Patents

Literature

148results about How to "Reduce the amount of work at height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

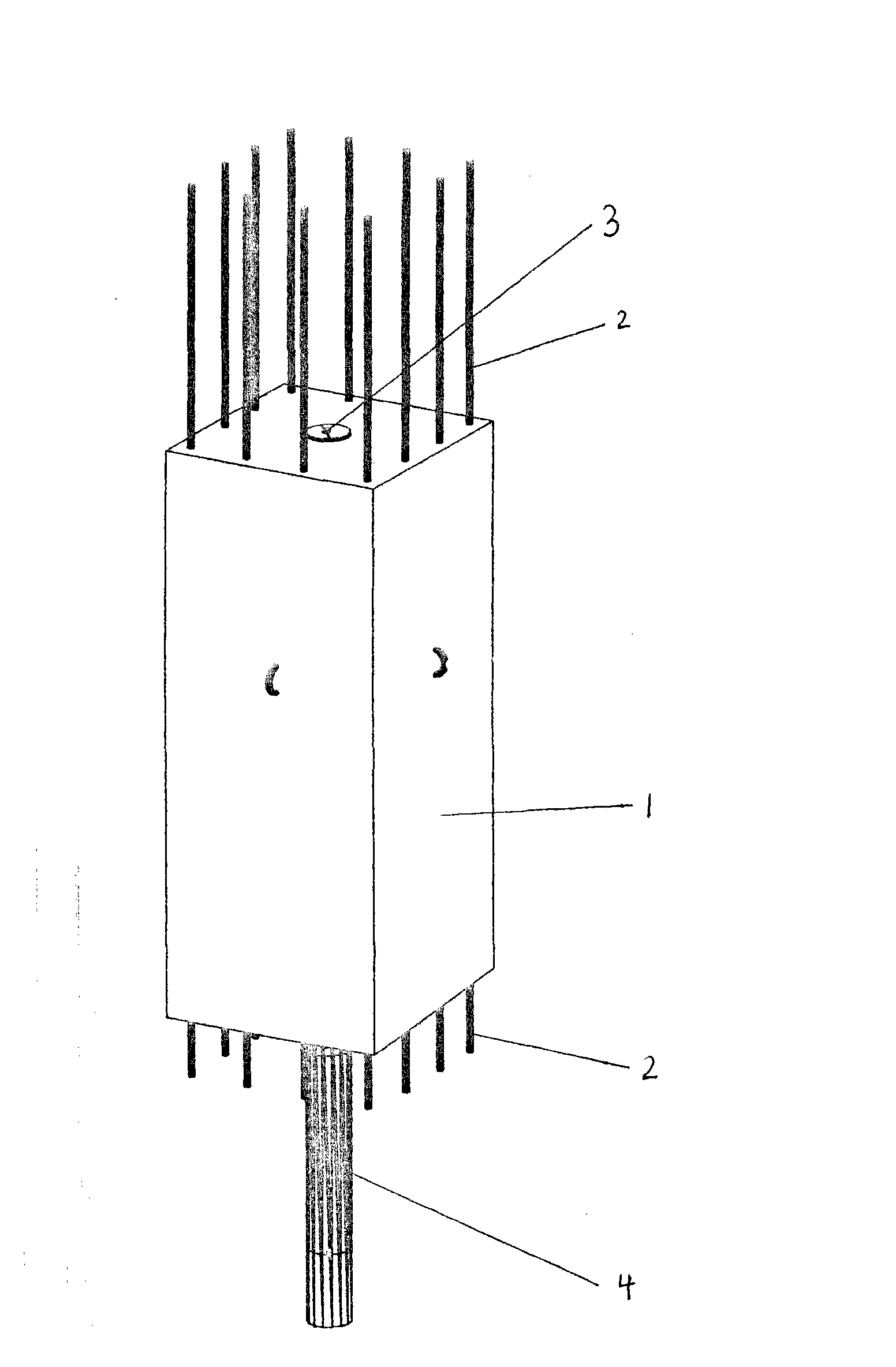

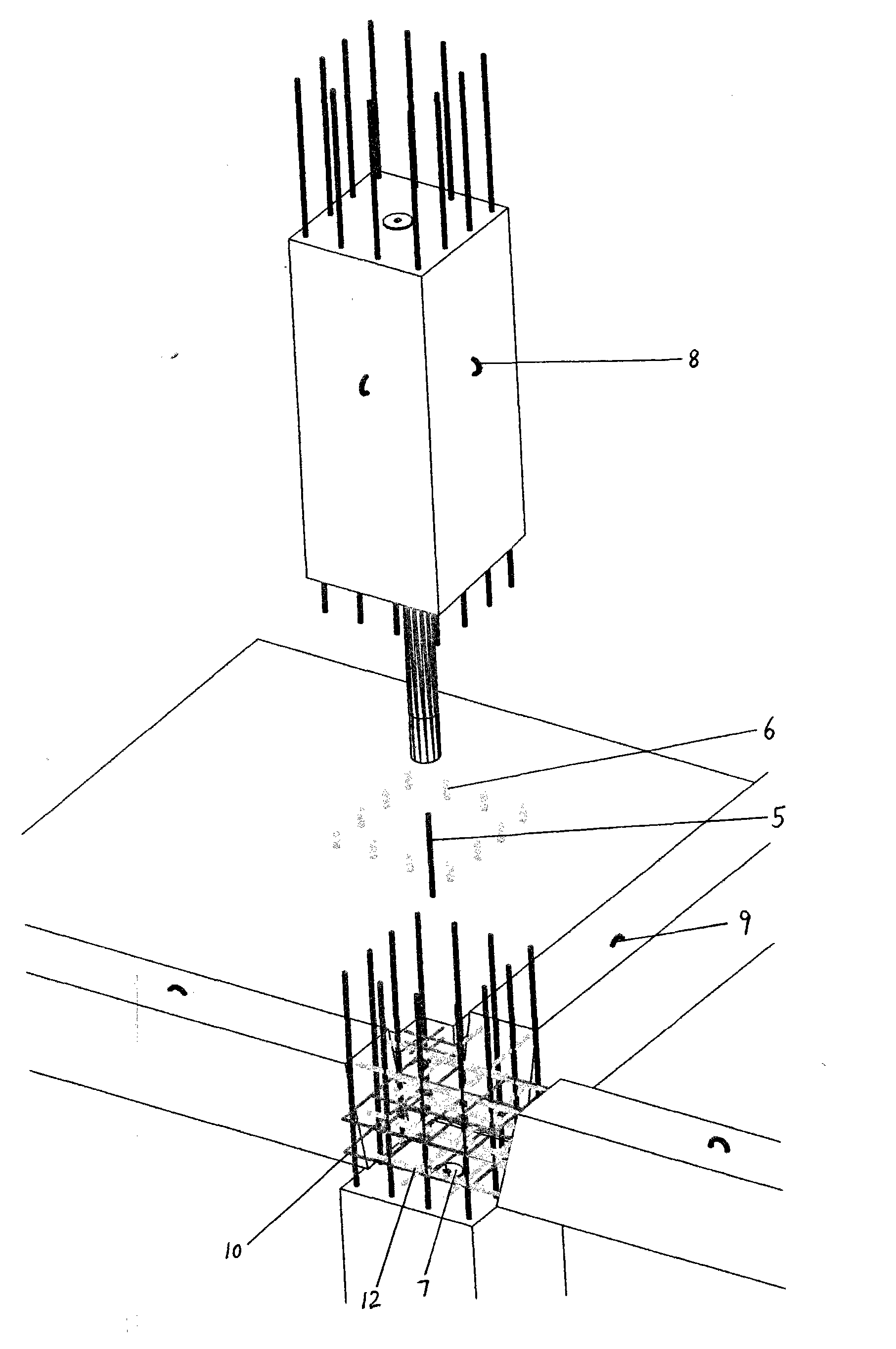

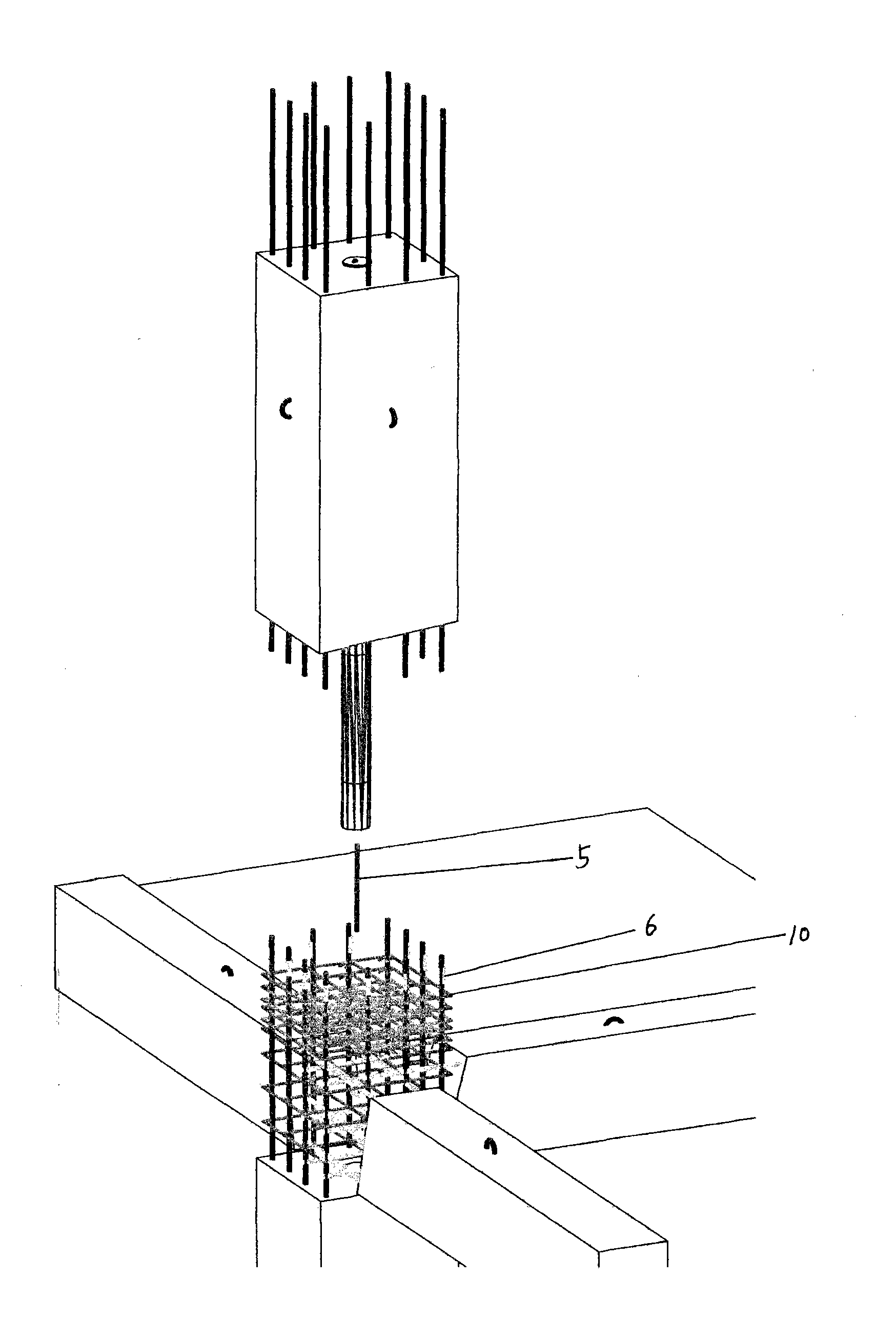

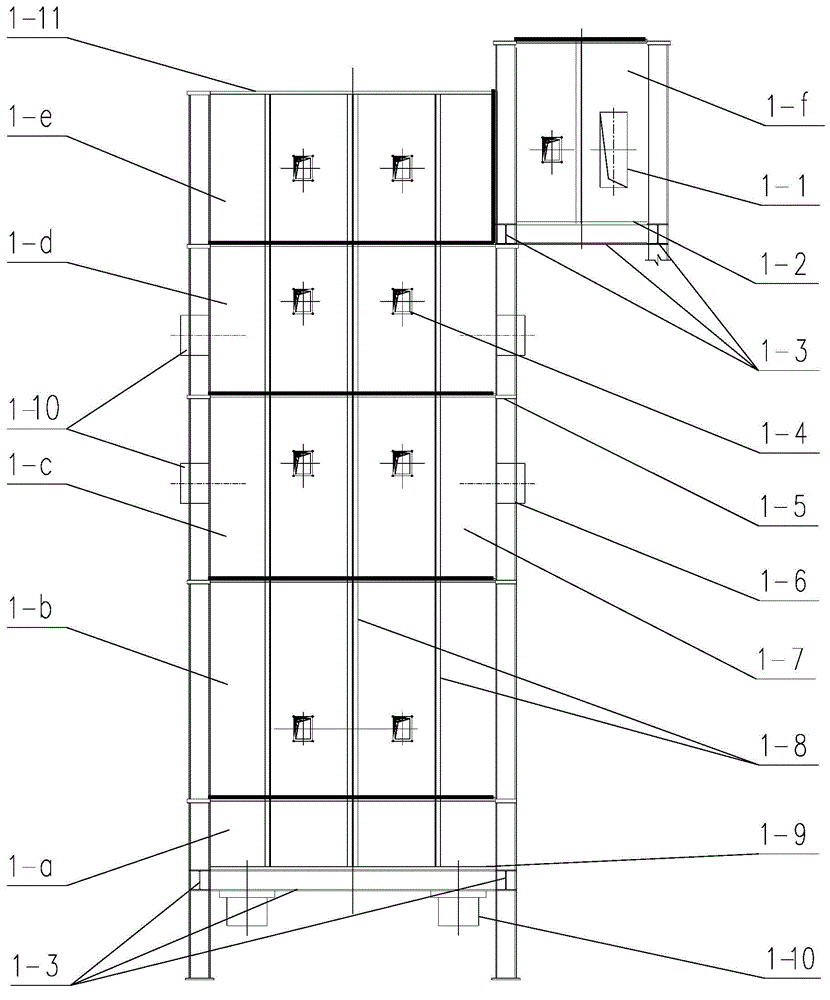

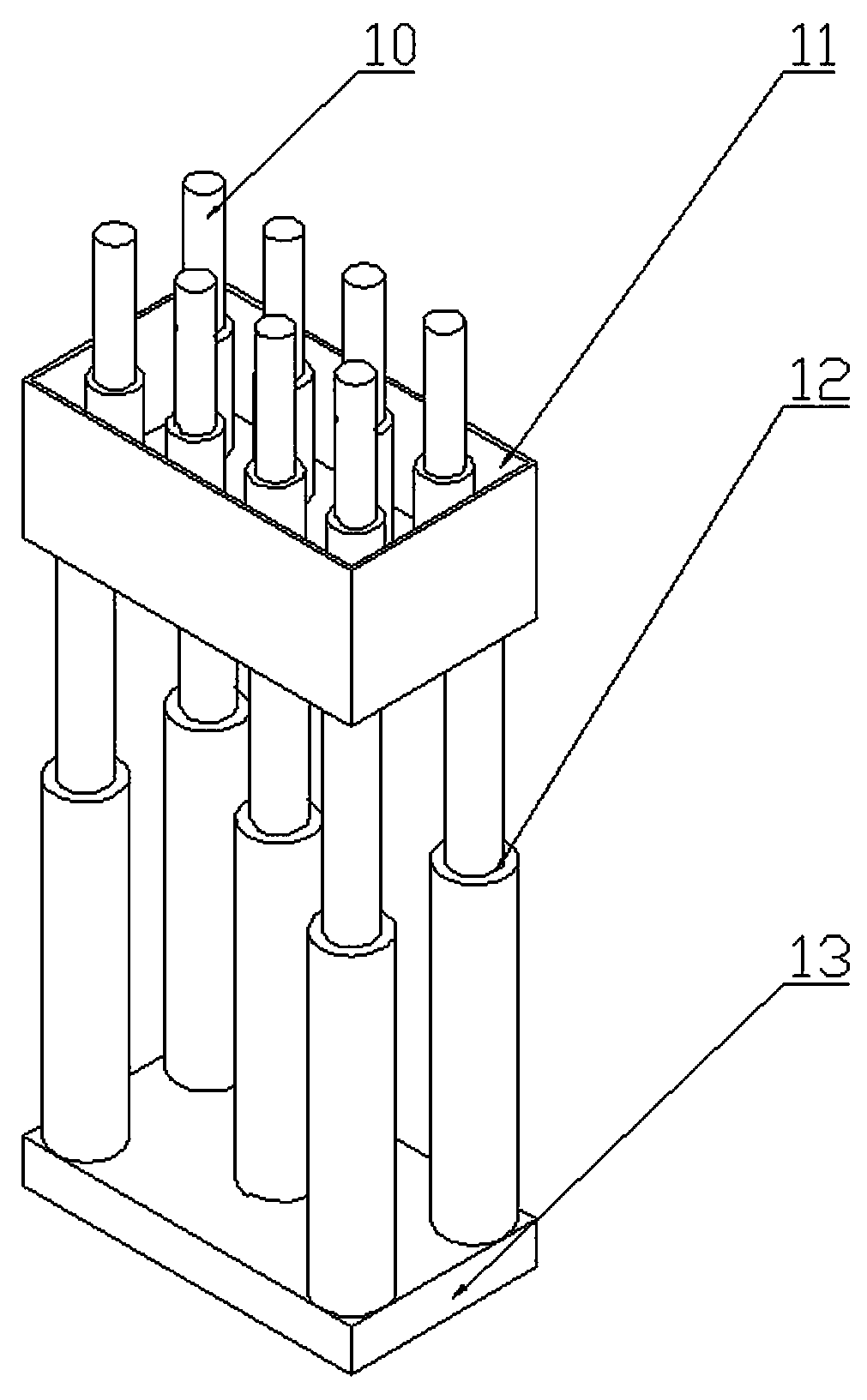

Prefabricated vertical member

The invention provides a prefabricated vertical member (including a pillar and a wall), which mainly comprises a member body and a prefabricated reinforcing bar (the reinforcing bar is the joint name of a principle bar longitudinally arranged along the member body, a vertically-distributed reinforcing bar, a hooping and a tie bar), and the principle bar or the principle bar and the vertically-distributed reinforcing bar stretch out of the upper end surface and the lower end surface of the member body. The prefabricated vertical member is characterized in that a core column is arranged in the middle of the lower end surface of the member body. The invention has the advantages that the installation of the prefabricated vertical member has no conflict with the anchoring of beam steel at a support, so as to meet the code requirement of the structure of cast-in-situ reinforced concrete; the core column is adopted for bearing load, the upper-layer construction operation can be carried out when in the joint concreting; no special design is needed; the connection of the reinforcing bar and the binding of a template are carried out at a floor slab, thereby not only ensuring the safety of workers, but also obviously improving the construction efficiency and the construction quality; the quantity of overhead work can be greatly decreased; the quantity of cast-in-situ concrete can be greatly decreased; and the operation is carried out at the floor slab, therefore, the construction speed is greatly improved.

Owner:管乃彦

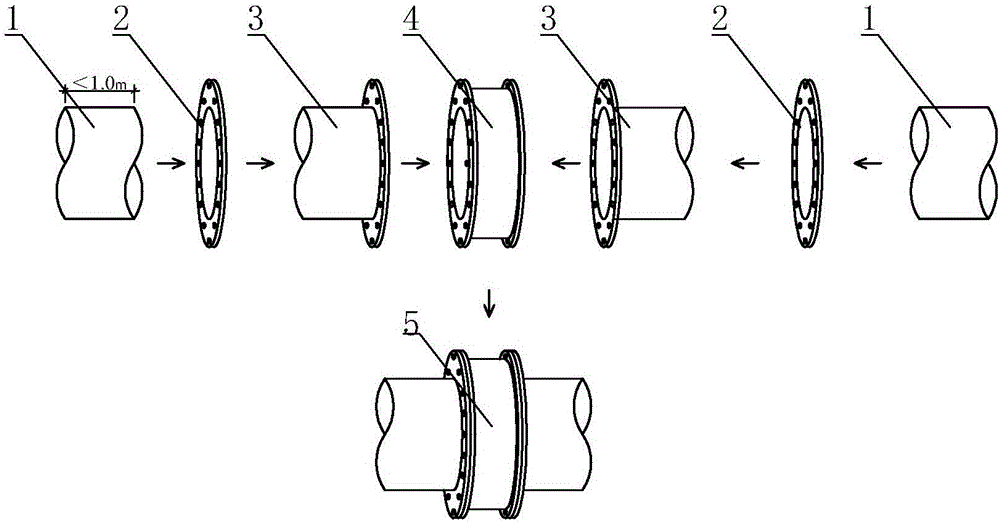

Large valve and large-diameter pipeline pre-assembly pup joint manufacturing and hoisting method

ActiveCN106624639ANo depressionNo damageWelding/cutting auxillary devicesPipeline systemsButt jointEconomic benefits

The invention discloses a large valve and large-diameter pipeline pre-assembly pup joint manufacturing and hoisting method. The manufacturing and hoisting method is characterized in that a prefabricated segment and a pre-assembly entirety are manufactured in a ground machining field, and the pre-assembly entirety is hoisted in place with a vertical transportation machine to be connected with an installed overhead large-diameter pipeline in a butt-joint welding mode; the method comprises the technological processes of construction preparing, prefabricated segment manufacturing, pre-assembly entirety manufacturing, pre-assembly entirety hoisting, butt-joint welding of the pre-assembly entirety and the installed overhead pipeline and checking and accepting. The hoisting method has the advantages that the tedious and high-difficulty high-altitude operation process is simplified and completed in the ground machining field, and therefore the problems that in traditional construction, the construction processes are tedious, the construction period is long, the high-altitude operation construction operation surface requirement is high, and the welding and installing quality is difficult to guarantee are solved; the whole construction process is in a safe, stable and controllable state, the installation precision is high, the construction period can be shortened, the construction efficiency is improved, the labor and material cost is reduced, and the economic benefit is significant.

