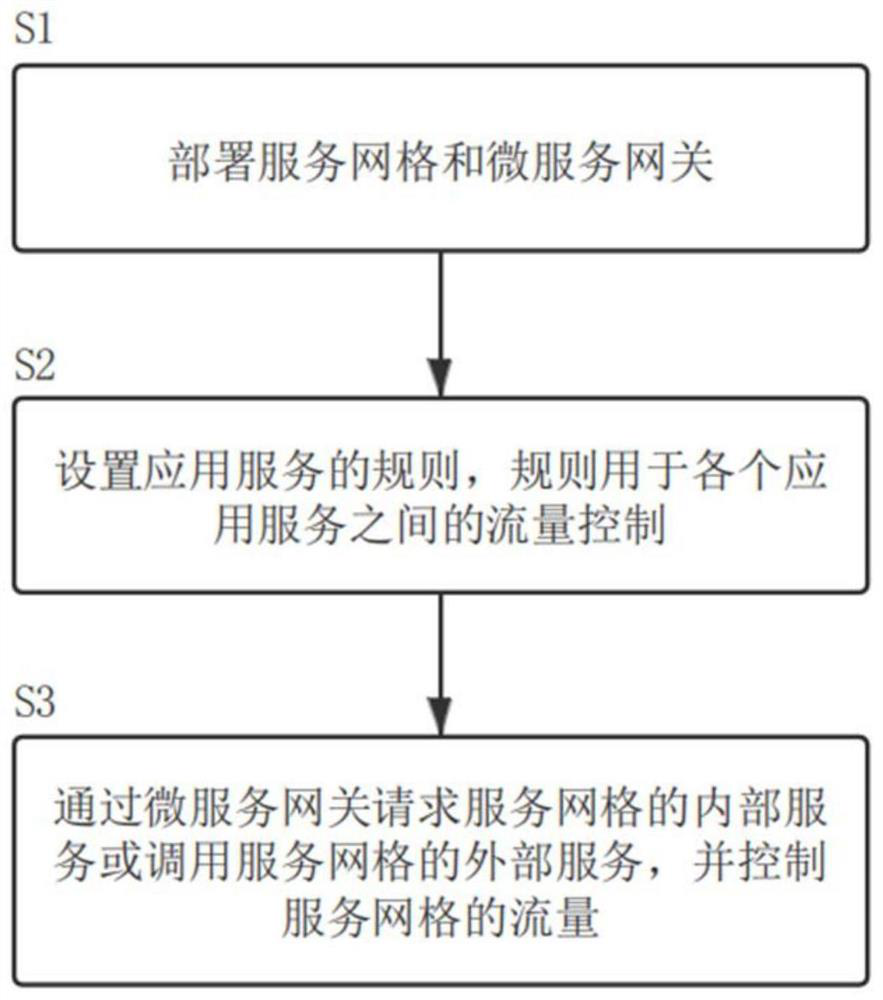

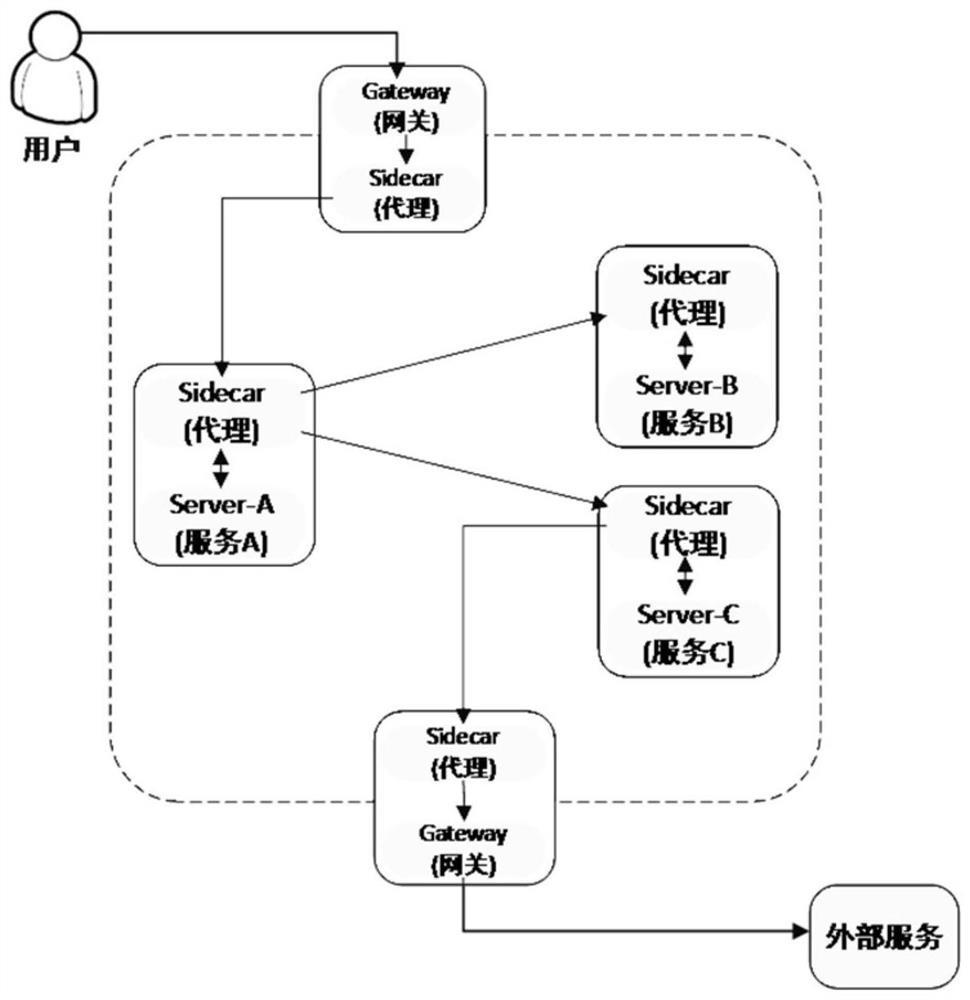

Service grid flow control method and system based on microservice gateway, and medium

ActiveCN112910692ASupport landing practiceMeet specification requirementsData switching networksComputer networkBusiness enterprise

The invention relates to a service grid flow control method and system based on a microservice gateway and a medium. The method comprises the following steps: S1, deploying a service grid and a micro-service gateway; S2, setting rules of the application services, wherein the rules are used for flow control among the application services; and S3, requesting an internal service of the service grid or calling an external service of the service grid through the micro-service gateway, and controlling the flow of the service grid. According to the method, the existing service of the enterprise is accessed to the service grid, the specification requirement of the gateway of the enterprise is met, secondary development of the original gateway is not needed, the development and maintenance cost of the gateway is reduced, and the landing practice of the service grid in the enterprise is supported.

Owner:中原银行股份有限公司

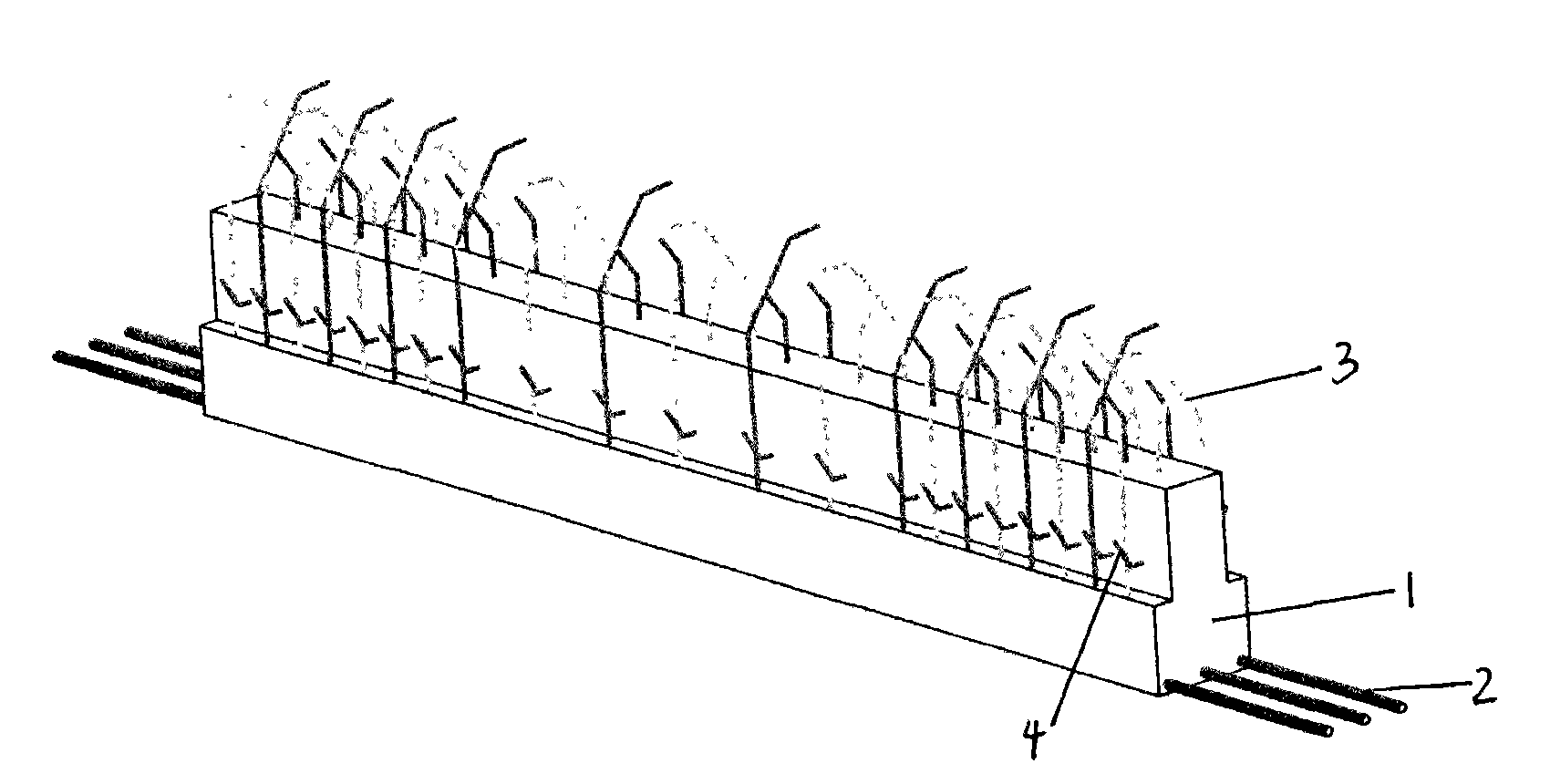

Semi-precast beam

InactiveCN101793075AEnsure safetyImprove construction efficiencyGirdersJoistsFalseworkReinforced concrete

