Large-span truss hydraulic multi-point synchronous lifting construction method

A construction method and synchronous lifting technology, which is applied in the direction of construction and building construction, can solve the problems of heavy workload of assembly operation platform, low reuse rate of tire frame materials, and low construction efficiency of high-altitude operations, so as to reduce high-altitude operations The effect of reducing the quantity, shortening the construction period and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

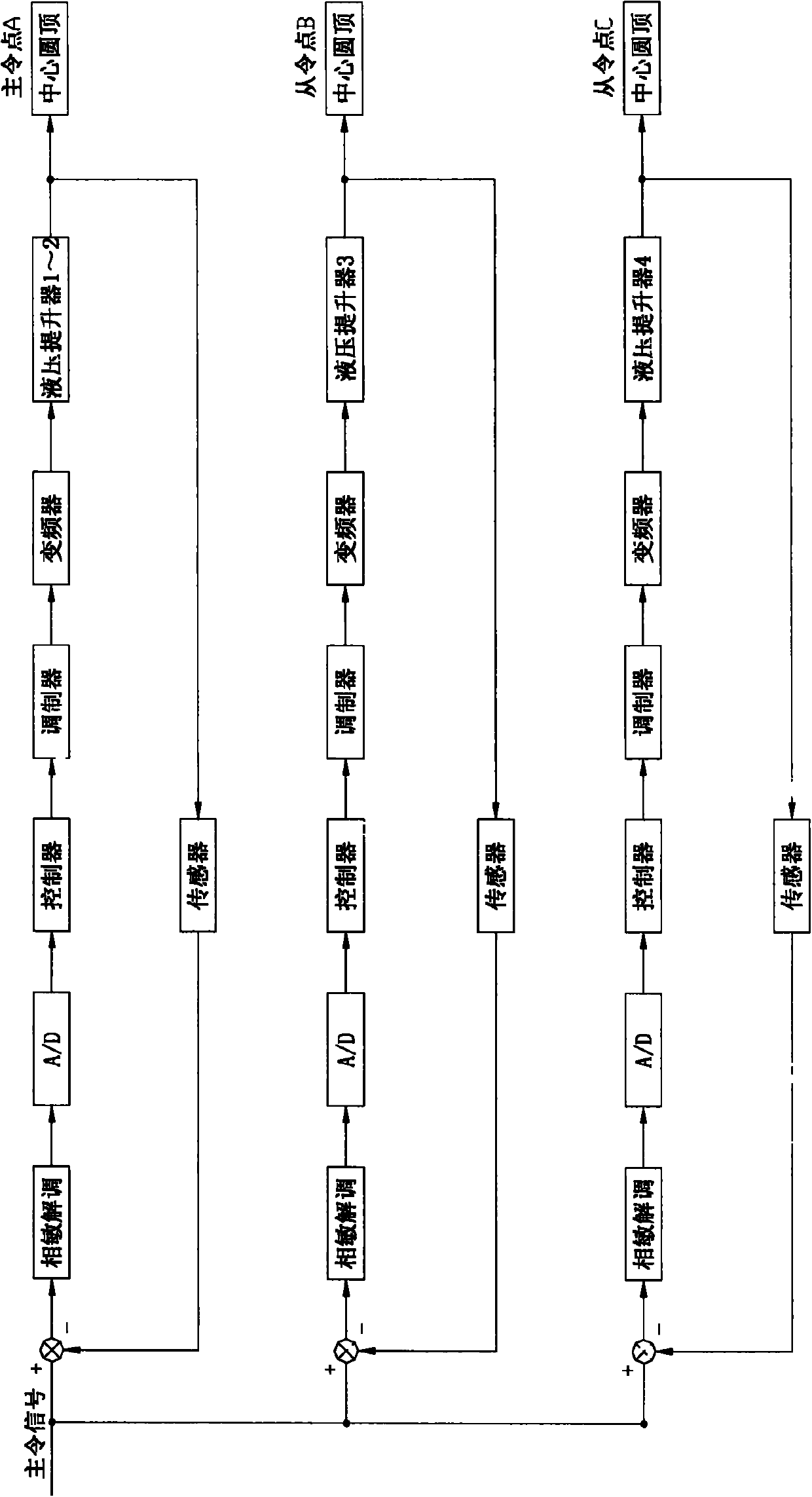

[0069] In this embodiment, the upper anchorage, the lifting cylinder and the lower anchorage are connected from top to bottom on the steel strand, wherein the lifting cylinder is connected with the hydraulic pump station, and a sensor detector is installed on the lifting cylinder, and the hydraulic pump station and The sensor detector is connected with the main control computer.

