Patents

Literature

81 results about "Waste-to-energy plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A waste-to-energy plant is a waste management facility that combusts wastes to produce electricity. This type of power plant is sometimes called a trash-to-energy, municipal waste incineration, energy recovery, or resource recovery plant.

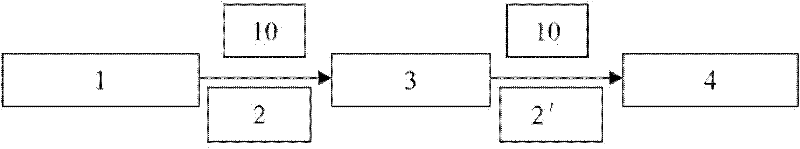

Multiple-target operation optimizing and coordinating control method and device of garbage power generator

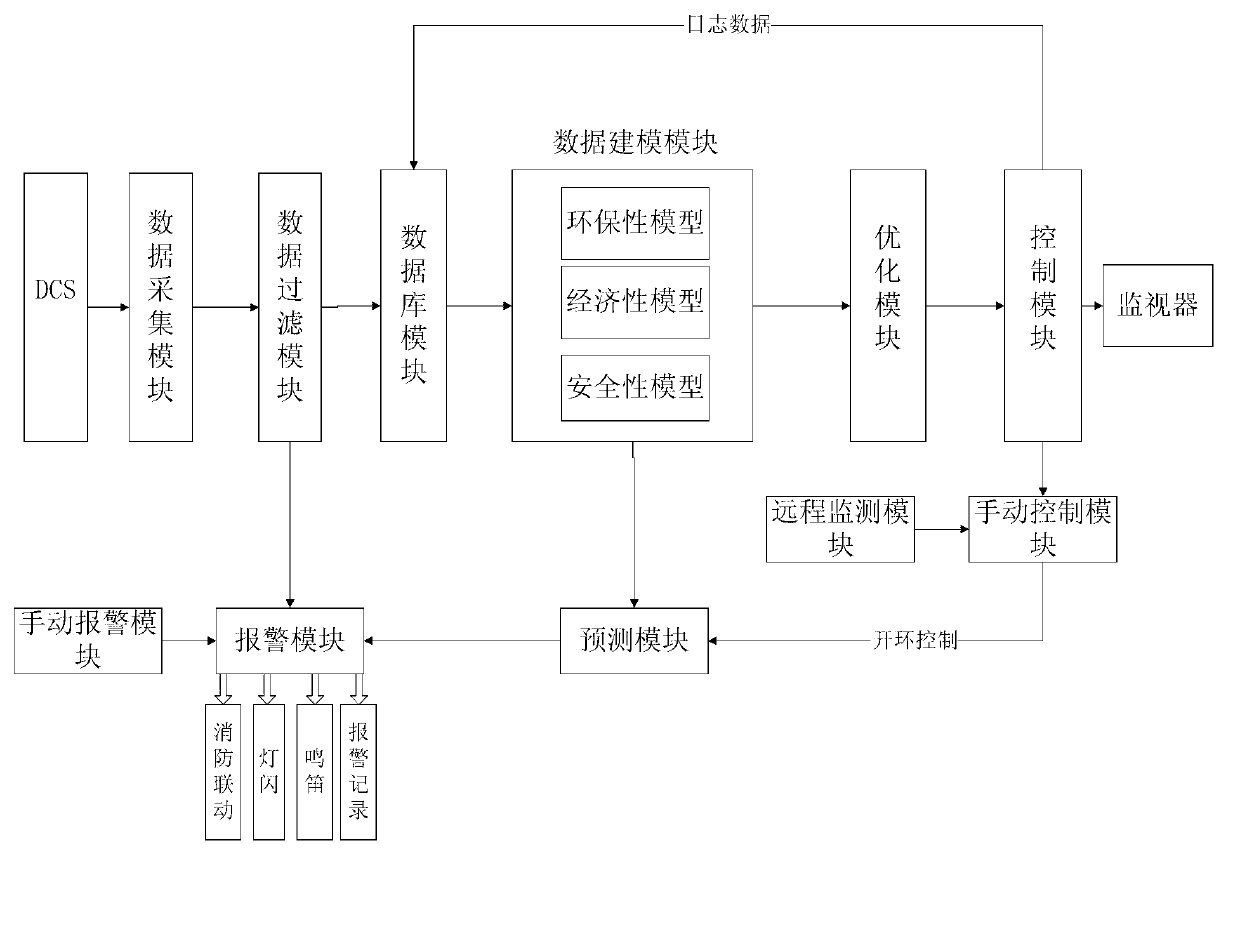

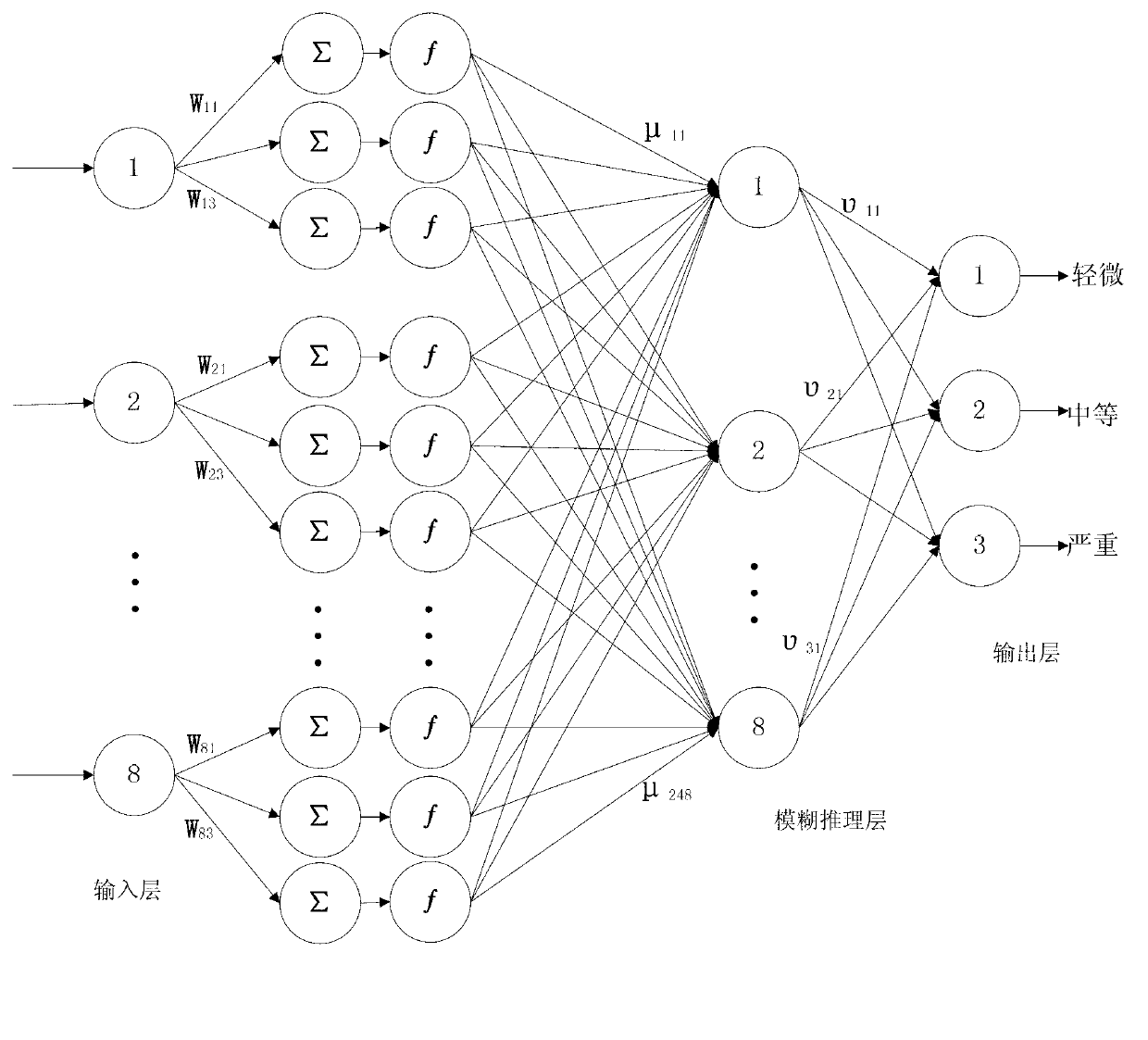

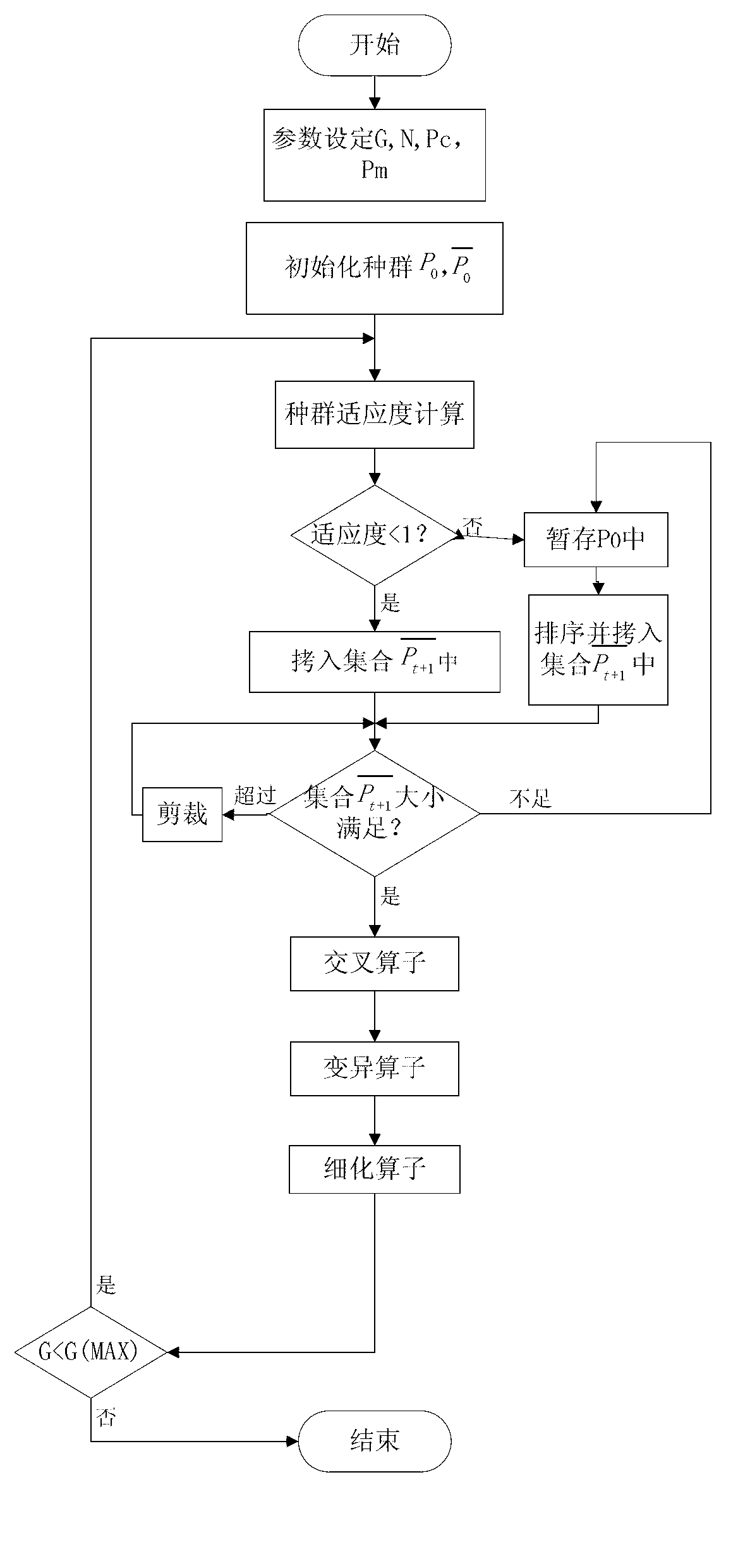

The invention provides a multiple-target operation optimizing and coordinating control method and a device of a garbage power generator. The multiple-target operation optimizing and coordinating control method includes the following steps. Operational parameters are downloaded from a data communication system (DCS), data judged as reasonable based on a threshold value are transmitted to a database. In terms of environmental protection, economy and safety of the power generator, three models are respectively set up by means of a support vector machine and a fuzzy neural network. A modified strength PARETO genetic algorithm is used for comprehensively optimizing multiple targets and then optimum operation parameters under the present working condition are worked out. Operational staff can adjust operation of corresponding parts based on the optimum operation parameters. The device comprises a data collecting module, a data filtering module, a database module, a data modeling module, an optimizing module, a forecasting module, a remote monitoring module, a monitor, an alarming module and a manual alarming module. The multiple-target operation optimizing and coordinating control method and the device of the garbage power generator achieve multiple functions of real-time forecasting, offline simulation, dynamic optimizing and the like and have the advantages of being strong in adaptability, good in self-learning ability, high in fitting precision, obvious in optimizing effect and the like.