The invention provides a semi-precast beam, which mainly comprises a beam body and steel bars (a general name of stressed steel bars, stirrups and tie bars), and is characterized in that: only the stressed steel bars and the stirrups on the lower part are pre-arranged in the semi-precast beam; and the beam body is exposed on a banding or welding part of the stirrups and other post-arranged stressed steel bars to prevent the steel bars on the upper part from impeding construction. The semi-precast beam has the advantages that: the steel bars of the semi-precast beam do not conflict with the steel bars of other components in the process of installation, so that the treatment of the steel bars at joints meets the requirement of a specification of a reinforced concrete structure; a beam holding component bears the construction load instead of a full scaffold by using a principle of simply supported beams; the connection of the steel bars and the banding of templates are performed on the floor, so that the safety of workers is ensured, and the construction efficiency and the construction quality are obviously improved; the amount of high-altitude operation is substantially reduced; and the post-casting of concrete is operated on the floor, and the amount of the post-cast concrete is substantially reduced, so the construction speed is substantially improved.

Owner:管乃彦

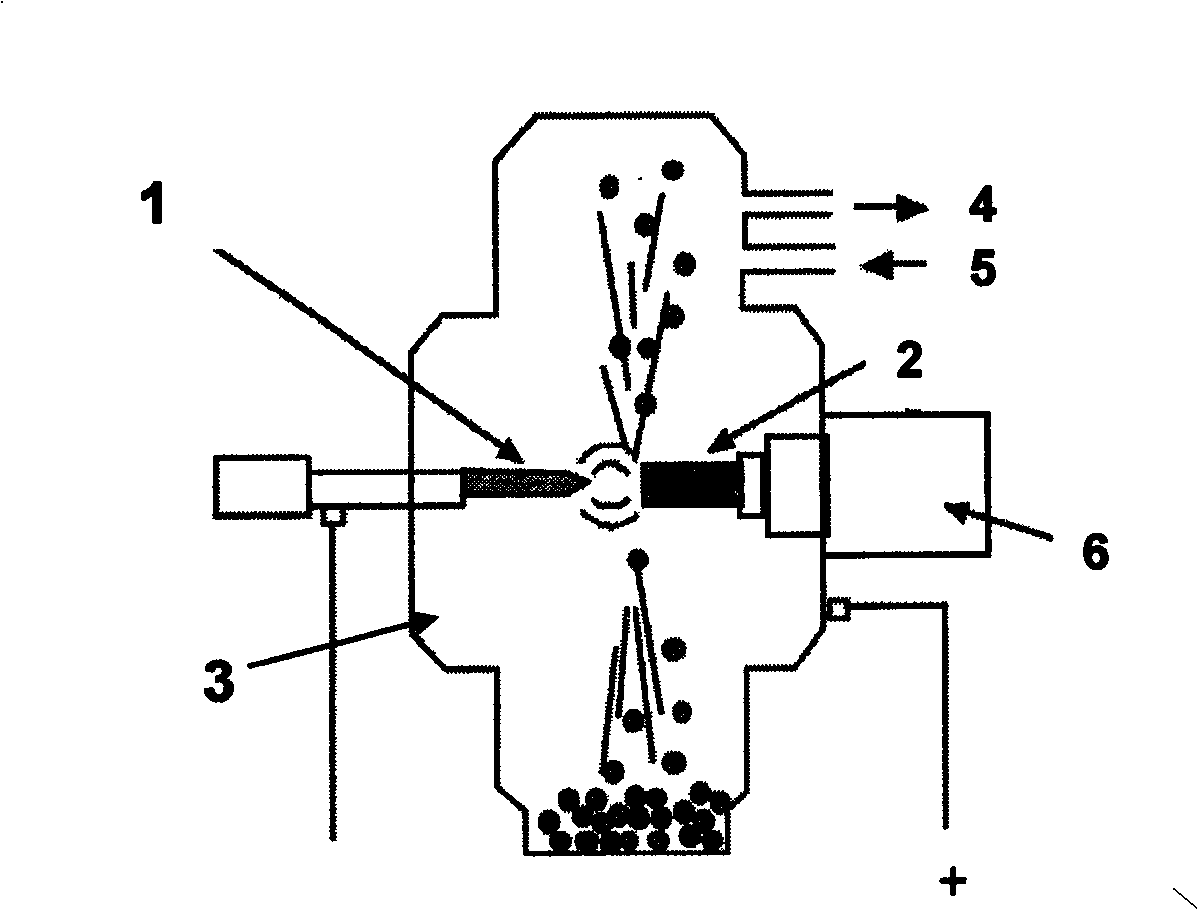

Method for producing beryllium prill using plasma auxiliary rotating electrode

The invention relates to a method for preparing a Be prill by centrifugal process of a plasma assisted rotary electrode. In a closed container protected by inert gases, the high temperature generated by glow discharge generated between the plasma assisted rotary electrode and a rotary cylindrical consumption Be electrode manufactured by the metal of Be is utilized for leading one section of Be electrode that is close to the voltaic arc of the plasma to form small drops of Be; the small drops of Be are thrown away by centrifugal force; the small drops of Be are cooled in air and solidified into sphere in the closed container under the environment of the inert gases, thus the Be prill is obtained. The method can obtain the prills with an average sphere diameter between 0.05mm to 2mm with good monodispersity by changing the technique parameters. The prepared Be prill has excellent sphericity and lower deformed particle proportion; besides, the sphere diameter is controllable; the Be prill can be used on the blanket or the fusion reactor of an ITER experiment for producing tritium in a solid state.

Owner:张建利 +1

High-performance nanofiber modified polymer cement-based repairing mortar and preparation method thereof

The invention relates to a high-performance nanofiber modified polymer cement-based repairing mortar. The repairing mortar comprises, by mass, 25.0-29.5% of cement, 52.2-52.7% of quartz sands, 1.4-2.0% of dispersible latex powder, 0.4-1.0% of nano-SiO2, 3.5-5.2% of fly ash, 1.8-3.5% of metakaolin, 0.07-0.14% of fibers, 0.18-0.24% of a water reducer, 0.03-0.04% of a silicone antifoaming agent, 0.01-0.02% of cellulose ether, and the balance of water. The invention discloses a preparation method of the repairing mortar. The method of the invention is simple and is easy to implement, and the obtained repairing mortar has excellent performances, and is suitable for repairing the reinforced concrete structure.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

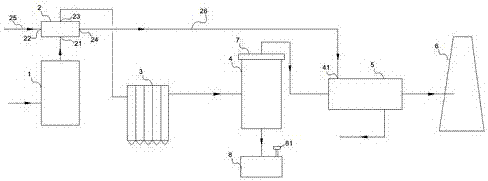

Multifunctional flue gas treatment system

InactiveCN107349785AEfficient removalSimple structureCombination devicesWater/sewage treatmentFlue gasNitrogen oxide

The invention relates to a multifunctional flue gas treatment system. The multifunctional flue gas treatment system comprises an SCR (selective catalytic reduction) denitrification unit, a flue gas-air heat exchange unit, a bag type dedusting unit, a desulfurizing tower, a heating unit and a flue gas exhaust system which are sequentially connected by pipelines, wherein a wet type electrical mist removing unit is arranged between the desulfurizing tower and the heating unit, and is used for removing mist droplets in the flue gas treated by the desulfurizing tower, and exhausting the treated flue gas into the heating unit; the flue gas exchanges heat with the hot air outputted by the flue gas-air heat exchange unit in the heating unit, and then is exhausted into the flue gas exhaust unit; the desulfurizing tower is communicated with a wastewater treatment unit, and the wastewater treatment unit is used for receiving wastewater drained by the desulfurizing tower, and treating the wastewater. The multifunctional flue gas treatment system has the advantages that the structure is simple, the sulfur dioxide and oxynitride in the flue gas can be effectively removed, the residual heat can be effectively utilized, and the wastewater can be effectively treated.

