Corridor mounting method and corridor

An installation method and corridor technology, which can be applied in construction, building structure, construction material processing, etc., can solve the problems of high cost and poor installation safety of corridors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

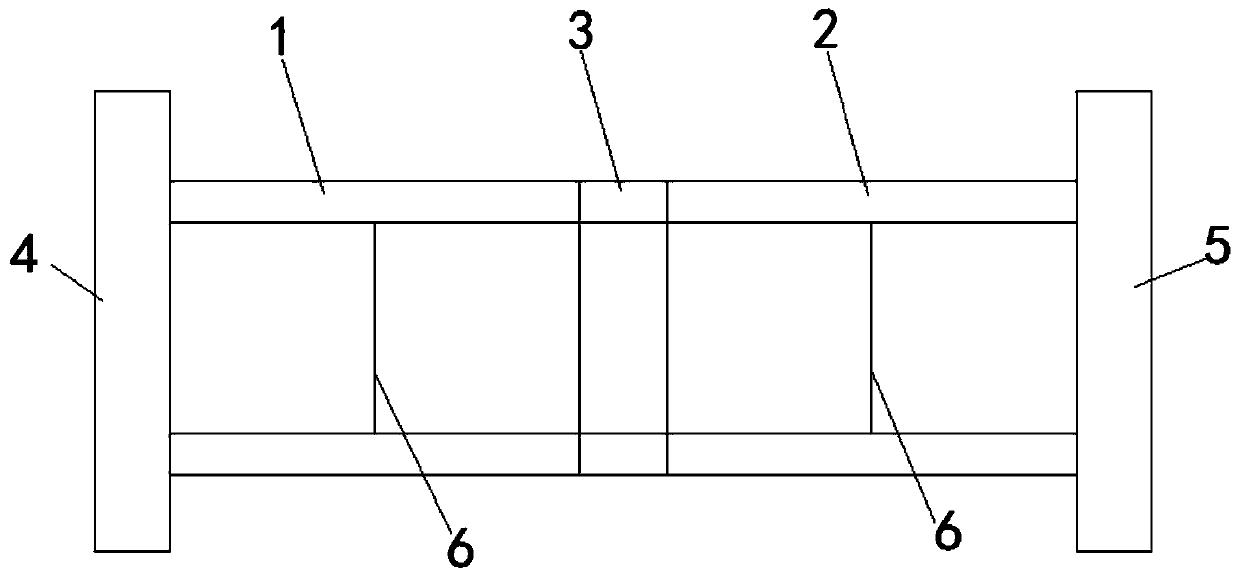

[0041] The corridor installation method provided by this embodiment, such as Figure 1 to Figure 4 shown, including the following steps:

[0042] Install the first main rods 1: hoist the two first main rods 1 to the preset position and fix them with the first building 4, and fix the two first main rods 1 by cable-staying. A horizontal structure is installed between the main rods 1 to form a frame structure;

[0043] Install the second main rod 2: hoist the two second main rods 2 to the preset position and fix them with the second building 5, and fix the two second main rods 2 by cable-staying;

[0044] Install the interlocking section 3: hoist the interlocking section 3 between the first main pole 1 and the second main pole 2, so that the two ends of the interlocking section 3 are respectively connected to the first main pole 1 and the second main pole Piece 2 fixed;