Owner:广西建工第五建筑工程集团有限公司

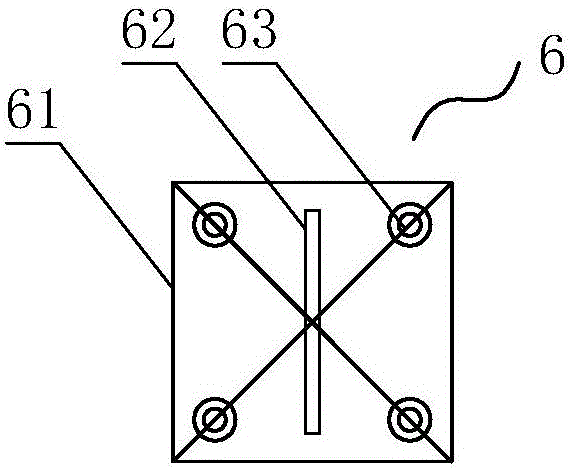

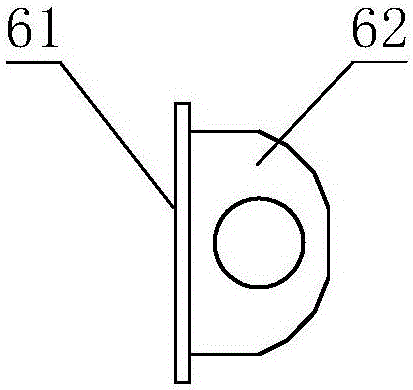

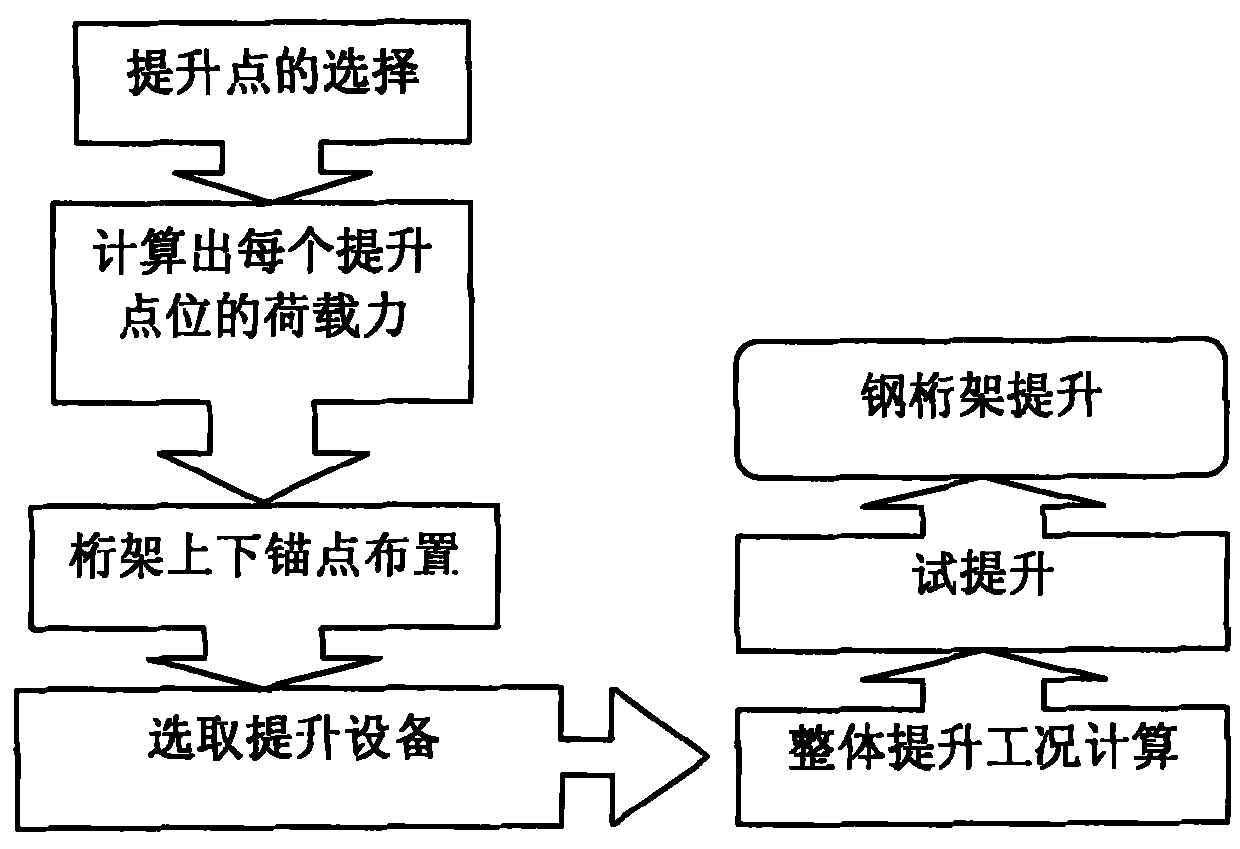

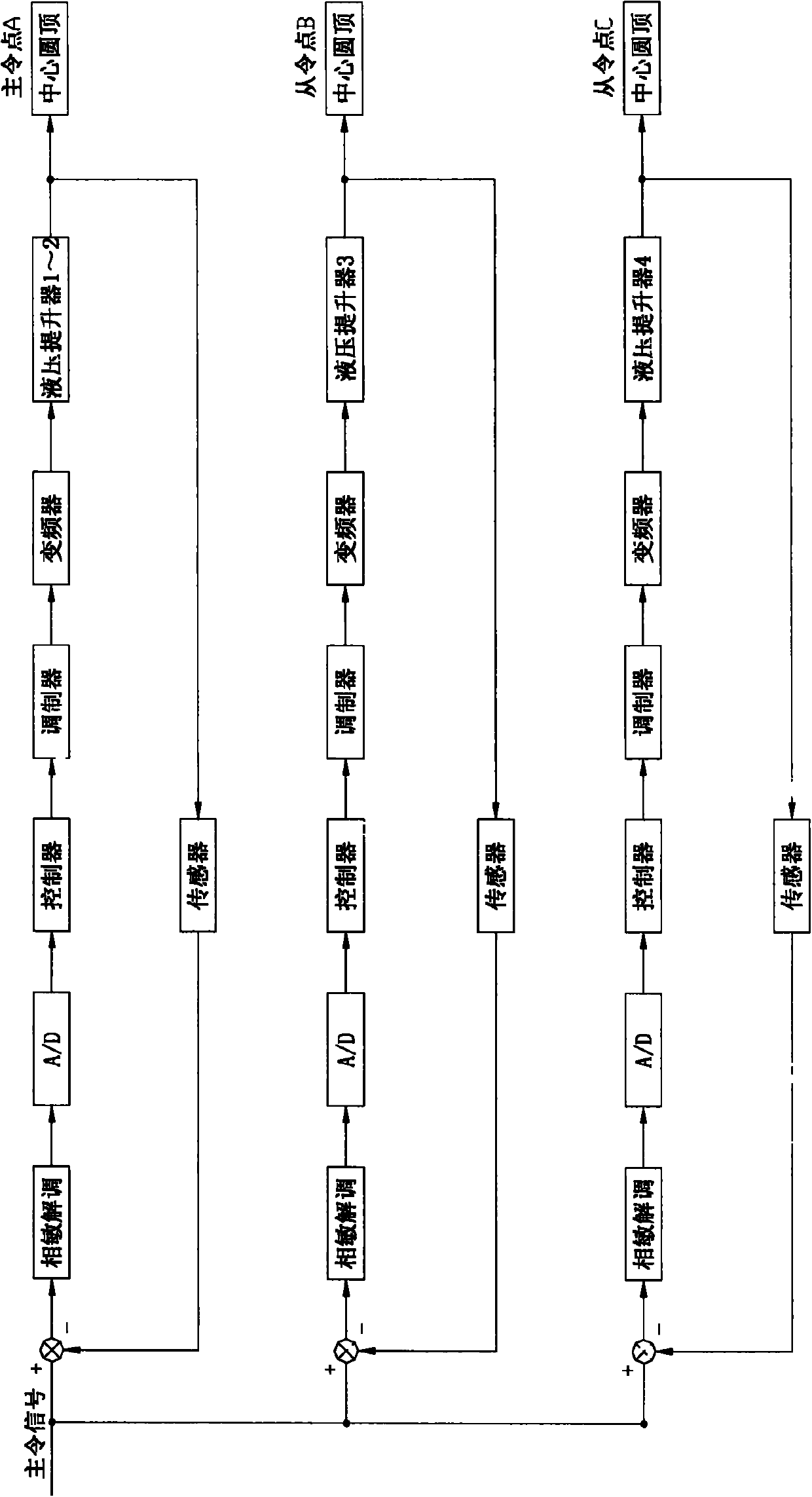

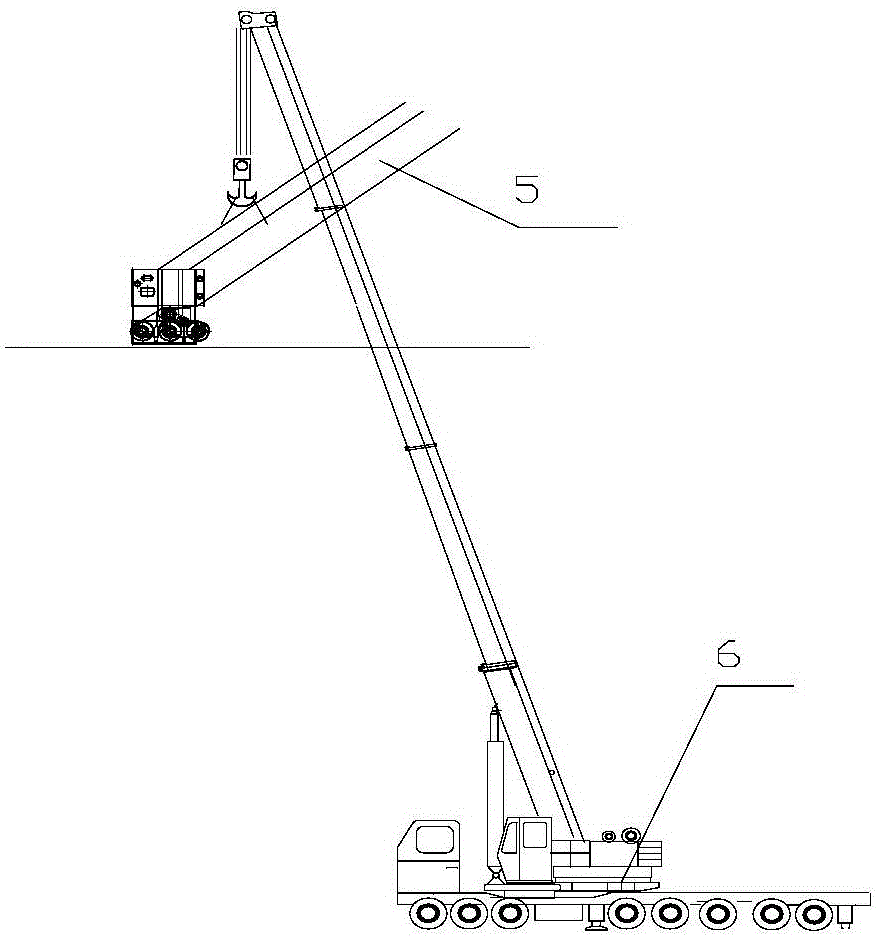

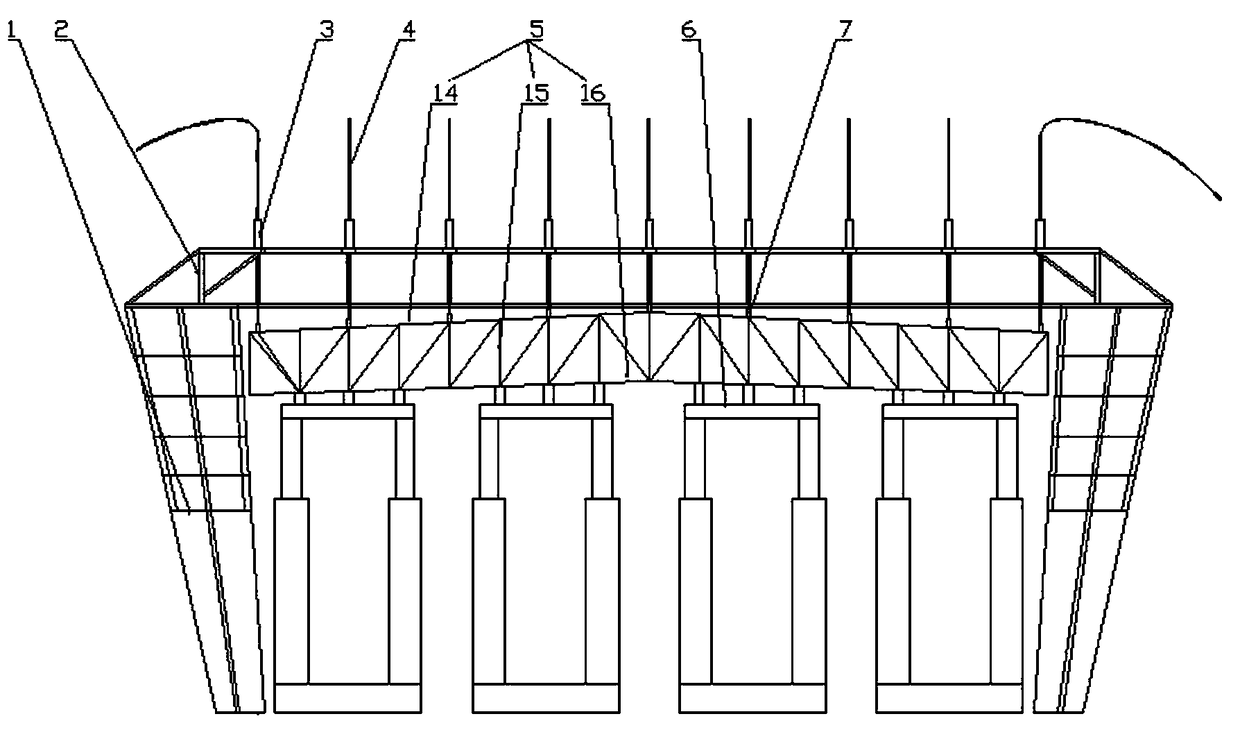

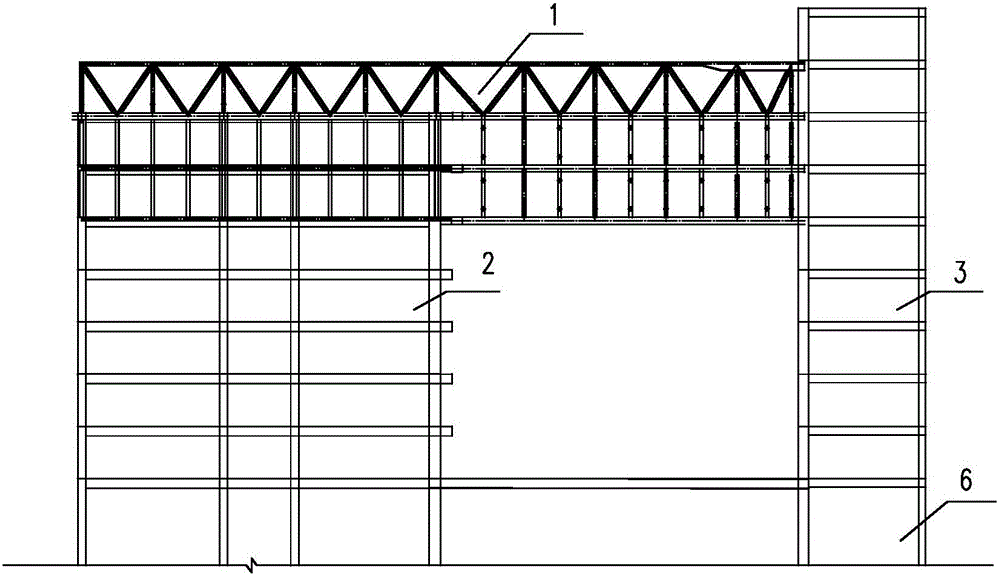

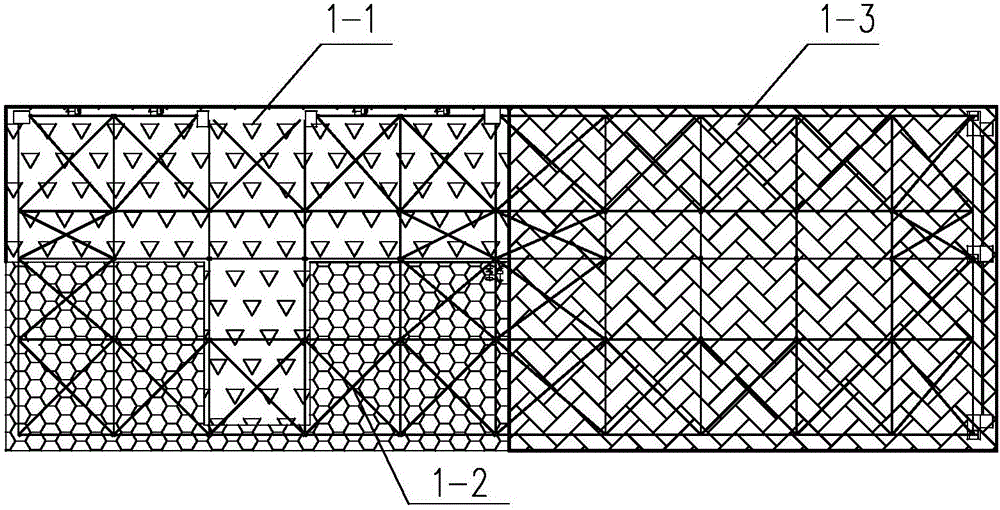

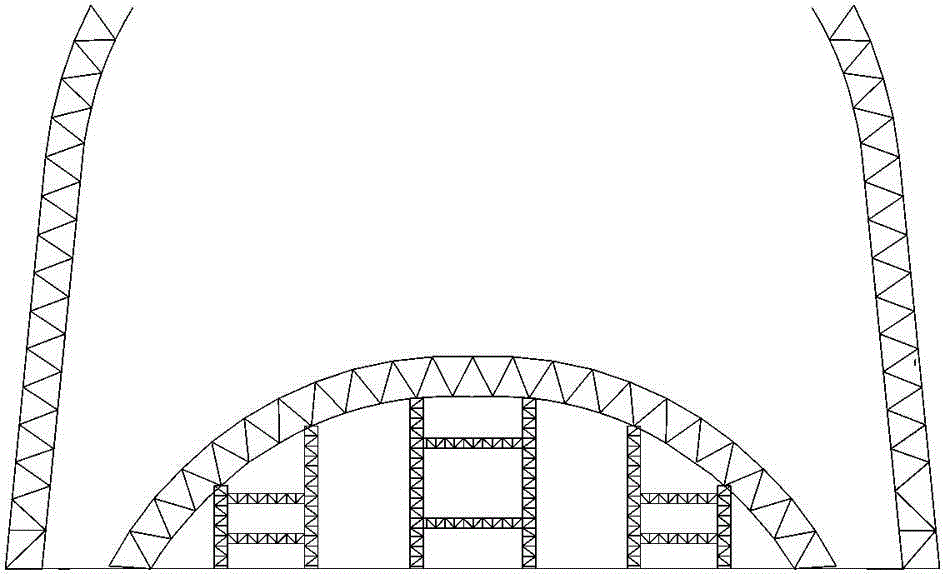

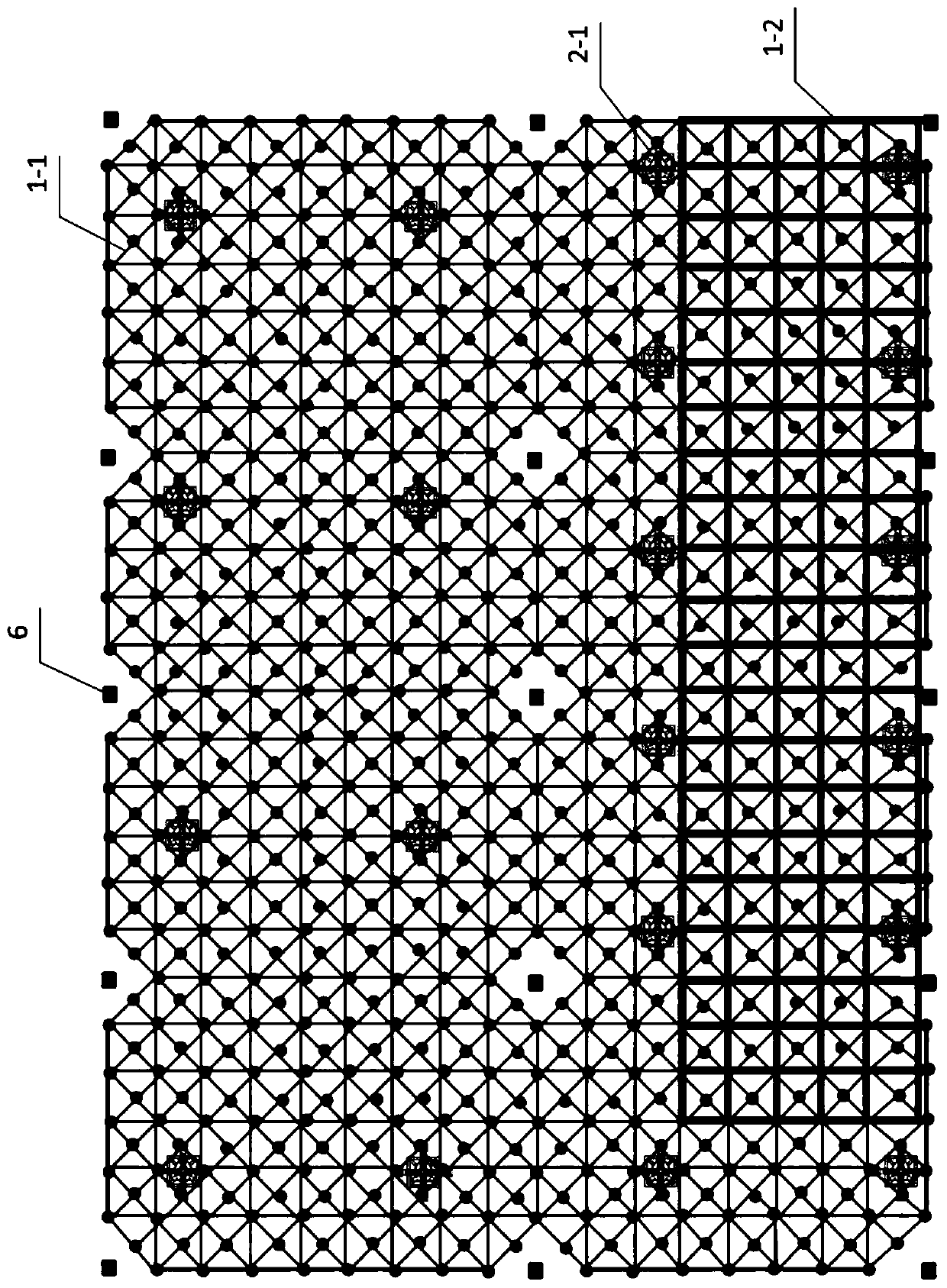

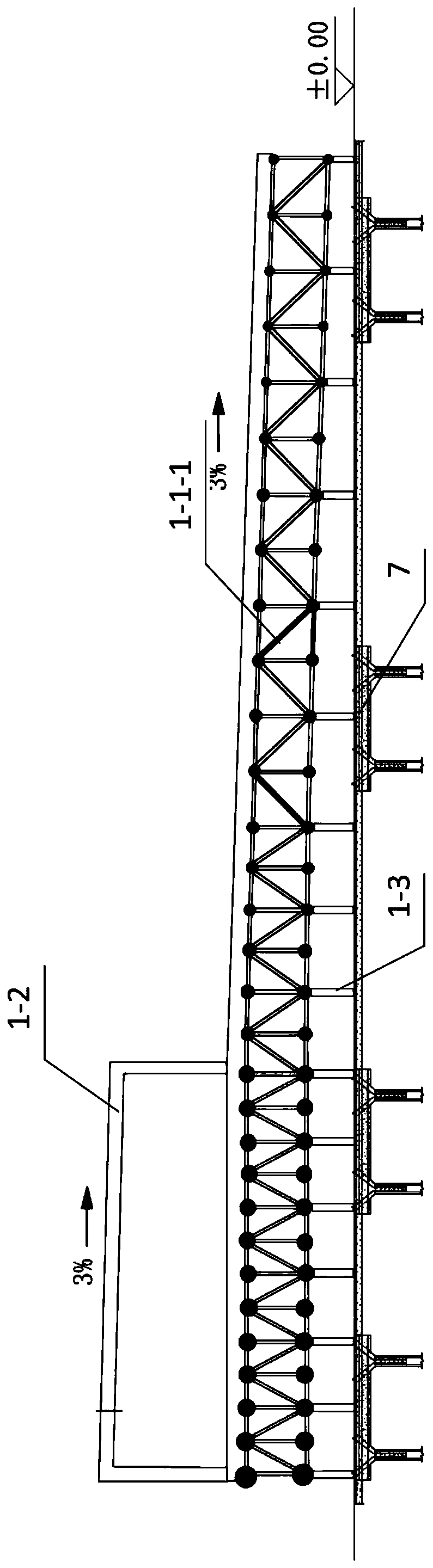

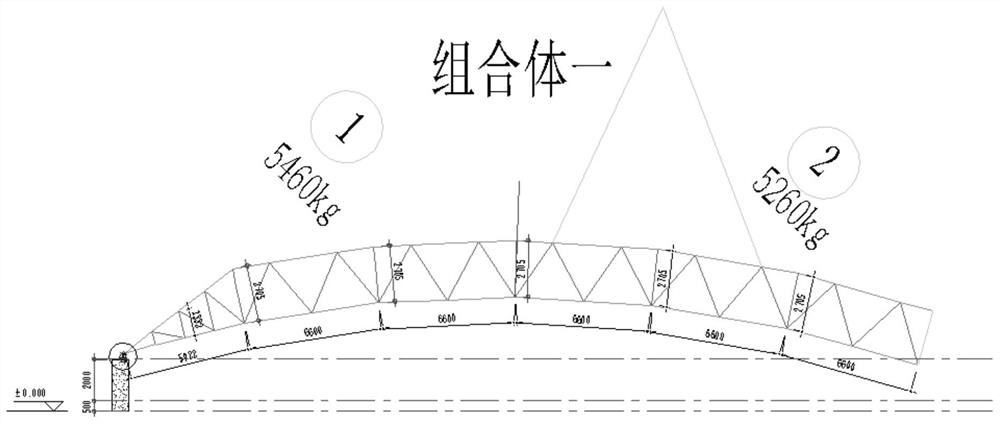

Large-span truss hydraulic multi-point synchronous lifting construction method

InactiveCN103790234AReduce distortionReduce the amount of work at heightBuilding constructionsLong spanControl theory

Disclosed is a large-span truss hydraulic multi-point synchronous lifting construction method. The construction method includes the steps of lifting point selection, calculation of load power of each lifting point position, upper and lower anchor point arrangement of a truss, lifting device selection, calculation of overall lifting conditions, lifting trial and steel truss lifting. Deformation caused by truss lifting can be reduced by adopting the flexible steel strand hydraulic synchronous lifting technology, reasonably selecting lifting point positions and utilizing an original structure to serve as upper and lower anchor points for lifting as much as possible; after assembled on the ground, components are integrally lifted to a preset position to be assembled in place; the large-span components can be synchronously integrally lifted at ultra-high altitude, high-altitude operating quantity can be reduced, quality can be improved, workload can be reduced, labor is saved, convenience in mounting and demounting is achieved, stress bearing is unaffected, cost is lowered, funds are saved, duration of work is shortened, and difficulty of safety protection is remarkably reduced.

Owner:YONGSHENG CONSTR GRP

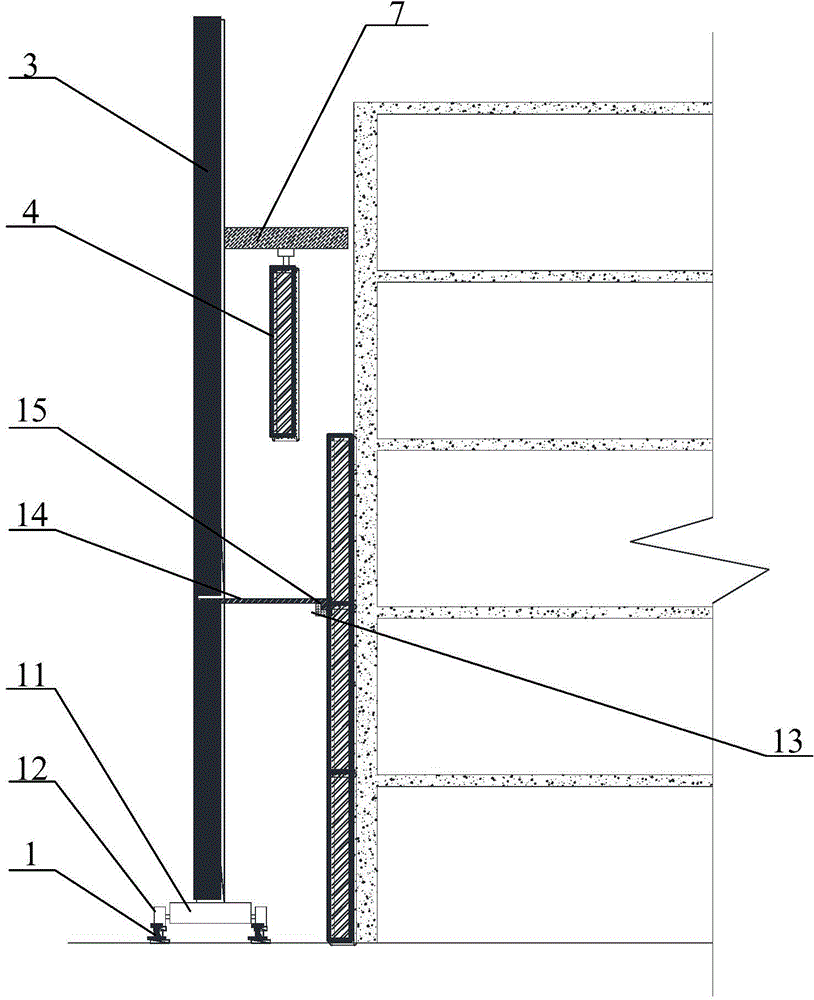

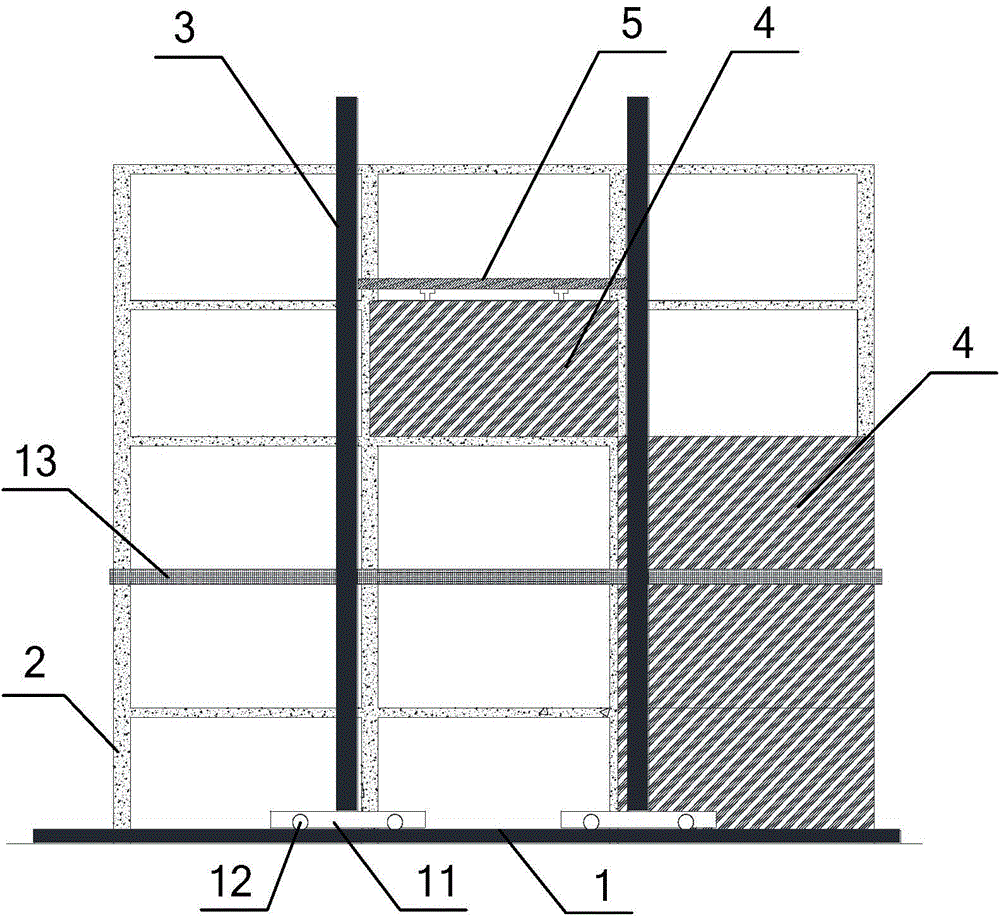

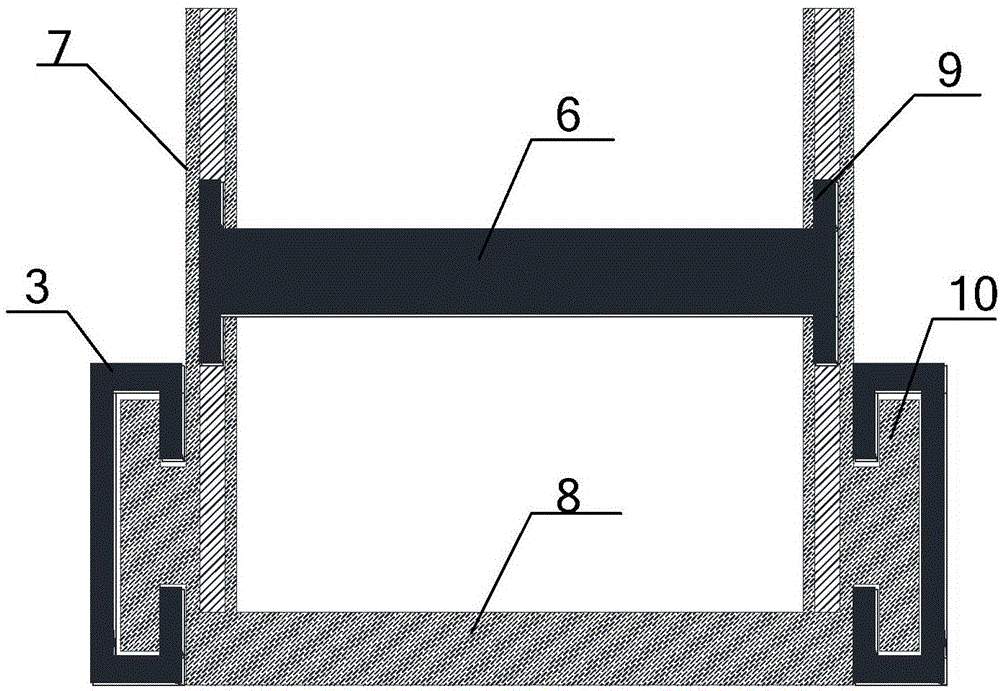

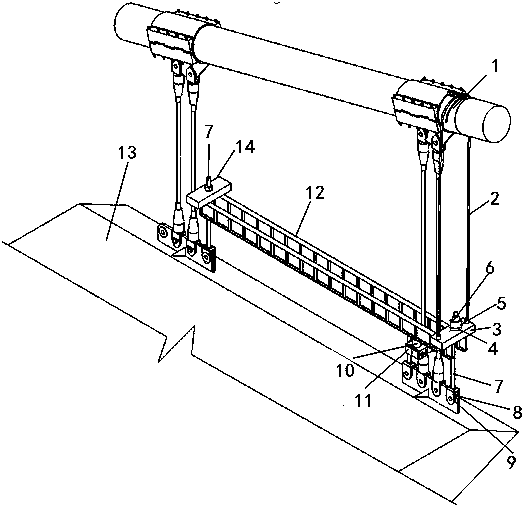

Rapid in-place device and rapid in-place method for prefabricated wallboard of prefabricated building

ActiveCN104563528AImprove efficiencyHigh precisionBuilding material handlingAgricultural engineeringEngineering

Owner:SHANGHAI CONSTRUCTION GROUP

Construction method for large-diameter barrel cabin top

InactiveCN103174302AImprove securityReduce labor intensityBuilding material handlingBulk storage containerArchitectural engineeringUltimate tensile strength

The invention discloses a construction method of a large-diameter barrel cabin top, and relates to the technical field of building construction engineering. H-shaped inclined steel beams are designed in groups. Welding of an H-shaped inclined steel beam assembly is finished on the ground. After a ring beam is temporarily positioned above a barrel body, the welded H-shaped inclined steel beam assembly is lifted and is respectively welded with the barrel body and the ring beam. Finally, temporary positioning pieces of the ring beam are removed. Due to the fact that the welding of the H-shaped inclined steel beam assembly is finished on the ground, the H-shaped inclined steel beam assembly is lifted between the barrel body and the ring beam according to a suspension center on a design drawing and then is welded, at least 75% of quantity of work on the upper air is saved, quality is effectively guaranteed, safety and high-labor-intensity defects brought by the work on the upper air are greatly reduced, work efficiency is improved, and construction cost of the large-diameter cabin top is greatly reduced.