Owner:佛山市亚科恒远科技有限公司

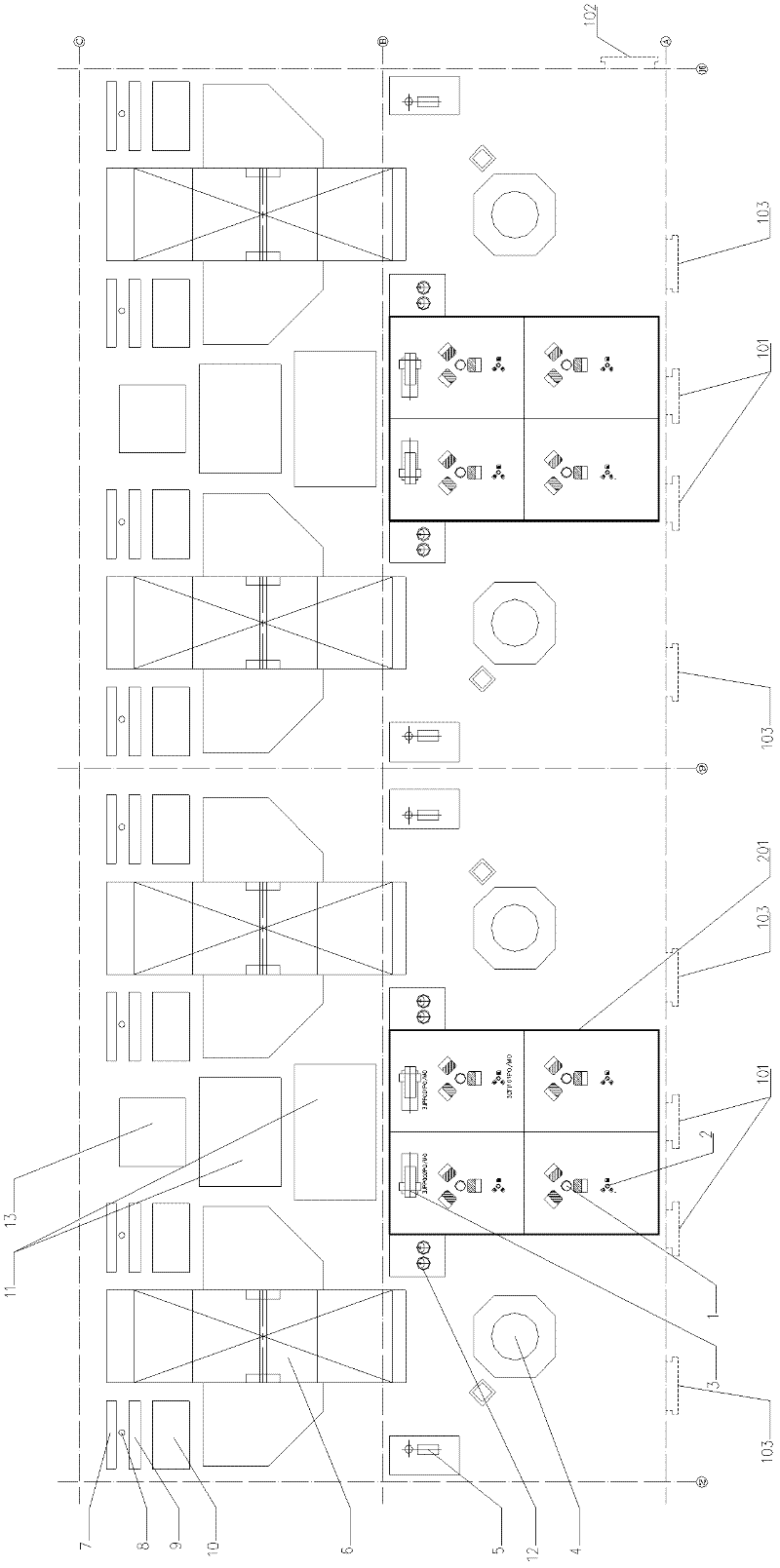

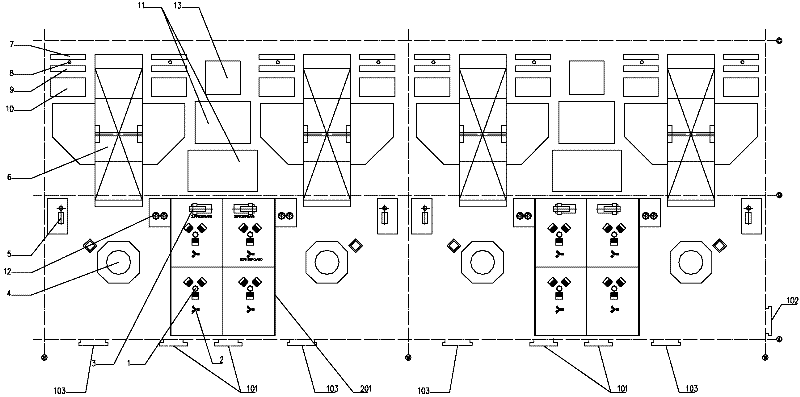

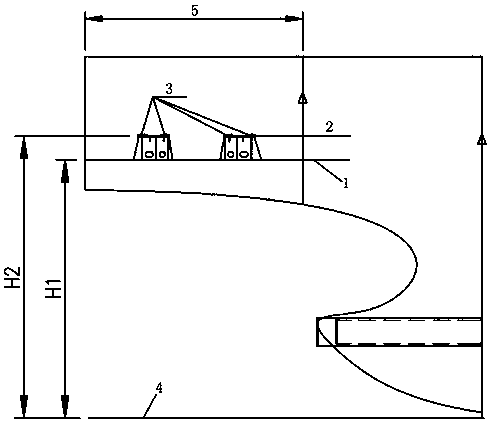

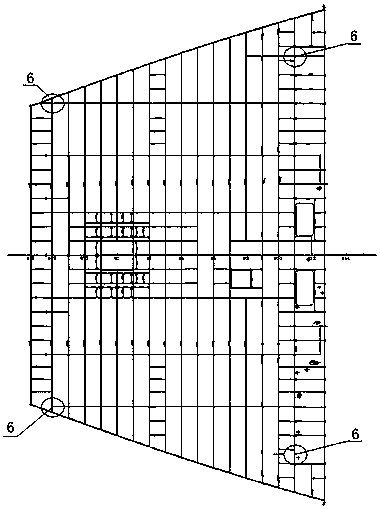

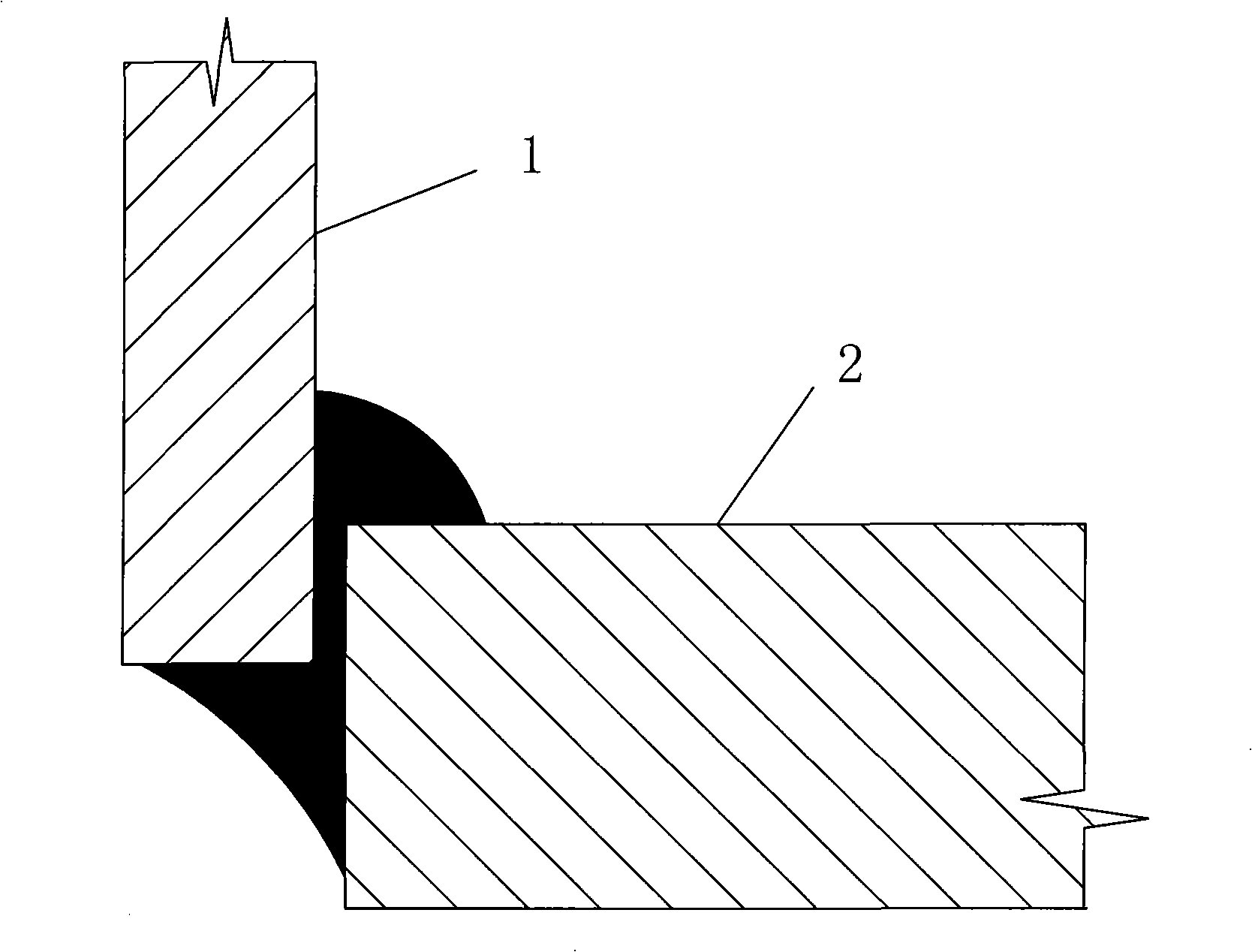

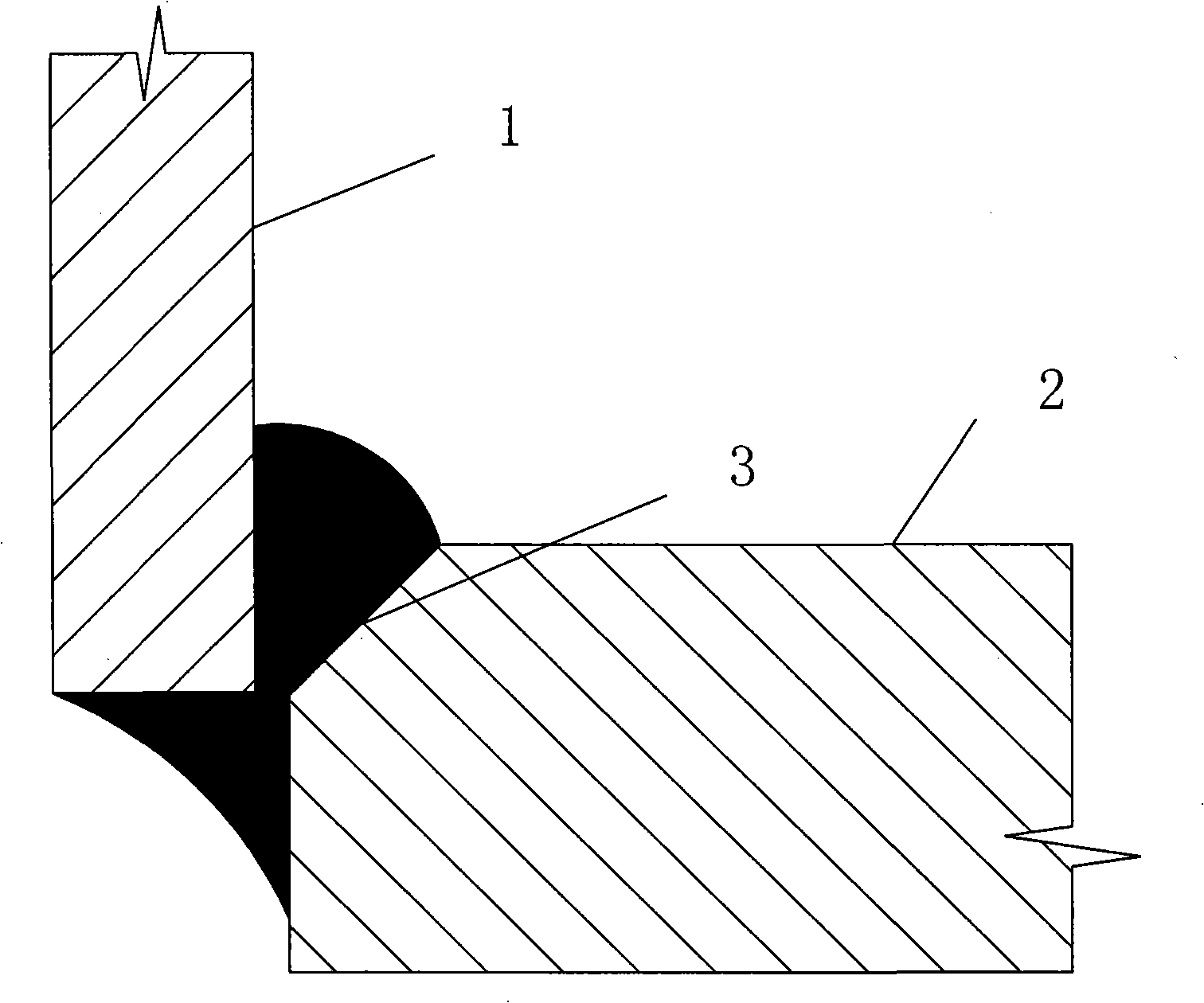

Combined pump room arrangement method

ActiveCN102409724AEconomical arrangementMeet specification requirementsPumping plantsState of artGrating

The invention discloses a combined pump room arrangement method, relating to the technical field of nuclear power. The invention solves the problem that the prior art lacks a compact and efficient arrangement method for reasonably arranging devices in a combined pump room. The embodiment of the invention provides a combined pump room arrangement method, wherein the combined pump room comprises a pump region and a filtering device region; the pump region comprises an important house service pump sump; the important house service pump sump is used