Semi-precast beam

A semi-prefabricated, beam-body technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of long construction period, large consumption of formwork and support materials, and difficult control of project quality, so as to achieve construction efficiency and construction quality Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

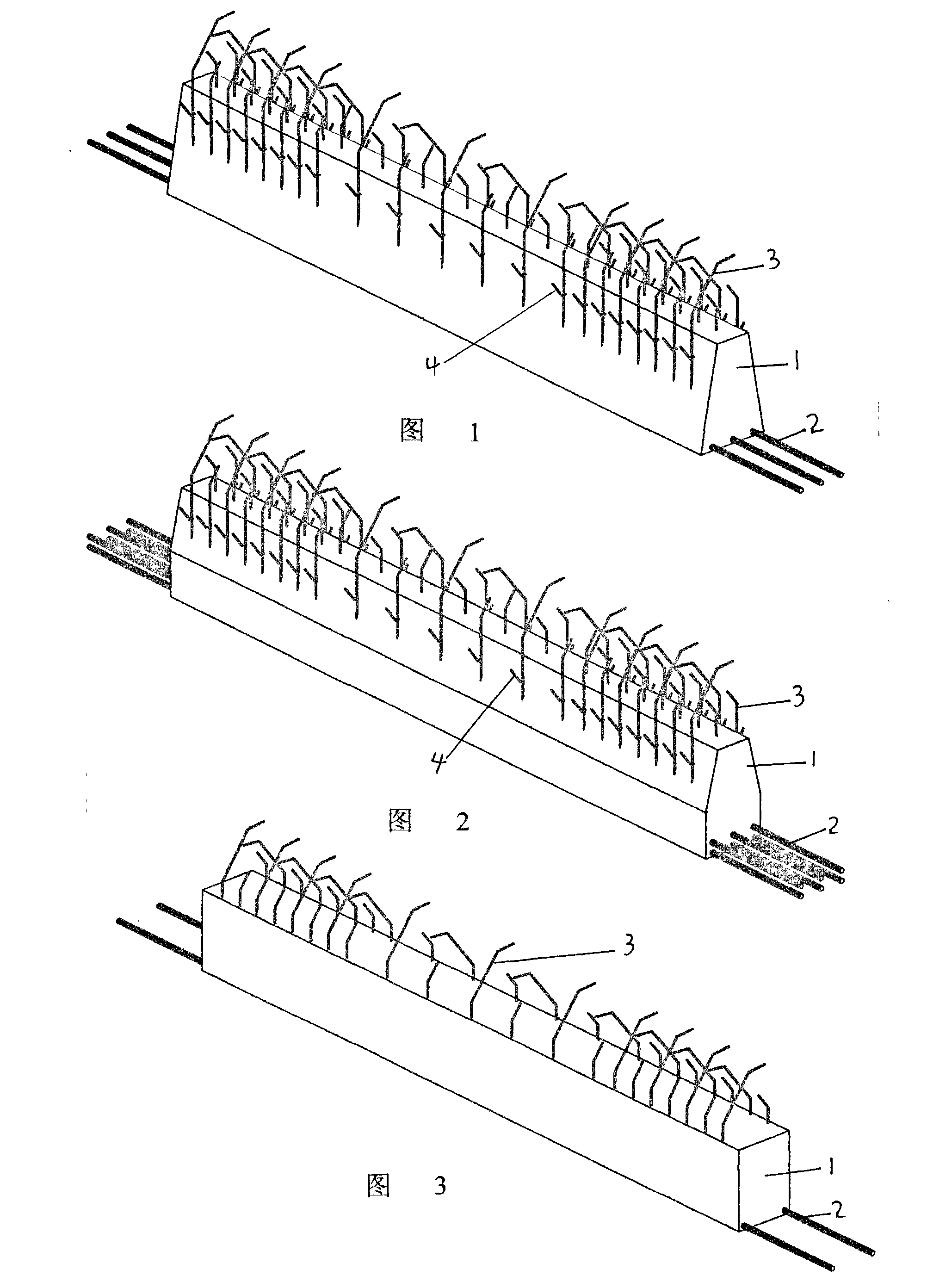

[0040] Embodiment 1 Trapezoidal section semi-prefabricated beam

[0041] Trapezoidal cross-section semi-prefabricated beam, its structure is as follows figure 1 As shown, it includes trapezoidal cross-section beam body 1 and stressed steel bars 2. There are three stressed steel bars 2 in a row, which are distributed in the lower part of beam body 1 and protrude outside beam body 1. On beam body 1, open stirrups 3 extend Out of the top of the beam body, the transverse tension bars 4 stretch out from the side of the beam body.