Owner:JIANGSU JIANGJIAN GRP CO LTD

Installing method for bridge crane in enclosed environment workshop

The invention discloses an installing method for a bridge crane in an enclosed environment workshop, and belongs to the technical field of hoisting device installing. The installing method includes the steps that a crane beam rail in the original workshop is retested, and a main beam supporting frame used for containing and assembling a main beam is manufactured; devices on the main beam are assembled through an auxiliary crane, the main beam is hoisted through a large crane, after the main beam is installed, end beams of the main beam are not connected, two large cranes are located on the two sides of the end beams, and hoisting lugs of two truck-mounted cranes are arranged at the ends of a main trolley; after the main trolley is evenly hoisted to be in place, assembling is carried out; and installing of the main beam bridge crane is completed. According to the installing method, the requirement for a site in the workshop is not high, the roof of the workshop does not need to be dismantled, the large crane is not used, ground assembling is rapid, hoisting is once achieved, the working efficiency is high, and the upper-air operational quantity is small; and the installing method has the beneficial effects that the practical hoisting time is short, the practicability is high, and the like.

Owner:CHINA MCC17 GRP

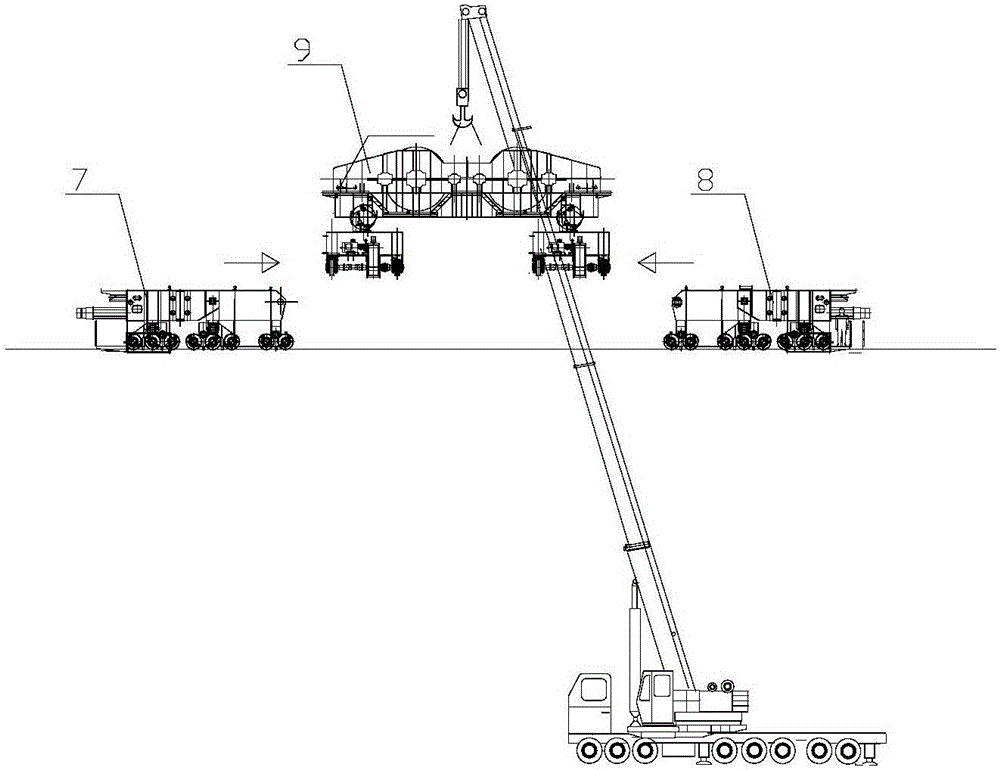

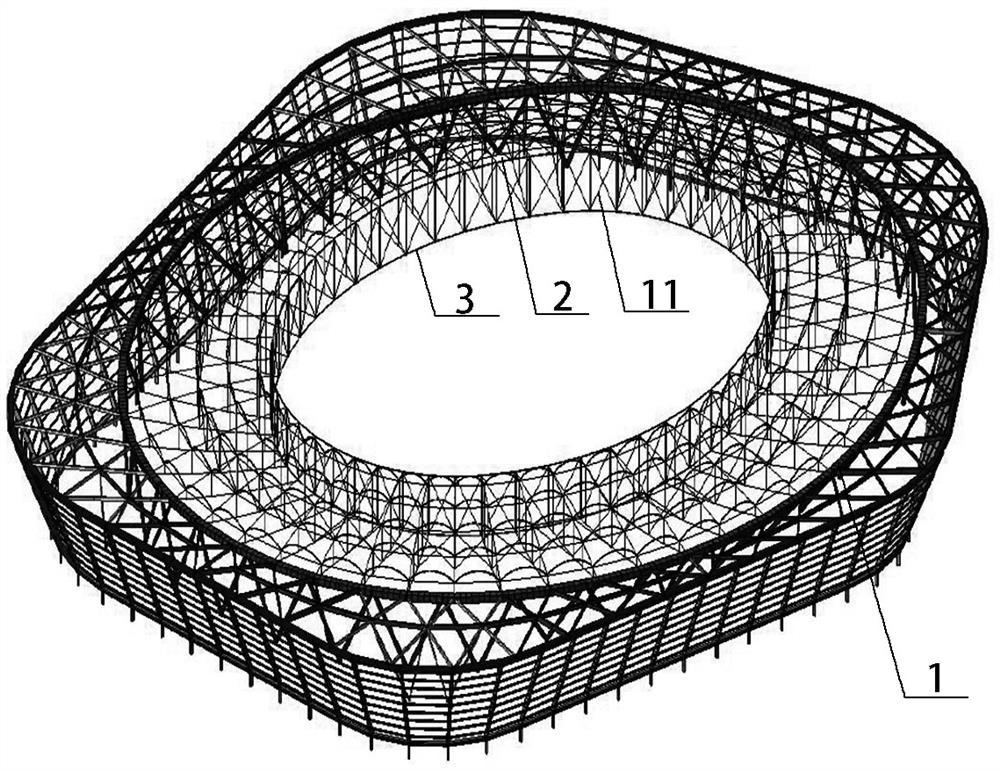

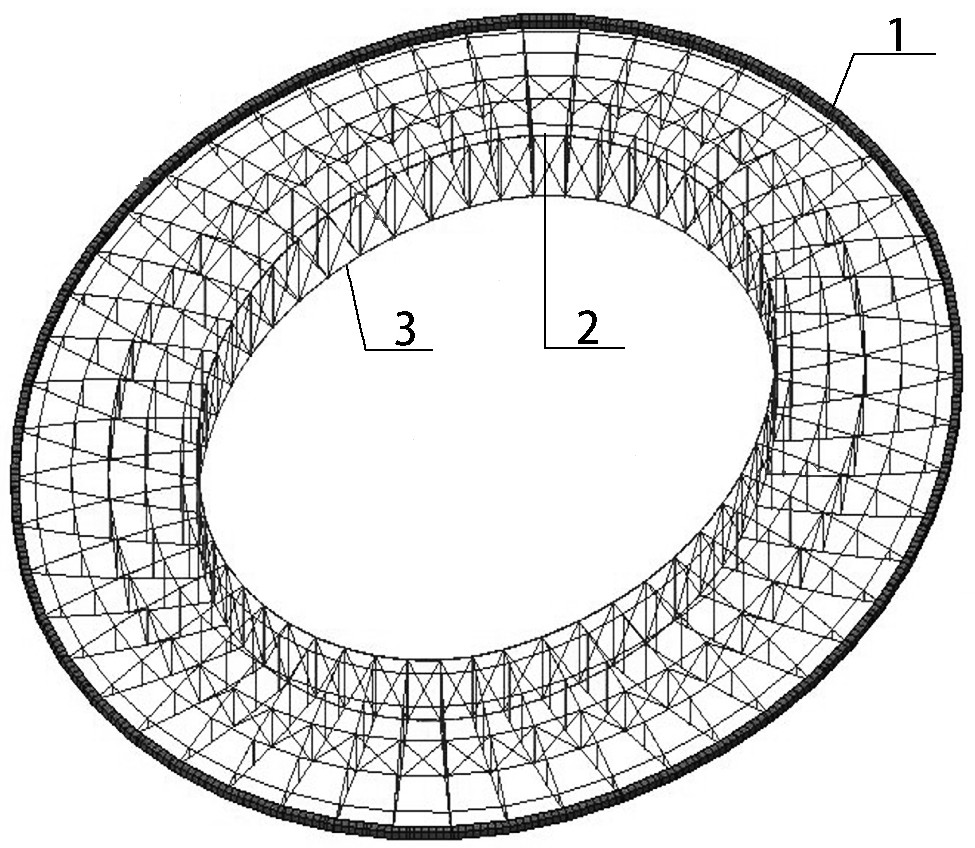

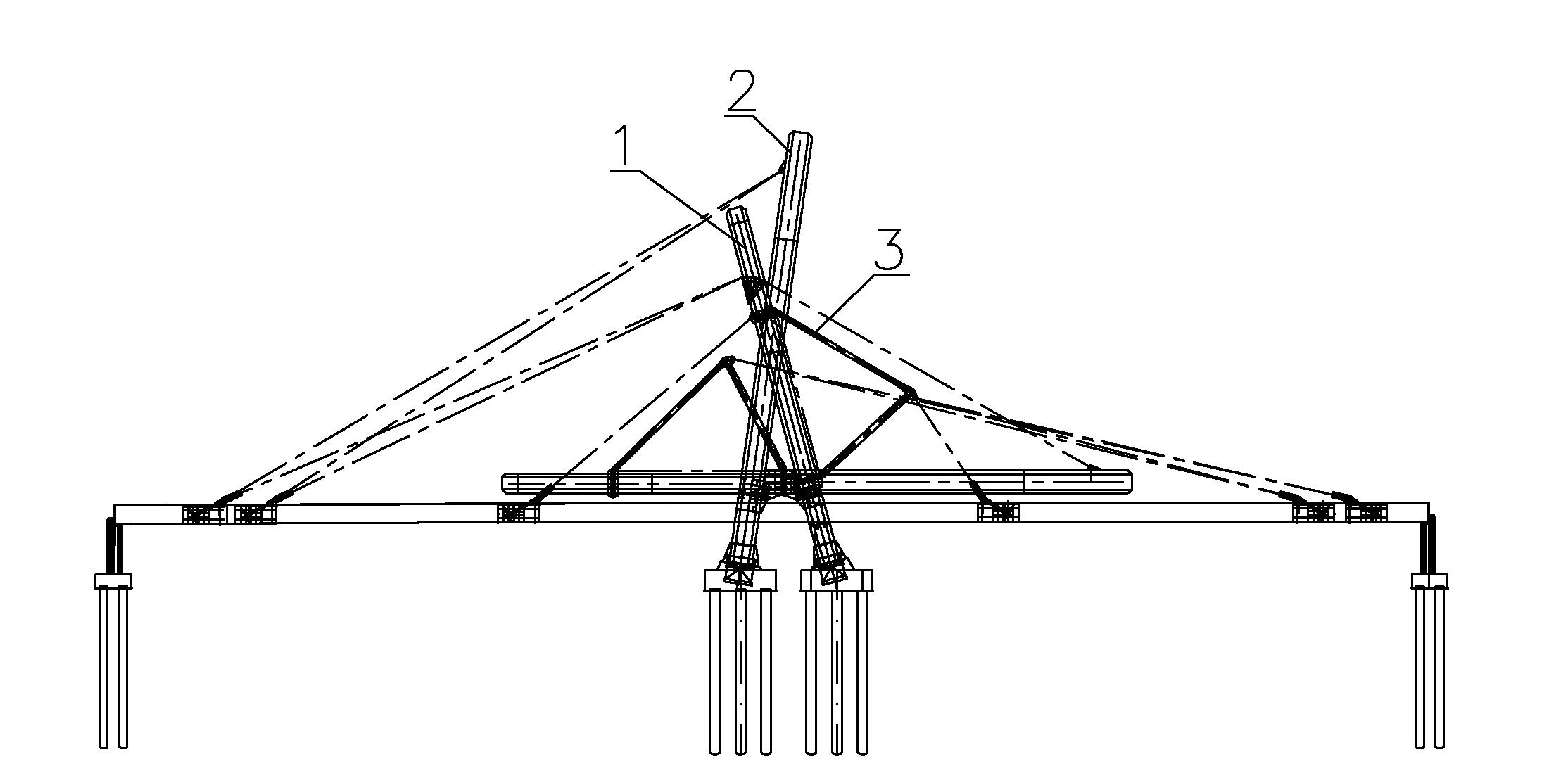

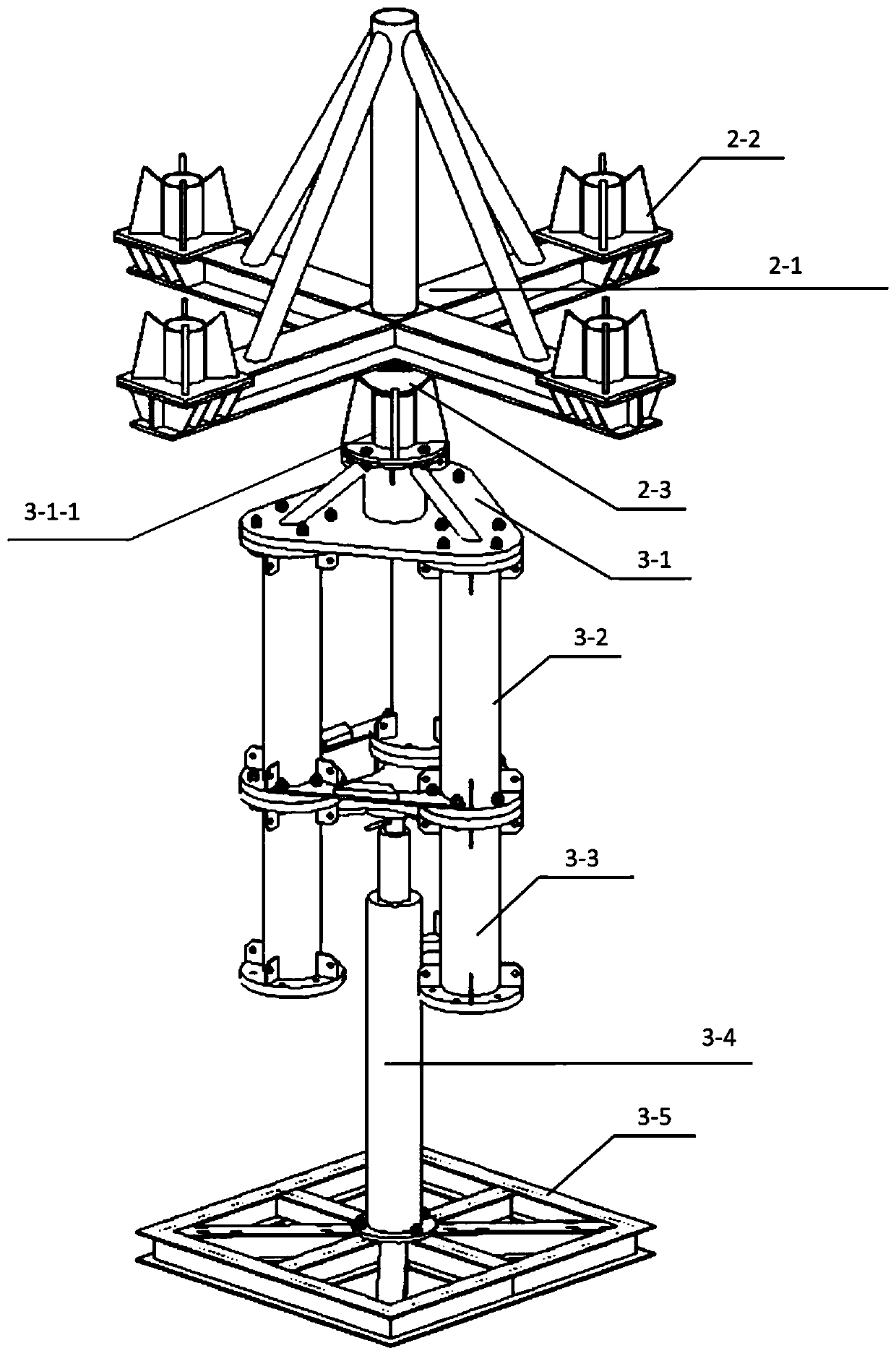

Spoke type double-layer cable truss structure and lifting method thereof

ActiveCN112127480AActive connectionEfficient deliveryExtraordinary structuresStructural engineeringControl theory

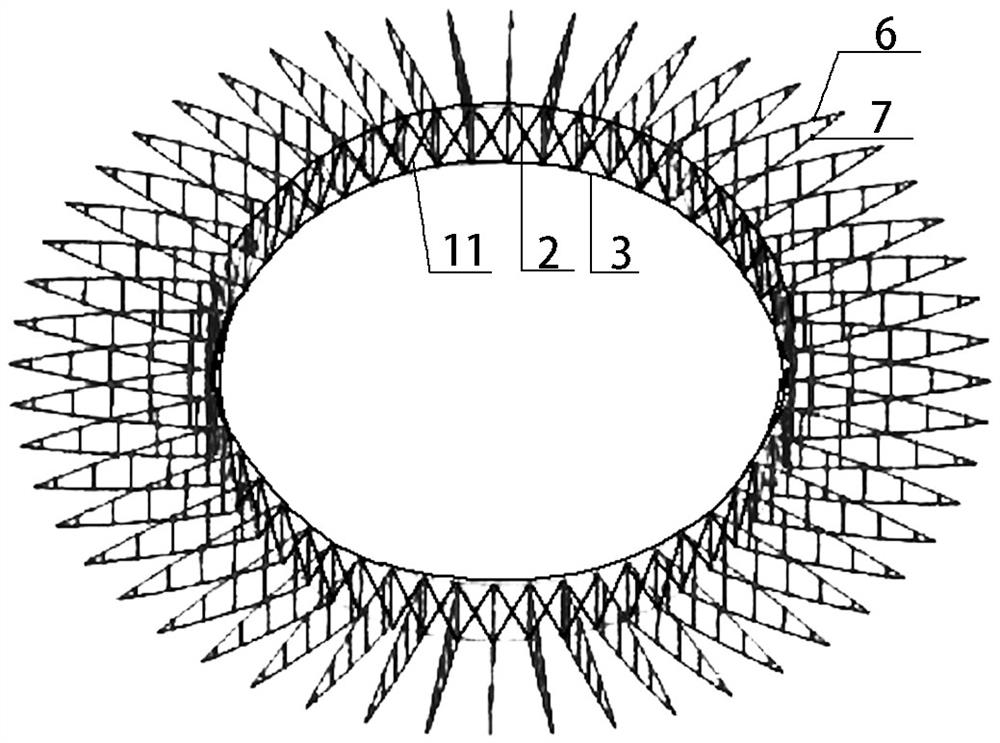

The invention provides a spoke type double-layer cable truss structure and a lifting method thereof. The structure comprises a double-layer ring cable, a compression ring beam and a series of radial cable trusses arranged between the double-layer ring cable and the compression ring beam in a radial shape, wherein the double-layer ring cable comprises an upper ring cable and a lower ring cable; theradial cable trusses are triangular trusses and comprise upper radial cables, lower radial cables and masts; the inner side ends of the upper radial cables and the lower radial cables are connected with the upper ring cable and the lower ring cable through an upper ring cable clamp and a lower ring cable clamp respectively, and the outer side ends of the upper radial cables and the lower radial cables are anchored to the compression ring beam; and the masts are vertically arranged between the upper radial cables and the lower radial cables at intervals, and the top ends and the bottom ends ofthe masts are connected with the upper radial cables and the lower radial cables through radial cable clamps respectively. According to the spoke type double-layer cable truss structure and the lifting method thereof, the passive tensioning technology is adopted for tensioning the cable trusses, the key lower radial cables are selected as active tensioning cables, and other cables and rods are all passively tensioned. The spoke type double-layer cable truss structure is simple in structure, the tensioning technology is advanced, no complex joint exists, the problem that all active tensioningcannot be achieved in large-scale truss construction is effectively solved, the equipment and personnel capital is greatly saved, and the construction period is effectively shortened.