for arranging important house service pumps, drum mesh backwash pumps and fire service pumps with higher safety degree requirements; the outer side of the important house service pump sump is used for arranging water circulating pumps and seawaterlift pumps with lower safety degree requirements; and the filtering device region is used for arranging steel gates, a coarse grating, chlorination pipe devices, a fine grating, cleaners and drum meshes. The combined pump room arrangement method provided by the embodiment of the invention is widely applied to nuclear power generating units and the like.

Owner:CHINA NUCLEAR POWER ENG CO LTD

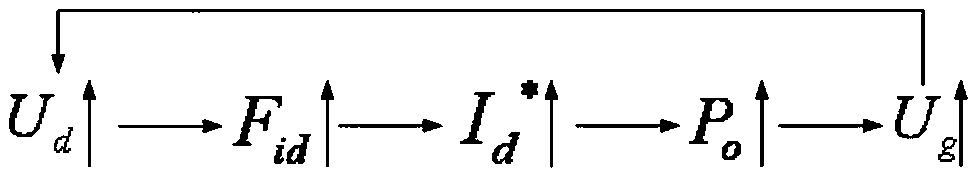

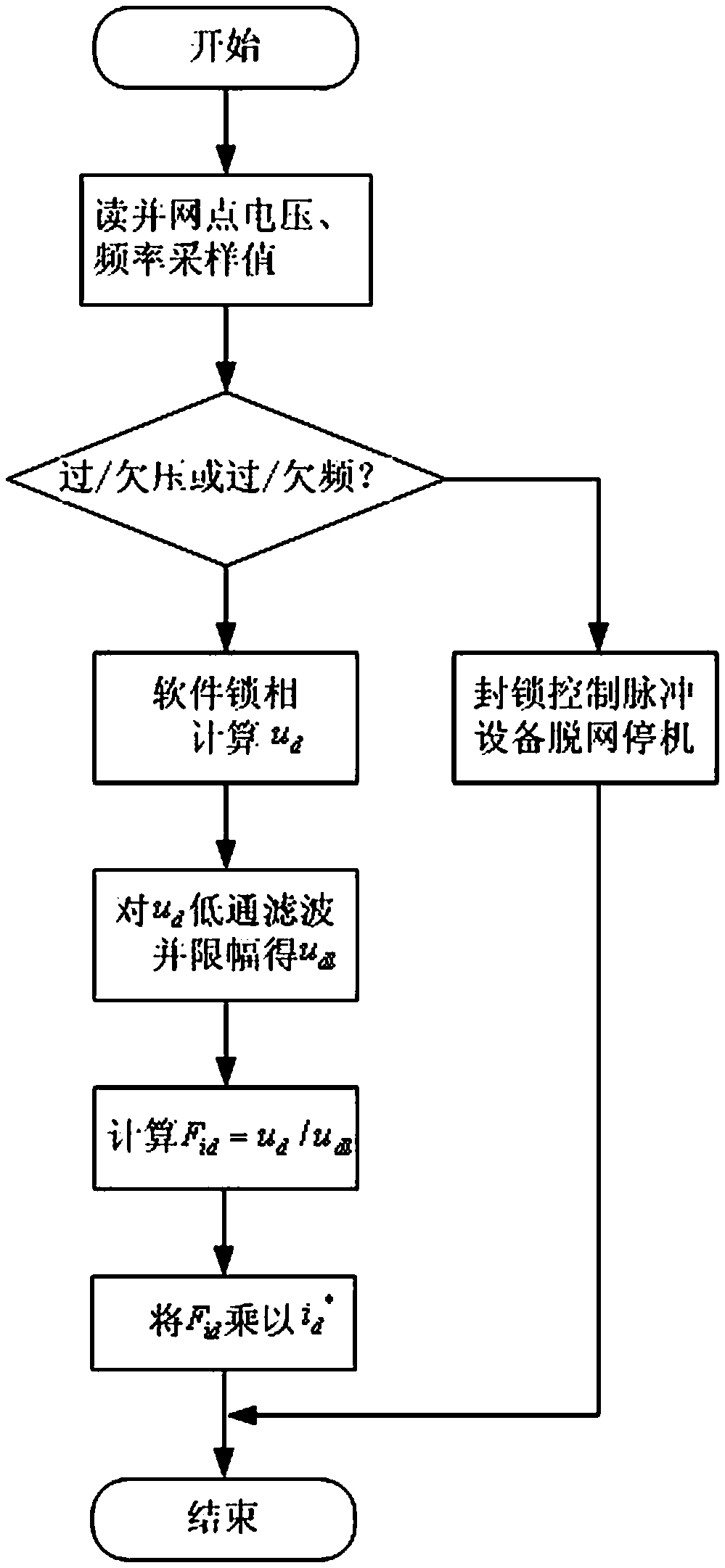

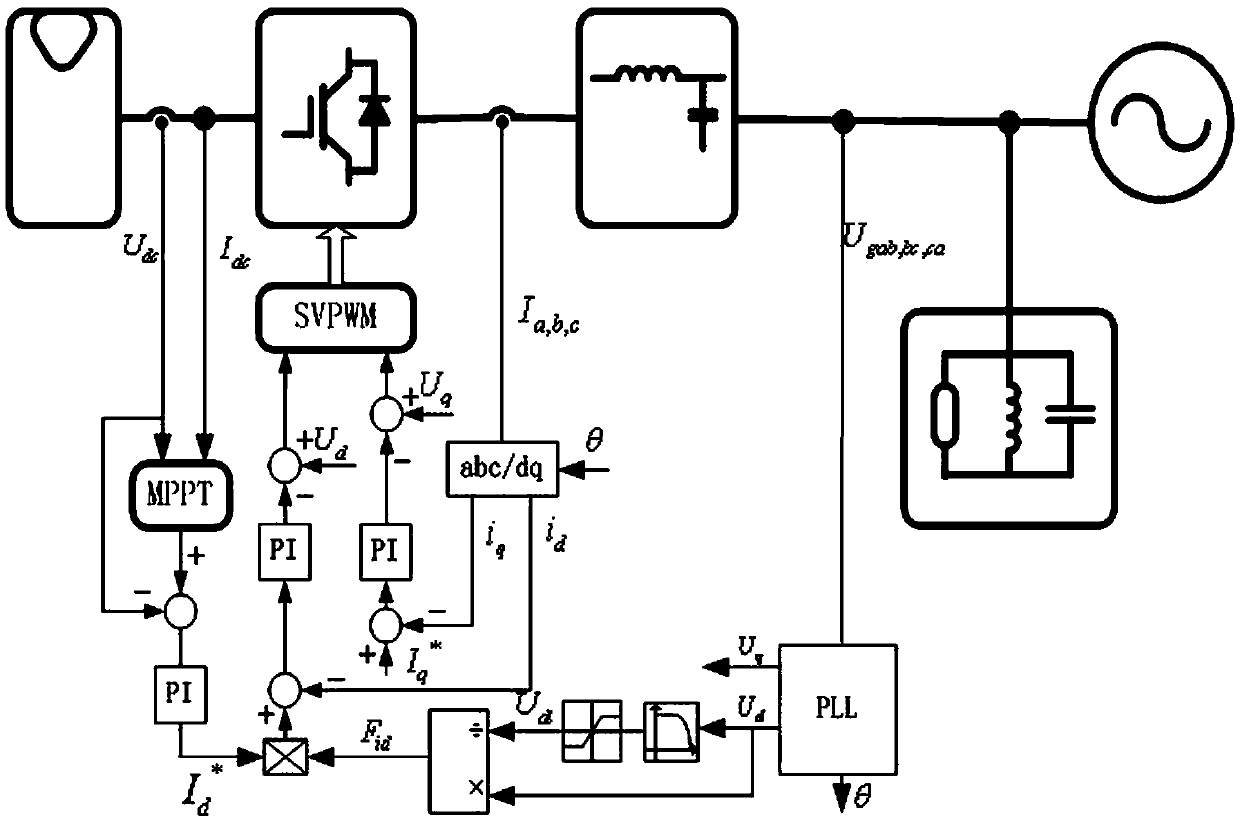

Positive feedback island detection method based on active current disturbance

InactiveCN105467237AHarmonic distortion has no effect onExpand the scope of detectionElectrical testingOvervoltageLower limit