Owner:SOUTH CHINA UNIV OF TECH

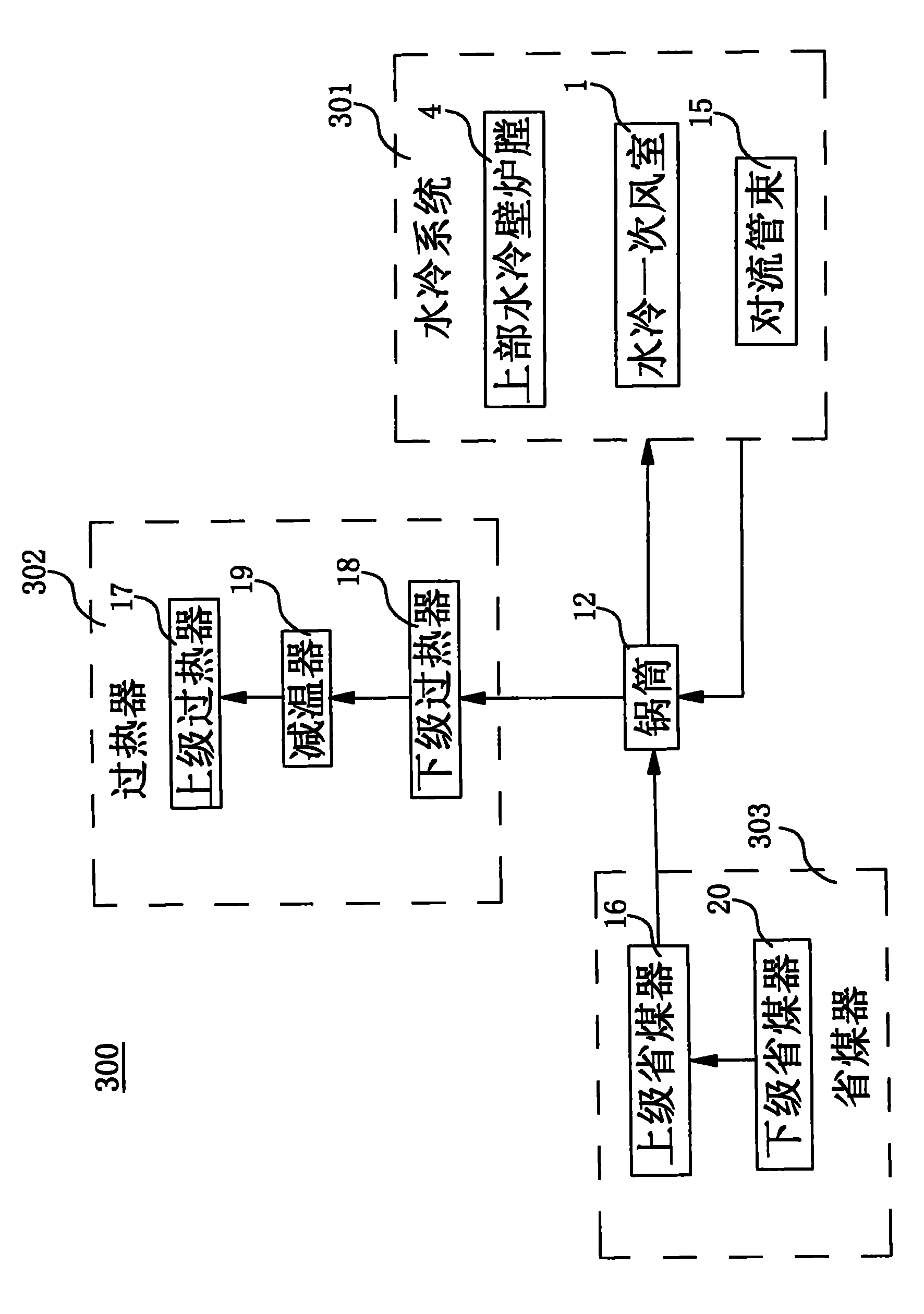

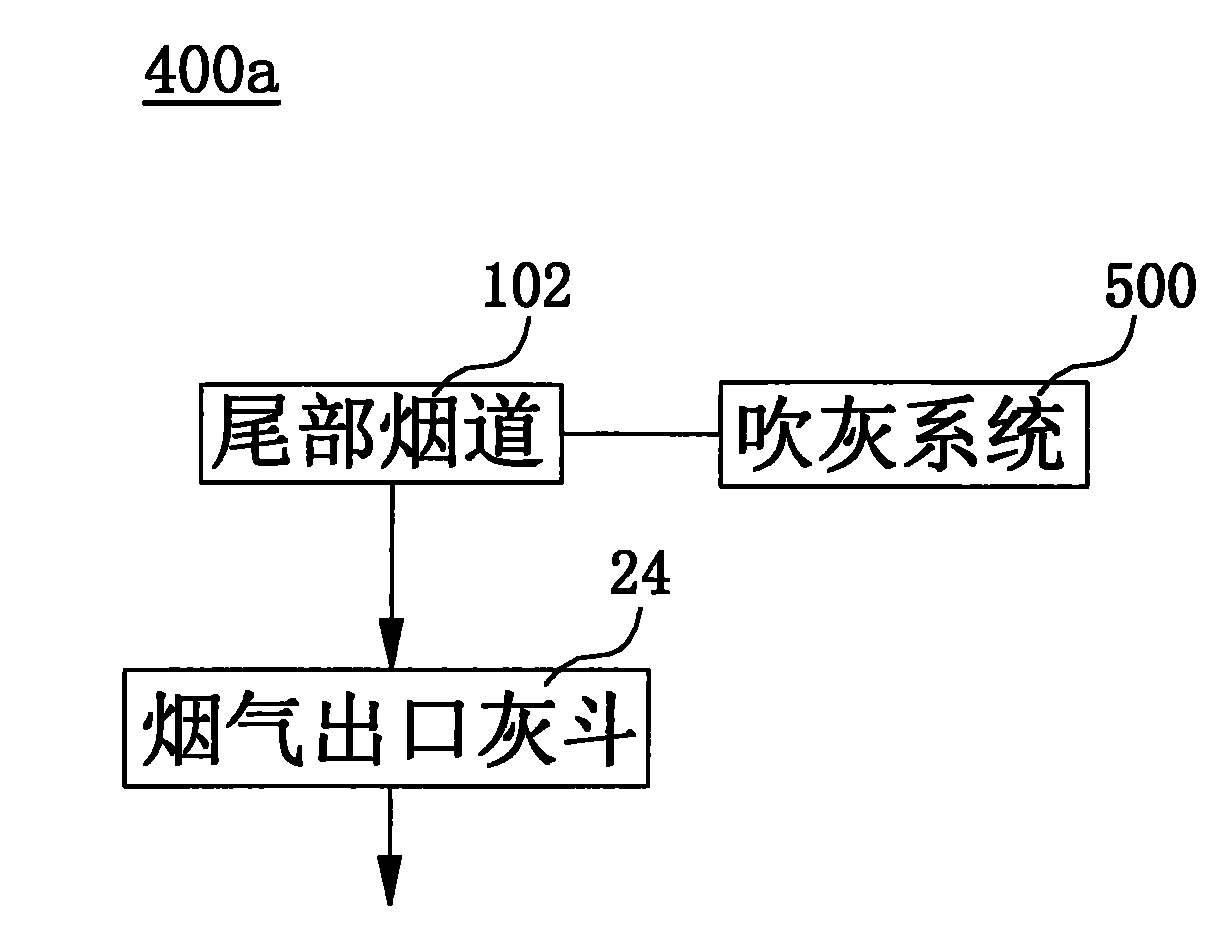

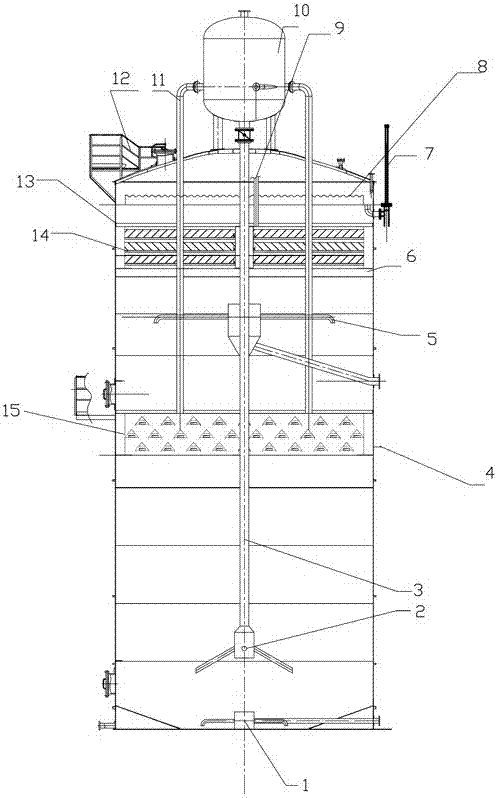

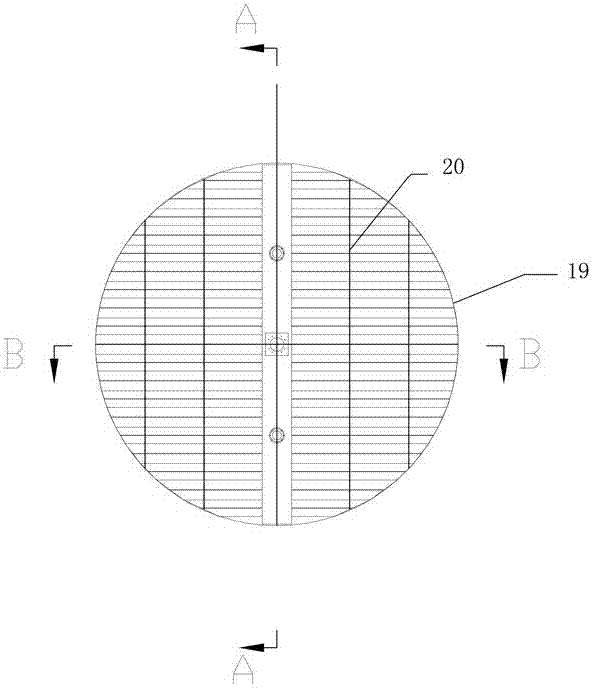

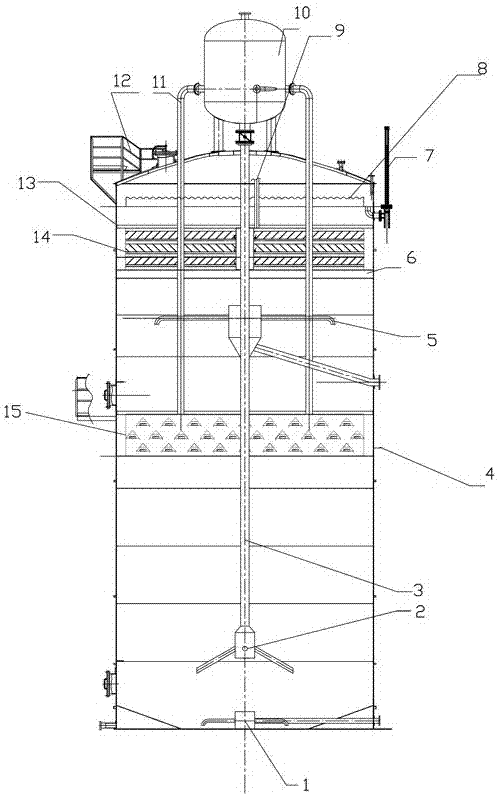

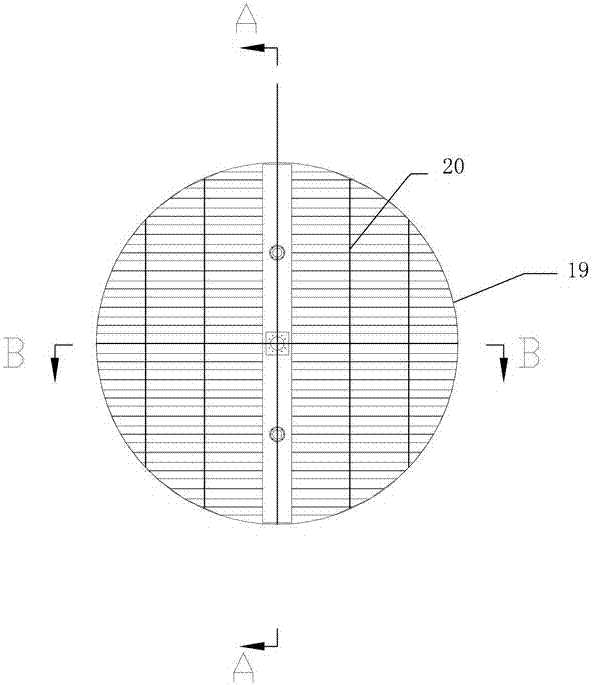

Circulating fluidized bed refuse incineration boiler and refuse incineration method thereof

ActiveCN102042600AImprove adaptabilityLow running costIncinerator apparatusPower stationFluidized bed

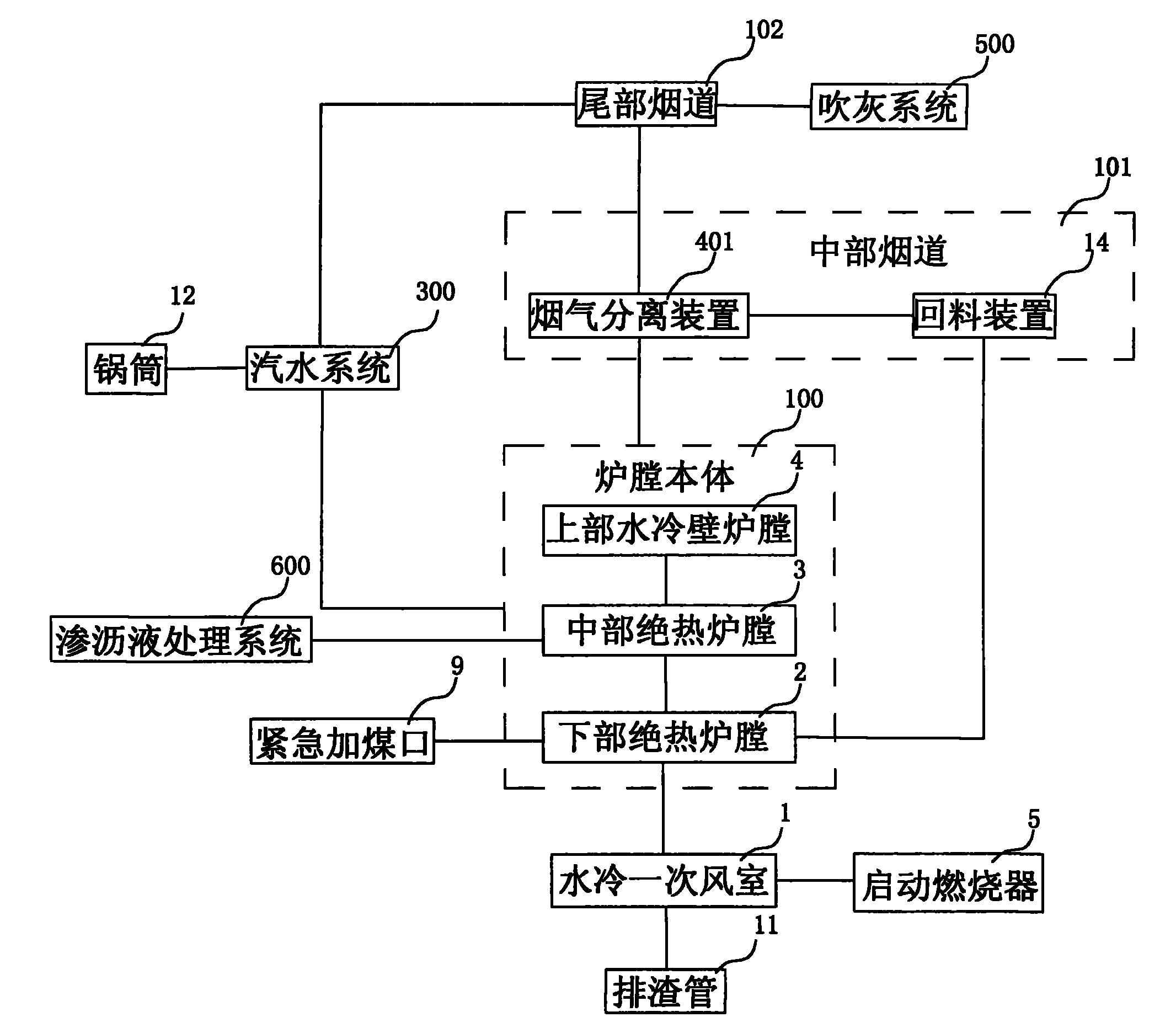

The invention relates to a circulating fluidized bed refuse incineration boiler and a refuse incineration method thereof. The boiler comprises a steel framework and a hearth body, a middle flue, a tail flue and a boiler barrel which are arranged on the steel framework. A smoke separation device and a return device are arranged in the middle flue; the smoke separation device and the return device are respectively connected with the hearth body; the tail flue and the smoke separation device are connected; vapor-water systems are arranged in the hearth body and the tail flue; the vapor-water systems are connected with the boiler barrel; the hearth body comprises an upper water cooled wall hearth, a lower insulation hearth and a middle insulation hearth, wherein the middle insulation hearth and the lower insulation hearth are hearth structures without heating surfaces and are used for preventing heat loss generated after refuse is burnt so as to make the heat used for preheating and igniting new put refuse. The refuse incineration boiler and the incineration method thereof reduce the operating cost of a refuse power station and enhance the adaptability to refuse quality changes.