Owner:BEIJING URBAN CONSTR SIXTH GRP

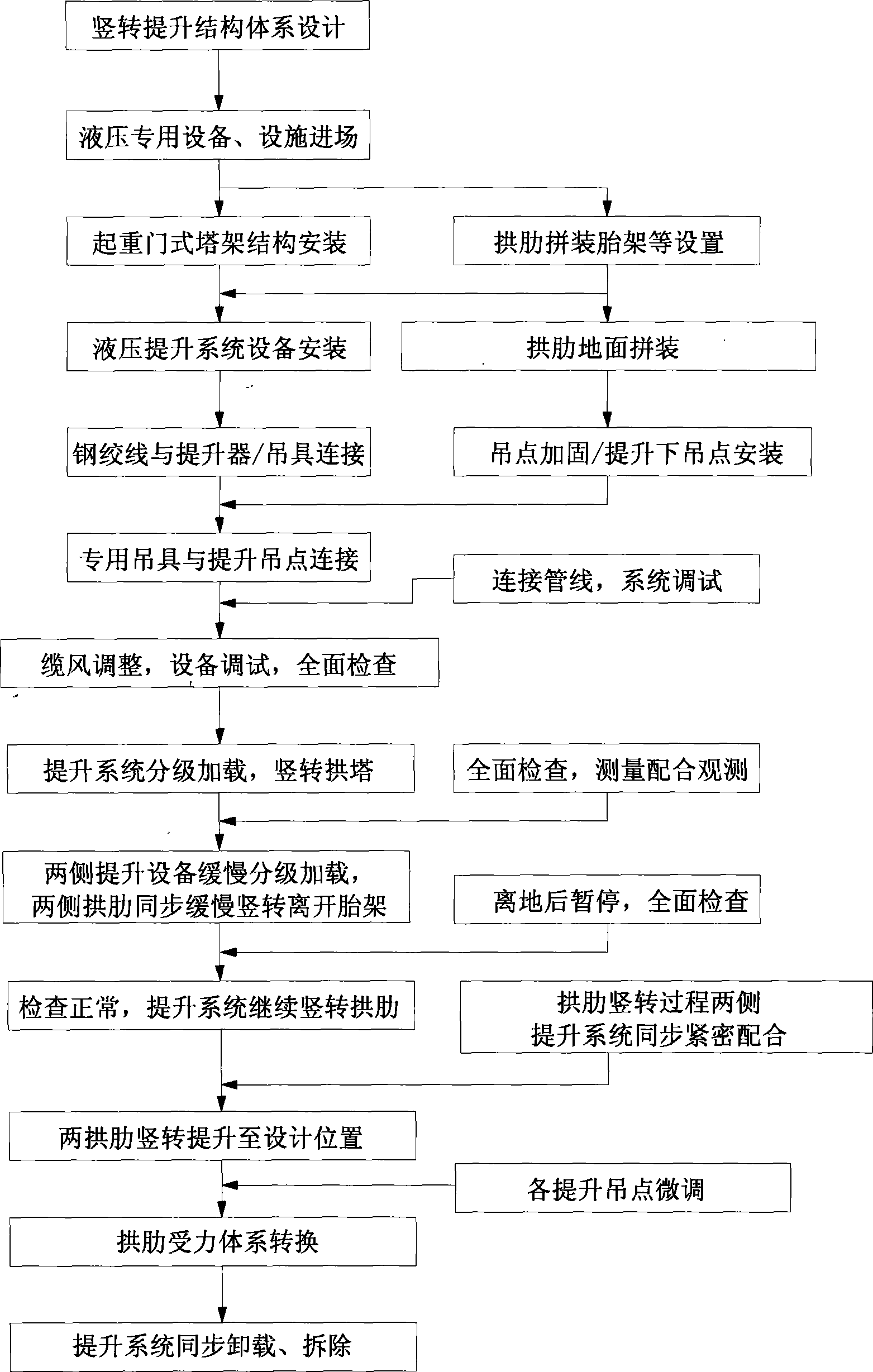

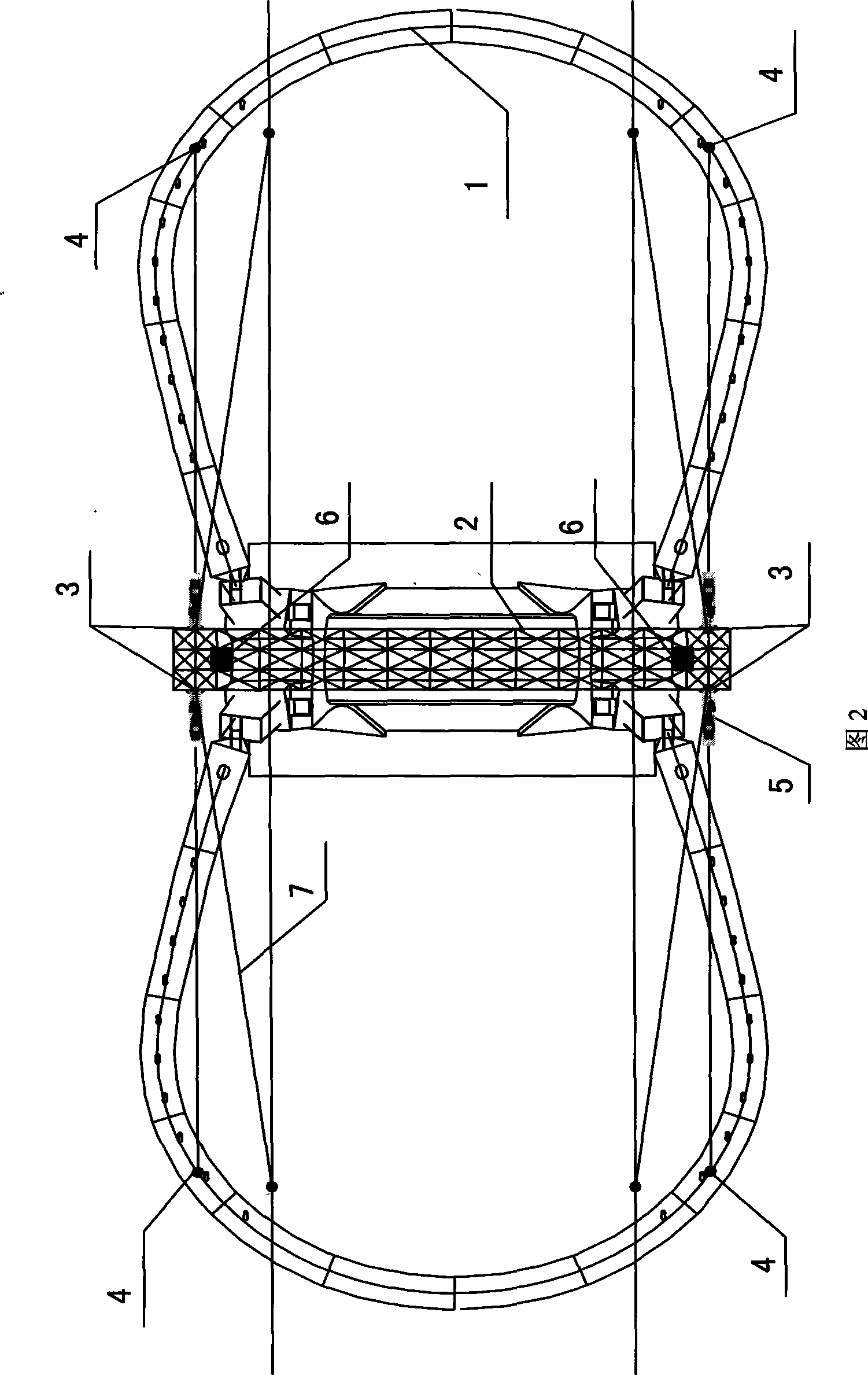

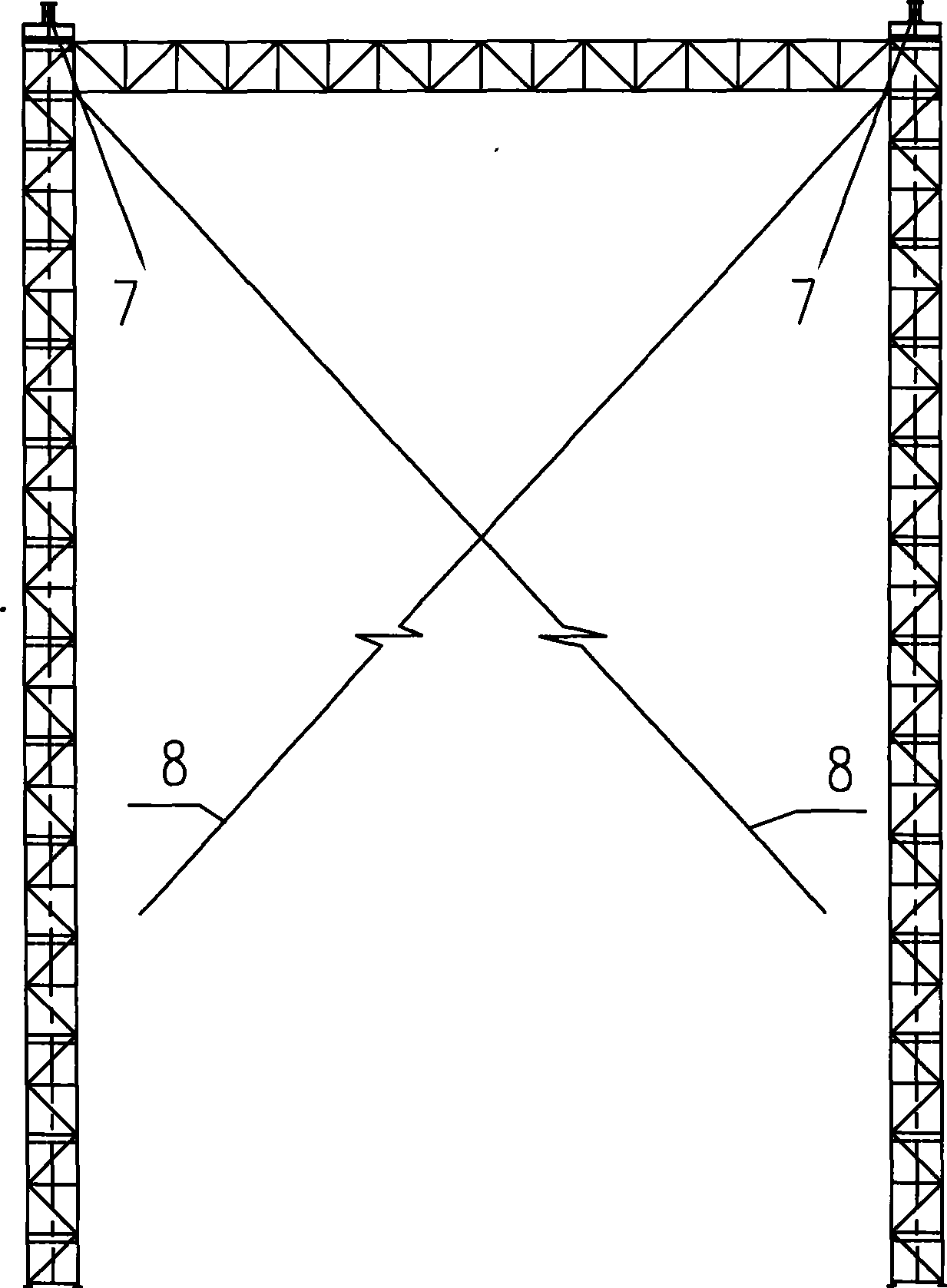

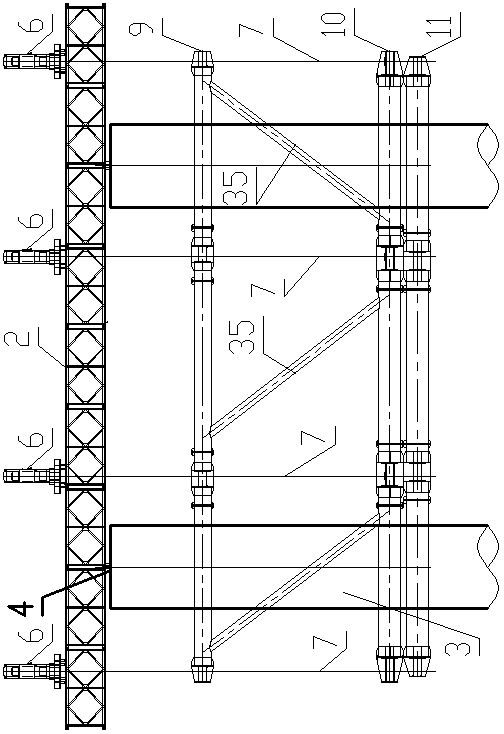

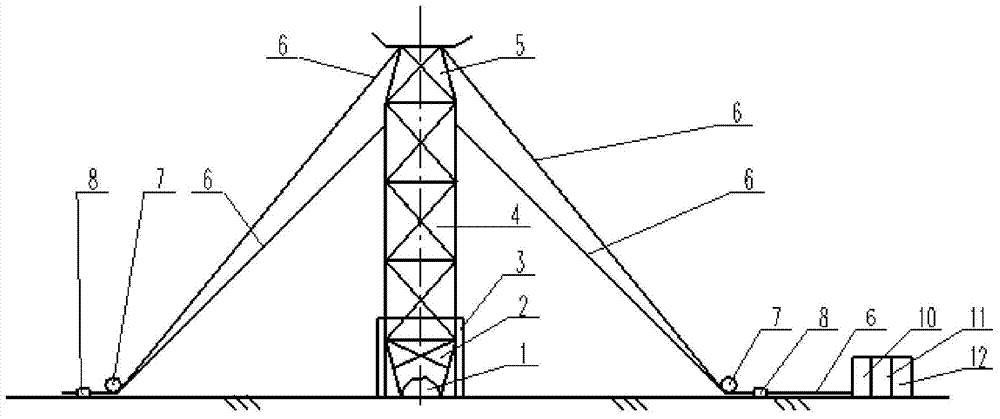

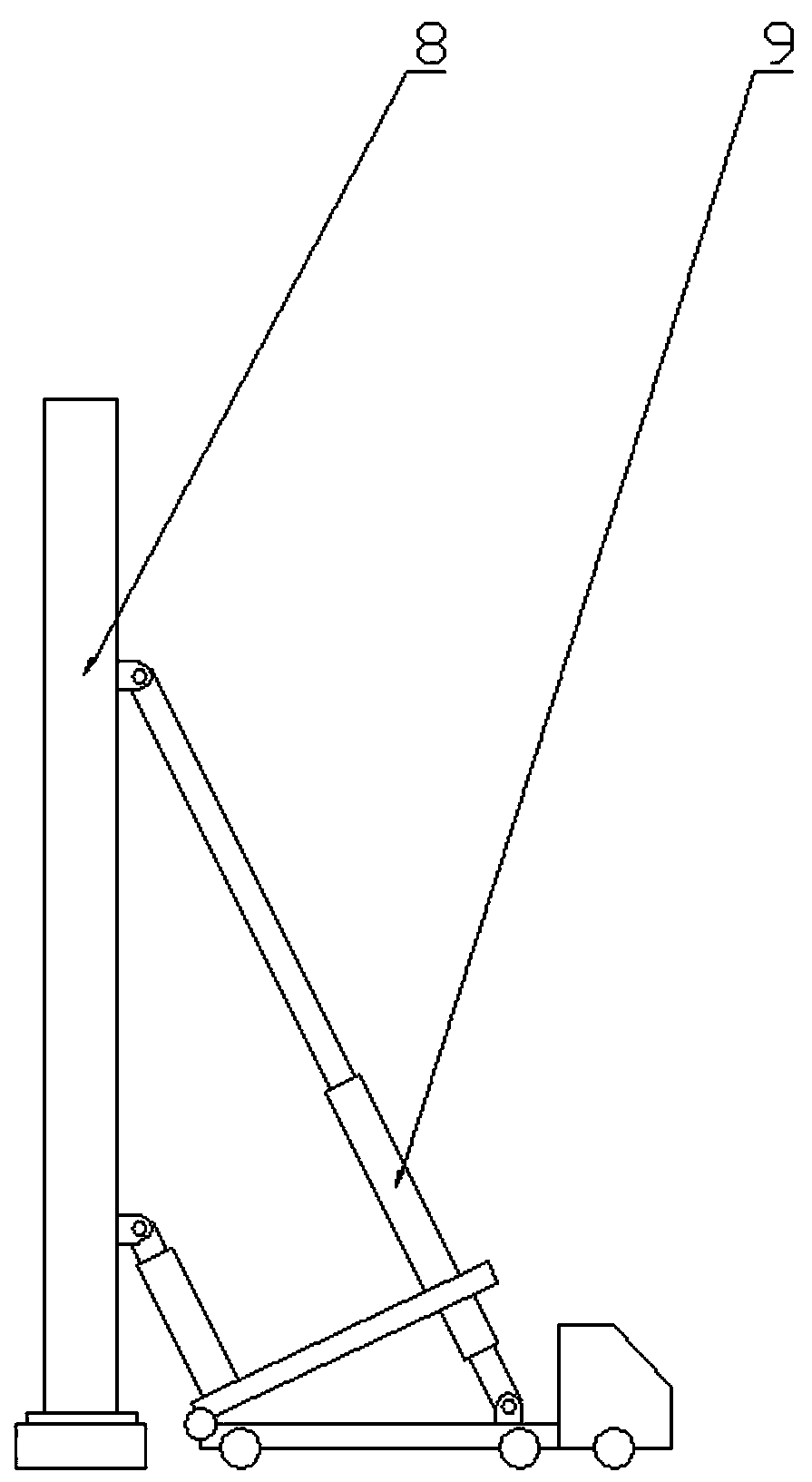

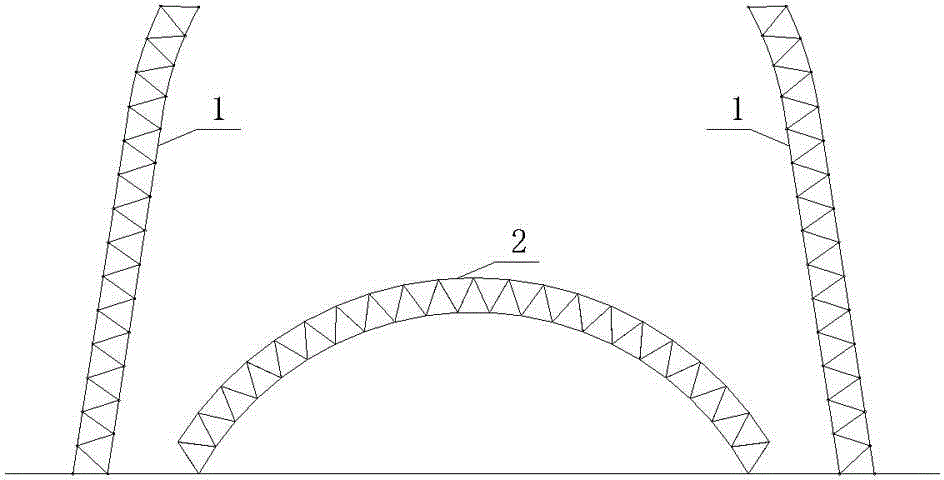

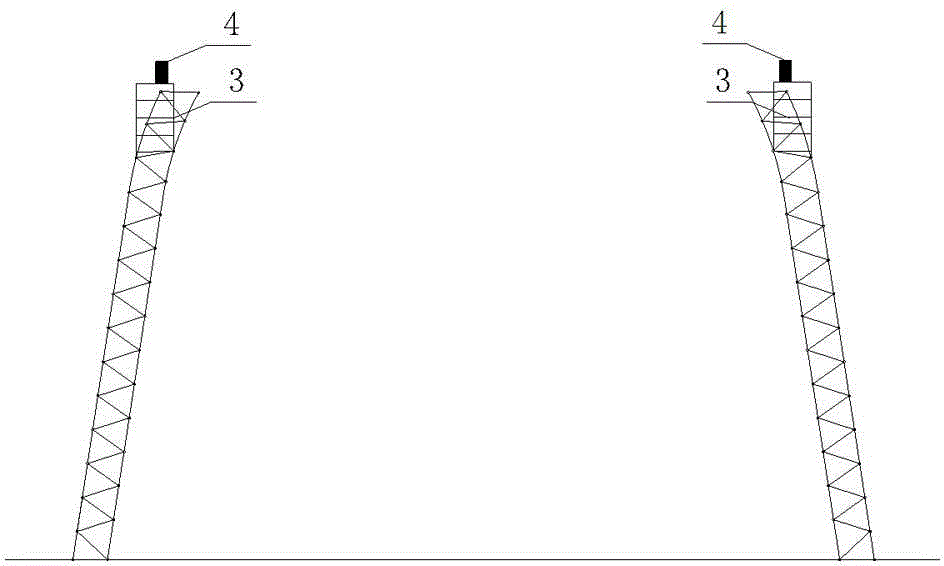

Synchronous vertical swing lift construction method for double inclination arc tower

ActiveCN101446075AIncrease the volume of the facilityReduce weightBridge erection/assemblyReinforced concreteCentral line placement

The invention discloses a synchronous vertical swing lift construction method for a double inclination arc tower. The method comprises the following steps: arranging a vertical swing winch at the combination of two gate-shaped arch ribs and reinforced concrete, arranging a bearing gate type lifting tower at the position of the symmetrical central line of the arch ribs, arranging an upper lifting sustained center and a lower lifting sustained center at the top of the tower and on the arch ribs respectively, and performing symmetrical synchronous vertical swing lift through two pairs of hydraulic lifters by utilizing the symmetry character of the double arch ribs, so as to achieve the purpose of vertically swinging the arch ribs from the planimetric position to the mounting position. The construction method has the advantages that the arc tower construction difficulty is reduced, tools and materials are saved, the construction period is shortened, and the installation of two mammoth arch rib structures can be completed with high precision and high quality; aloft work of the arch ribs is converted into ground integral assembly work, the construction efficiency is high, the safety protection work is easy to organize, and the construction quality is easy to guarantee; machines and equipment required for the construction are in a small quantity, the process is simple, and the operation is safe; the construction speed is high, the manufacture cost is low, and the investment is saved.

Owner:JIANGSU HUNING STEEL MECHANISM

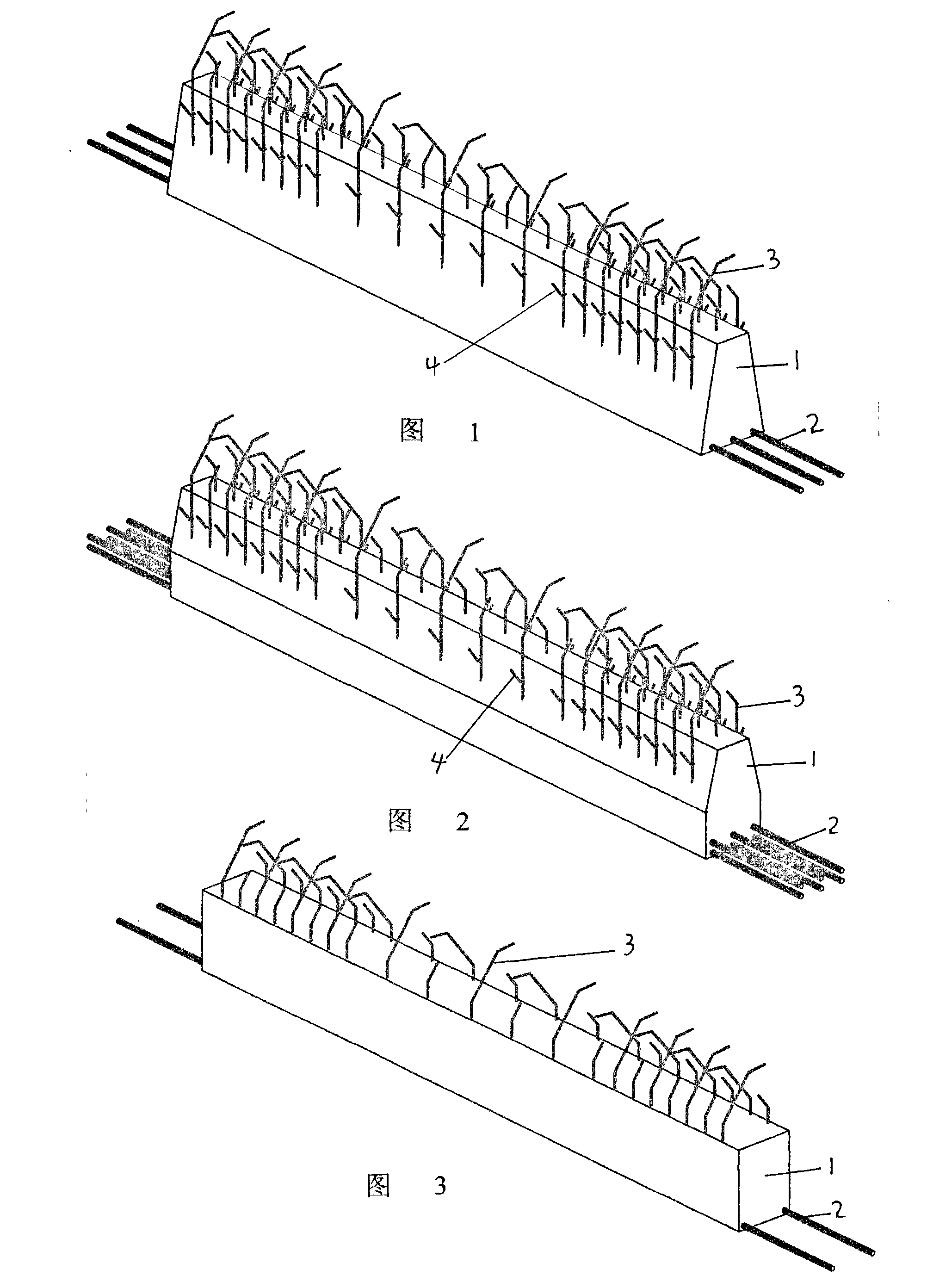

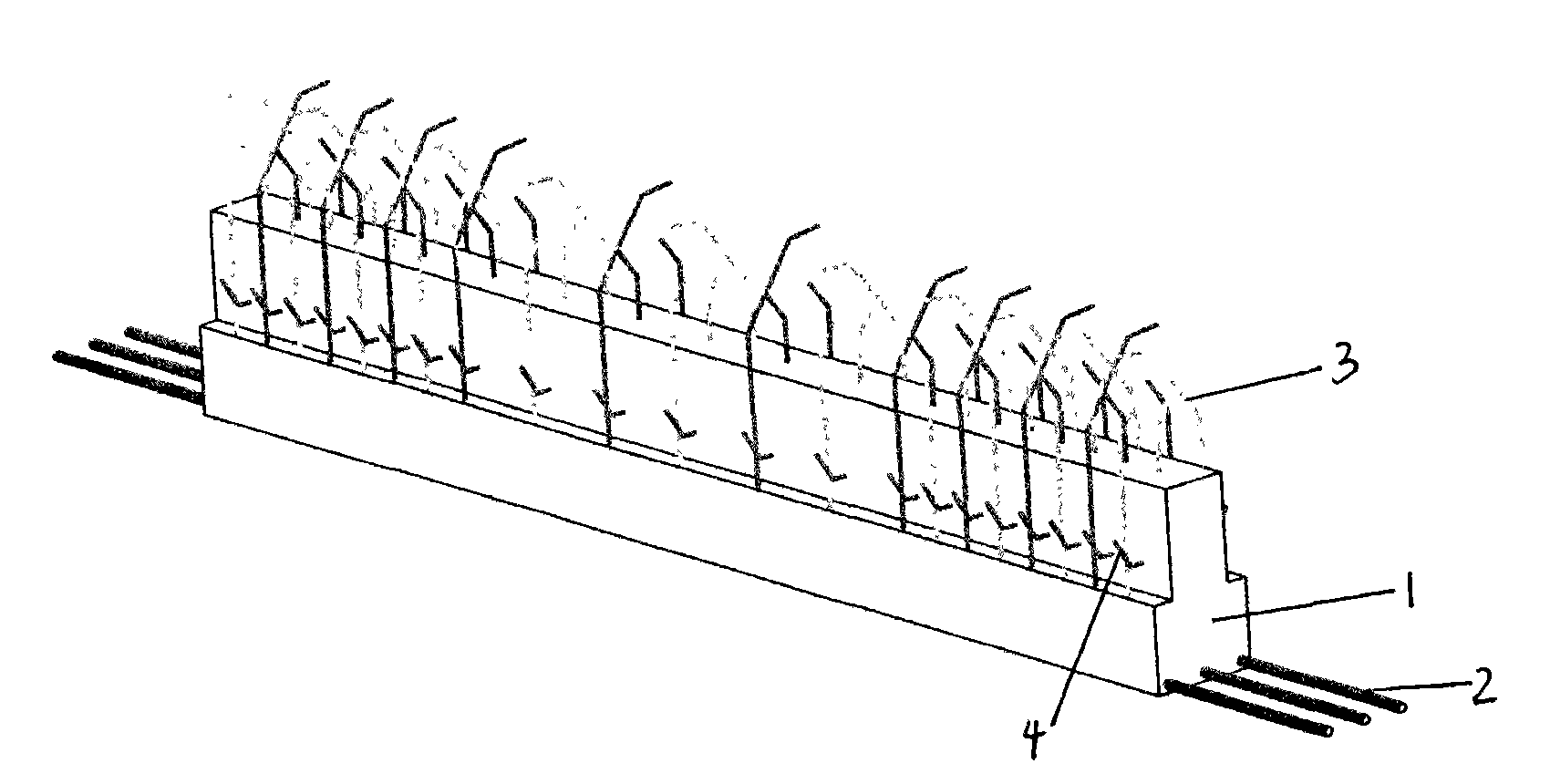

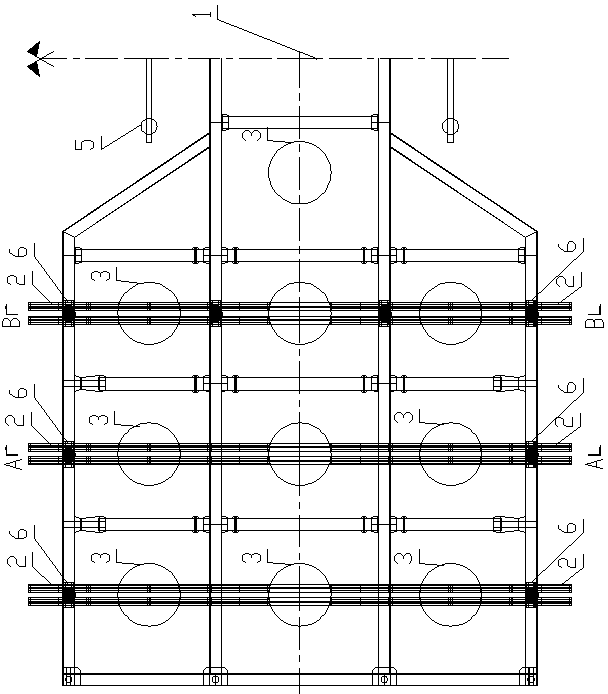

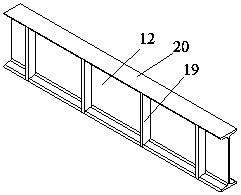

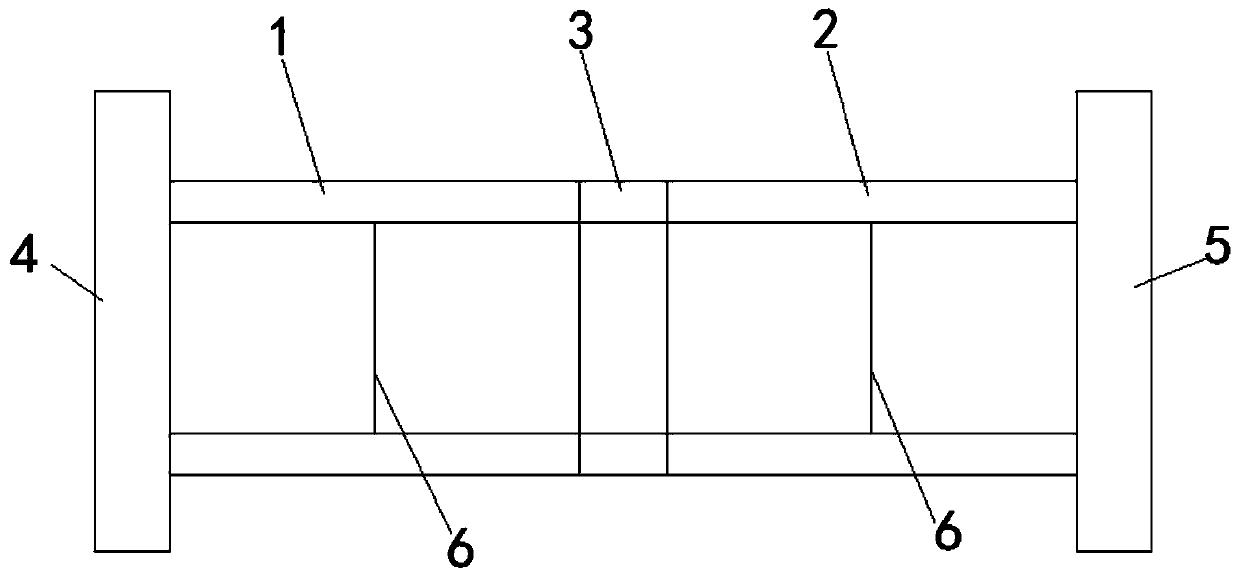

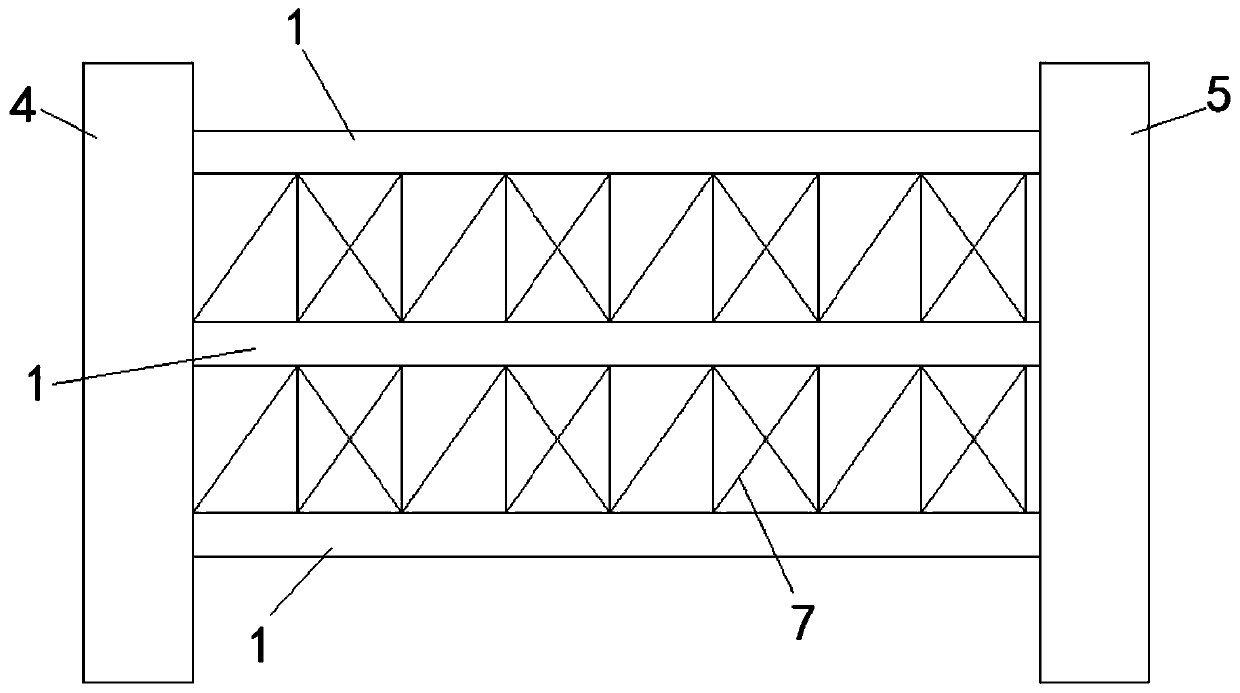

Semi-precast beam

InactiveCN101793075AEnsure safetyImprove construction efficiencyGirdersJoistsFalseworkReinforced concrete

The invention provides a semi-precast beam, which mainly comprises a beam body and steel bars (a general name of stressed steel bars, stirrups and tie bars), and is characterized in that: only the stressed steel bars and the stirrups on the lower part are pre-arranged in the semi-precast beam; and the beam body is exposed on a banding or welding part of the stirrups and other post-arranged stressed steel bars to prevent the steel bars on the upper part from impeding construction. The semi-precast beam has the advantages that: the steel bars of the semi-precast beam do not conflict with the steel bars of other components in the process of installation, so that the treatment of the steel bars at joints meets the requirement of a specification of a reinforced concrete structure; a beam holding component bears the construction load instead of a full scaffold by using a principle of simply supported beams; the connection of the steel bars and the banding of templates are performed on the floor, so that the safety of workers is ensured, and the construction efficiency and the construction quality are obviously improved; the amount of high-altitude operation is substantially reduced; and the post-casting of concrete is operated on the floor, and the amount of the post-cast concrete is substantially reduced, so the construction speed is substantially improved.