The invention provides a positive feedback island detection method based on active current disturbance. The detection method comprises four portions: grid-connected point voltage vector angle calculating, D axis control coefficient calculating of an output current under a synchronous rotating coordinate system, grid-connected current control and grid-connected point overvoltage / undervoltage, and overfrequency / underfrequency protection. Through carrying out disturbance control on an active current of an inversion apparatus, the inversion apparatus can be guaranteed not to influence a harmonic distortion rate of the output current during normal operation; and when an island is generated, the island detection method can be guaranteed not to be used to detect a blind area so that an island detection scope is greatly increased. Simultaneously, because of the positive feedback, a detection speed can easily satisfy a standard requirement. In addition, because an normal operation scope of the inversion apparatus is determined in a standard, determination of an upper limit and a lower limit of a D axis component after low-pass filtering is simple.

Owner:DONGFANG HITACHI CHENGDU ELECTRICAL CONTROL EQUIP CO LTD

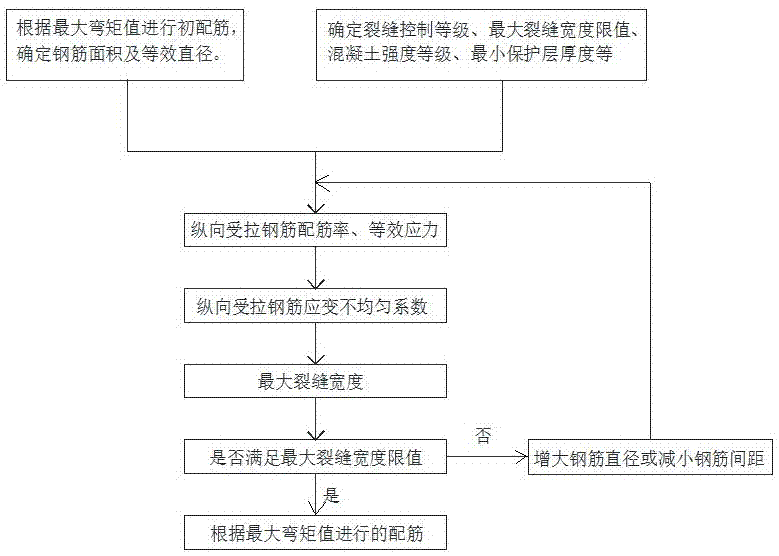

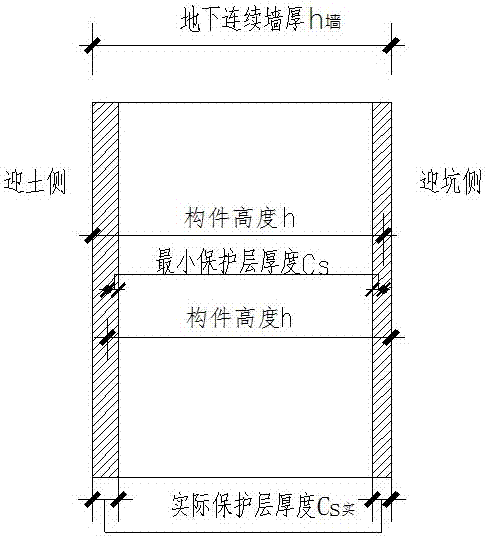

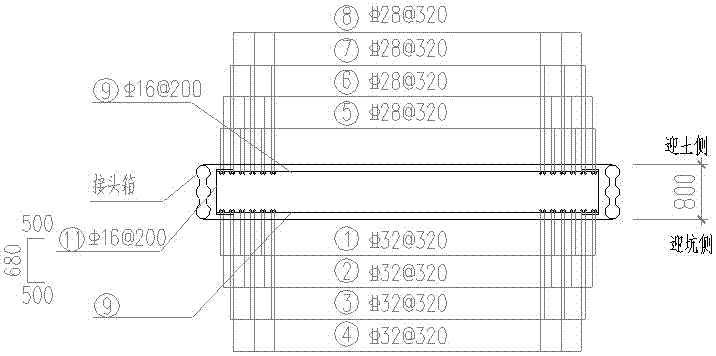

Crack width checking and control method of underground continuous wall

InactiveCN107341327AReasonable configurationTake advantage ofGeometric CADSpecial data processing applicationsSlurry wallEngineering

The invention discloses a crack width checking and control method of an underground continuous wall. The method is characterized in that a maximum bending moment under the characteristic combination of some working condition at a foundation pit construction stage is adopted, and a minimal protective cover thickness and a suggested component height are substituted into a formula required by a standard for checking until reinforcing bars of the underground continuous wall meets the requirements; the checking specifically comprises the following steps: calculating widths of primary reinforcing bars and cracks, thickness of a protective cover and height of a component, reinforcement ratio, equivalent stress of reinforcing steel bars, non-uniform coefficient of stress and maximum crack width. Compared with the prior art, the method has the advantage that on the premise of meeting and ensuring the safety of the structure, the waste of reinforcement for the underground continuous wall is reduced to the greatest extent, so that the engineering cost is further lowered.

Owner:中船勘察设计研究院有限公司

Opening structure of reinforced concrete beam

The invention discloses an opening structure of a reinforced concrete beam. The opening structure is characterized in that a position of an opening formed in the abdomen of the cast-in-place reinforced concrete beam is reserved, and reinforcing steel bars, confined stirrups and steel tie bars are configured at the opening; the reinforcing steel bars comprise opening upper-part reinforcing steel bars and opening lower-part reinforcing steel bars which are configured at the upper part and the lower part of the opening respectively; the opening upper-part reinforcing steel bars and beam upper-part reinforcing steel bars are wound with the confined stirrups, and the opening lower-part reinforcing steel bars and beam lower-part reinforcing steel bars are wound with the confined stirrups; and the steel tie bars are also configured nearby the opening of the beam, pulled from the lower part of a side wall of one side of the beam to the upper part of a side wall of the other side of the beam and extend into a beam plate. The reinforcing steel bars, the confined stirrups and the steel tie bars are configured nearby the opening of the beam, and by means of characteristics and performance of region constraints, the intensity and ductility reduction which is caused by opening of the beam abdomen is effectively reduced, the anti-bending and shear-resisting capacity of the reinforced concrete beam is guaranteed, the phenomenon of stress concentration of the periphery of the opening is relieved, and the reliability of the structure is improved.