Embodiment 2

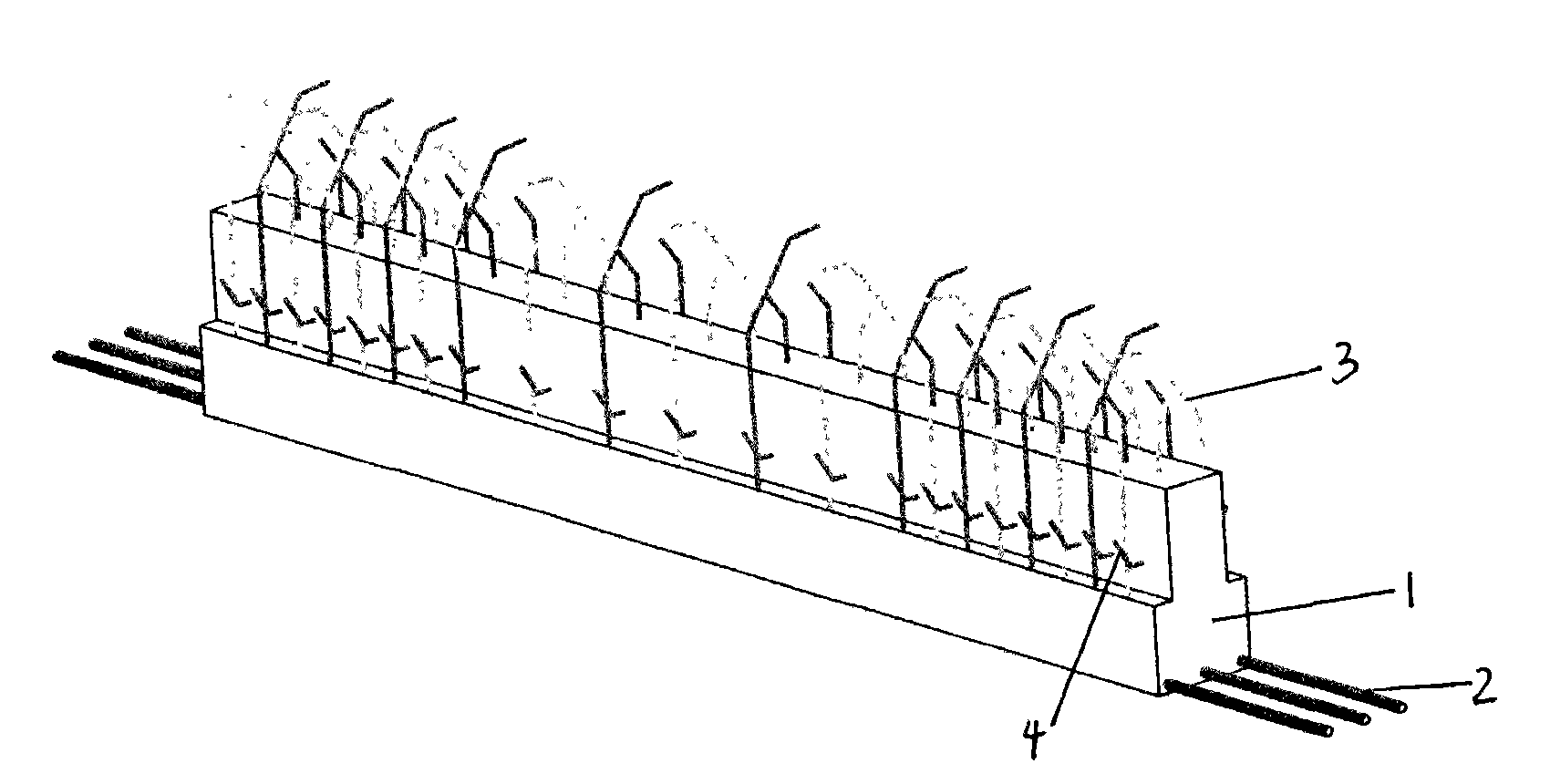

[0042] Embodiment 2 Semi-prefabricated beam with table-shaped cross-section

[0043] Semi-prefabricated girder with trapezoidal section, its structure is as follows figure 2 As shown, it includes a table-shaped cross-section beam body 1 and two rows of stressed steel bars 2 in the lower part. There are 3 stressed steel bars 2 in each row, which are distributed in the lower part of the beam body 1 and protrude outside the beam body 1. The open stirrup bars in the beam body 1 3. Stretch out the top of the beam body, stretch the ribs 4 horizontally, and stretch out the side of the beam body.