Owner:管乃彦

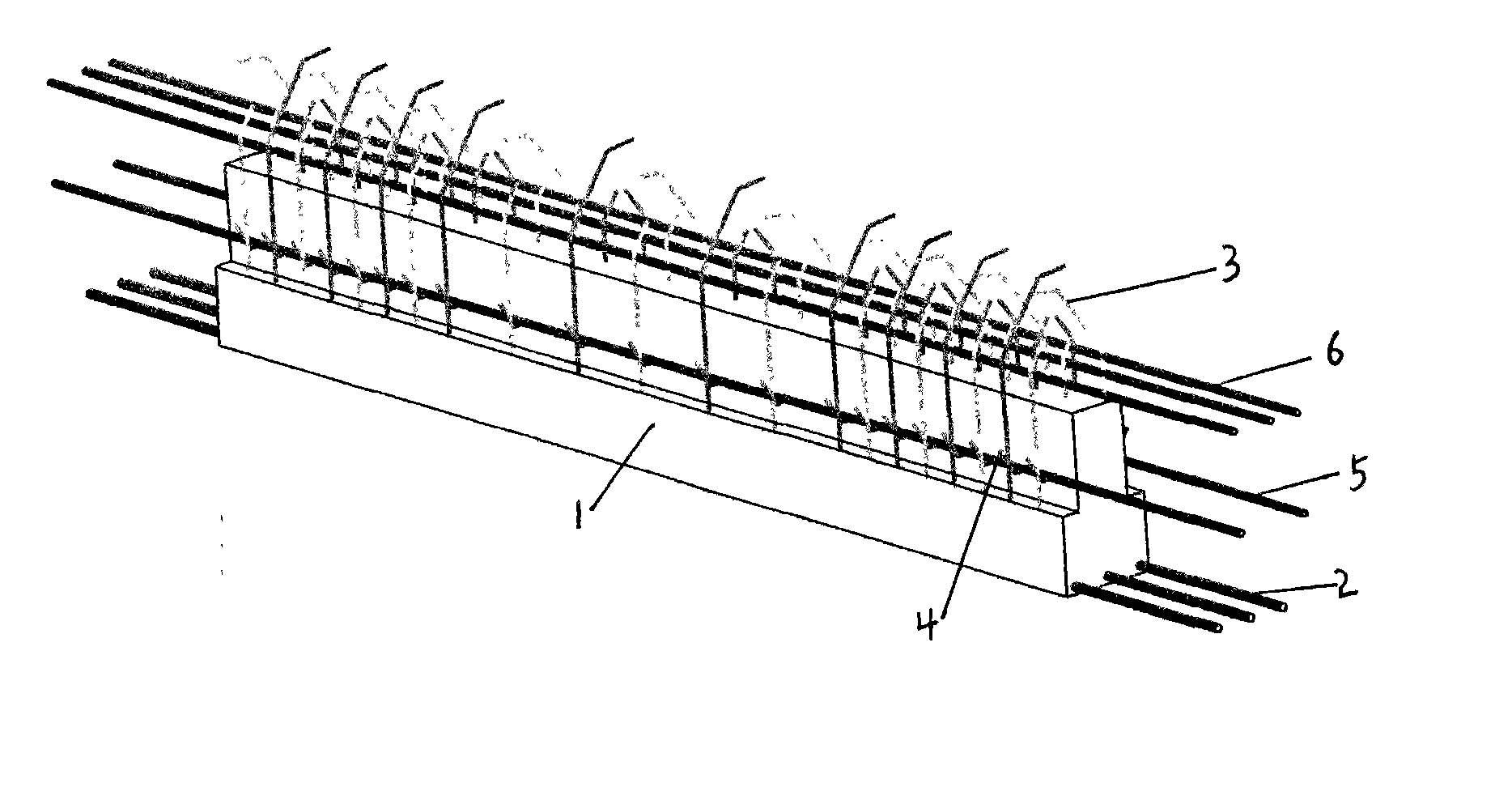

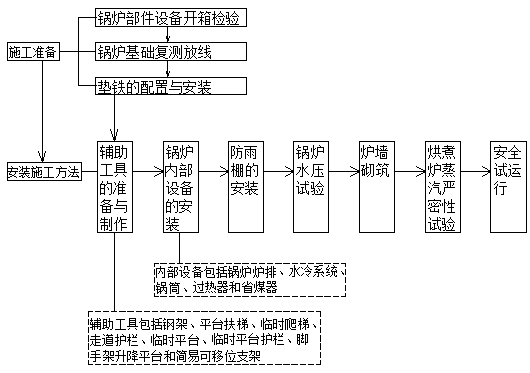

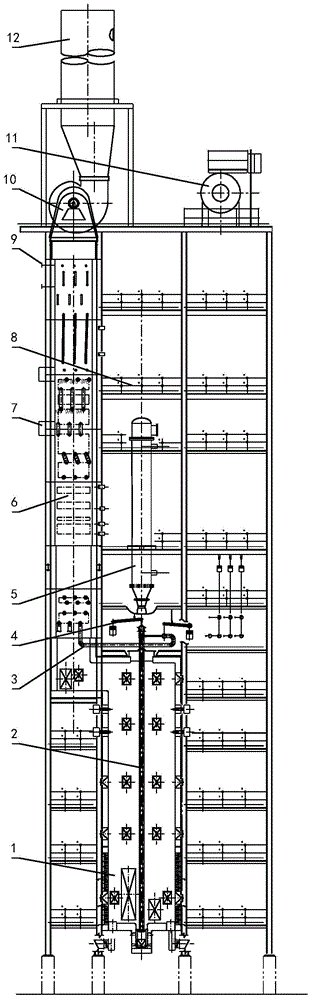

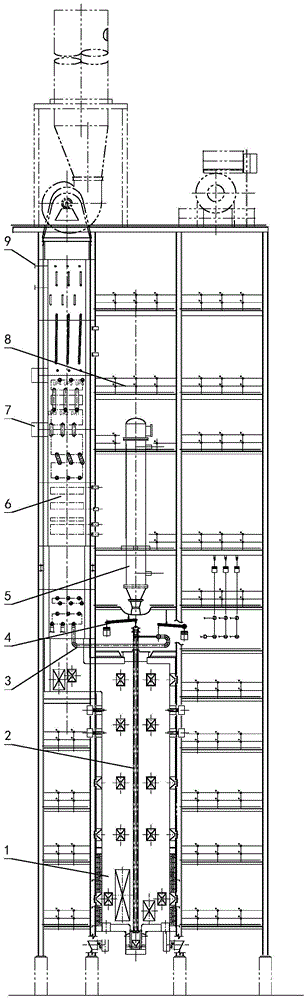

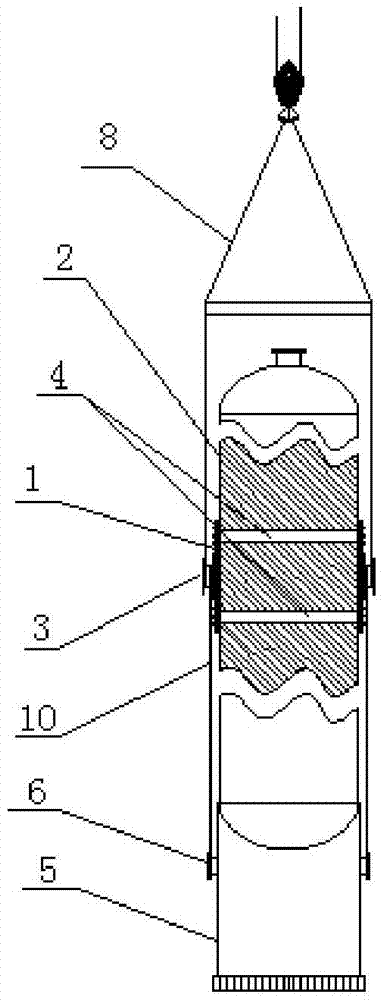

Installation and construction method of mechanical grate type waste incineration boiler

InactiveCN109000261AGive full consideration to reuseReduce the amount of work at heightIncinerator apparatusSteel frameSuperheater

The invention discloses an installation and construction method of a mechanical grate type waste incineration boiler. The installation and construction method includes the following specific steps ofconstruction preparation, specifically, unpacking inspection of boiler parts and equipment, retesting and paying off of boiler foundation, and configuration and installation of parallels; and installation and construction method, specifically, preparation and manufacturing of auxiliary tools, installation of boiler internal equipment, installation of rainproof shed, hydrostatic test of boiler, installation of boiler wall, steam tightness test of drying and boiling boiler, and safe trial operation, wherein the auxiliary tools includes a steel frame, a platform escalator, a temporary climbing ladder, an aisle guardrail, a temporary platform, a temporary platform guardrail, a scaffold lifting platform and a simple removable support, and the internal equipment includes a boiler grate, a watercooling system, a drum, a superheater and an economizer. The installation and construction method of the mechanical grate type waste incineration boiler is applicable to installation of the mechanicalgrate type waste incineration boiler with a daily garbage disposal of about 500t / d by a single unit in a domestic garbage power plant, the degree of mechanized construction is improved, the labor intensity is reduced, the project quality is guaranteed, the construction period is shortened, and the productivity and economic benefits are improved.

Owner:POWER CHINA HENAN ENG CO LTD

Integral modular structure of industrial furnace and construction method

ActiveCN104976894AShorten the construction periodGuaranteed Build QualityMonolithic liningsModular designModular structure

The invention discloses an integral modular structure of an industrial furnace and a construction method. The integral modular structure comprises a main body part and accessory equipment and accessories. The main body part of the integral modular structure of the industrial furnace comprises a radiation section modular structure, a convection segment, a radiation furnace pipe, a crossing pipe for connecting a convection furnace pipe with the radiation furnace pipe and a supporting hanging system for the radiation furnace pipe and the crossing pipe. The accessory equipment and accessories comprise a chimney, a waste heat boiler, a steam pocket, a draught fan, an ash ejector, parts of platform and ladder, an instrument and a cable of the instrument. The method comprises the steps that the main body part of an integral module of the industrial furnace and the accessory equipment and accessories of the integral module of the industrial furnace are manufactured and assembled in a workshop, integrally transported and integrally mounted to be in place. Integral modular design, workshop modular manufacturing, integral assembly, integral transportation and field integral mounting to be in place are adopted in the industrial furnace; the construction difficulty is reduced, the manufacturing precision and the construction schedule are ensured, the labor cost of site operation is low, the construction period is short, and construction is safe.

Owner:SINOPEC ENG +1

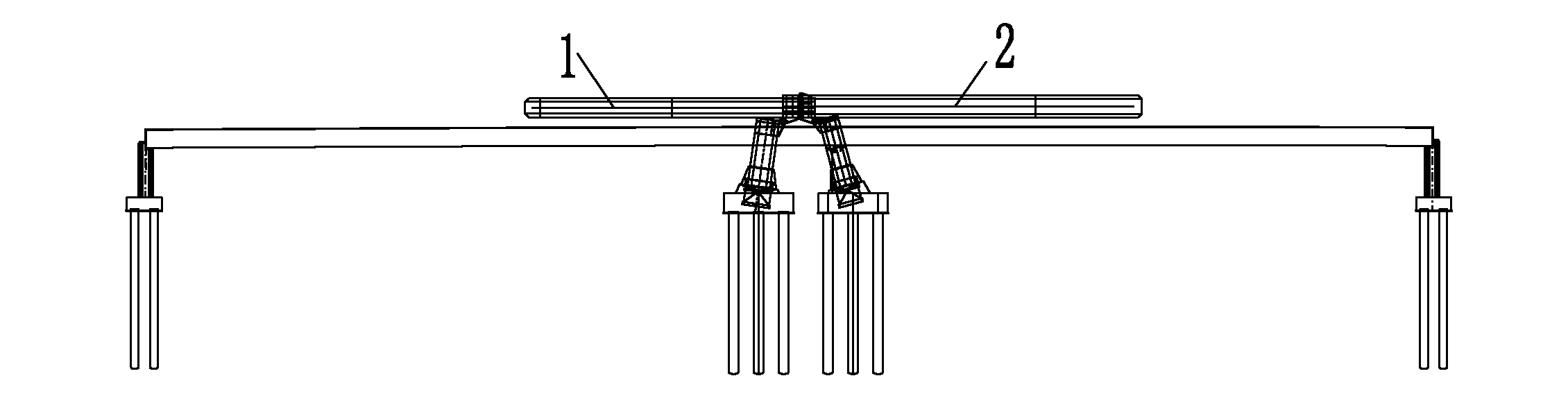

Construction method for integrally and downward putting cofferdam ring beams by means of continuous jack method

The invention discloses a construction method for integrally and downward putting cofferdam ring beams by means of a continuous jack method. The construction method sequentially comprises: step one, installing a ring beam hanging system; step two, integrally uplifting ring beams and dismounting ring beam butt-joint platform bailey beams; step three, firstly putting the ring beams downward; step four, converting a ring beam system; and step five, secondarily putting lower-layer ring beams downward. A jack is continuously used for providing force for putting the ring beams downward, so that the demand for labor force is reduced, and temporarily organized large-scale labor force is avoided. In addition, corresponding cost is reduced, the ring beam splicing time on a cofferdam is shortened, and time is saved for tubular pile inserting and driving and sludge suction of the cofferdam. The integral downward putting of the ring beams can reach 2m each hour, and time is saved for the overall downward putting process. The high-altitude operation amount is decreased during construction. Original upper-layer ring beams are used as a downward putting platform, and integral underwater downward putting of the lower-layer ring beams is achieved.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP +1

Vertical swiveling construction method of dual-steel-arch tower

InactiveCN102061668AImprove construction efficiencyEasy to organizeBridge structural detailsBridge erection/assemblyEngineeringTower

The invention relates to a vertical swiveling construction method of a dual-steel-arch tower, belonging to the field of bridge construction. A vertical swiveling construction mode is adopted in the vertical swiveling construction method which is characterized in that the vertical swiveling construction of dual steel arcs is realized by utilizing the self durable structure of a bridge. The method comprises the following steps of: firstly, mounting a plate-lifting tripod, a steering cable saddle and a steel stranded wire on an inner arch tower for vertically swiveling an inwards arch tower and finishing the welding of an annual welding line of the inwards arch tower; then, carrying out the swiveling construction on an outer arch tower: firstly penetrating the plate-lifting steel stranded wire through the steering cable saddle on the inwards arch tower before construction and carrying out the vertical swiveling construction on the outer arch tower by utilizing the inwards arch tower as a support for swiveling the outer arch tower; and finally, finishing the welding of the annual welding line of the outer arch tower. The invention has the advantages of simple construction, high mounting accuracy, convenience of welding, quality guarantee, smaller danger, less overhead operation, low manufacture cost, short construction period, high construction efficiency, and the like.

Owner:TIANJIN NO 7 MUNICIPAL&HIGHWAY ENG CORP LTD +1

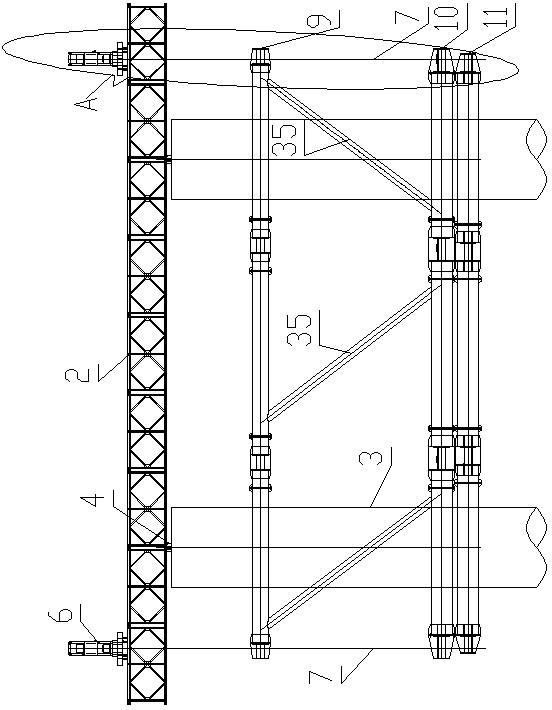

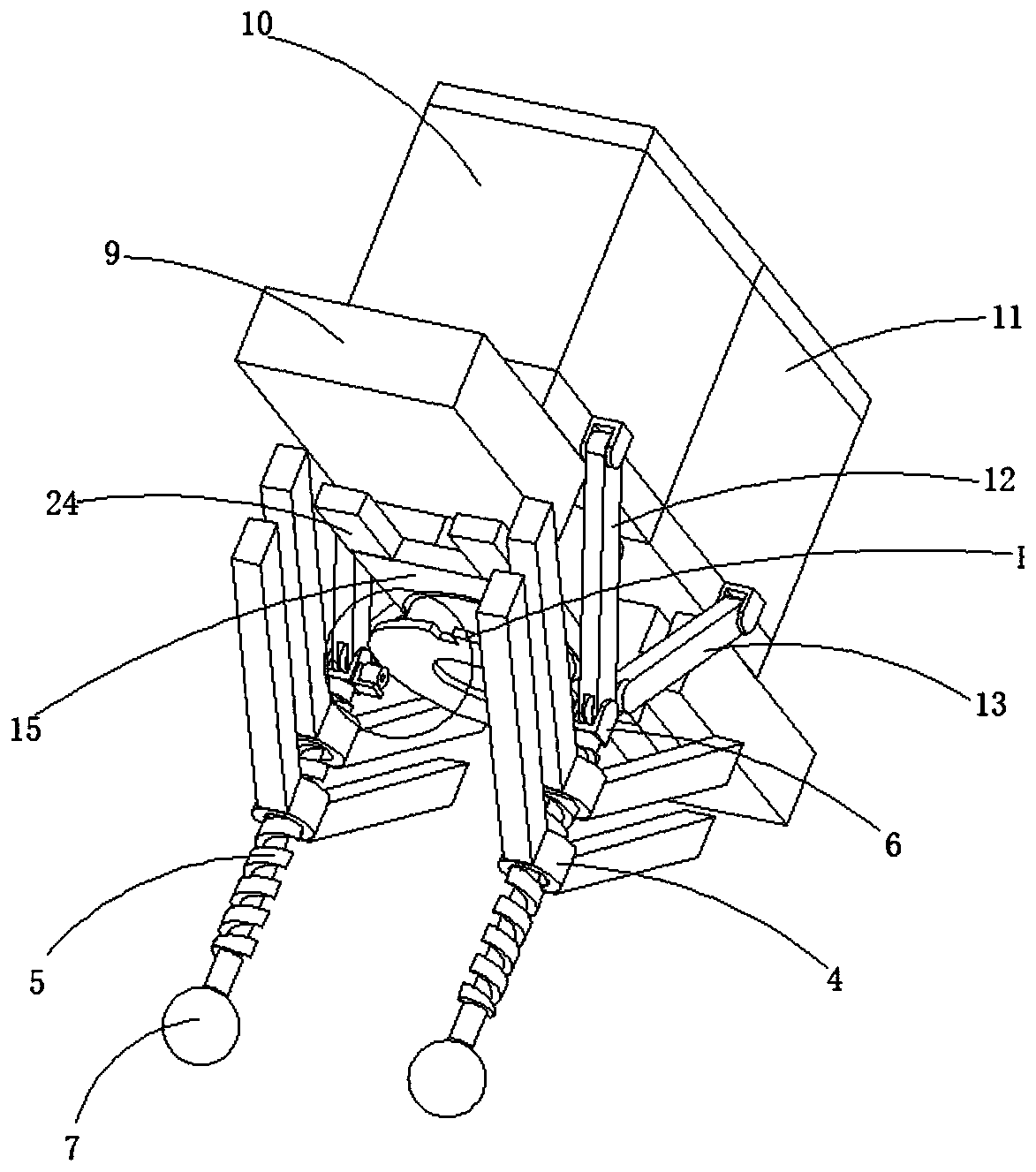

Device and method for constructing assembled crossing frame

The invention provides a device and method for constructing an assembled crossing frame. The device and method are characterized in that the crossing frame comprises a tower base, a middle section and a tower head which are sequentially arranged in the vertical direction; the device comprises a jacking frame, a control device, a rope collecting and releasing mechanism and a power source; the rope collecting and releasing mechanism comprises two layers of stay wires which are symmetrically arranged on two sides of the tower head and two sides of the middle section respectively, and steering blocks and tension sensors are arranged between the stay wires and the rope collecting and releasing mechanism respectively; the jacking frame, the synchronous control device and the rope collecting and releasing mechanism are connected with the power source respectively. Compared with the prior art, the device and method for constructing the assembled crossing frame have the advantages that an inverted assembly mode is adopted, so that the quantity of aerial work is reduced, and safety is high; an assembly mode that the middle section is jacked hydraulically is adopted, so that tower assembly construction efficiency is high, and labor intensity of construction workers is relieved; it is guaranteed that the crossing frame is perpendicular to the horizontal plane all the time in an assembly process and after assembly is finished.

Owner:STATE GRID CORP OF CHINA +3

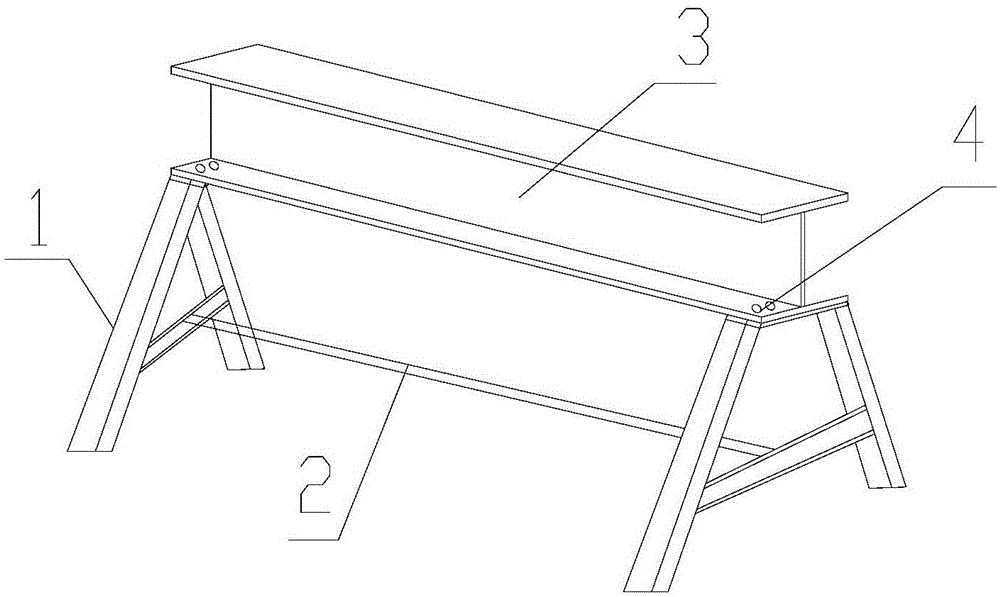

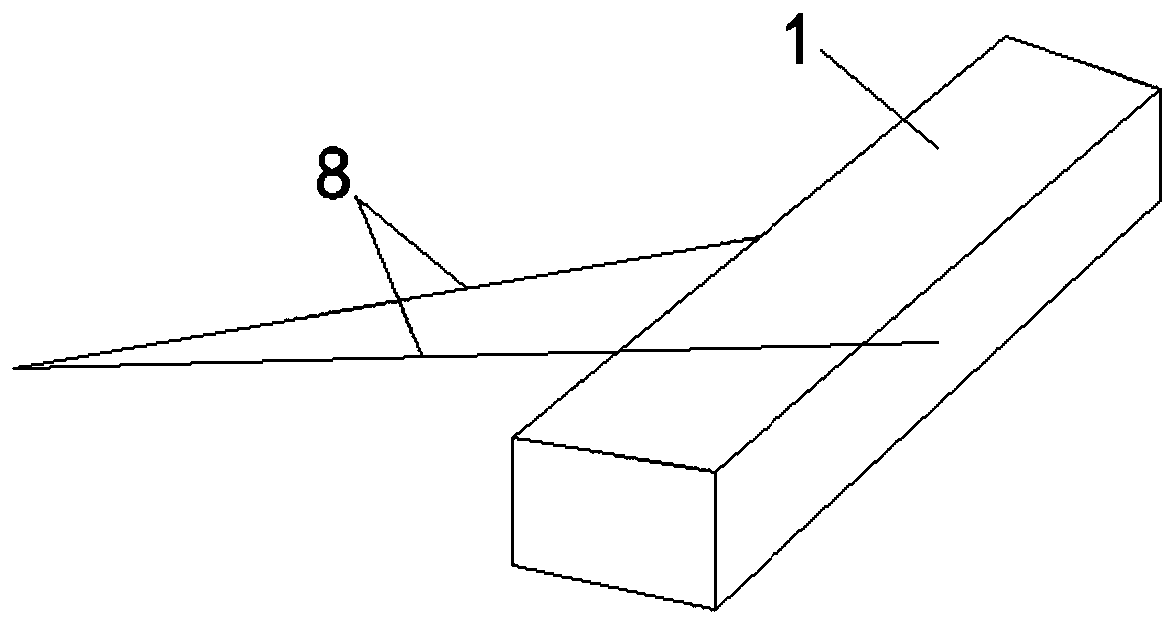

Manufacturing method of reinforcing steel bar section and adjustable reinforcing steel bar section splitting jig frame thereof