Owner:SUZHOU INDAL PARK DESIGN & RES INST

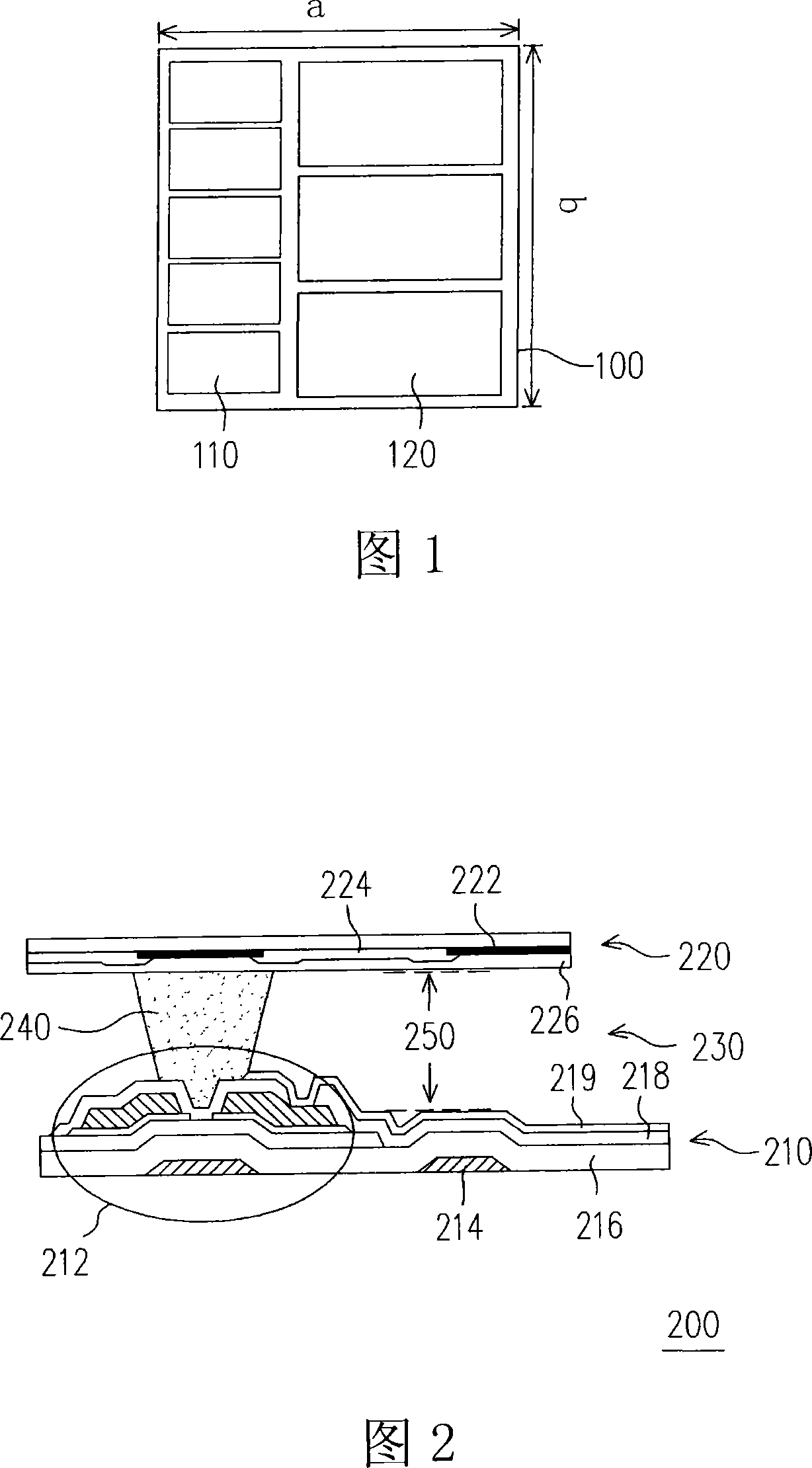

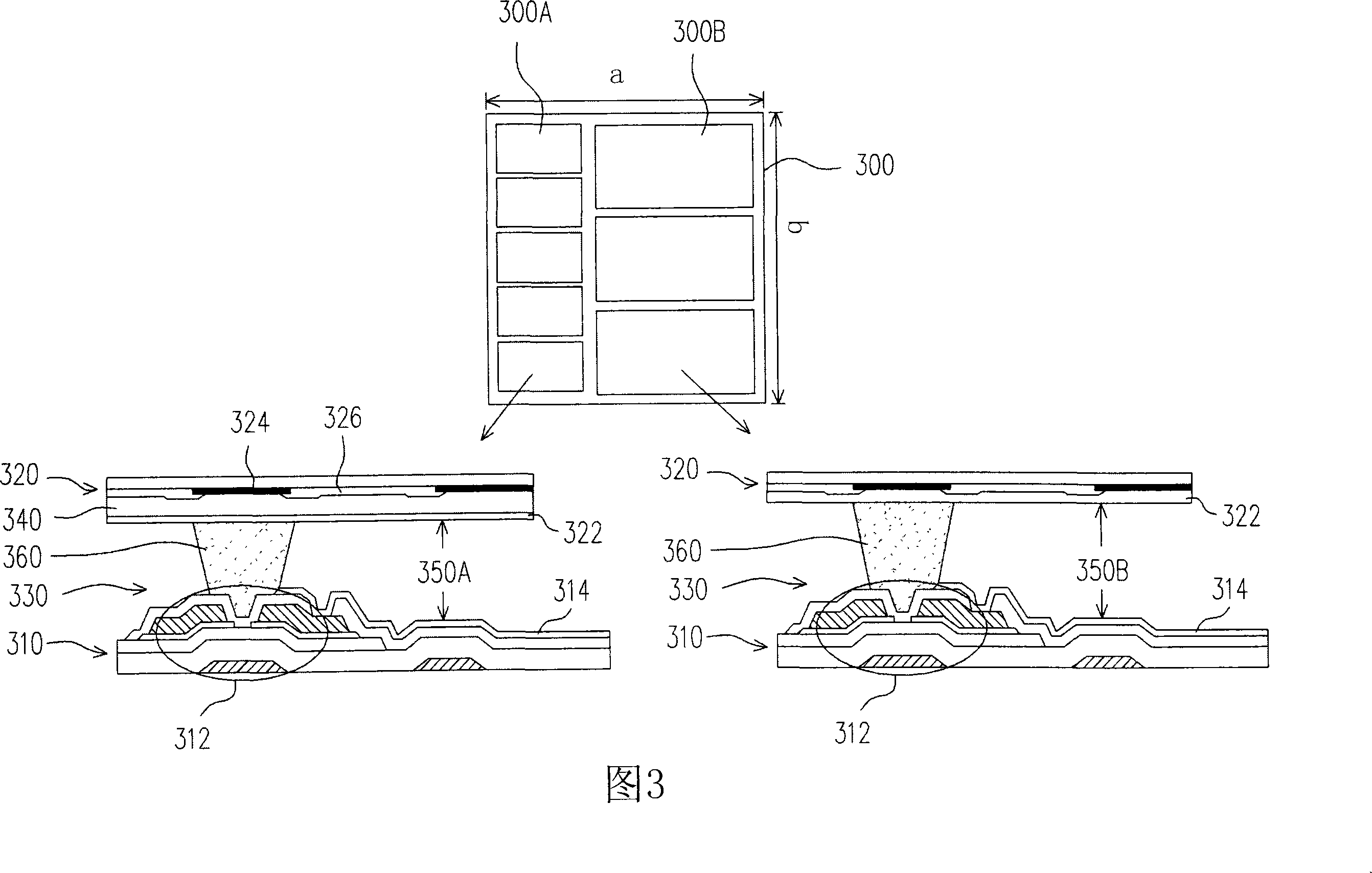

Motherboard of display panel and production method thereof

ActiveCN101221326AIncrease profitMeet specification requirementsSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMedia layer

The invention discloses a mother board of a display panel and a method for making the same, wherein the mother board has first panel cells and second panel cells which are different in size and are provided with different cell gaps. The mother board is mainly composed of a switchover element array substrate, a counter substrate, a display medium layer and an underlayer. The switchover element array substrate is provided with a plurality of switchover elements which are arranged in an array and a plurality of pixel electrodes correspondingly connected with the switchover elements. The counter substrate is actually parallel to the switchover elements. The display medium layer is arranged between the switchover element array substrate and the counter substrate. The underlayer is arranged between the switchover element array substrate and the counter substrate and is corresponding to the first panel cells for compensating for the cell gaps between the first panel cells and the second panel cells.

Owner:AU OPTRONICS CORP

Grouting material for underground mine roadway and grouting water control method

InactiveCN106567714AChoose economical and reasonableWide variety of sourcesUnderground chambersTunnel liningBlock effectCement paste

The invention discloses a grouting material for an underground mine roadway and a grouting water control method. The grouting water control method comprises the steps that (1) 11-15 grouting drill holes are formed round the outline of the roadway, and the angles of the drill holes extend to the outside of the outline of the roadway; (2) grouting is conducted thought the grouting material, the grouting material is formed by mixing cement paste, sodium silicate and an admixture, and the ratio of the cement paste to the sodium silicate is 1:1-1:0.8; and (3) after grouting, an inspection hole is formed in the center of the roadway for inspecting the grouting condition. According to the grouting water control method, the design of the grouting material, forming of the grouting holes, grouting equipment and grouting pressure are improved, the grouting construction process is optimized, the grouting quality is improved, and the effect that the grouting effect reaches the design requirement is ensured. According to the grouting water control method, on the one hand, rock cracks are blocked so as to achieve the water burst blocking effect, on the other hand, surrounding rock is reinforced, and construction safety is ensured. The characteristics of the good grouting effect, safety, low cost and the like are achieved.