Owner:烟台鑫丰源电站设备有限公司

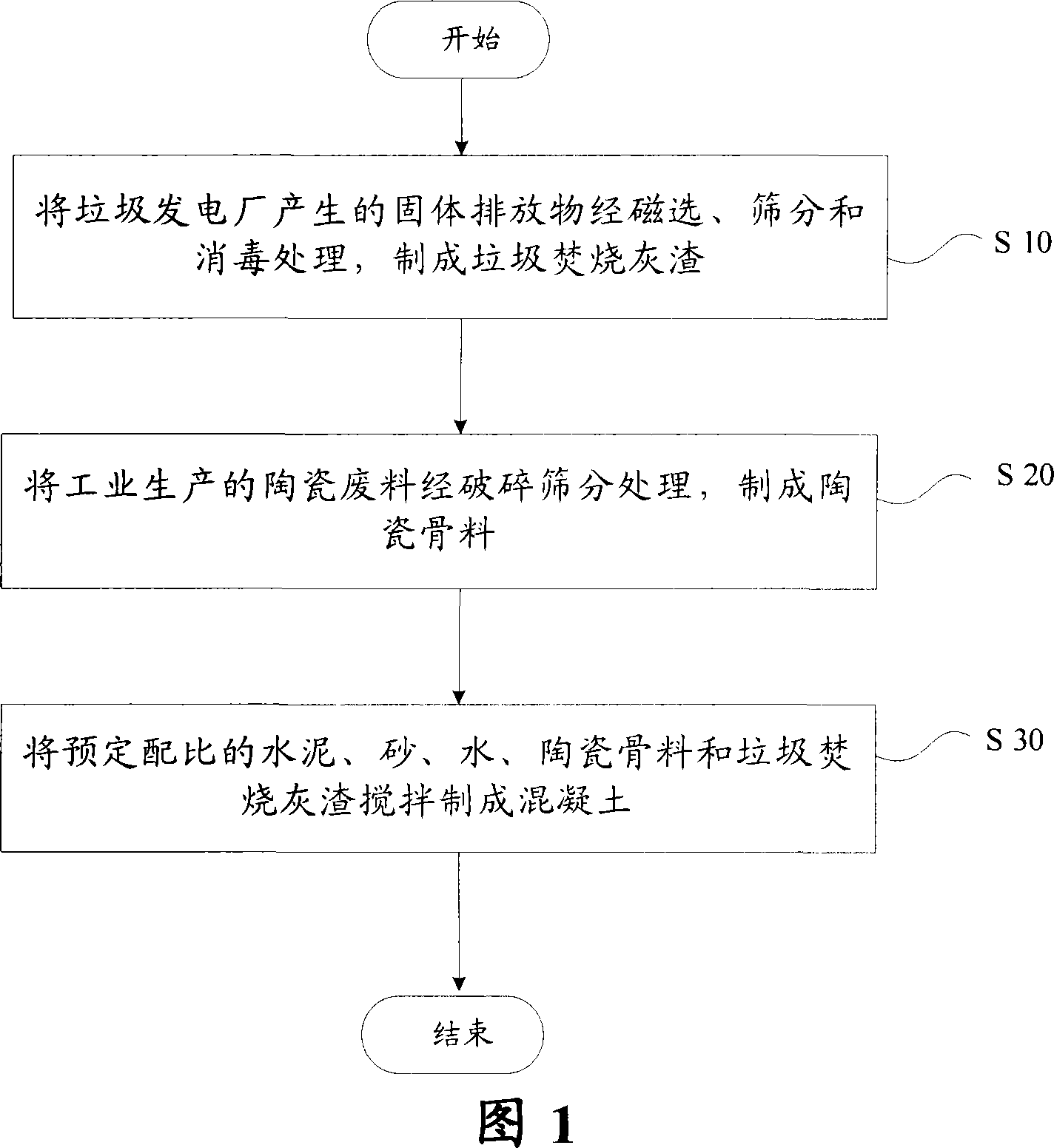

Concrete and preparation method thereof, and method for treating refuse burning ash

InactiveCN101186473AEfficient and environmentally friendly treatmentReduce pollutionSolid waste managementPower stationLitter

The invention provides a concrete, which comprises cement, sand, water, ceramic aggregate and wastes incineration ash. The invention further provides a preparation method of the concrete, which comprises the following steps: the solid wastes generated by garbage power plants are treated through magnetic separation, screening and disinfection and then are made into the wastes incineration ash; the industrial ceramic wastes generated by industries are treated through crushing and screening and then made into the ceramic aggregate; the predetermined compound of cement, sand, water, ceramic aggregate and wastes incineration ash are stirred and made into the concrete. The invention also provides a processing method of wastes incineration ash. Furthermore, the invention fully uses a plurality of solid wastes and can high effectively and environmentally treat wastes incineration ash and ceramic aggregate, thus reducing land occupancy and environmental pollution.

Owner:董再发

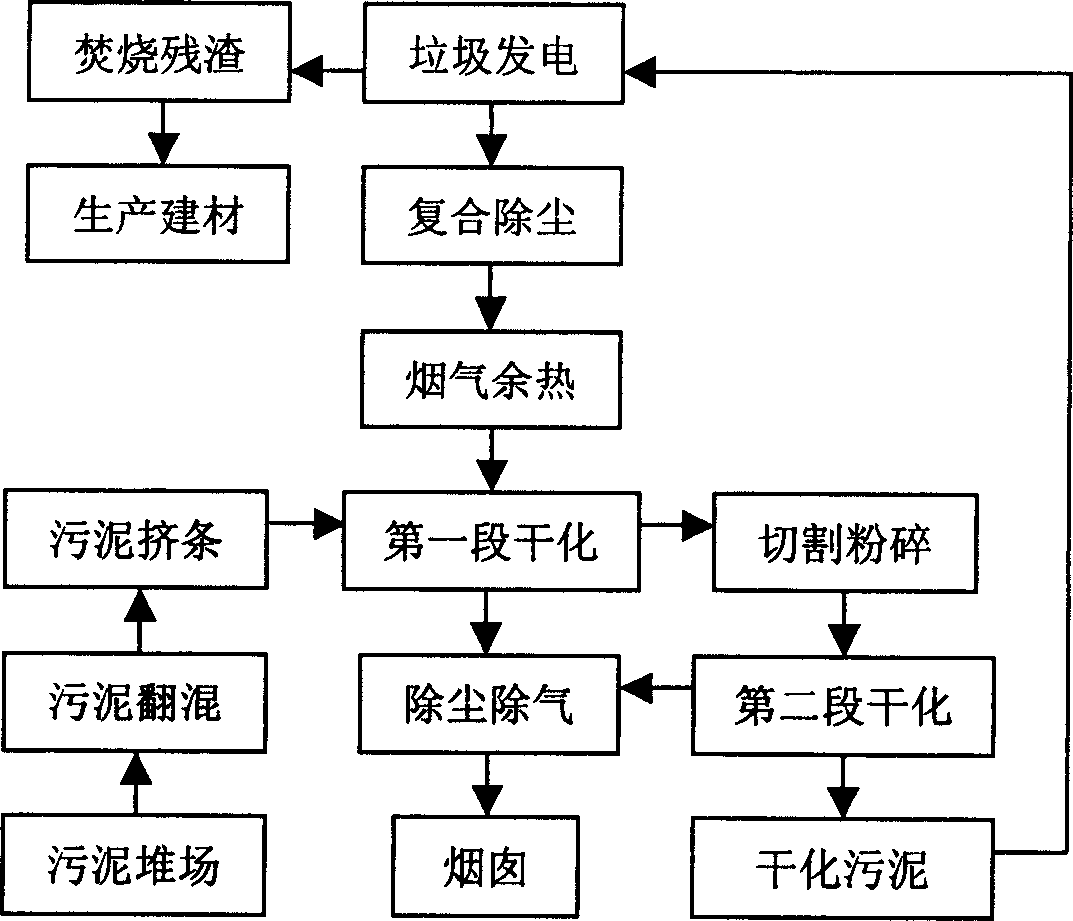

Method for integrating drying sludge using remaining heat of flume from power plant by rubbish and electricity generation using sludge

InactiveCN1733629ATake advantage ofReduce moisture contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeEngineering

The invention discloses an integrative method to use residue heat of garbage power plant to dry sludge and generate electricity by sludge, which comprises: 1) removing dust to the discharged smoke gas and drying sludge with two-stage; 2) pretreating the sludge from urban sewage disposal plant, or dredged sludge; 3) processing the pretreated sludge into column shape by machine for first drying stage; 4) cutting the said sludge out of kiln into particle; 5) taking second drying stage to sludge particle of size less than 6-10mm; 6) conveying the sludge to garbage electricity generating system to mix with garbage and coal and burn for electricity. This method has well social, environmental and economic benefits.

Owner:ZHEJIANG UNIV

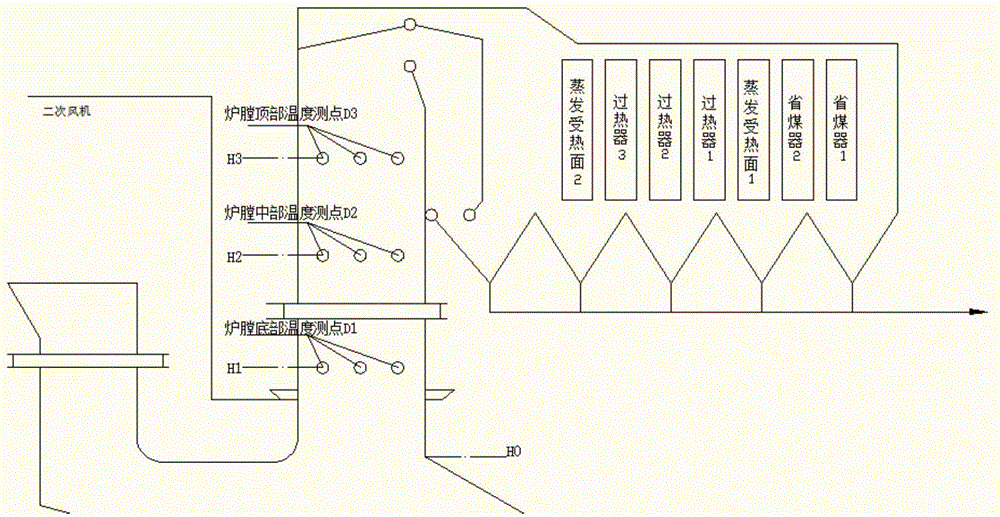

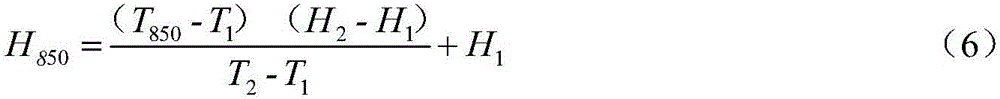

Real-time measurement method for retention time of flue gas in garbage incinerator at 850 DEG C