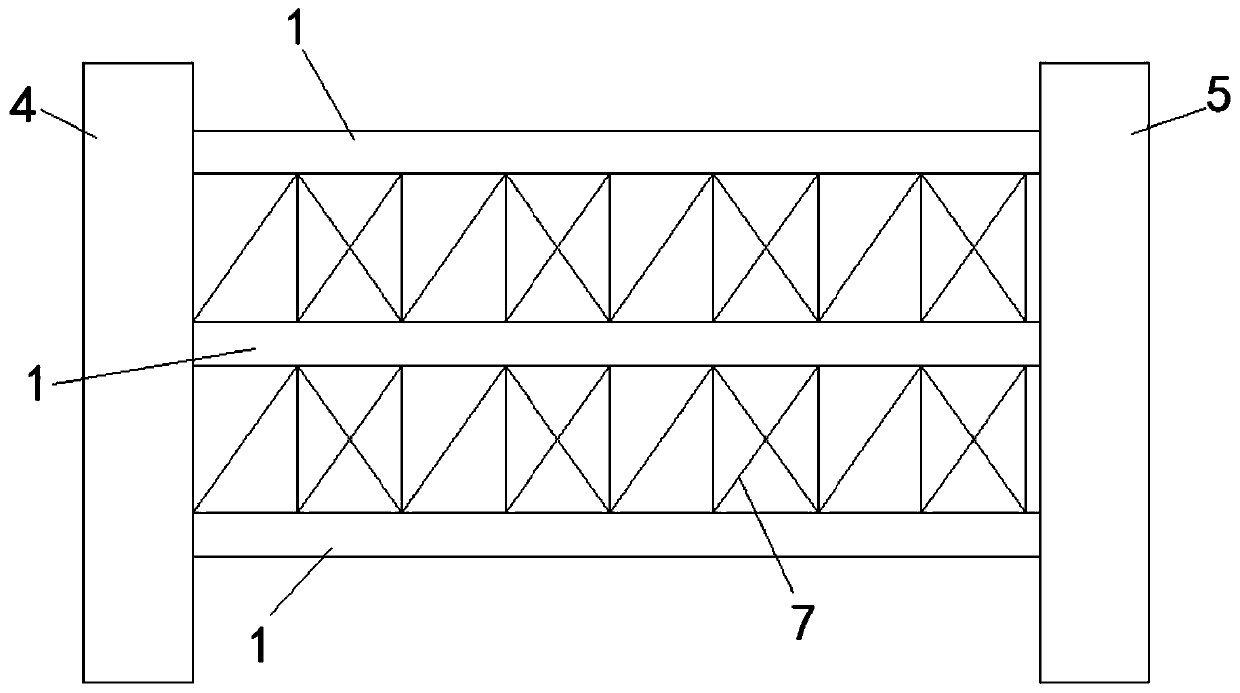

[0045] Install the vertical structure 7 and the horizontal structure: hoist and install the vertical struc...

Embodiment 2

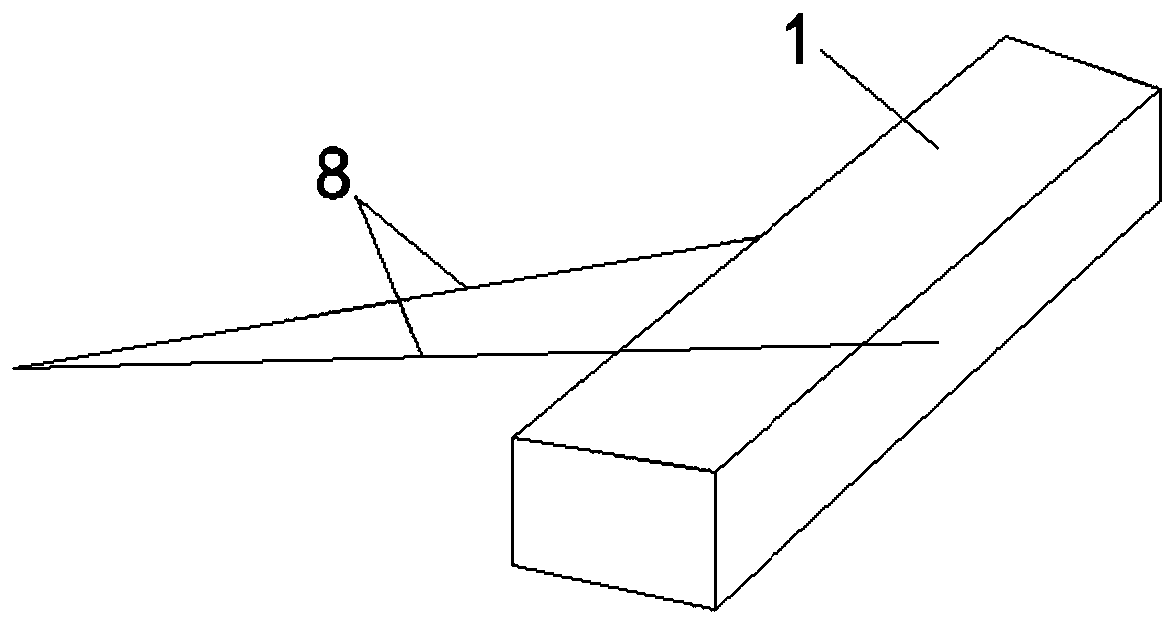

[0077] The corridor provided in this embodiment is manufactured by using the corridor installation method provided in Embodiment 1. By hoisting the first main rod 1, the second main rod 2, the vertical structure 7, the horizontal structure and the interlocking section 3 and other components, it avoids setting up a large number of support measures, saves material and labor costs, and reduces The amount of high-altitude work is reduced, which improves the safety of the construction; the use of temporary measures such as the embedded section 3 and the inverted chain 8 improves the construction safety of the steel structure of the corridor; unloading at the end of the installation process ensures the stability of the steel structure installation , installation accuracy and stability after unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com