Owner:HEBEI IRON & STEEL GRP MINING

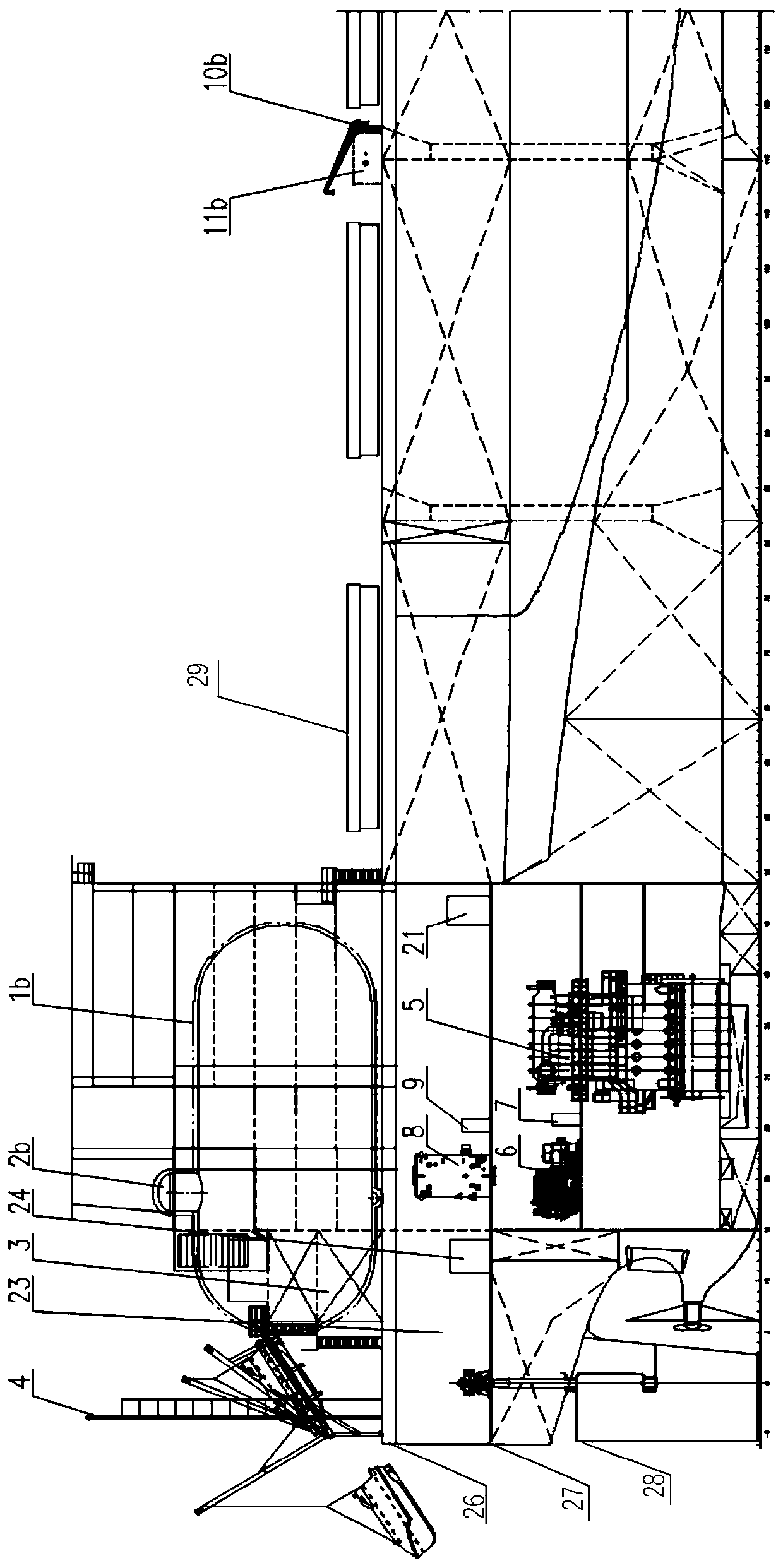

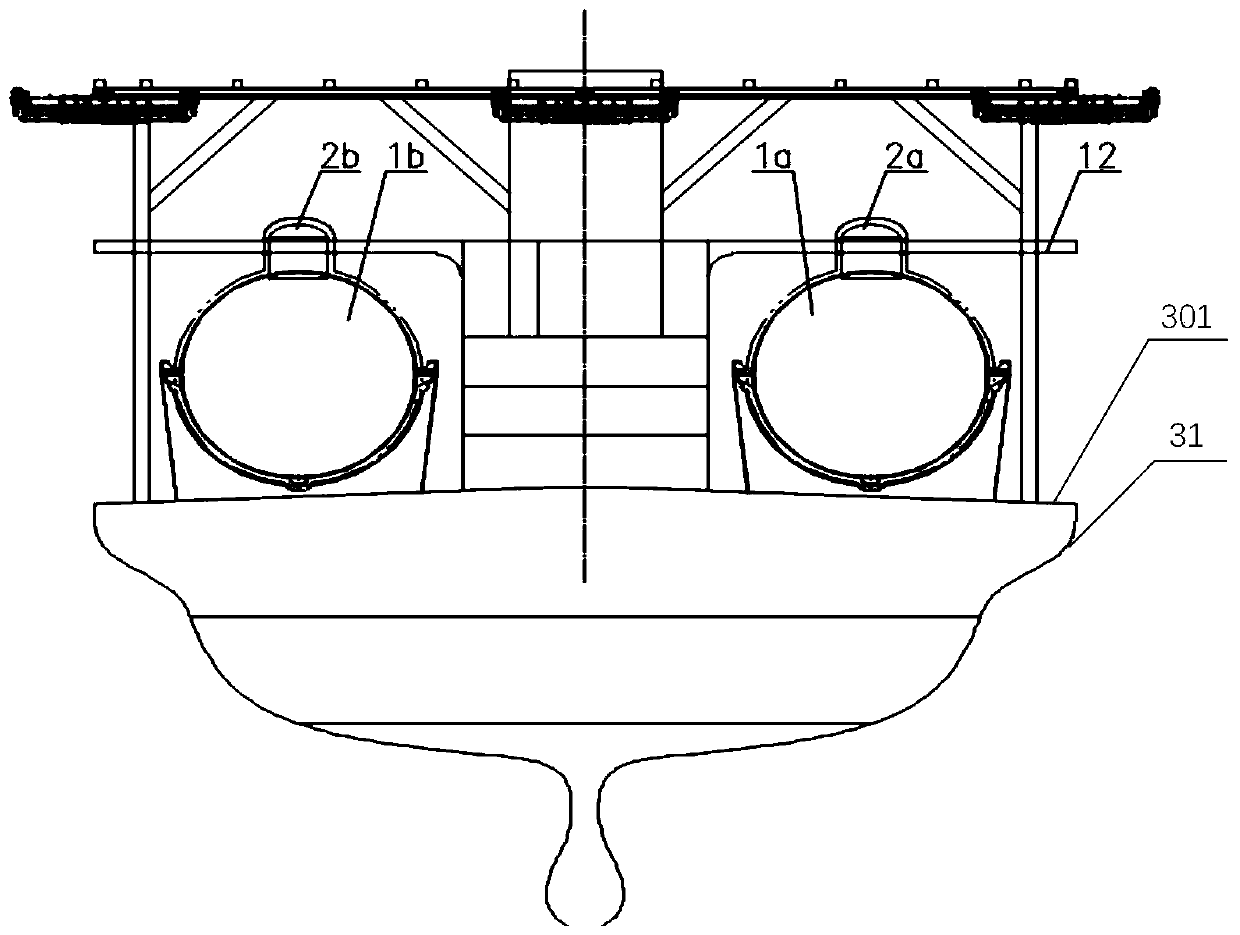

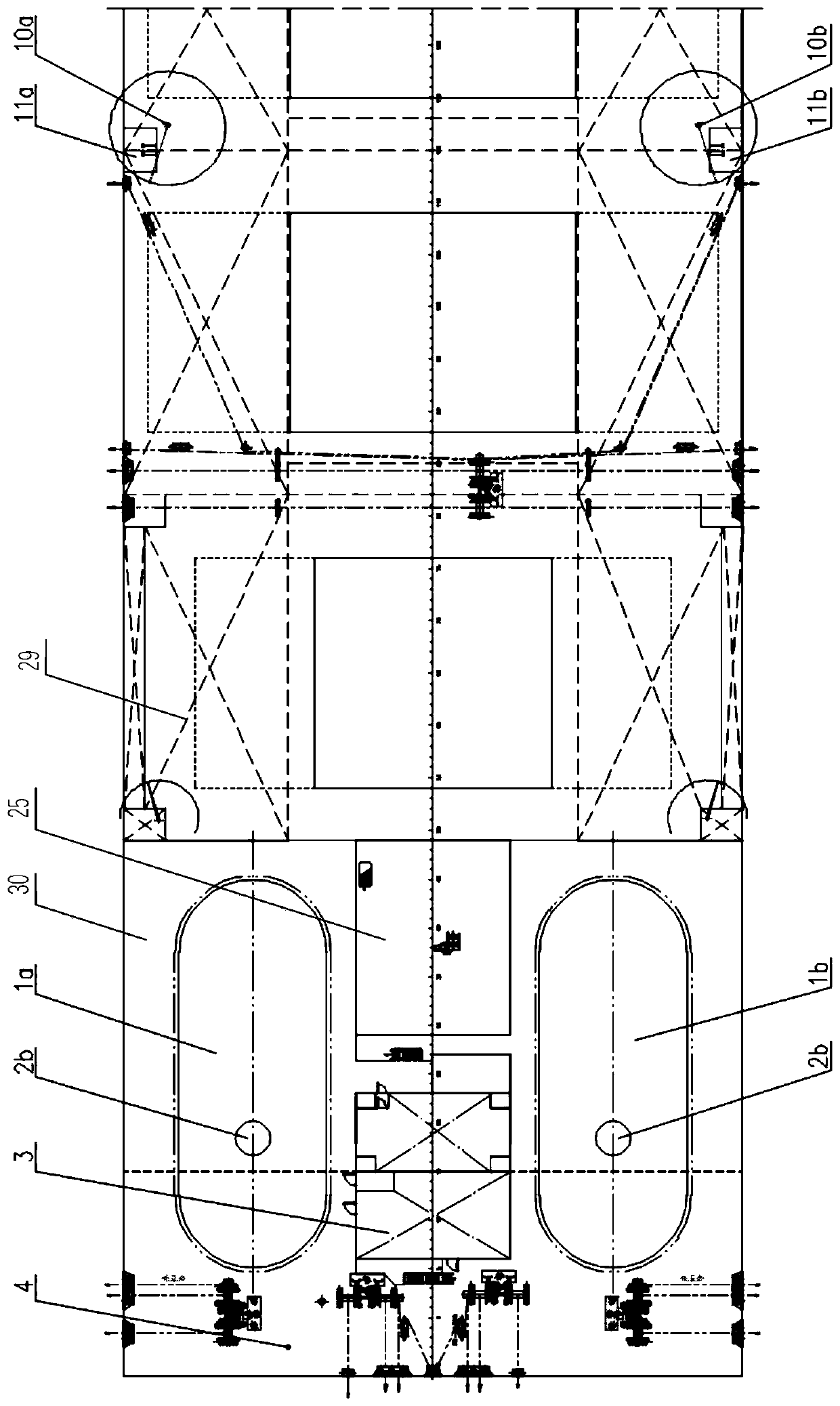

Dual-fuel bulk cargo ship

ActiveCN111422300AMeet specification requirementsAdequate natural ventilationCargo handling apparatusPropulsion based emission reductionBulk cargoStern

The invention discloses a dual-fuel bulk cargo ship, which comprises a dual-fuel bulk cargo ship gas supply system. A main deck of the dual-fuel bulk cargo ship comprises a cargo hold area and an openarea. The open area is positioned at the stern; the open area comprises an extending area; the extending areas are located on the two sides of the stern and extend in the direction away from the midship. An extending part is arranged below the extending area to support the extending area, an upper-layer building is arranged on the side, close to the cargo hold area, of the open area, and the dual-fuel bulk cargo ship gas supply system comprises LNG fuel cabins which are arranged above the open area and located on the left side and the right side of the upper-layer building, a cabin which is arranged below the main deck, and a fuel gas treatment room which is arranged above the open area and located between the two LNG fuel cabins. Fuel in the LNG fuel cabins is conveyed to the fuel gas treatment room to be treated and conveyed to gas equipment in the cabin.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