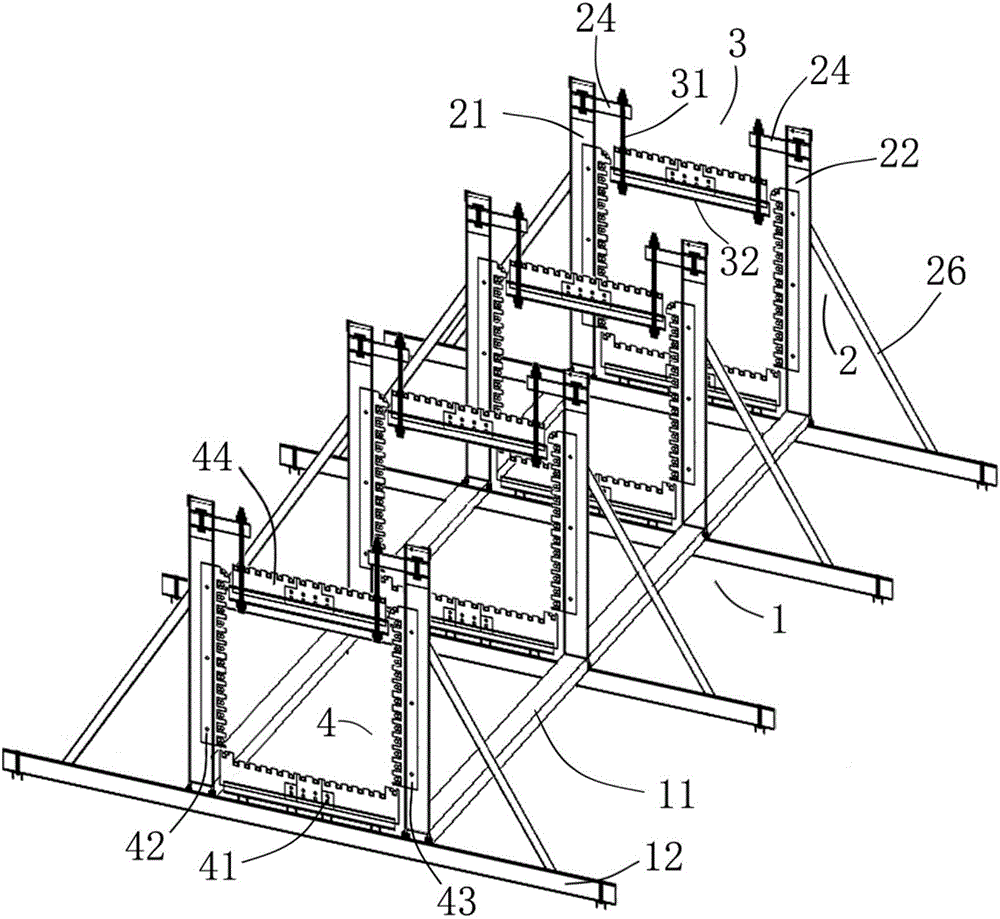

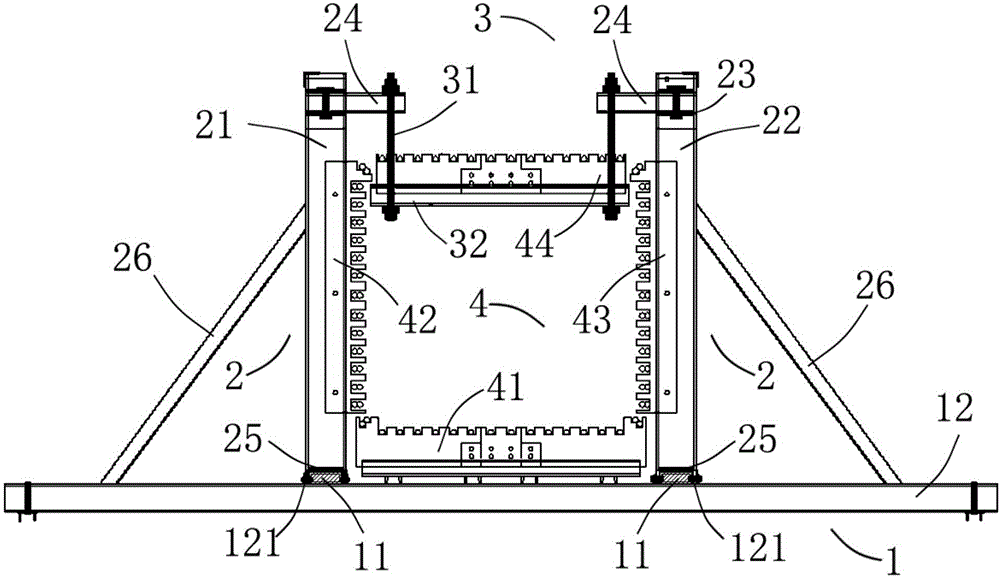

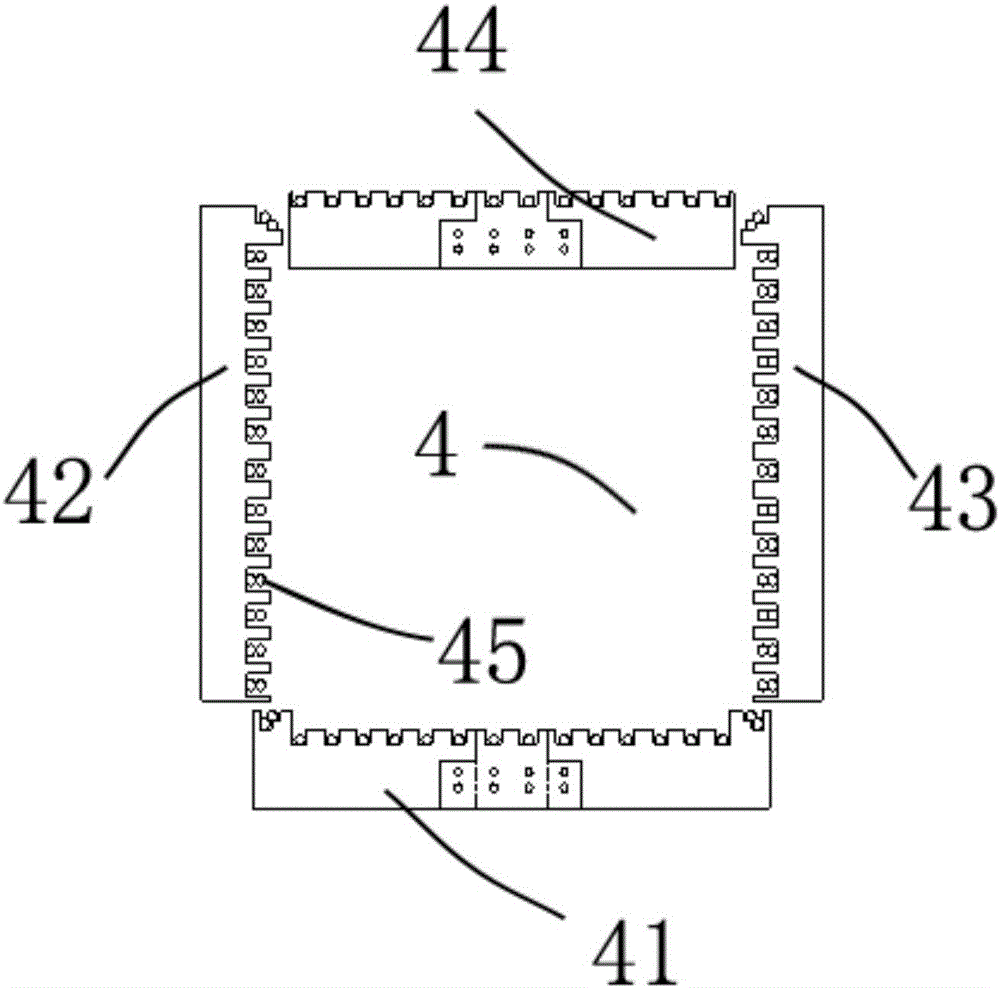

ActiveCN106400690AOperational securityConstruction environment safetyBridge erection/assemblyRebarSupport plane

The invention discloses a manufacturing method of a reinforcing steel bar section and an adjustable reinforcing steel bar section splitting jig frame thereof. The adjustable reinforcing steel bar section splitting jig frame comprises a bearing platform, a vertical supporting frame, a suspension frame and a toothed plate set, wherein the bearing platform comprises a pair of longitudinal bearing steels, and a plurality of transverse bearing steels which are orthogonally connected below the longitudinal bearing steels; the vertical supporting frame comprises a plurality of pairs of left supports and right supports; the left supports and the right supports are vertically arranged on the transverse bearing steels; the suspension frame comprises hoisting ribs, and suspension plates which are connected with the left supports and the right supports through the hoisting ribs in a suspension manner; the toothed plate set comprises lower toothed plates which are connected with the corresponding transverse bearing steels, left toothed plates which are connected with the corresponding left supports, right toothed plates connected with the corresponding right supports, and upper toothed plates connected with the corresponding suspension plates. With the adoption of the adjustable reinforcing steel bar section splitting jig frame, a safe and reliable construction environment is provided; in addition, the adjustable reinforcing steel bar section splitting jig frame can be transferred to use and has the characteristics of being fast to bind and manufacture, high in reinforcing steel bar mounting accuracy, and small in workload of aloft work.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Prefabricated cast-in-place combination type superposed shear wall

The invention relates to the field of building materials. In order to be adapted to housing industrialization, the invention discloses a prefabricated cast-in-place combination type superposed shear wall which comprises an outer wall layer, a heat insulating material layer and an inner wall layer, wherein the heat insulating material layer is located between the outer wall layer and the inner wall layer, and the outer wall layer and the inner wall layer are connected through tie bars or connectors; the inner wall layer comprises a prefabricated part and a cast-in-place part, the prefabricated part of the inner wall layer is basically located at the middle portion of the outer wall layer, the area of the prefabricated part of the inner wall layer is smaller than or equal to that of the outer wall layer, and the prefabricated part of the inner wall layer reserves lateral and longitudinal reinforced steel bars; and the outer wall layer, the heat insulating material layer and the prefabricated part of the inner wall layer are made into a whole in advance; and the prefabricated part reserves the lateral and longitudinal reinforced steel bars to be anchored into the cast-in-place part of the inner wall layer. The invention has the advantages of improved building quality, energy saving, environmental protection, short working period, industrial production and increased construction safety.

Owner:沈阳万科企业有限公司

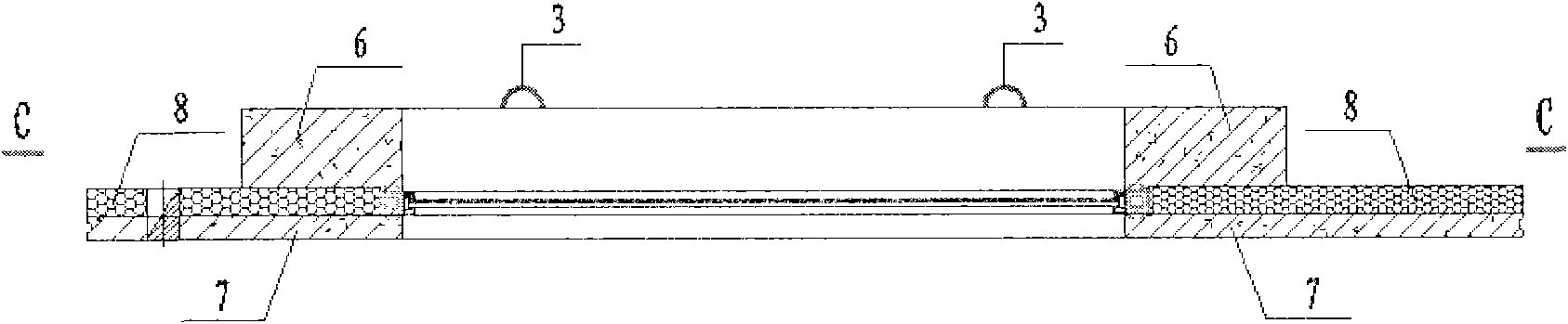

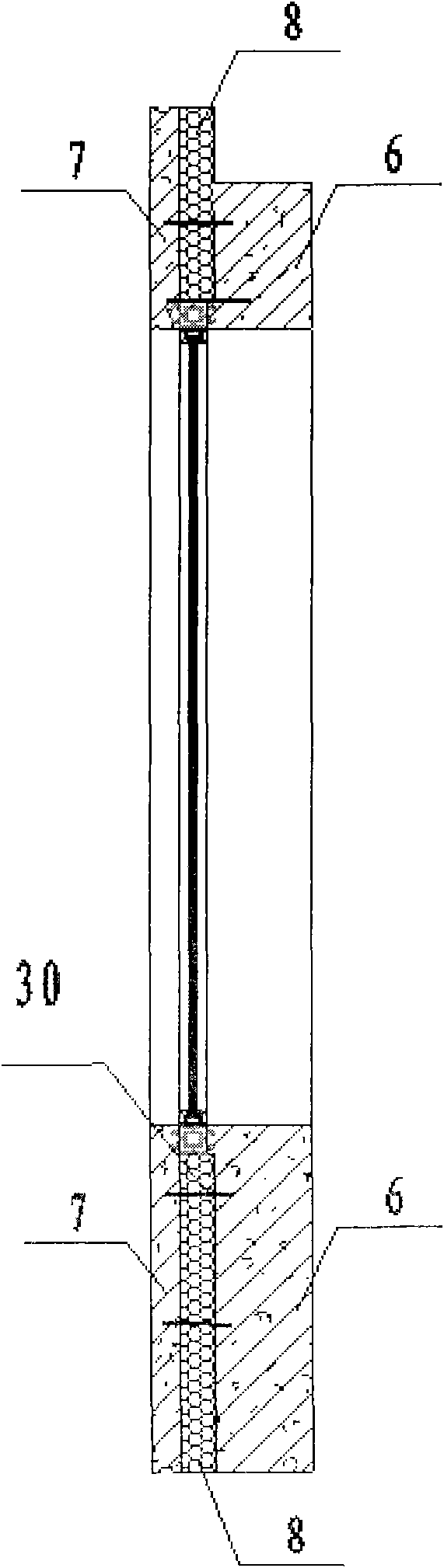

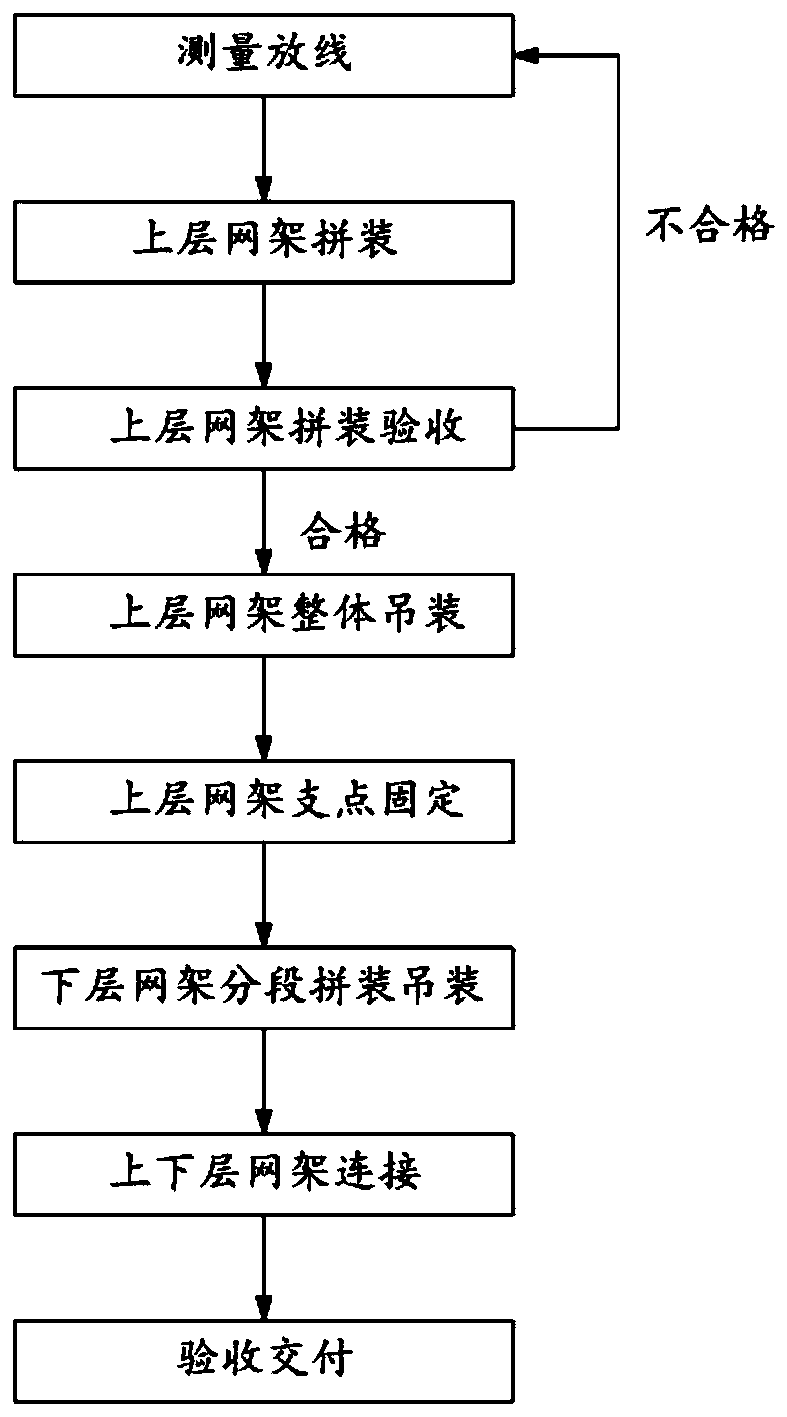

Large-span spherical net frame integral lifting method

The invention discloses a large-span spherical net frame integral lifting method. The large-span spherical net frame integral lifting method lifts large-span spherical net frames by adopting a mode ofcombining integral lifting with segmented lifting; upper chords and lower chords of upper layers of the net frames are integrally lofted through a total station for integral assembly; a reserved value of a springing height is set in the assembly process; multiple lifting equipment is used for integrally lifting and mounting the upper layers of the net frames; upper part structures integrally lifted are used for forming an operation platform; and lower part structures are assembled, lifted and connected in a segmented mode to form a whole, so that the aerial bulking of components is reduced, the scaffold use level is reduced, the aerial workload is reduced, the construction is safe and reliable, the construction risk is reduced, the construction efficiency is improved, and the control of the quality of the net frames and the control of the production safety are facilitated.

Owner:CHENGDU NO 1 CONSTR

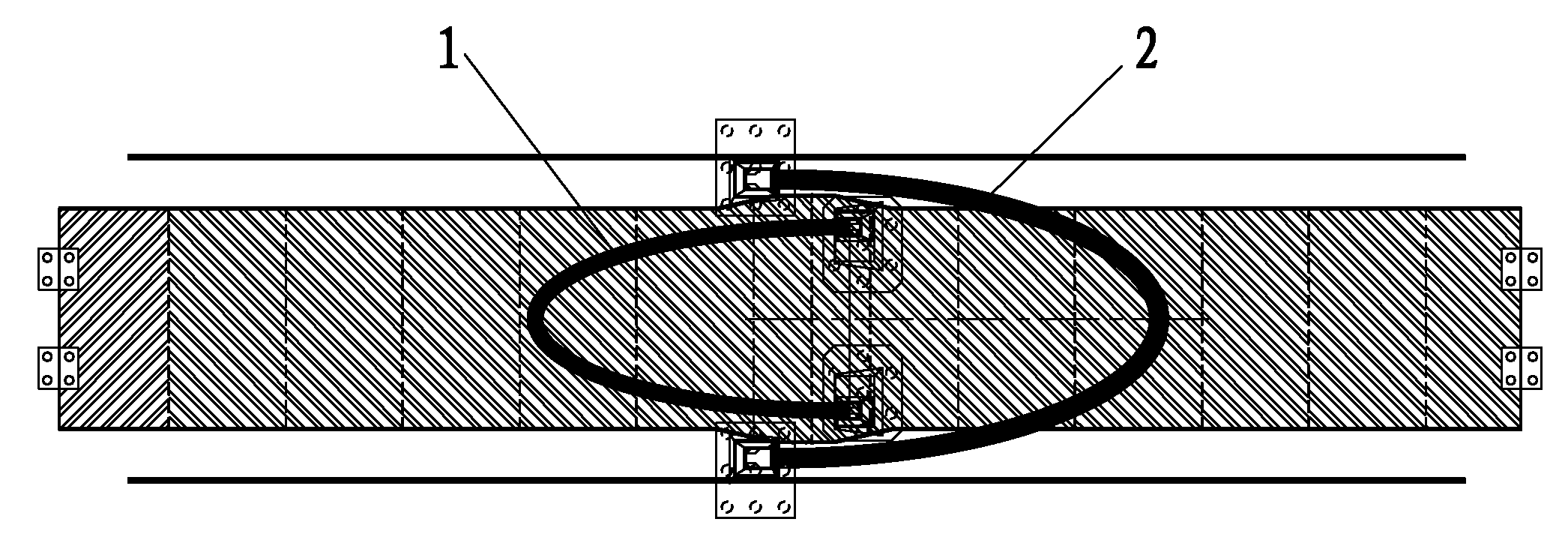

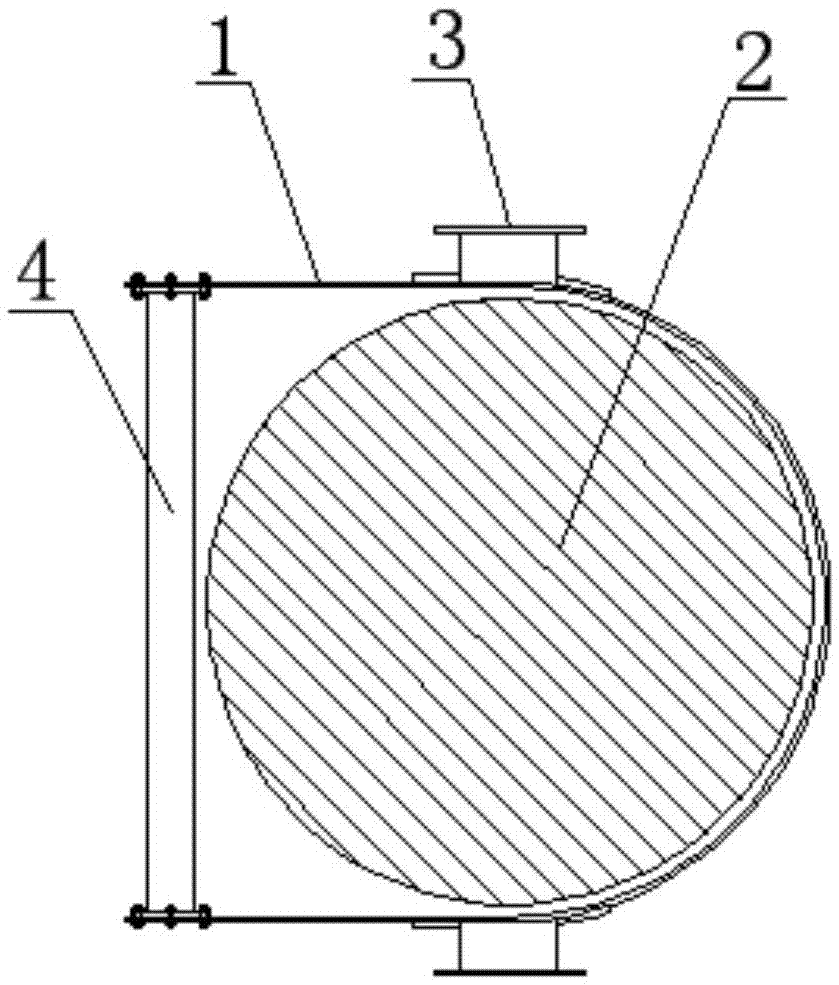

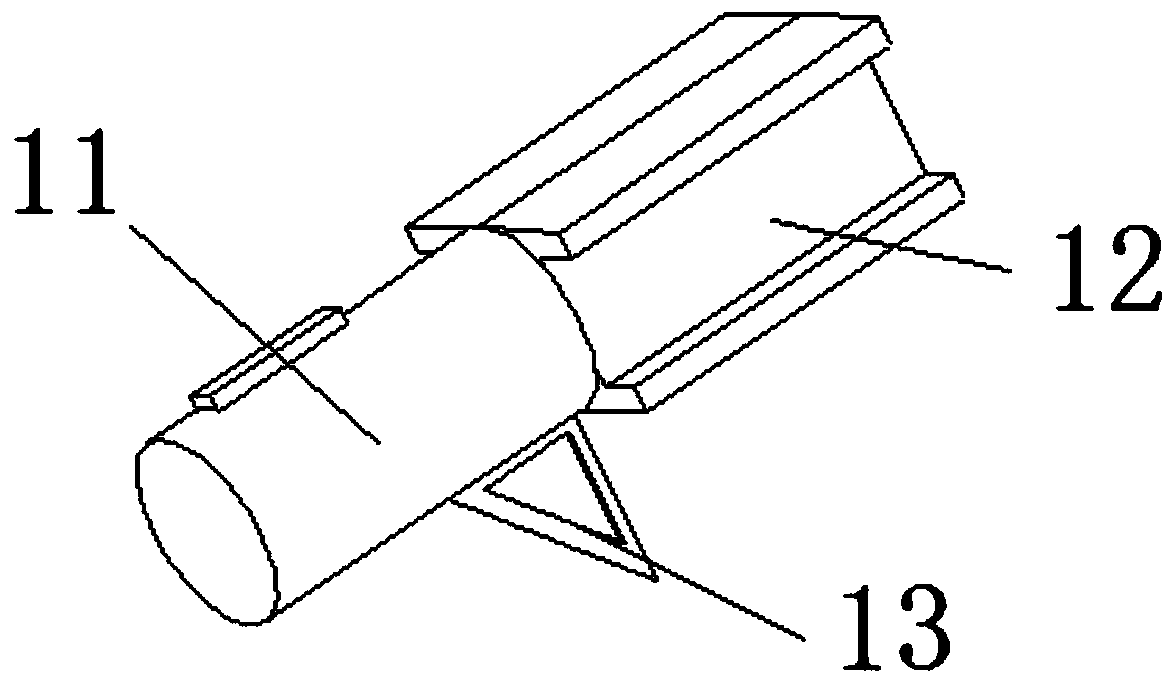

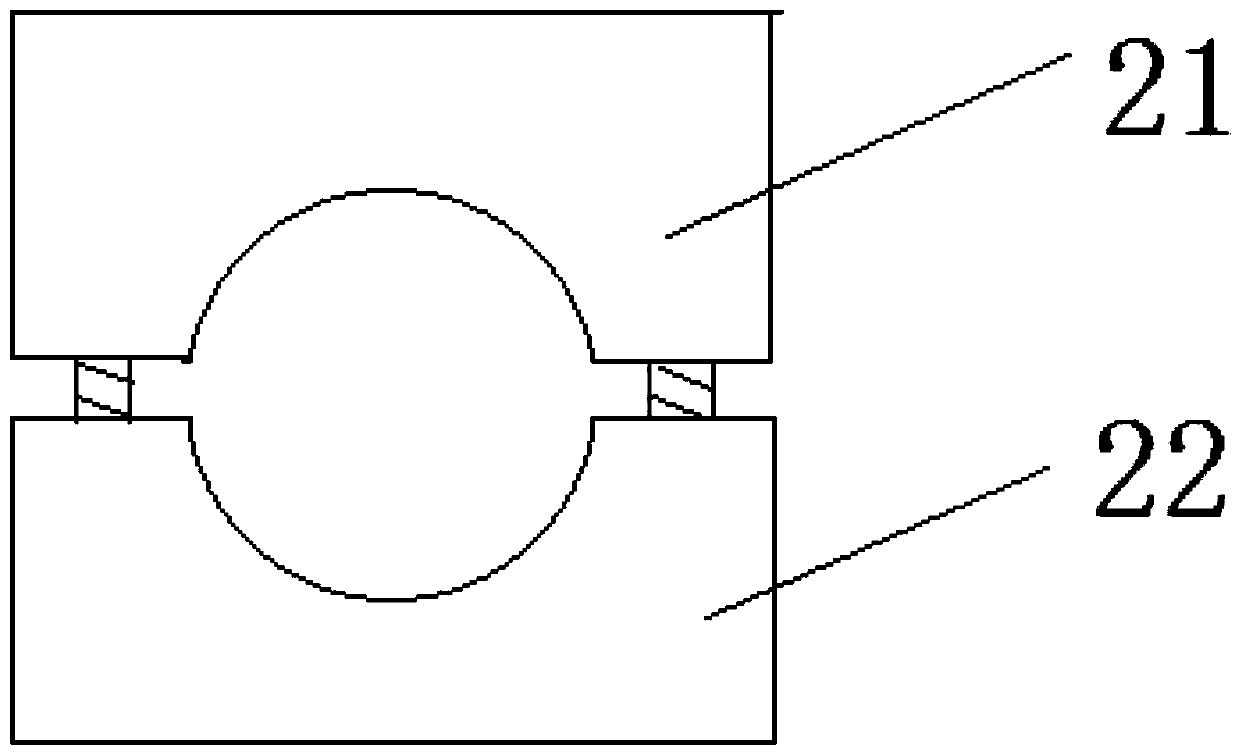

U-shaped movable hold hoop type lifting lug for hoisting tower facility and hoisting method thereof

ActiveCN105438960AAvoid WeldingEliminate heat treatmentLoad-engaging elementsTowerIndustrial engineering

The invention discloses a U-shaped movable hold hoop type lifting lug for hoisting a tower facility and a hoisting method thereof. The U-shaped movable hold hoop type lifting lug comprises a U-shaped hold hoop, wherein a hoop ring of the U-shaped hold hoop hoops the side wall of a tower body, a pair of pipe shaft type lifting lugs is symmetrically arranged on two sides of the U-shaped hold hoop, the circle center of the cross section of the side wall of the tower body is rightly located on the axis connection of the two pipe shaft type lifting lugs, connecting rods are connected between the open ends of the U-shaped hold hoop, the tower body is hooped through the U-shaped hold hoop, the pipe shaft type lifting lugs on the U-shaped hold hoop are hoisted through a sling of a main hoisting crane during hoisting, and the pipe shaft type lifting lugs are connected with auxiliary lifting lugs. Therefore, the lifting force of the sling is transferred to the auxiliary lifting lugs to avoid sliding of the U-shaped hold hoop, the sling of an auxiliary hoisting crane hoists a tail-lifting lifting lug, enables the tower body to be changed from a vertical state to a horizontal state under the cooperative effect with the main hoisting crane and enables the U-shaped hold hoop to bear the radial pressure of the tower body, and safety is ensured. The tower body is hoisted by using the U-shaped movable hold hoop type lifting lug and the hoisting method, welding operation required to be performed on the tower body is avoided, and the tower body is protected.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

High-altitude large-span curved roof hydraulic lifting construction method

ActiveCN109098454ALarge working spaceShort construction periodBuilding roofsBuilding material handlingEngineeringSpandrel

The invention relates to a high-altitude large-span curved roof hydraulic lifting construction method, and belongs to the technical field of structural engineering steel structures. A high-altitude large-span curved roof hydraulic lifting device comprises a curved roof, wherein the curved roof comprises truss upper chords, roof surfaces and truss lower chords; a plurality of roof support columns are arranged on the lower end surfaces of the truss lower chords; a plurality of hydraulic lifting assemblies are arranged between the roof support columns; a plurality of lifting frames arranged at equal intervals are uniformly arranged at the periphery of the curved roof; lifting platform frames are arranged on the lifting frames; hydraulic lifters are arranged at the front ends of the lifting platform frames; steel structure lifting appliances which are in lug type pin connection with the truss upper chords are arranged below the hydraulic lifters; and steel strands which are connected withthe hydraulic lifters in a movable and sleeved manner are arranged between the hydraulic lifters and the steel structure lifting appliances. The construction method has the advantages of large liftingtonnage, short construction period, large operation space, reduction of high-altitude operation volume and reduction of safety risks, and solves the problems of large high-altitude bulk welding volume, large operation risks and unstable construction quality.