ActiveCN106770456ARealize multi-point stereo measurementHigh sensitivityMaterial heat developmentPower stationFlue gas

The invention solves the problem to provide a real-time measurement method for retention time of flue gas in a garbage incinerator at 850 DEG C, comprising the steps of building real-time temperature field distribution along the furnace height in the incinerator, determining flue gas temperature change gradient in a flue, correcting flue gas velocity in real time, and determining whether the retention time of the flue gas in a hearth at the temperature of not lower than 850 DEG C can meet 850 DEG C / 2S emission index verification under the running of a garbage power plant; during the running of a unit, collecting a thermocouple measurement value in real time by a DCS (distributed control system), displaying the value on a DCS display and sending to an SIS system of the power plant synchronously, receiving data, sent from the DCS, by the SIS system, then storing in a real-time server of the SIS system, transmitting the data to a compute server, calculating the retention time t of the flue gas at the temperature of higher than 850 DEG C in real time, and a position at the temperature below 850 DEG C, and displaying in the production process of an SIS page in real time; operating crew of the power plant can monitor in the SIS page in real time, and monitor the retention time, meeting the temperature condition of 850 DEG C, of the flue gas in the hearth, so that the environmental requirement is met.

Owner:XIAN THERMAL POWER RES INST CO LTD

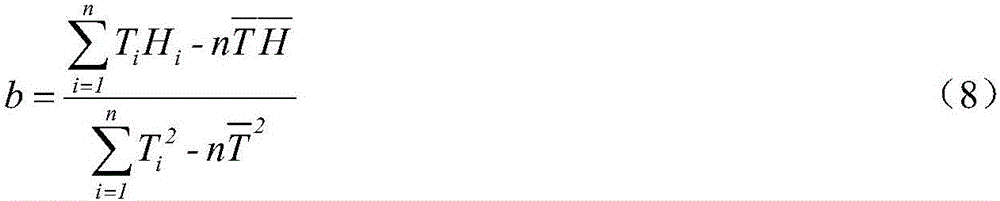

Installation and construction method of mechanical grate type waste incineration boiler

InactiveCN109000261AGive full consideration to reuseReduce the amount of work at heightIncinerator apparatusSteel frameSuperheater

The invention discloses an installation and construction method of a mechanical grate type waste incineration boiler. The installation and construction method includes the following specific steps ofconstruction preparation, specifically, unpacking inspection of boiler parts and equipment, retesting and paying off of boiler foundation, and configuration and installation of parallels; and installation and construction method, specifically, preparation and manufacturing of auxiliary tools, installation of boiler internal equipment, installation of rainproof shed, hydrostatic test of boiler, installation of boiler wall, steam tightness test of drying and boiling boiler, and safe trial operation, wherein the auxiliary tools includes a steel frame, a platform escalator, a temporary climbing ladder, an aisle guardrail, a temporary platform, a temporary platform guardrail, a scaffold lifting platform and a simple removable support, and the internal equipment includes a boiler grate, a watercooling system, a drum, a superheater and an economizer. The installation and construction method of the mechanical grate type waste incineration boiler is applicable to installation of the mechanicalgrate type waste incineration boiler with a daily garbage disposal of about 500t / d by a single unit in a domestic garbage power plant, the degree of mechanized construction is improved, the labor intensity is reduced, the project quality is guaranteed, the construction period is shortened, and the productivity and economic benefits are improved.

Owner:POWER CHINA HENAN ENG CO LTD

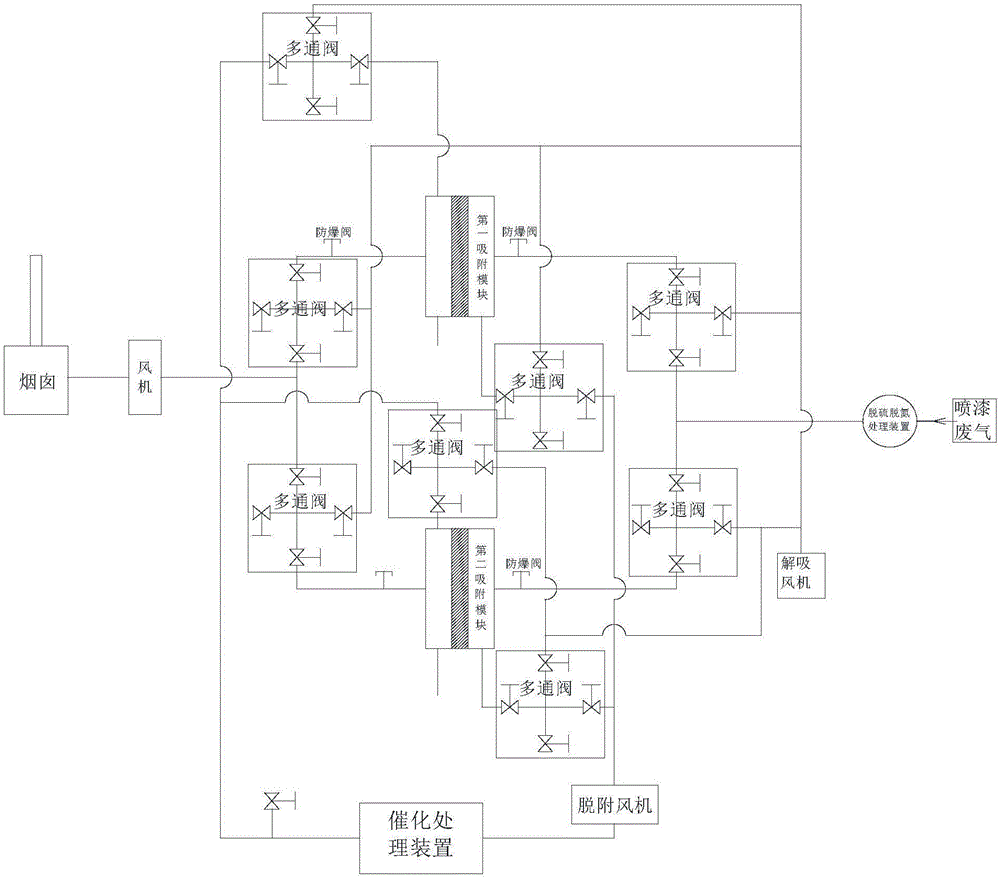

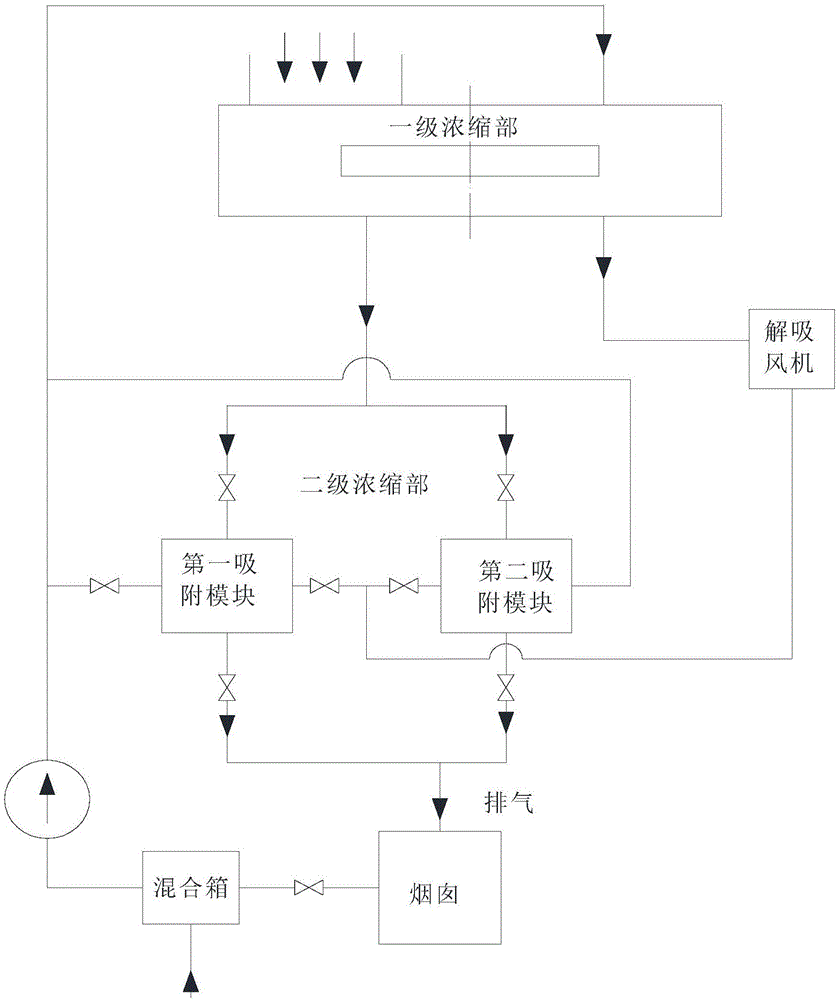

Switching concentration type heat accumulation catalytic combustion organic waste gas treatment system

ActiveCN106196105ANo more pollutionEfficient purificationIncinerator apparatusAir quality improvementAlcoholDesorption

The invention discloses a switching concentration type heat accumulation catalytic combustion organic waste gas treatment system. The switching concentration type heat accumulation catalytic combustion organic waste gas treatment system comprises a desulfurization and denitrification treatment device, a switching type concentration desorption device and a heat accumulation catalytic combustion device. An outlet of the desulfurization and denitrification treatment device is connected with an inlet of the switching type concentration desorption device, and a purification discharge port of the switching type concentration desorption device is connected with a chimney. A concentration discharge port of the switching type concentration desorption device is connected with the heat accumulation catalytic combustion device through a pipeline. A desorption inlet of a first adsorption module and a desorption inlet of a second adsorption module are connected with a desorption air inlet pipe provided with a valve. The switching concentration type heat accumulation catalytic combustion organic waste gas treatment system has the technical beneficial effects that contained organic waste gas can be effectively purified, and the energy saving effect is obvious; and VOC is completely catalyzed and degraded and does not pollute the environment any more, and the switching concentration type heat accumulation catalytic combustion organic waste gas treatment system is suitable for conducting waste gas purification on chemical plants, printing and dyeing mills, pharmaceutical factories, alcohol plants, feed plants, sewage treatment plants, garbage treatment stations, garbage power plants and other enterprises generating organic waste gas such as waste and smelly gas.