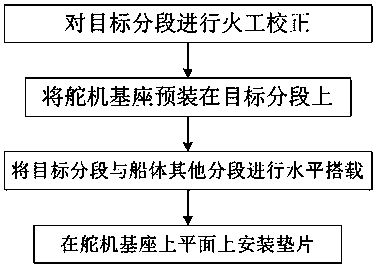

Installation method for base of steering engine

ActiveCN108189960AGuaranteed installation accuracyWon't breakVessel designingEngineeringBallast tank

The invention discloses an installation method for a base of a steering engine. The installation method mainly comprises the following steps that firework correction is carried out on a target segment; the base of the steering engine is pre-installed on the target segment, and loading of the target segment is carried out; and gaskets on the base of the steering engine are installed. A completely new method is adopted to achieve accuracy control of pre-assembly and loading of the section where the base of the steering engine is located, it is ensured that the deviation between the measured height value and the theoretical height value of a steering engine platform to a hull baseline is within the tolerance range, the installation accuracy of the base of the steering engine is ensured, height allowance does not need to be added to the base of the steering engine in advance, and cutting of the allowance of the base of the steering engine on the spot is not required; and since the base ofthe steering engine is pre-installed and welded in the segmentation stage, no later welding work exists, therefore oil paint of a ballast tank below the base of the steering engine cannot be damaged,requirements of the PSPC specification are fully met, materials are saved, a lot of manpower is saved, and the period of dock construction is shortened.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

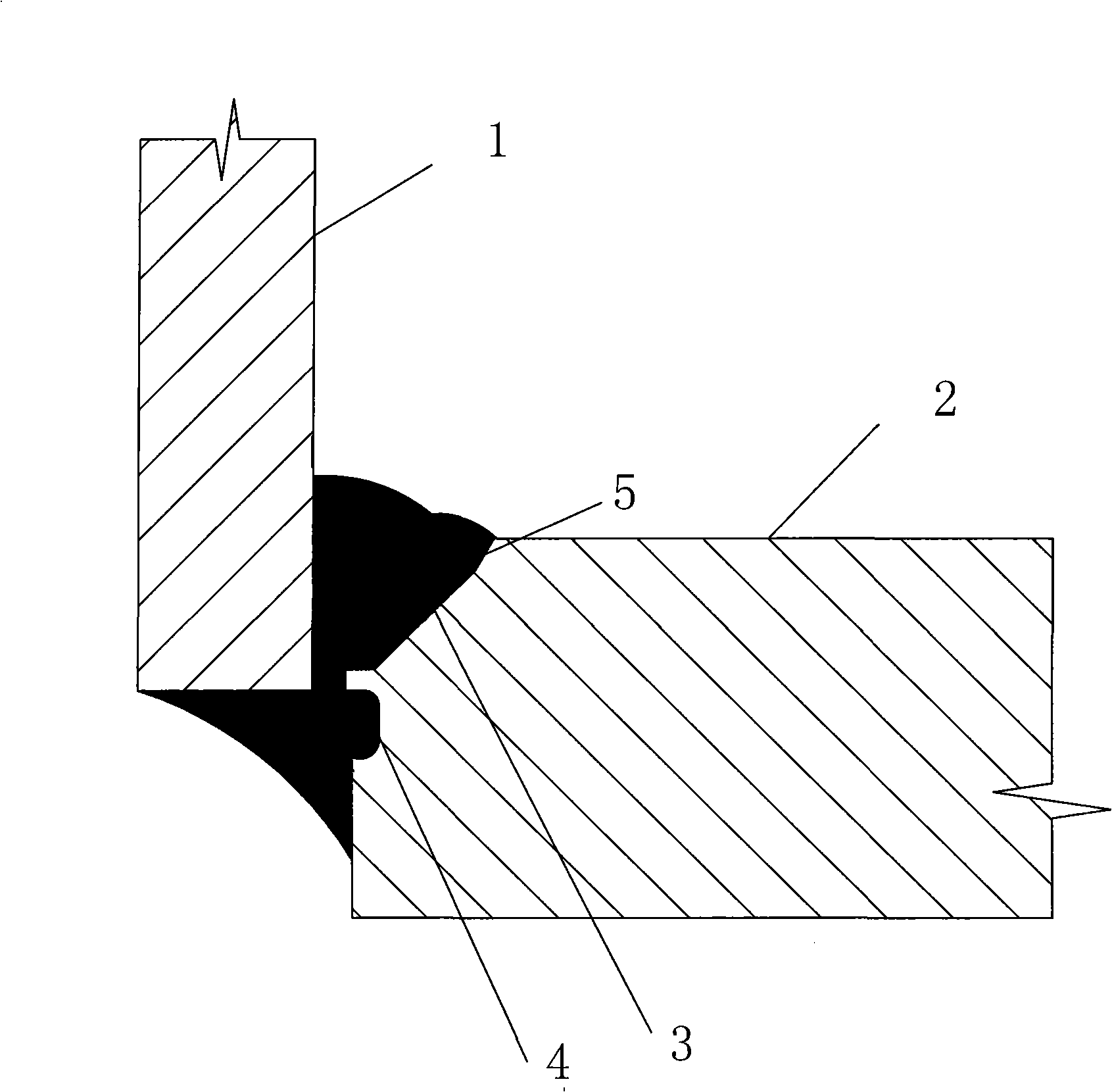

Plane welding flange divided edge structure

InactiveCN101259570AReduce welding distortionSpot welding is firmWorkpiece edge portionsEdge surfaceLap joint

The invention relates to a plane welding flange groove structure, the inner edge surface of a flange is lap-jointed with the outer wall of the end part of a steel pipe, the flange is divided into a lap joint section and an exposed section along the thickness direction, the flange is provided with a circumferential groove along the lap joint section, an annular slot is arranged on the exposed section, and an interval exists between the annular slot and the bottom part of the circumferential groove. The invention provides the plane welding flange groove structure with the firm point welding, full-penetration weld and good welding quality.

Owner:ZHEJIANG SHENGDA STEEL TOWER +2

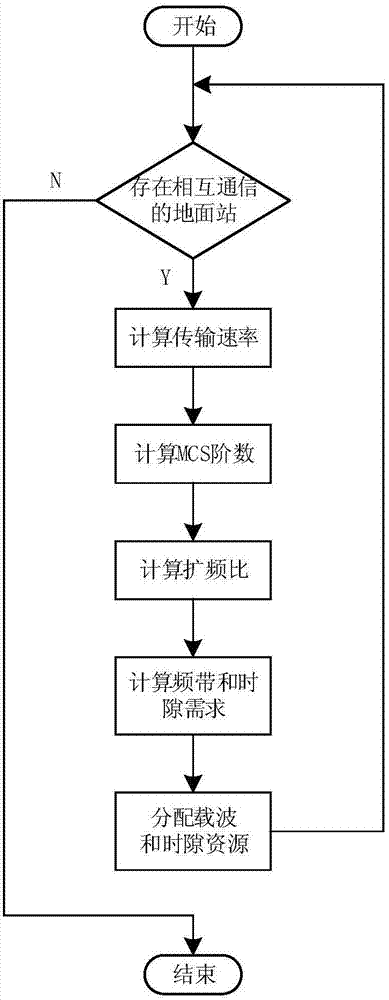

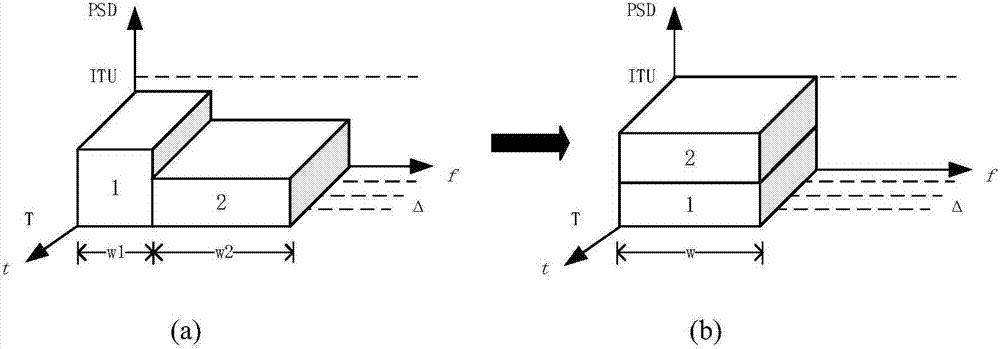

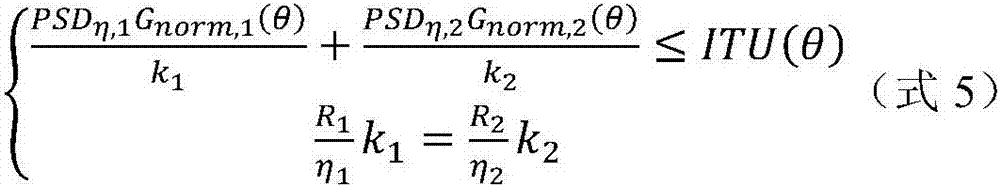

Method for suppressing adjacent satellite interference in satellite communication system

InactiveCN107342804AMeet interference requirementsReduce occupancyRadio transmissionCarrier signalGround station

The invention discloses a method for suppressing adjacent satellite interference in a satellite communication system. The method for suppressing adjacent satellite interference in the satellite communication system comprises the following steps: when ground stations communicating with each other exists in the communication network system, marking the two communication parties communicating with each other in the system as a ground station 1 and a ground station 2 respectively; forming the non-orthogonal multiple access through making the ground station 1 and the ground station 2 occupy the same time slot and frequency resource, and performing resource optimal distribution; wherein the resource optimal distribution comprises calculating and obtaining the modulation coding scheme order, the spread spectrum ratio, the communication bandwidth and the slot number respectively according to the transmission rate of the two communication parties, and allocating idle carriers and time slot resources to make the ground station 1 and the ground station 2 occupy the same carriers and time slot resources to send, so as to save the time frequency channel resource; and reducing the off-axis radiation intensity through the modulation coding scheme and the spread spectrum ratio selection method; therefore, the effects that the interference requirements of the adjacent satellite is met and the time and frequency resources are saved compared with direct spread spectrum are achieved.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com