Synchronous jacking construction method for large-span steel roof truss by multiple hydraulic equipment

A technology of synchronous jacking and hydraulic equipment, which is applied in the direction of construction and building construction, and can solve the problems of poor safety guarantee, poor safety guarantee of construction personnel, and high cost of renting scaffolding. , to achieve the effect of reducing human error, saving construction period and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] With reference to the accompanying drawings, the construction method for synchronous jacking of multiple hydraulic equipment for long-span steel roof trusses will be further explained.

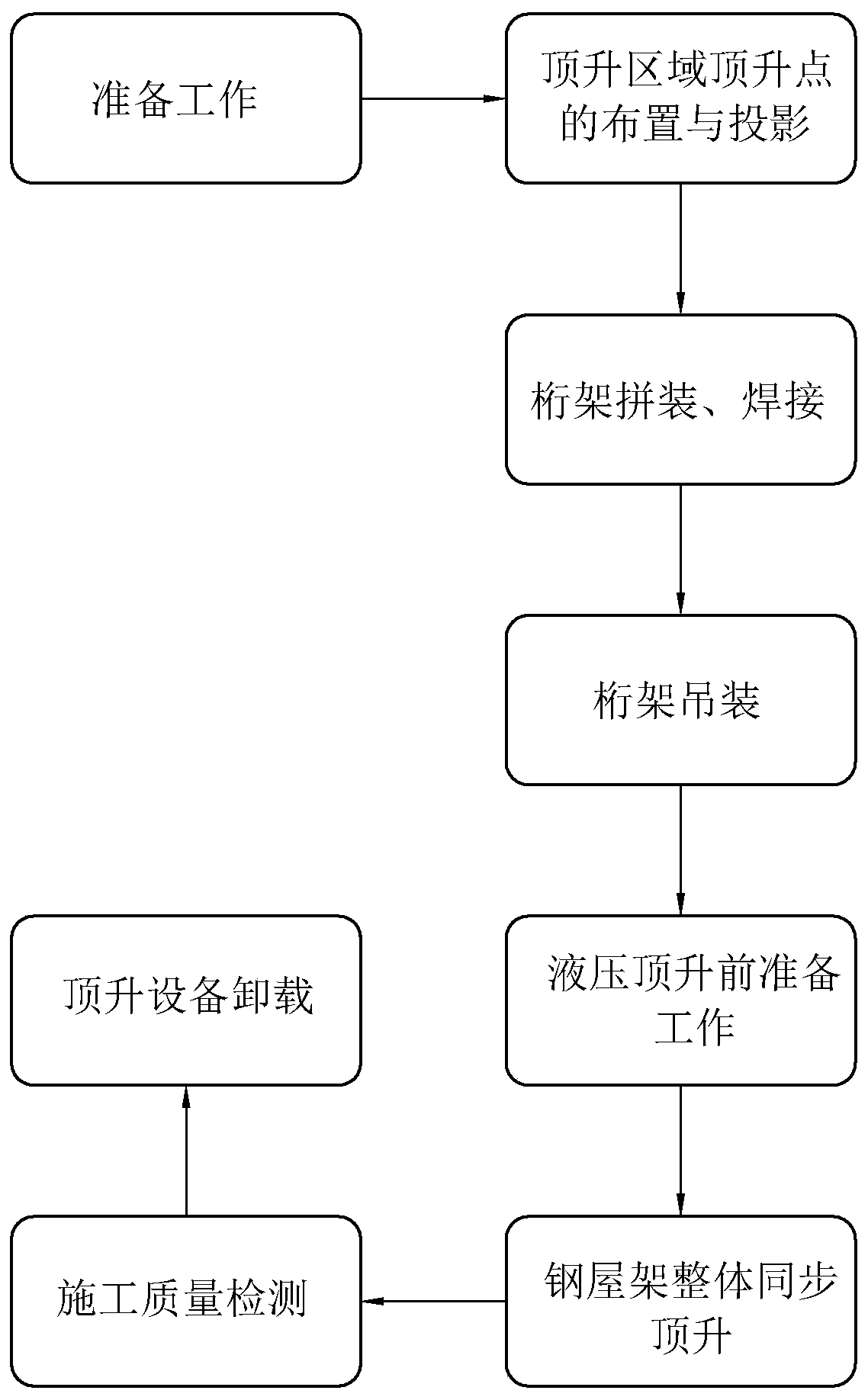

[0035] A construction method for synchronous jacking up of multiple hydraulic equipment for large-span steel roof trusses, combining figure 1 shown, including the following steps:

[0036] Preparatory work: Check the steel roof truss materials entering the project site. The balls and rods are required to be sorted and stacked. The components in different parts are labeled and distinguished. If necessary, their processing dimensions should be checked to ensure the accuracy of construction and installation.