Owner:潮峰钢构集团有限公司

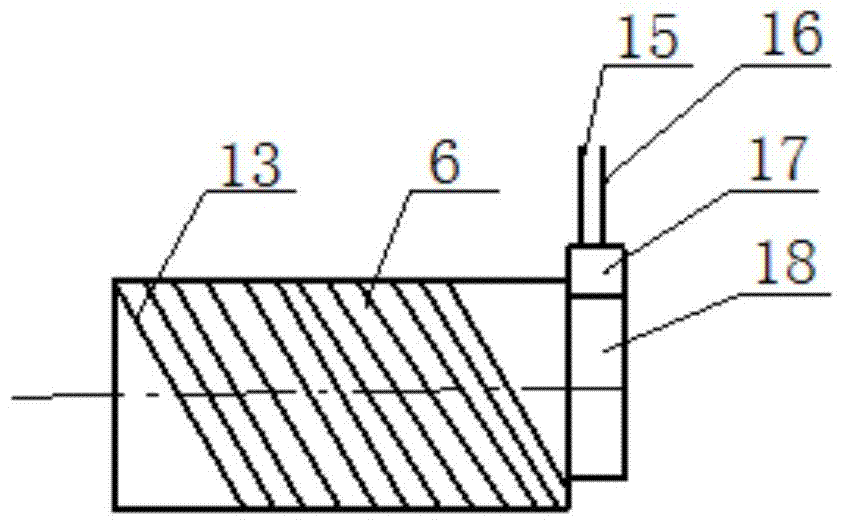

Straddle-type temporary cable self-balancing push-type cable change underpinning apparatus for suspension bridge cables

PendingCN109487709ATemporary Cable Clamp LightEasy to install and constructBridge structural detailsBridge erection/assemblyInternal forcesSteel box girder

The invention discloses a straddle-type temporary cable self-balancing push-type cable change underpinning apparatus for suspension bridge cables and belongs to the technical field of maintenance andreinforcement engineering of civil engineering suspension bridges. The straddle-type temporary cable self-balancing push-type cable change underpinning apparatus for suspension bridge cables comprisesa main cable that is inclined; steel box girder (13) is arranged blow the main cable; lugs are arranged on the upper surface of the steel box girder (13); the main cable is provided with a pluralityof permanent cable clamps; the top end of a permanent cable is connected with each permanent cable clamp; the bottom end of each permanent cable is connected with one lug; each lug is provided with apinhole. The straddle-type temporary cable self-balancing push-type cable change underpinning apparatus for suspension bridge cables helps solve the problem that cables are difficult to change when each cable lug of a suspension bridge has only one hanging hole, the fact that multiple-point lifting is carried out change one cable is avoided, aerial operation quantity is low, construction is simple, and the line shape and internal force of existing suspension bridge main cables and stiffening beams are less perturbed.

Owner:HOHAI UNIV +1

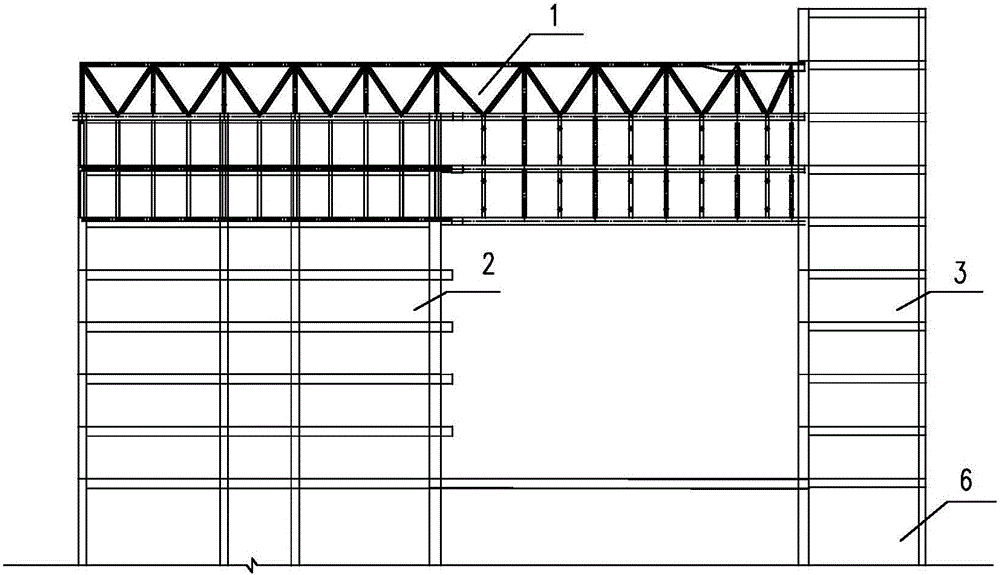

Construction method for long-span overhung specially-shaped limit exceeding structure steel corridor

ActiveCN106013419AStrong targetingSave man hoursBuilding material handlingArchitectural engineeringEngineering

The invention discloses a construction method for a long-span overhung specially-shaped limit exceeding structure steel corridor. The method includes the following steps that firstly, the steel corridor is divided into construction units, wherein the inner part of a corridor structure and middle strip blocks of an upper steel structure of a corridor overhung part are classified as the first construction unit, the remaining part of the corridor overhung part is classified as the second construction unit, and a corridor suspension part is classified as the third construction unit; secondly, a high-altitude bulk assembly method and a cantilever installation method are adopted for finishing construction of the first construction unit on a floor panel of a tower A; thirdly, construction of the second construction unit is finished through integral lifting; and fourthly, construction of the third construction unit is finished through sliding after integral lifting. The high-altitude bulk assembly technology, the integral lifting technology, the sliding after integral lifting technology and the like are applied, work hours are reduced, the material cost and equipment cost are saved, and the requirements for integral control over multiple aspects of the construction process, the quality, the safety, the schedule, the cost and the like are met.

Owner:中建六局第一建设有限公司 +1

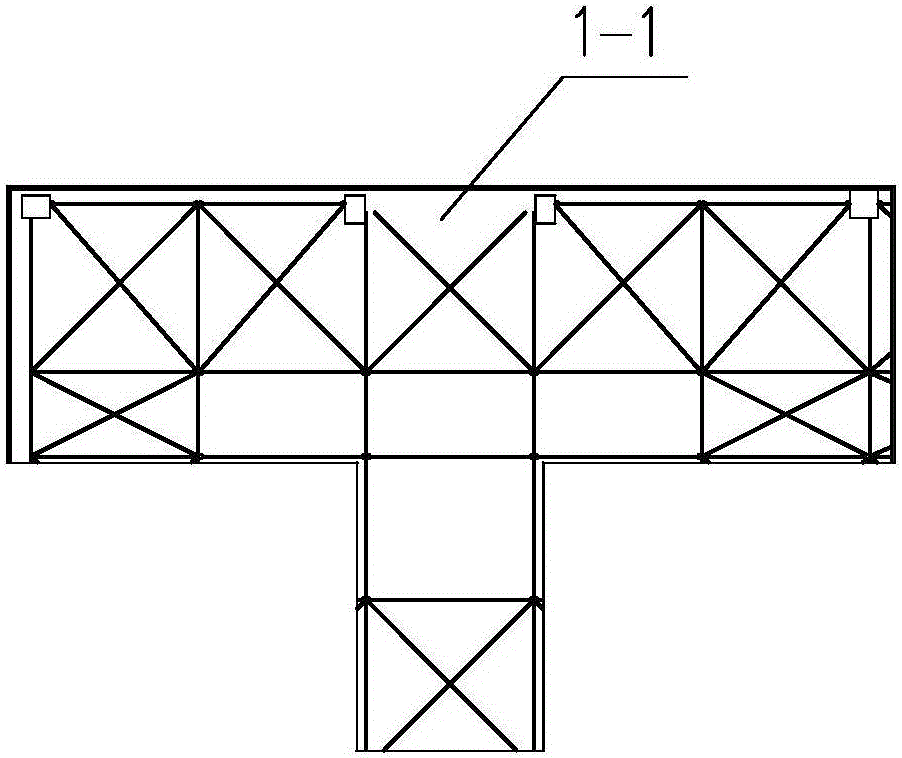

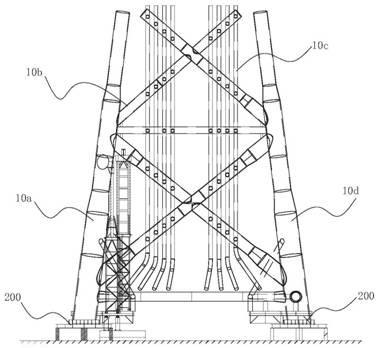

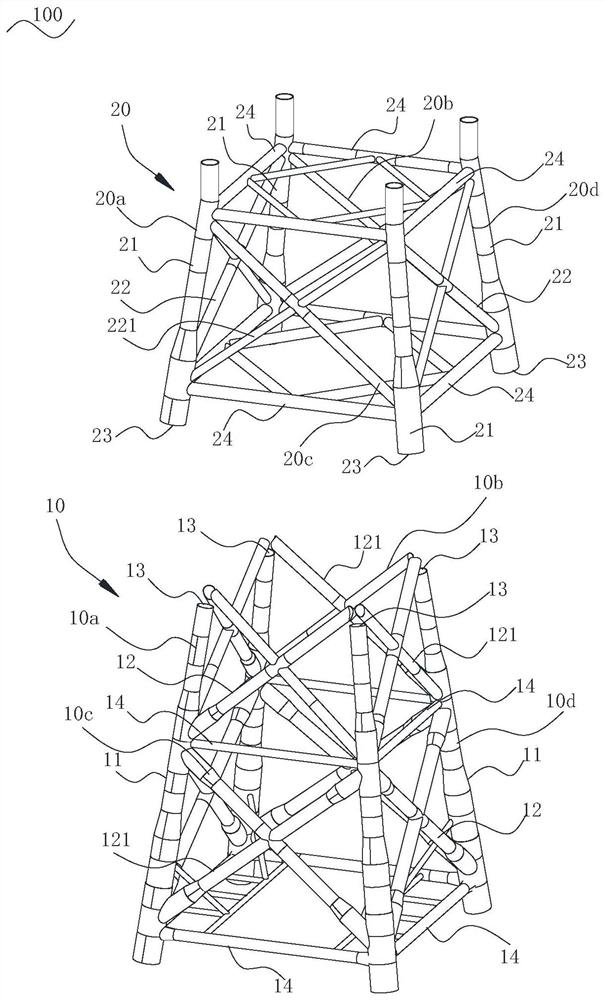

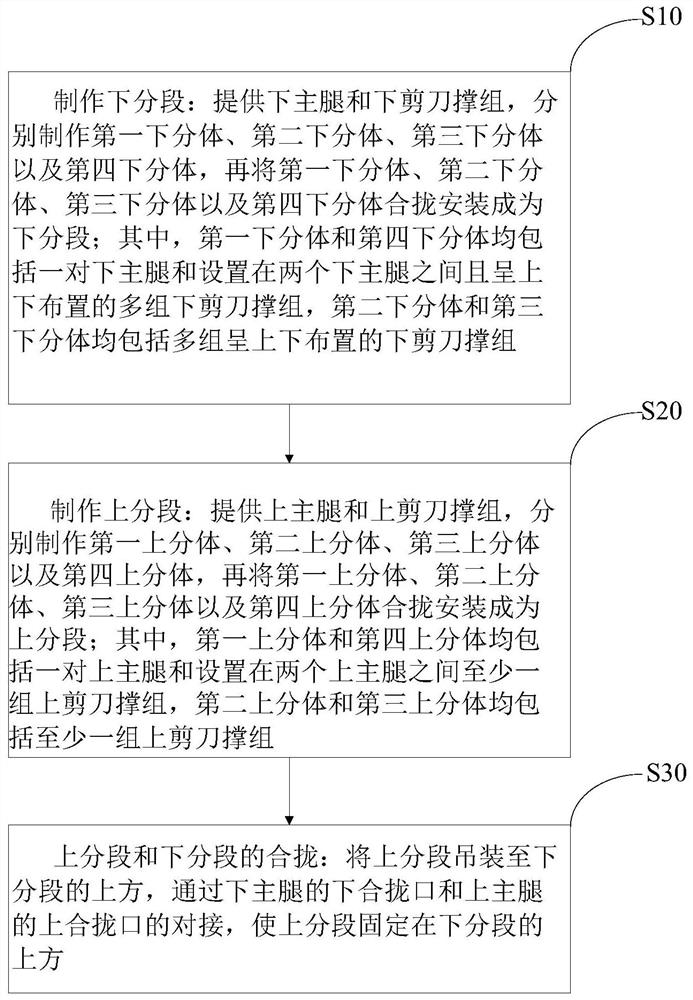

Jacket and jacket construction method

PendingCN112709253AImprove securityReduce site occupancyFoundation engineeringButt jointOffshore construction

The invention provides a jacket and a jacket construction method. The jacket can be divided into an upper segment and a lower segment for segmented manufacturing. After the two segments are manufactured, the two segments are folded and fixed. In the whole construction process, only butt joint operation of an upper folding opening and a lower folding opening exists in high-altitude operation, the high-altitude operation amount is greatly reduced, and the safety of construction operation is improved. Meanwhile, according to the jacket and the jacket construction method, the turnover operation of the segments is avoided, and the jacket can be positioned in advance according to offshore construction and transportation requirements. In addition, the upper segment and the lower segment of the jacket can be constructed and constructed at the same time, the site occupation of raw materials can be reduced, time can be saved, the project manufacturing period can be shortened, and the production efficiency can be improved.

Owner:烟台铁中宝钢铁加工有限公司 +1

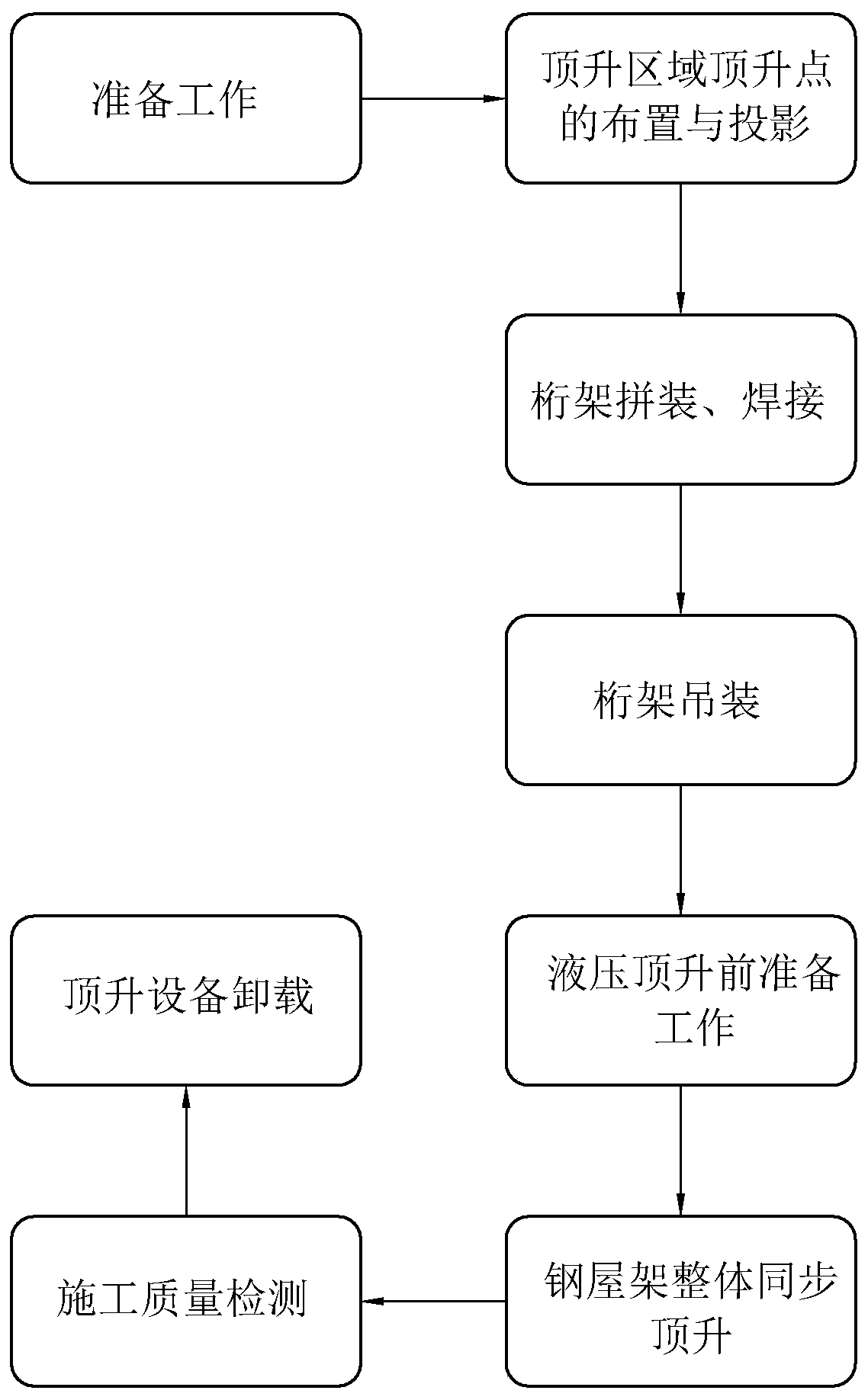

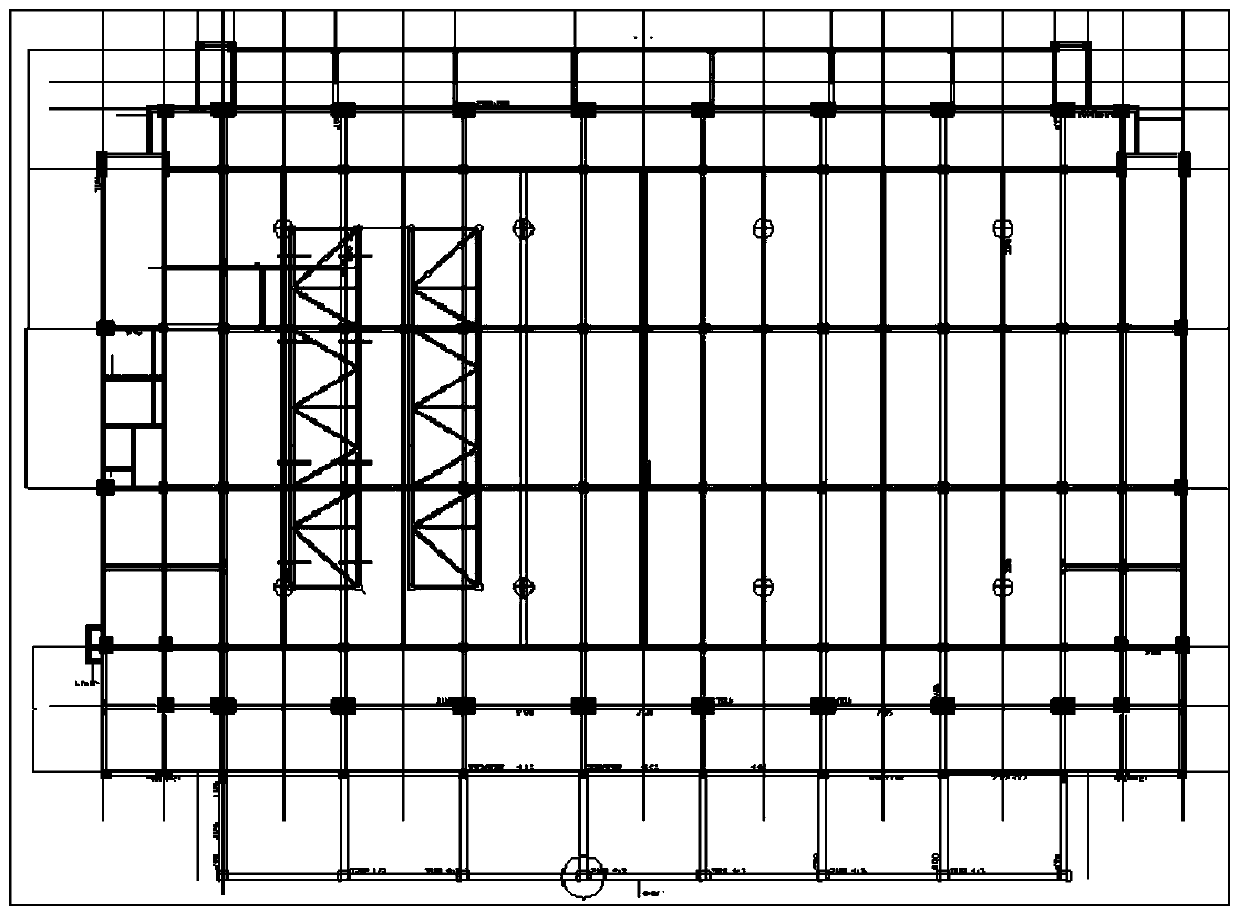

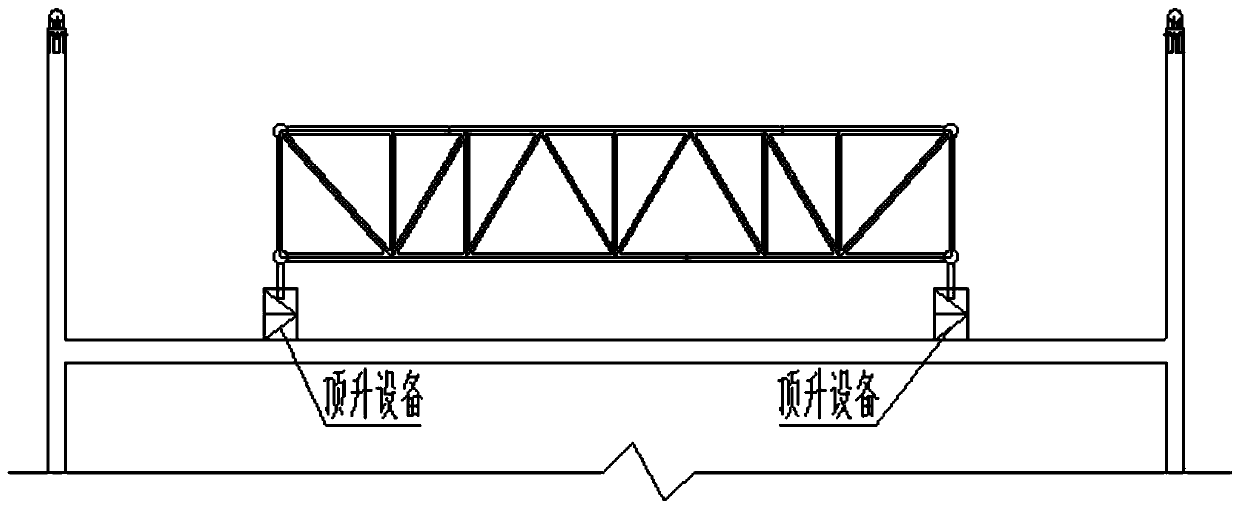

Synchronous jacking construction method for large-span steel roof truss by multiple hydraulic equipment

InactiveCN110185151AThe construction process takes less timeShorten the construction periodBuilding constructionsArchitectural engineeringHydraulic equipment

The invention discloses a synchronous jacking construction method for a large-span steel roof truss by multiple hydraulic equipment, and relates to the technical field of building construction. The synchronous jacking construction method comprises the following steps of arrangement and projection of jacking points of a jacking area, truss assembly, welding, truss lifting, preparation work before hydraulic jacking, steel roof truss overall synchronous jacking, construction quality inspection and jacking equipment unloading; and through the synchronous jacking construction method, the large-spansteel roof truss is simultaneously jacked up by the multiple hydraulic equipment, and the effects of shortening the construction period of the entire long-span steel roof truss, improving construction safety and construction quality and reducing construction cost are achieved.

Owner:SANJIAN CONSTR ENG GROUP

Lifting and installation method of high curved-surface net racks

ActiveCN104060836AMeet the mechanicsFulfil requirementsBuilding material handlingMechanical equipmentEngineering

The invention relates to high curved-surface net racks, particularly to a lifting and installation method of high curved-surface net racks, which can be applied in building steel structures. The lifting and installation method proceeds according to the processes of a lifting preparation stage and a lifting stage. According to the lifting and installation method of high curved-surface net racks, the structure is compact, the requirements for mechanical equipment is low, the construction efficiency is improved, the construction cost is reduced, and the construction safety is improved.