Owner:重庆市德昭明润环境技术开发有限公司

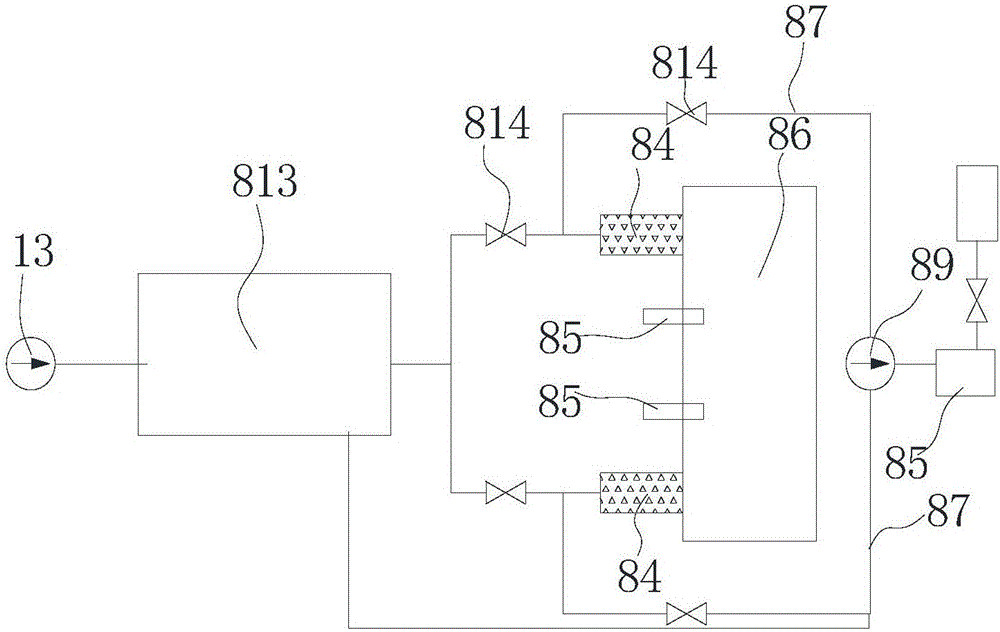

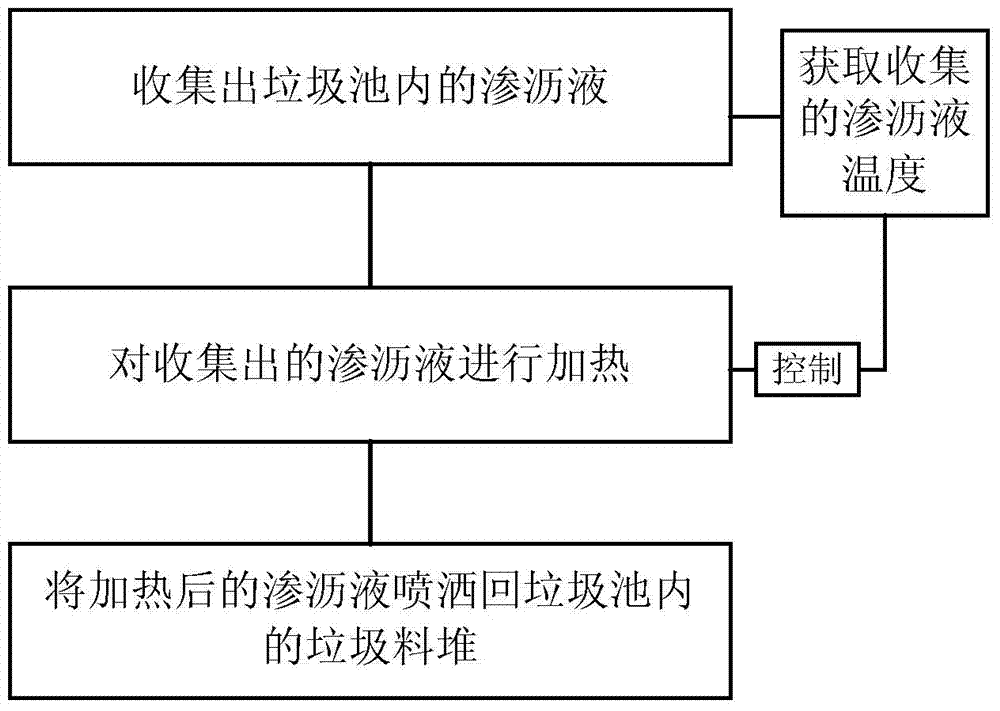

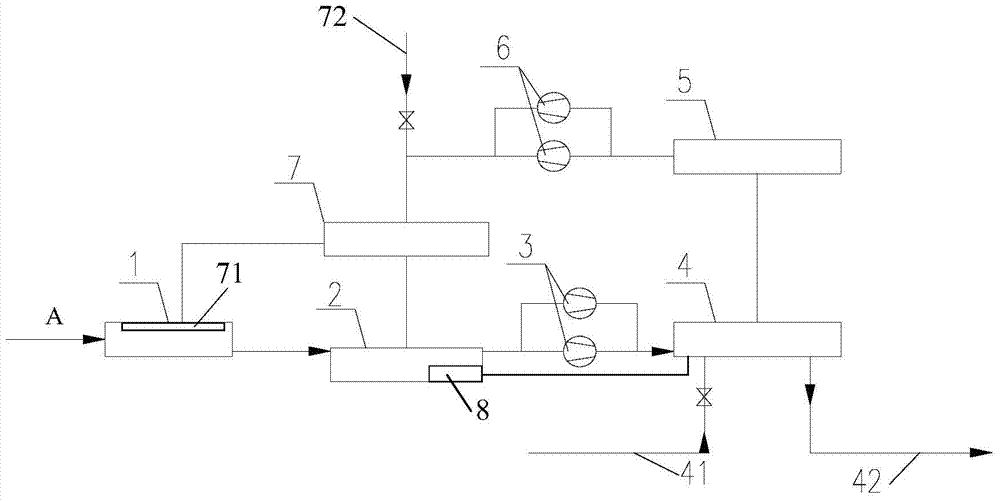

Method and system of increasing temperature of garbage piles in leachate sewer of garbage power plant in winter

The invention discloses a method and a system of increasing temperature of garbage piles in a leachate sewer of a garbage power plant in winter and belongs to the field of household garbage incineration power generation. The method includes collecting leachate in the leachate sewer; heating the leachate collected; spraying the heated leachate to the garbage piles in the leachate sewer. The system comprises a leachate collecting pond connected with the leachate sewer, cold leachate conveying pumps, a heat pump heating device, hot leachate conveying pumps and a leachate spraying-back device. According to the arrangement, the heat pump technology is adopted to use low-temperature heat energy of circulating water of a condenser of a power generation plant, and accordingly the leachate is heated and prayed back to the garbage piles in the leachate sewer; in this way, increased is the temperature of the garbage piles in the leachate sewer of the garbage power plant in northeast cold areas in winter, and fermentation and leaching of the household garbage in the sewer are facilitated, thus heat value of the garbage incinerated in the furnace is increased, additive amount of auxiliary fuel is reduced and stable and continuous running of the garbage power plant is facilitated.