[0037] 1. Layout and projection of jacking points in the jacking area

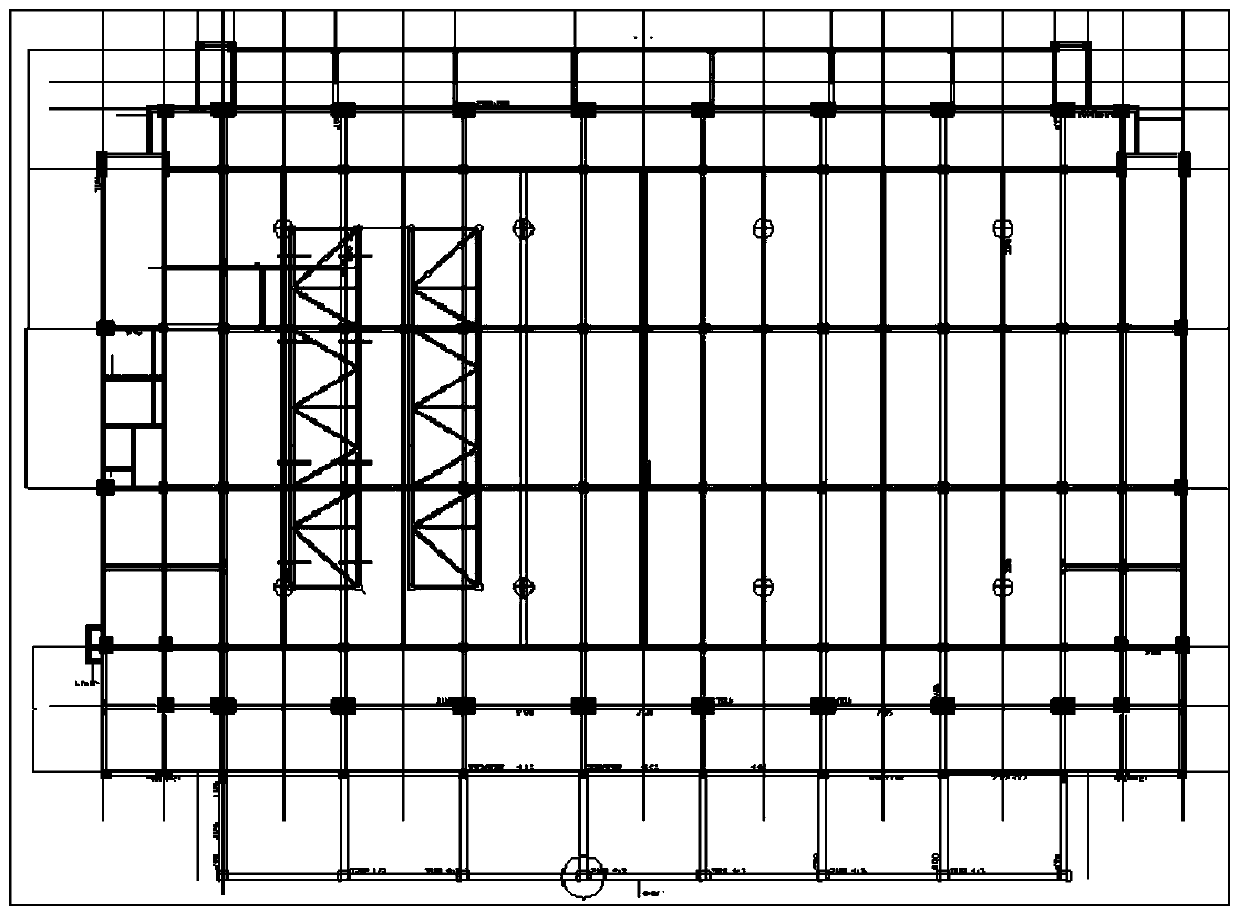

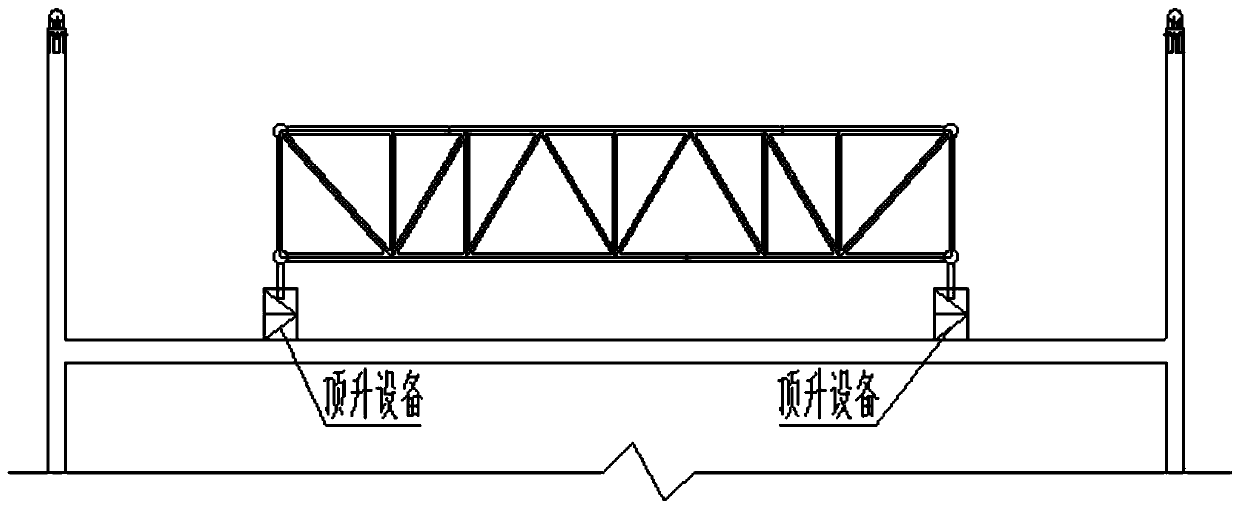

[0038] Mark the jacking position of the main truss of the steel roof truss on the ground level of the jacking site with horizontal projection, and hoist the steel roof truss members on the same plane; assemble t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com