[0070] In the above, the steel strand and the lifting cylinder are the load-bearing parts of the system, which are used to bear the weight of the lifting component. The number of lifting cylinders is configured according to the lifting weight of the component and the size of the load, and the lifting cylinders in each lifting point can be used in parallel.

[0071] In the above, the hydraulic pump station is the power-driven part of the lifting system, and its performance and reliability have the greatest impact on the stable and reliable operation of the entire lifting system; in the hydraulic syste...

Embodiment 2

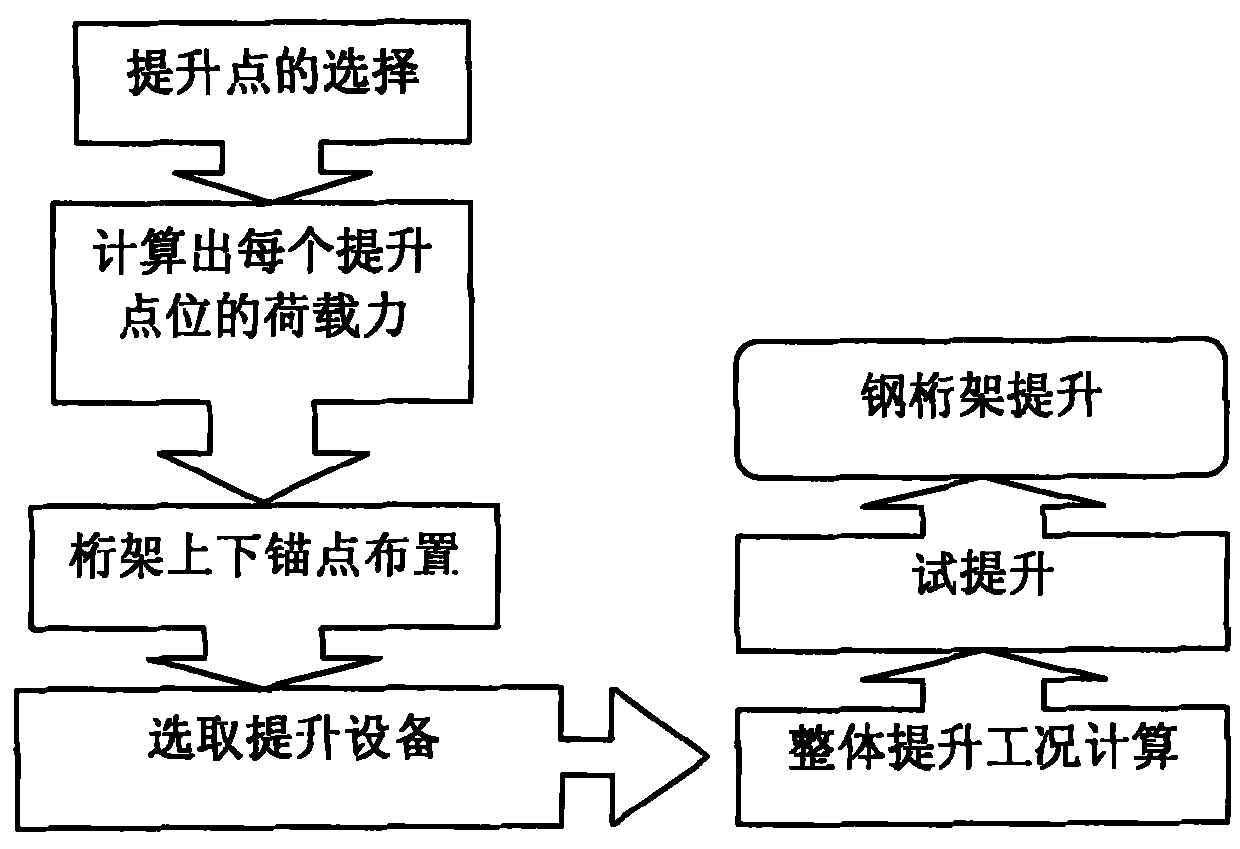

[0104] 1) Overview of truss lifting:

[0105]The roof is installed after the hoisting of the giant trusses, and the overall lifting installation is adopted; the roof is mainly composed of three trusses, a number of steel beams, and diagonal braces. Due to the heavy weight of the trusses in this division, the total weight is about 190t, and the span of C area is about 27.4m, and the installation height is 30m. Combined with the construction conditions on site, the lower part of the roof of this partition is overhead, and the concrete floor below is suitable for in-situ assembly. Therefore, the truss is installed on site after the floor assembly is completed, using a hydraulic lifter for synchronous lifting and installation;

[0106] 2) On-site layout of the hydraulic lifter:

[0107] The roof is lifted as a whole, using 6 hydraulic lifters, and lifting brackets are set on the top of the giant truss, and the trusses assembled on the floor are synchronously lifted into place by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com