Owner:SOUND ENVIRONMENTAL RESOURCES

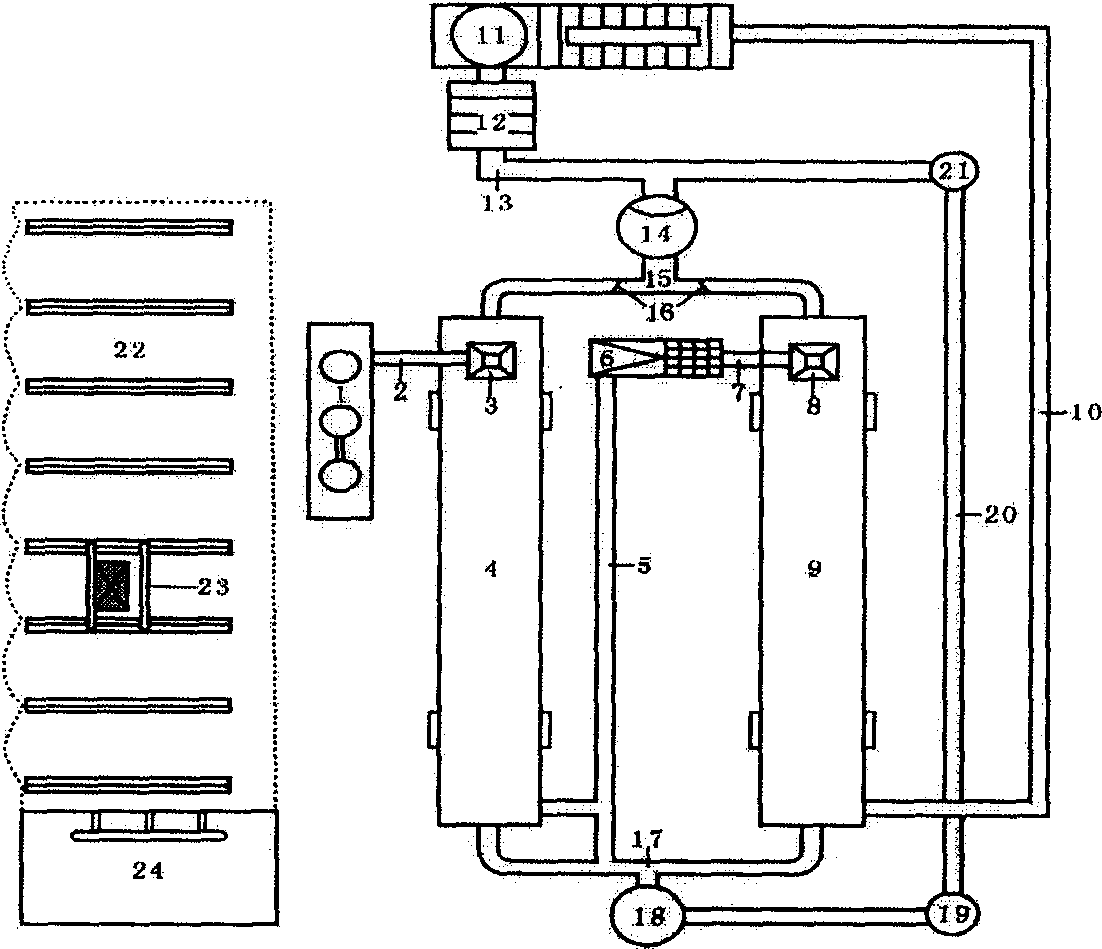

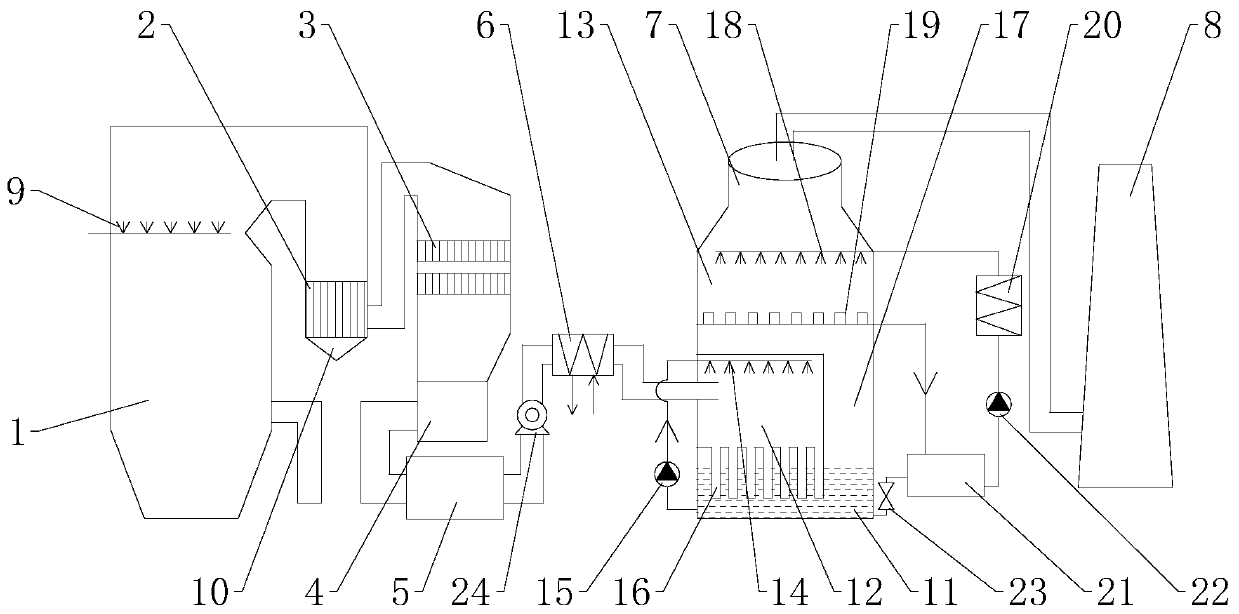

Integrated system of using garbage power plant smoke residual heat to dry sludge and sludge power generation

InactiveCN1752037AWill not affect normal operationSmooth dischargeSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationPower stationSludge

A system for drying the sludge by the fume afterheat of electric power plant using garbage as its fuel and using the dried sludge to generate electric energy is composed of a sludge pre-treating system, a feeding system consisting of strip extruding unit, bucket belt type conveyer and feeding inlet, a heat source unit, a sludge drying system consisting of the first rotary baking kiln, cooling belt conveyer, pulverizing, the second bucket belt type conveyer, feeding inlet and the second rotary baking kiln, a dust and gas removing system, and a garbage and sludge burning and electric generating system.

Owner:ZHEJIANG UNIV

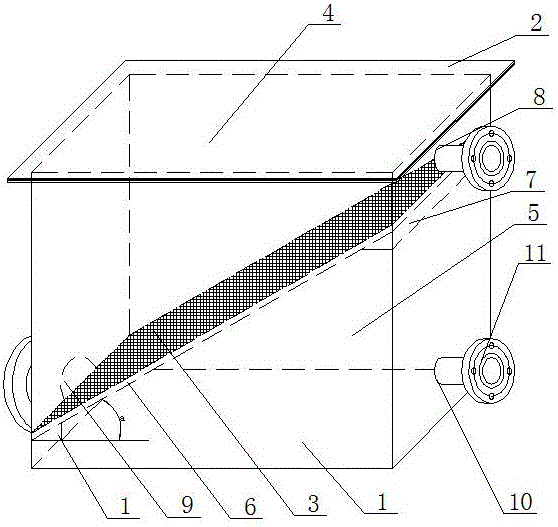

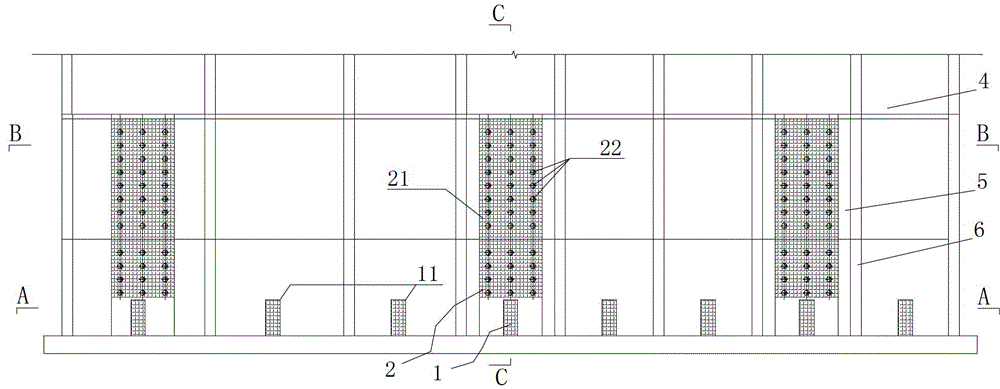

Leachate suspended matter removal device for garbage power plant

InactiveCN105833584AReduce the probability of cloggingEasy to dryMembrane filtersStationary filtering element filtersEnvironmental resistancePower station

The utility model relates to a leachate suspended substance removal device of a garbage power plant, which relates to the field of environmental protection power generation equipment. It includes a box body and a box cover connected to the upper end of the box body. The box body is provided with an obliquely arranged screen to divide the box body into an upper cavity and a lower cavity. The inlet, the lower part of the upper cavity located at the lower end of the screen is provided with a slag outlet, and the lower part of the lower cavity is provided with a water outlet. The leachate enters the box through the leachate inlet, and the leachate has a flushing effect on the screen, which can flush the filter residue to the slag discharge port and reduce the clogging rate of the screen. The leachate flows into the adjustment tank by itself, and there is basically no stagnant water on the screen, which is convenient for drying and cleaning the filter residue.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

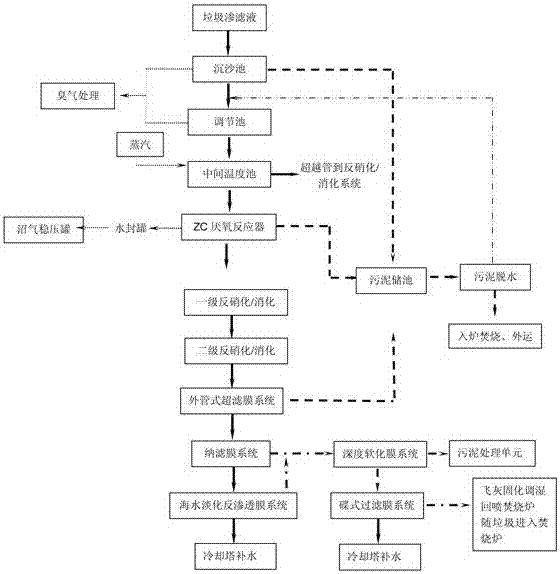

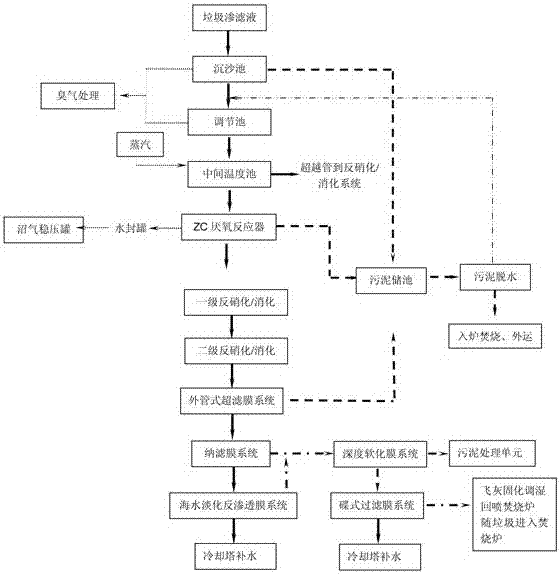

Leachate treatment method of waste incineration power station

InactiveCN107200440AIncrease water production rateGuaranteed normal consumptionWater treatment parameter controlGeneral water supply conservationAnaerobic decompositionAnaerobic reactor

The invention discloses a leachate treatment method of a waste incineration power station. The leachate treatment method comprises the following steps: 1) introducing the waste incineration leachate into a sand settling pond, and preprocessing the waste incineration leachate to remove a great amount of settled sand in sewage; 2) introducing the leachate into a regulating pond, tempering the leachate, so that the PH of the inlet water of the sewage is kept at 5 to 6 in 2 days; 3) enabling the leachate to enter an intermediate temperature pond, introducing steam to adjust the temperature to be between 35 DEG C and 39 DEG C, and homogenizing the sewage temperature by virtue of a stirrer in the intermediate temperature pond; 4) introducing the incineration waste leachate after being processed in the intermediate temperature pond to have anaerobic decomposition, decomposing and converting various complex organic matters into marsh gas, so that the incineration waste leachate is primarily purified; 5) carrying out the denitrification / nitrification treatment; and 6) filtering. By adopting the leachate treatment method, the water yield of a leachate treatment system in the waste incineration power station, the residual concentrated liquid can be ensured to be completely consumed in the waste incineration power station, and the emission of the concentrated liquid can be prevented from severely polluting the environment.

