Installation and construction method of mechanical grate type waste incineration boiler

A construction method and mechanical grate technology, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve problems such as improper selection of auxiliary tools, prolonging the construction period, and increasing project costs, so as to reduce the amount of high-altitude operations and ensure construction quality , The effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

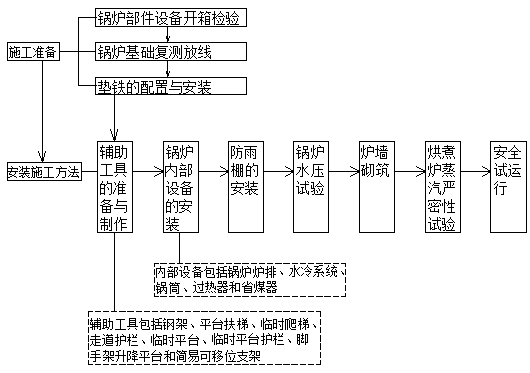

[0042] Example: see figure 1 , a mechanical grate type waste incineration boiler installation and construction method, the specific steps are as follows:

[0043] Construction preparation:

[0044] 1) Unpacking inspection of boiler components and equipment:

[0045] According to the packing list, verify the arrival quantity and specifications of the equipment and accessories, check the defects in the manufacturing and transportation process of the equipment, and make corrections and repairs; the received equipment and materials should be stored in separate warehouses and partitions according to the storage level to ensure that the equipment and material intact.

[0046] 2) Boiler foundation retest and set-out:

[0047] Recheck the foundation according to the foundation acceptance record, check the positioning axis and the standard point of the factory building, and select the vertical and horizontal datum lines and elevations of the benchmark steel frame for laying out acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com