Embodiment 3

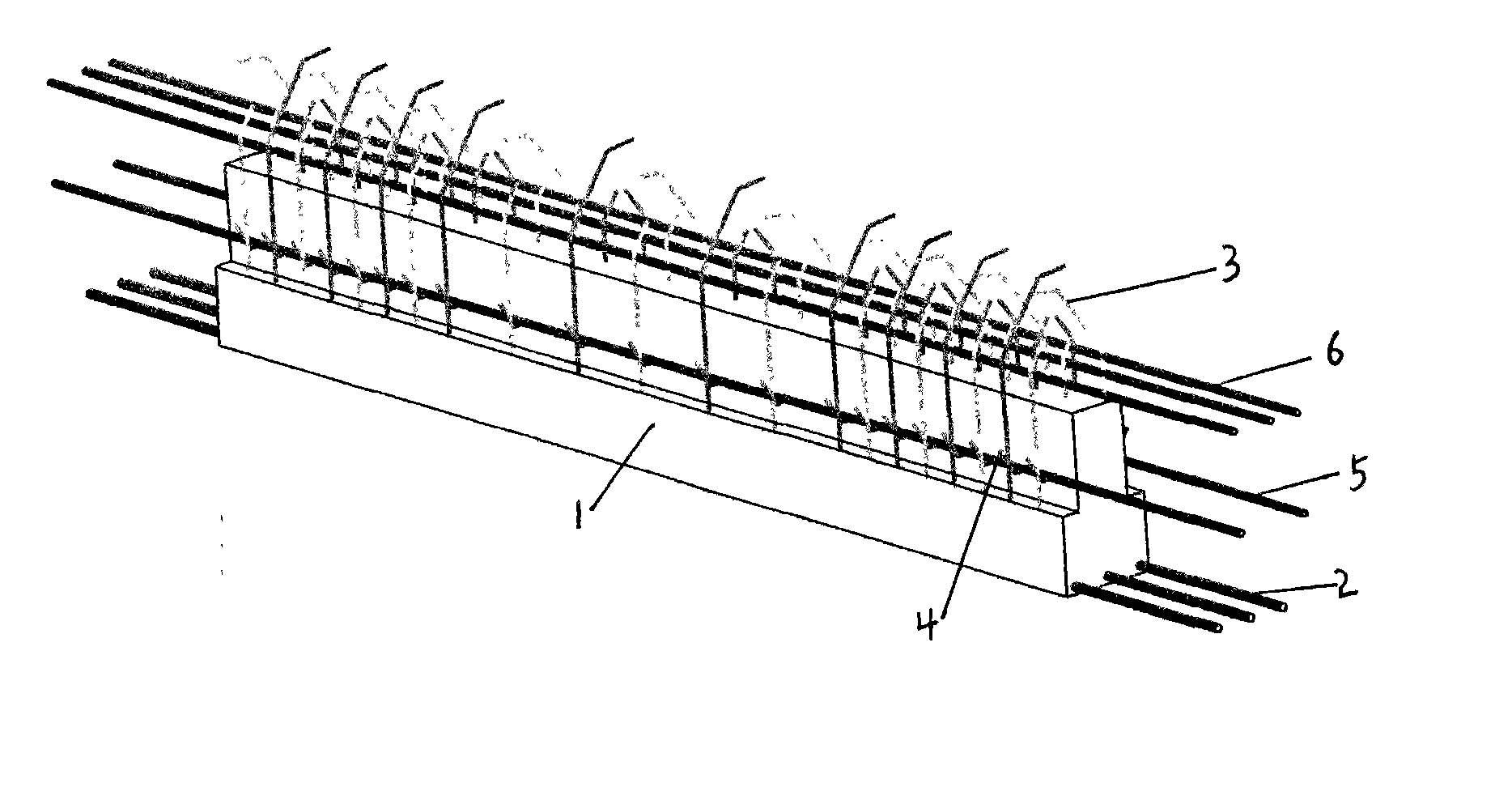

[0044] Embodiment 3 Rectangular section semi-prefabricated beam

[0045] Rectangular cross-section semi-prefabricated beam, its structure is as follows image 3 As shown, it includes a rectangular cross-section beam body 1 and a stressed steel bar 2. There are two stressed steel bars 2 in a row, distributed at the lower part of the beam body 1 and protruding out of the beam body 1, and the open stirrup 3 protrudes from the beam body 1. the top of the beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com