Owner:浙江东南网架股份有限公司

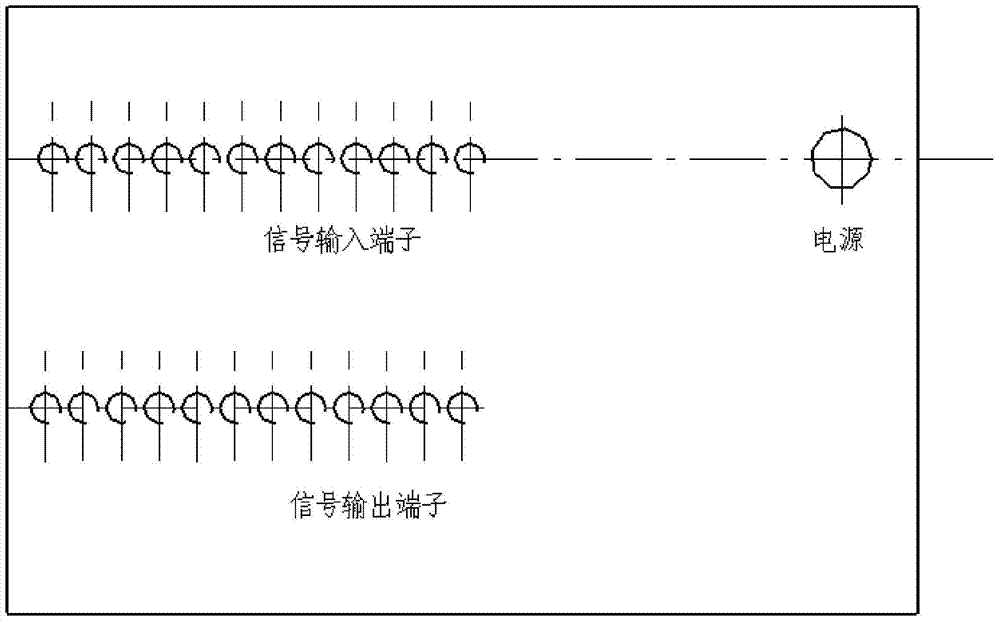

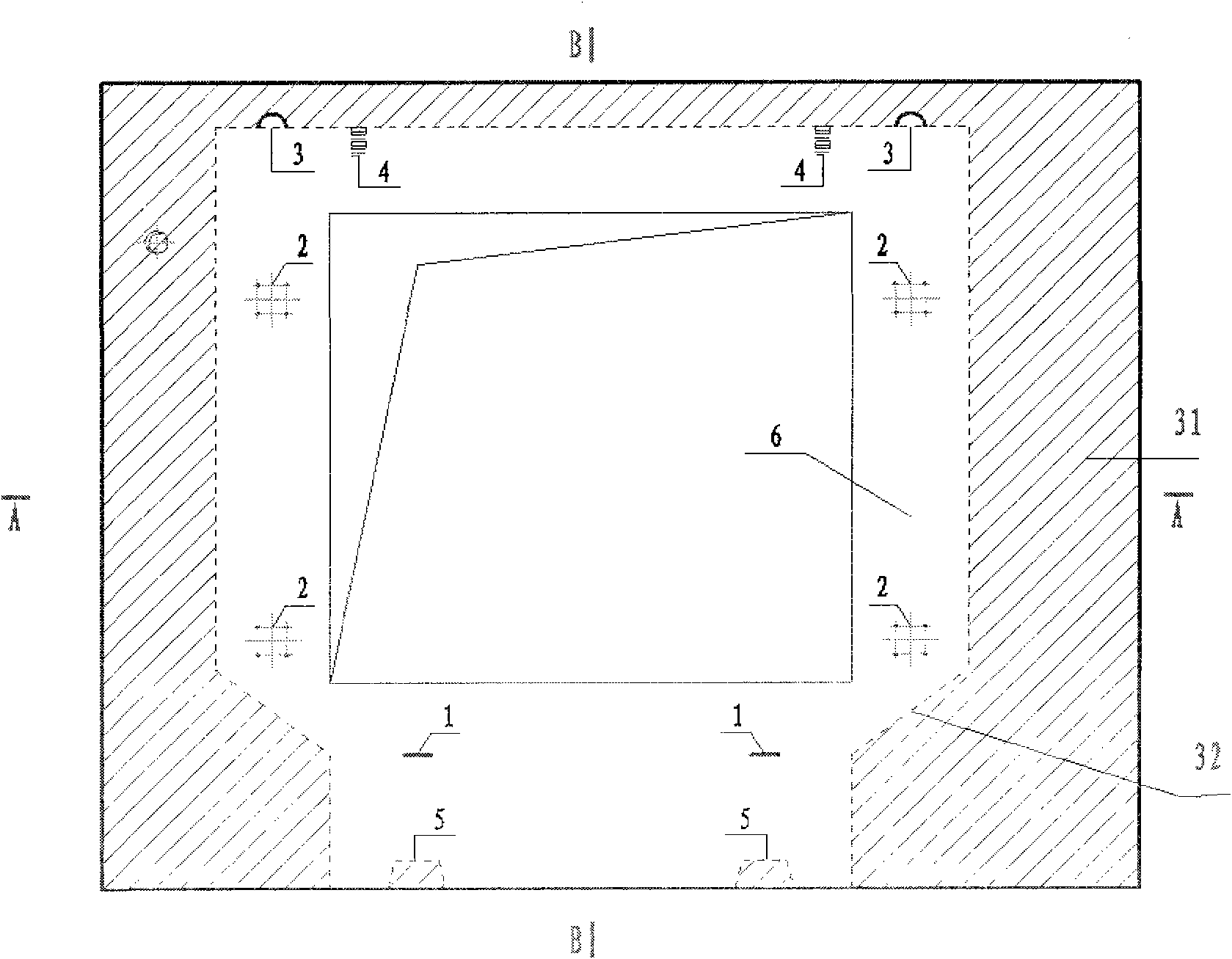

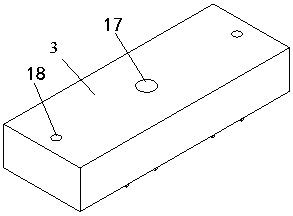

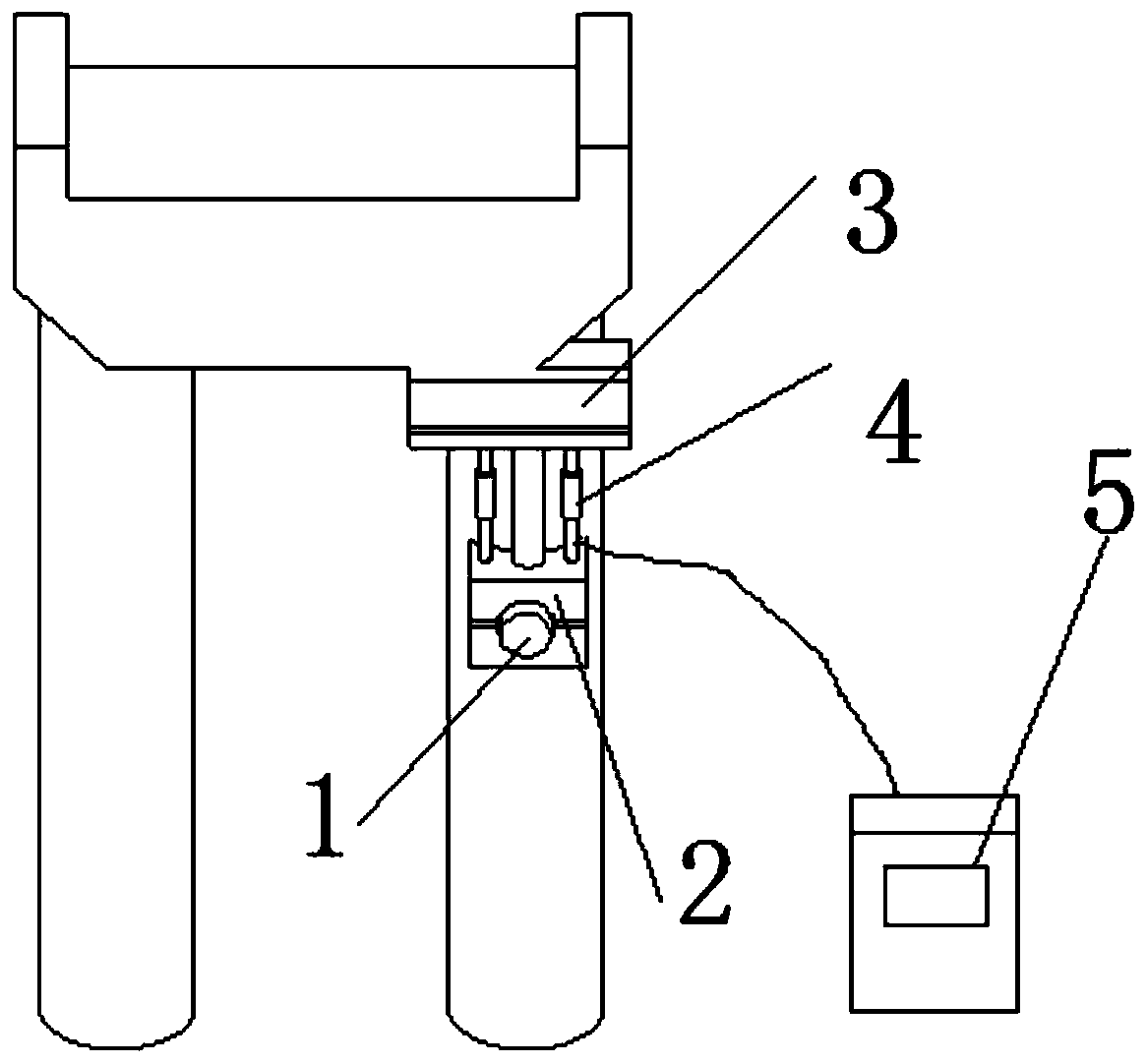

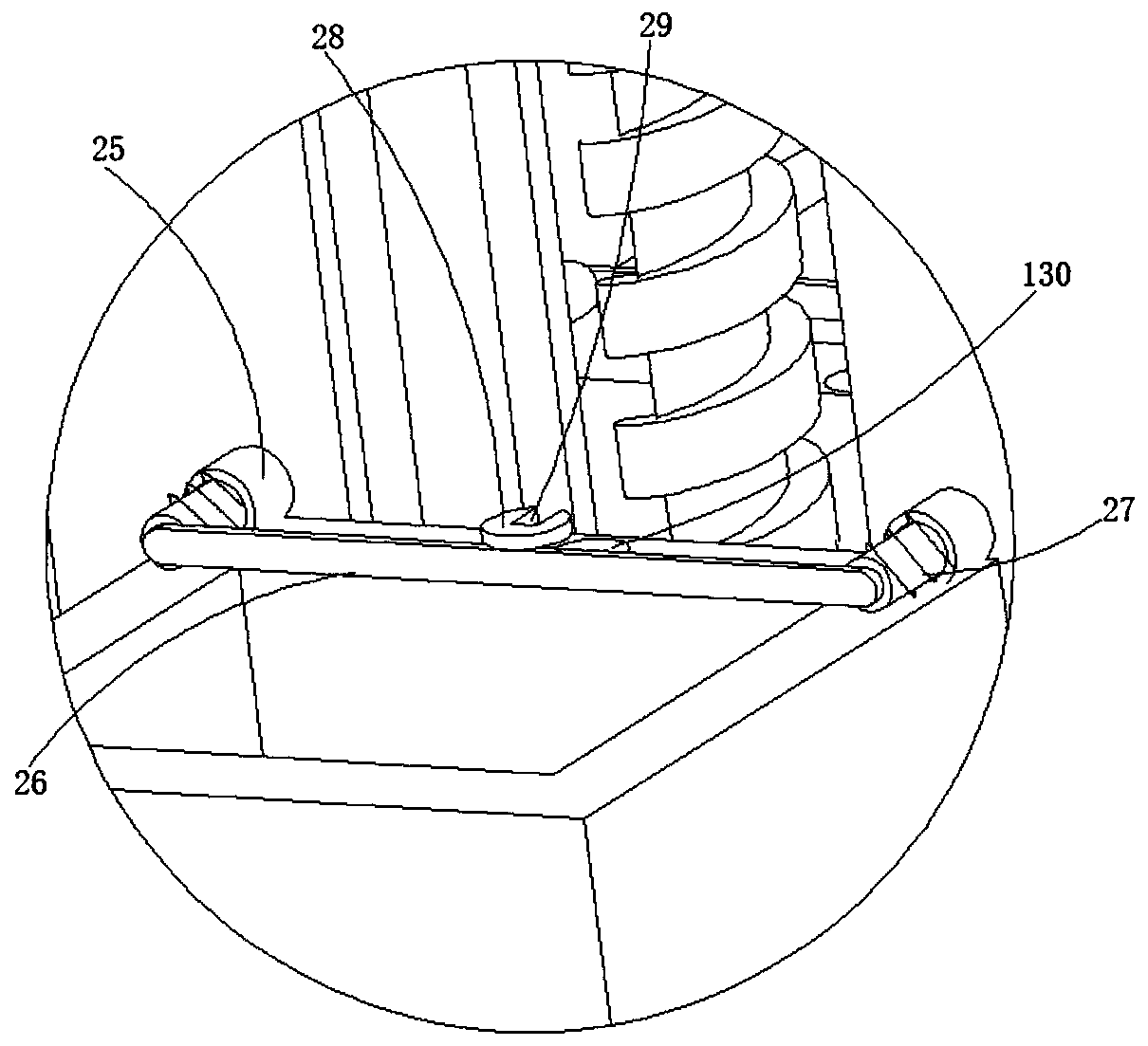

Bent cap supporting safety system

PendingCN111335170AEasy to adjust longitudinal slopePrevent excessive displacementBridge erection/assemblyElectrical connectionSteel bar

The invention discloses a bent cap supporting safety system. The device comprises a steel bar (1), supporting platform (2), i-shaped steel (3), a support adjusting device (4), logic controller (5), wherein the steel bar (1) comprises a front half part (11) and a rear half part (12); the rear half part (12) is pre-buried in the side surface of the pier and penetrates through the axis of the pier; the supporting platform (2) is tightly attached to the side surface of a pier, the front half portion (11) is exposed out of the side surface of the supporting platform (2), the supporting adjusting device (4) is arranged on the upper surface of the supporting platform (2), the I-shaped steel (3) is arranged on the upper surface of the supporting adjusting device (4), and the logic controller (5) is electrically connected with the supporting adjusting device (4). A supporting adjusting system is arranged, automatic synchronous adjustment is achieved, and high-altitude operation is reduced; thelongitudinal gradient is convenient to adjust by adopting the adjusting rod; after the cover plate template is installed, data collection is carried out in real time, and an alarm is given at the first time when a settlement problem occurs.

Owner:中铁北京工程局集团北京有限公司 +1

Large-span combined type overload eccentric slope angle steel structure integrated synchronous jacking construction method

ActiveCN110820950AReduced ground assembly heightGuaranteed installation qualityLifting framesBuilding constructionsButtressArchitectural engineering

The invention discloses a large-span combined type overload eccentric slope angle steel structure integrated synchronous jacking construction method. The method comprises the following steps that 1, acorresponding number of jacking foundations are constructed on a terrace according to a plurality of set jacking point locations; 2, after the terrace is hardened, ground splicing and acceptance inspection of combined steel structures are performed; 3, jacking equipment is installed, and jacking is performed; 3.1, ground assembling of crossed joists is performed on the multiple set jacking pointlocations; 3.2, the crossed joists are lifted to the positions of net rack upper chord balls; 3.3, hemispherical hinged supports are concentrically welded to the bottoms of the crossed joists; 3.4, the combined steel structures achieve supporting conversion from net rack lower chord balls supported by buttresses to the net rack upper chord balls supported by jacking frames through a jack; 3.5, synchronous jacking is performed; 3.6, supplementing and splicing installing of net rack support position balls and connecting rod pieces thereof can be performed, and then the whole structure falls backin position. Overhead operation can be greatly reduced, and safety and reliability are achieved.

Owner:中建六局第一建设有限公司 +1

Construction method for large-span overhung ultra-limit structure

ActiveCN106013453ASolve the problem that cannot be builtReduce security risksBuilding constructionsArchitectural engineeringTower

The invention discloses a construction method for a large-span overhung ultra-limit structure. The method includes the following steps that 1, construction unit classification is carried out on the ultra-limit structure, wherein the internal part of the structure and a middle strip block of an upper steel structure of the overhung part of the structure are classified as a first construction unit, and the rest part of the overhung part is classified as a second construction unit; 2, construction of the first construction unit is completed on a tower floorboard through a high-altitude assembly method and a cantilever installation method; 3, construction of the second construction unit is completed through integral lifting and slipping after integral lifting. According to the method, the multiple technologies of high-altitude assembly, integral lifting, slipping after integral lifting and the like are adopted, labor time is shortened, material expense and equipment expense are reduced, and the requirement for integral control over the construction technology, quality, safety, progress, cost and the like is met.

Owner:中建六局第一建设有限公司 +1

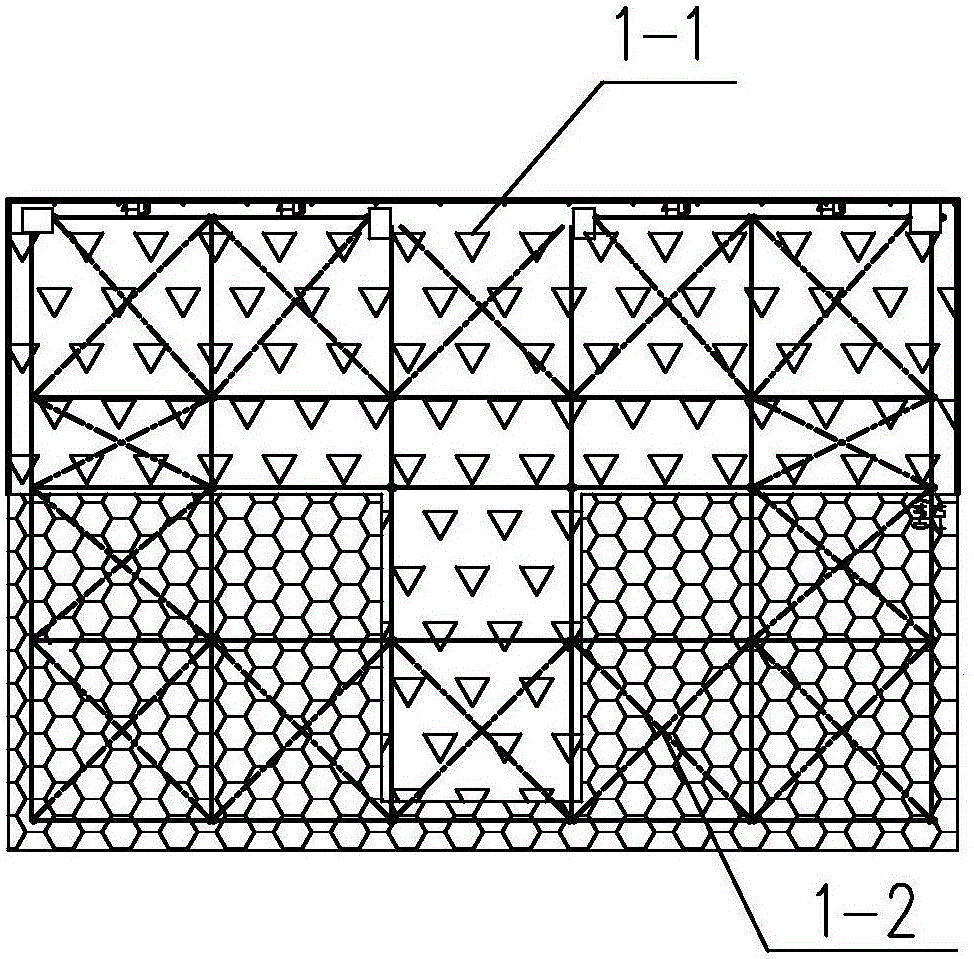

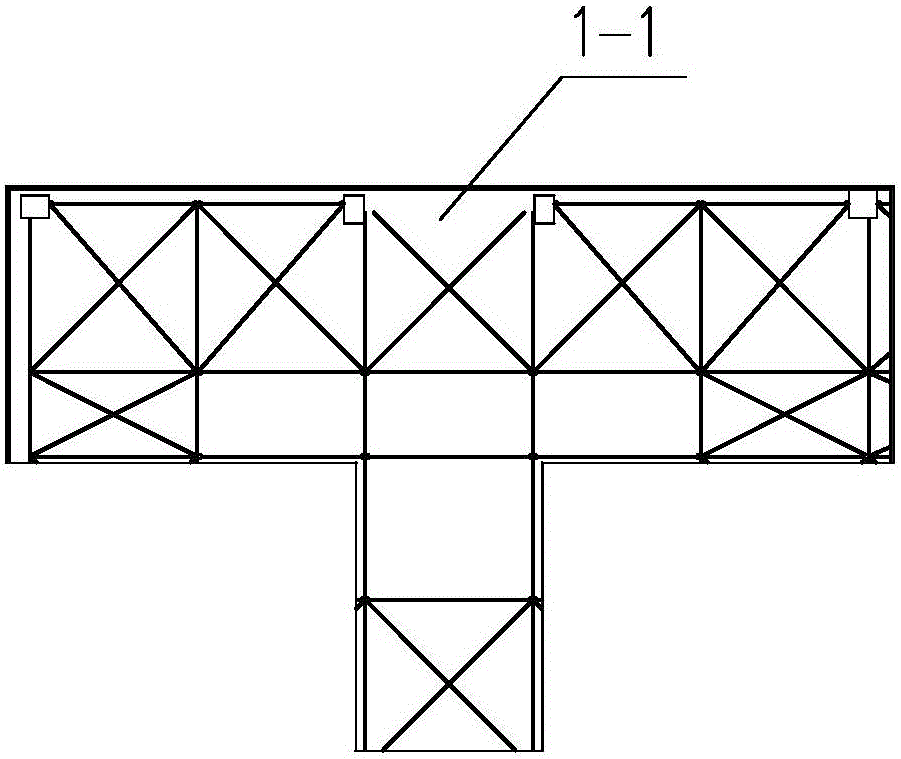

Hoisting method for modular vault-type space tube truss steel structure system building

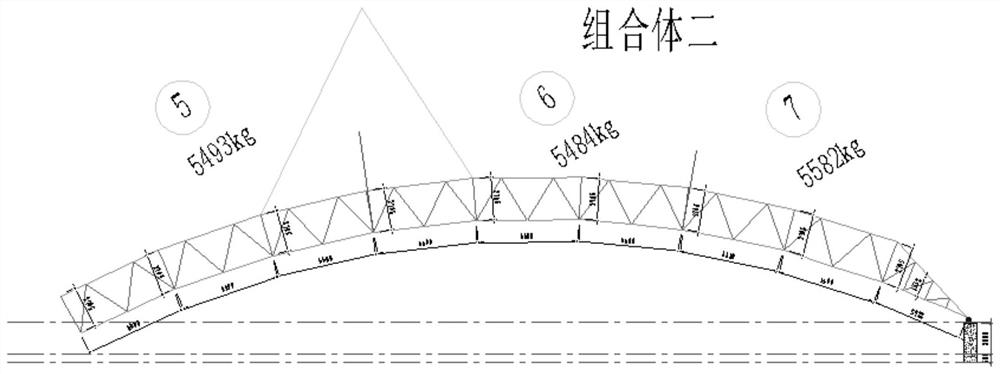

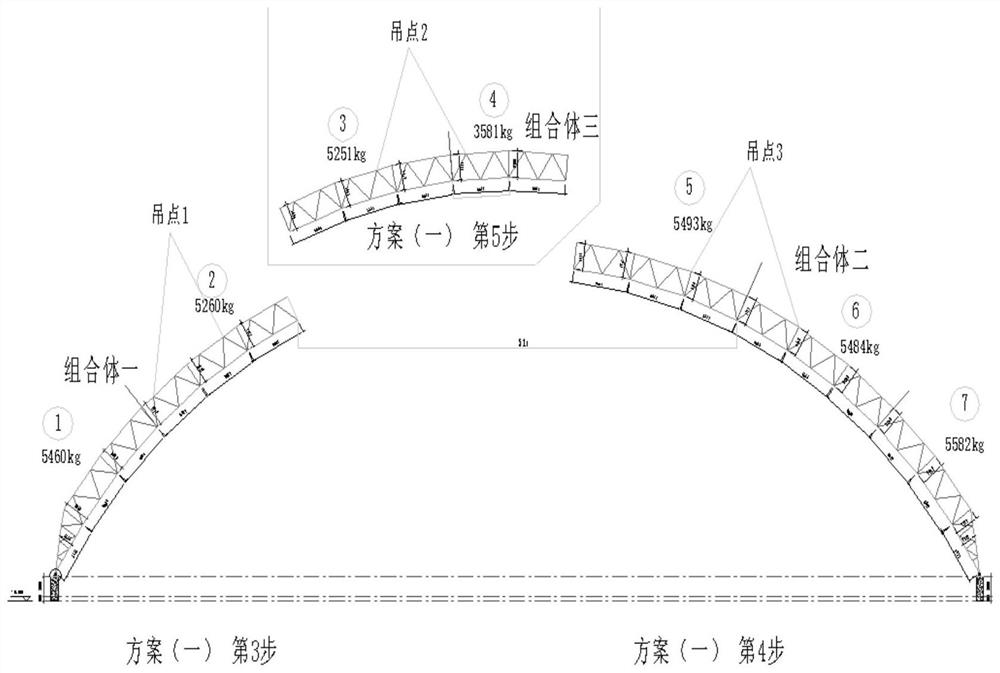

InactiveCN111794529APrecise DimensionsReduce use of shiftsArched girdersPortal framesModular unitArchitectural engineering

The invention belongs to the technical field of steel structure building hoisting methods, and particularly relates to a hoisting method for a modular vault-type space tube truss steel structure system building. A modular unit of two or more steel trusses is divided into combinations with two or three sections, a ground splicing mode is adopted, all modular assemblies with steel structures are assembled into a plurality of unit bodies, then the several unit bodies are spliced into a combination, and a hoisting mode of simultaneous closing of the multiple high-altitude trusses is adopted. The aloft work processes such as truss and tie bar hoisting and high-altitude tie bar screwing and high-strength bolt fastening are reduced, the using machine-team of a crane is greatly reduced, because ofthe hoisting mode of the combinations, the working face is large, after multi-station truss hoisting is completed, the safe stability can be good, boundary dimension deformation of the trusses is small, all hole positions of high-strength bolts can be ensured, and the later bar filling process is facilitated.

Owner:沈阳科维润工程技术有限公司

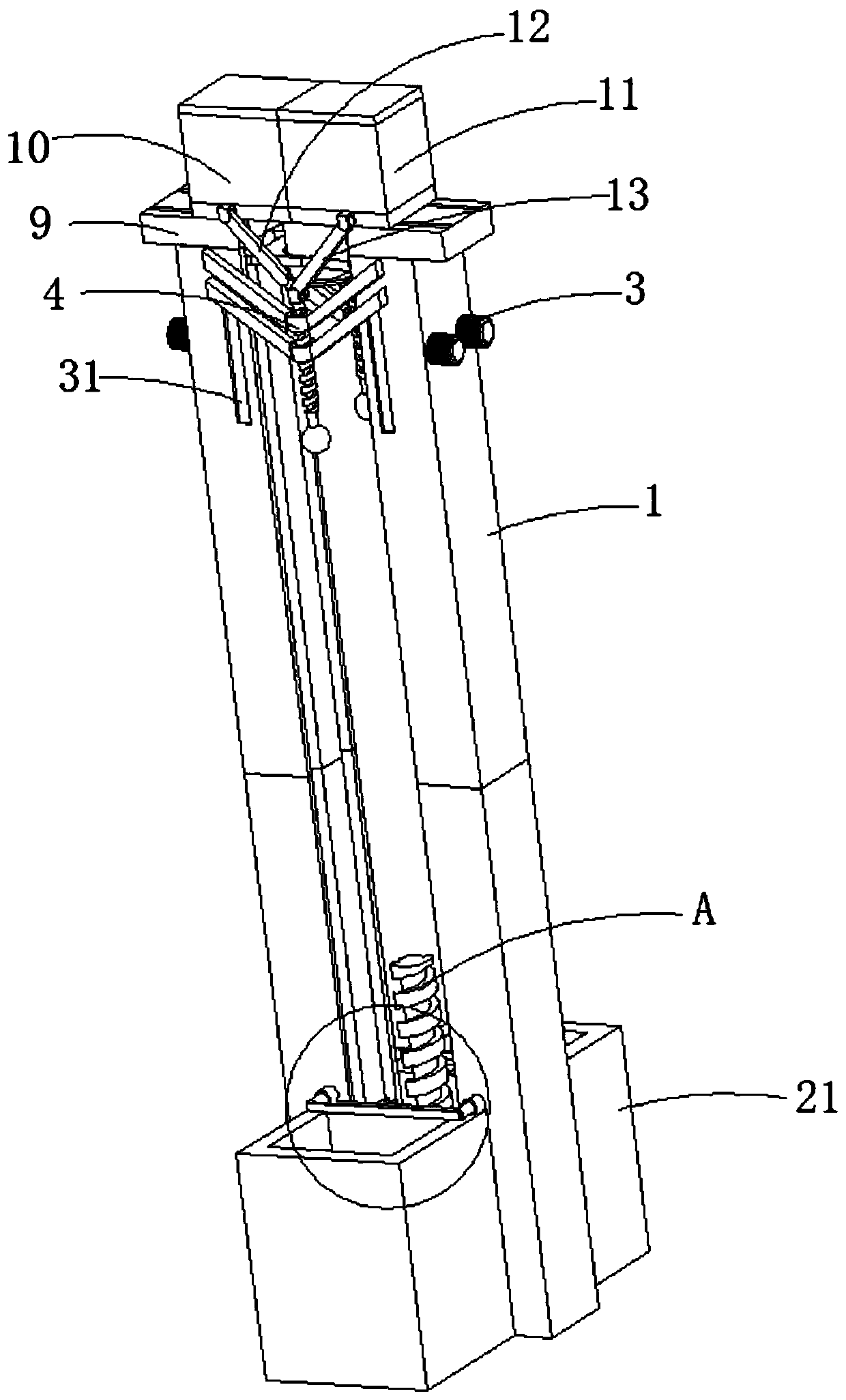

Vertical lifting type communication maintenance equipment

ActiveCN111005614AReduce the amount of work at heightImprove maintenance efficiencyTowersBuilding support scaffoldsElectric machineryDrive motor

The invention discloses vertical lifting type communication maintenance equipment, and belongs to the technical field of communication equipment. The vertical lifting type communication maintenance equipment comprises two oppositely-arranged stand columns, the opposite sides of the two stand columns are slidably connected with a lifting workbench, the top of the lifting workbench is fixedly connected with a first screw, the outer side walls, close to the top ends, of the stand columns are further provided with driving motors, the driving ends of the driving motors are connected with the lifting workbench through mooring ropes, the outer side walls, close to the top ends, of the stand columns are fixedly connected with symmetrically-distributed nut bases through supports, and a second screwis in threaded connection with the interior of each nut base. According to the vertical lifting type communication maintenance equipment, the automatic separation function of an outer communication box in the ascending process of the lifting workbench is achieved, the locking function of alignment embedding of the outer communication box is achieved through the dead weight of an inner communication box, the embedding stability of the outer communication box is improved, the excellent protection performance of the outer communication box is kept, the efficiency of high-altitude disassembling of the damaged communication box is improved, and the danger under high-altitude operation is reduced.

Owner:陕西通信规划设计研究院有限公司

Corridor mounting method and corridor

PendingCN109779007AImprove securityGuaranteed stabilityBuilding material handlingEngineeringBuilding construction

The invention provides a corridor mounting method and a corridor, and relates to the technical field of constructional engineering. The corridor mounting method avoids erecting a large number of supporting measures, saves materials and labor cost, reduces high-altitude operation amount and improves construction safety by means of a construction mode of hoisting components such as a first main rodpiece, a second main rod piece, a vertical structure, a horizontal structure and an inlaying section. Temporary measures such as embedding sections and chain blocks are used, so that the constructionsafety of the corridor steel structure is improved; and finally, the steel structure is unloaded in the installation process, so that the installation stability, the installation precision and the stability after unloading of the steel structure are ensured.

Owner:CHINA CONSTR STEEL STRUCTURE CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com