Owner:佛山市银禾工业设计有限公司

Efficient denitration and dust removal system and method for garbage power plant flue gas

InactiveCN110124486AEmission reductionReduce dust contentCombination devicesGas treatmentEngineeringWaste-to-energy plant

The invention discloses efficient denitration and dust removal system and method for flue gas of a garbage power plant. The dust removal system comprises a waste heat boiler; an SNCR sprayer is mounted in the waste heat boiler and is used for spraying ammonia or urea, so that NOx in the flue gas is primarily reduced, and primary denitration is completed; the high-temperature metal dust remover isused for filtering and intercepting heavy metals, dust and dioxin in the flue gas; the filtered flue gas selectively reacts with NOx under the action of a catalyst through a microporous SCR device togenerate N2 and H2O so as to complete deep denitration; initial deacidification is carried out to the denitrified flue gas in a deacidification device, and deep deacidification and dust removal are carried out in a wet-process tower, thereby achieving ultra-low emission. According to the system and the method, high-temperature dust removal is combined with microporous SCR to deeply remove pollutants such as dust and NOx, so that ultra-low emission is realized. The technology does not need high-temperature steam heating, a large amount of steam can be saved, and the power generation amount is increased.

Owner:凤阳海泰科能源环境管理服务有限公司

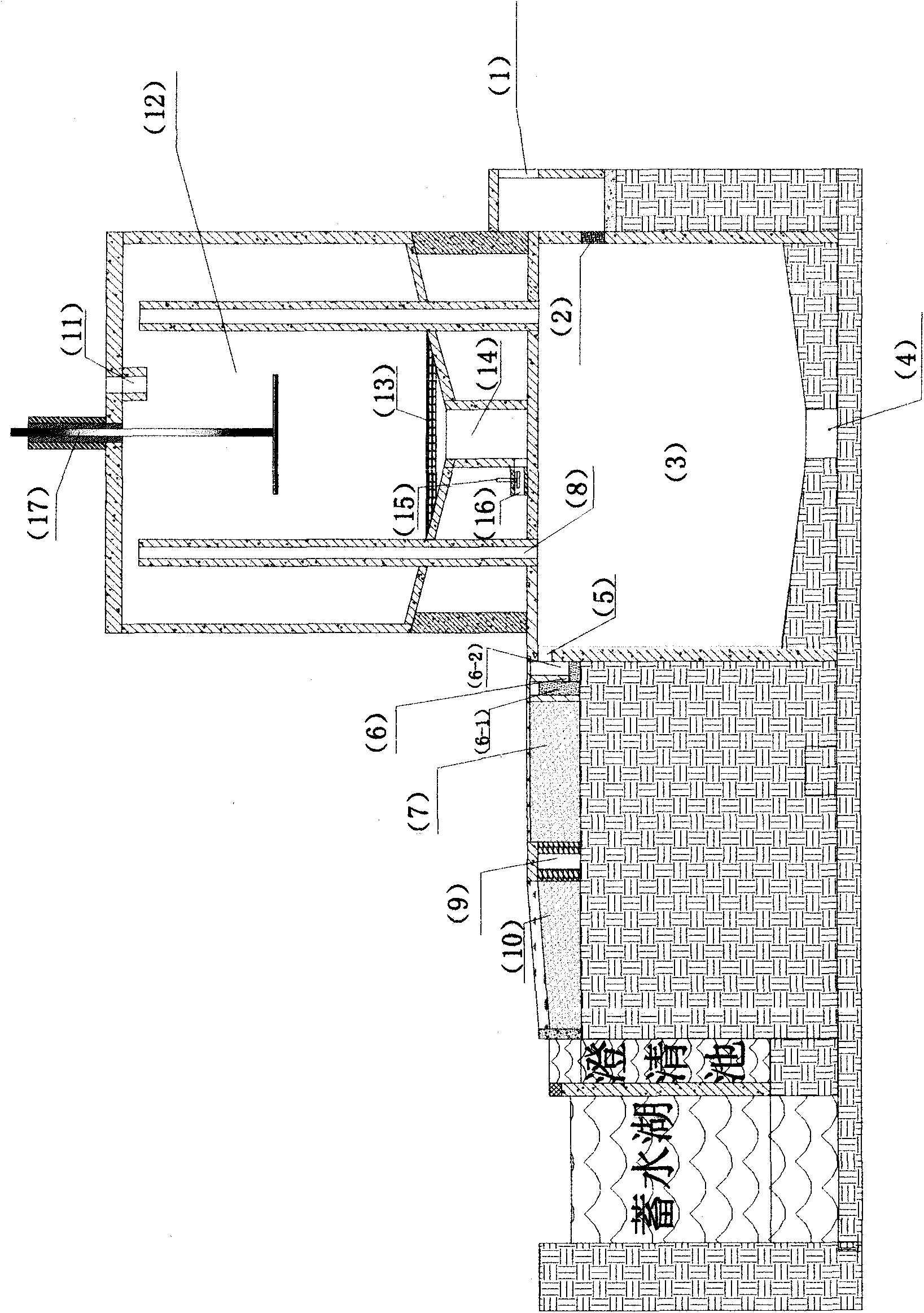

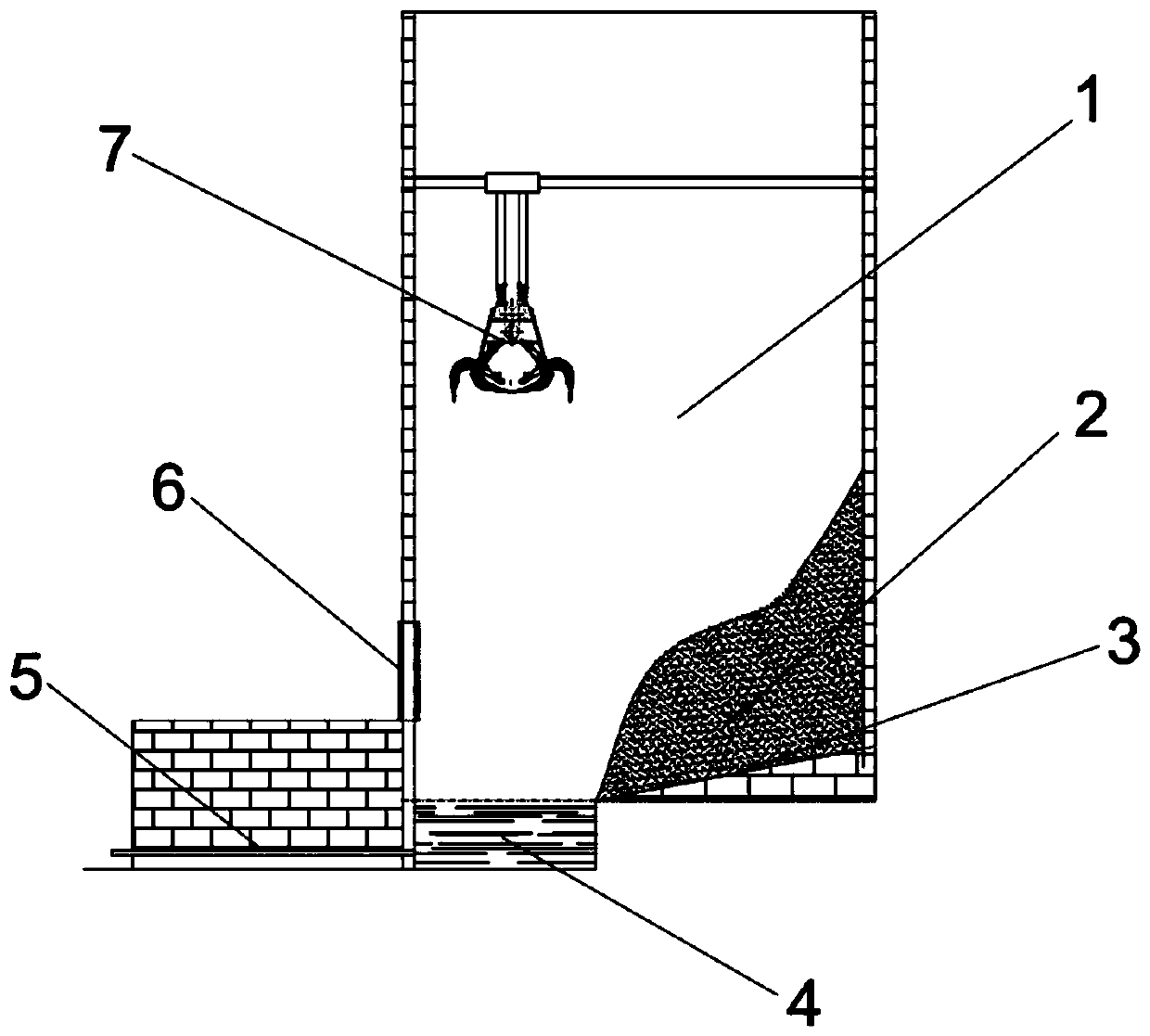

Modified trash storing pit landfill leachate collecting system

The invention discloses a modified trash storing pit landfill leachate collecting system. The system comprises a horizontal collecting system, wherein the horizontal collecting system comprises a landfill leachate collecting trench and a plurality of collecting grids which are arranged at the bottom of the side wall of a trash storing pit along the horizontal direction. The system is characterized by also comprising a vertical collecting system, wherein the vertical collecting system is arranged on the side wall of the trash storing pit on the upper portion of the horizontal collecting system. A bottom horizontal collecting system easy to block is modified to the solid collecting system formed by the horizontal collecting system and the vertical collecting system, the landfill leachate in the trash pit can be discharged smoothly under the condition that the construction cost is not increased too much, and the problems that the horizontal collecting system is blocked, loses effect and cannot discharge the landfill leachate due to excessive trash in the trash pit are solved. The load of the trash pit is reduced, the structure of the trash pit is safe and durable, the trash water in an incinerator is reduced, the temperature of the hearth of the trash incinerator is guaranteed, the Dioxins decomposition is facilitated, the burning efficiency is improved, the pollution for the environment due to trash incineration generation is reduced, the efficiency of a trash generator is improved, the energy source can be utilized well and the environment is protected.

Owner:CHINA GDE ENG

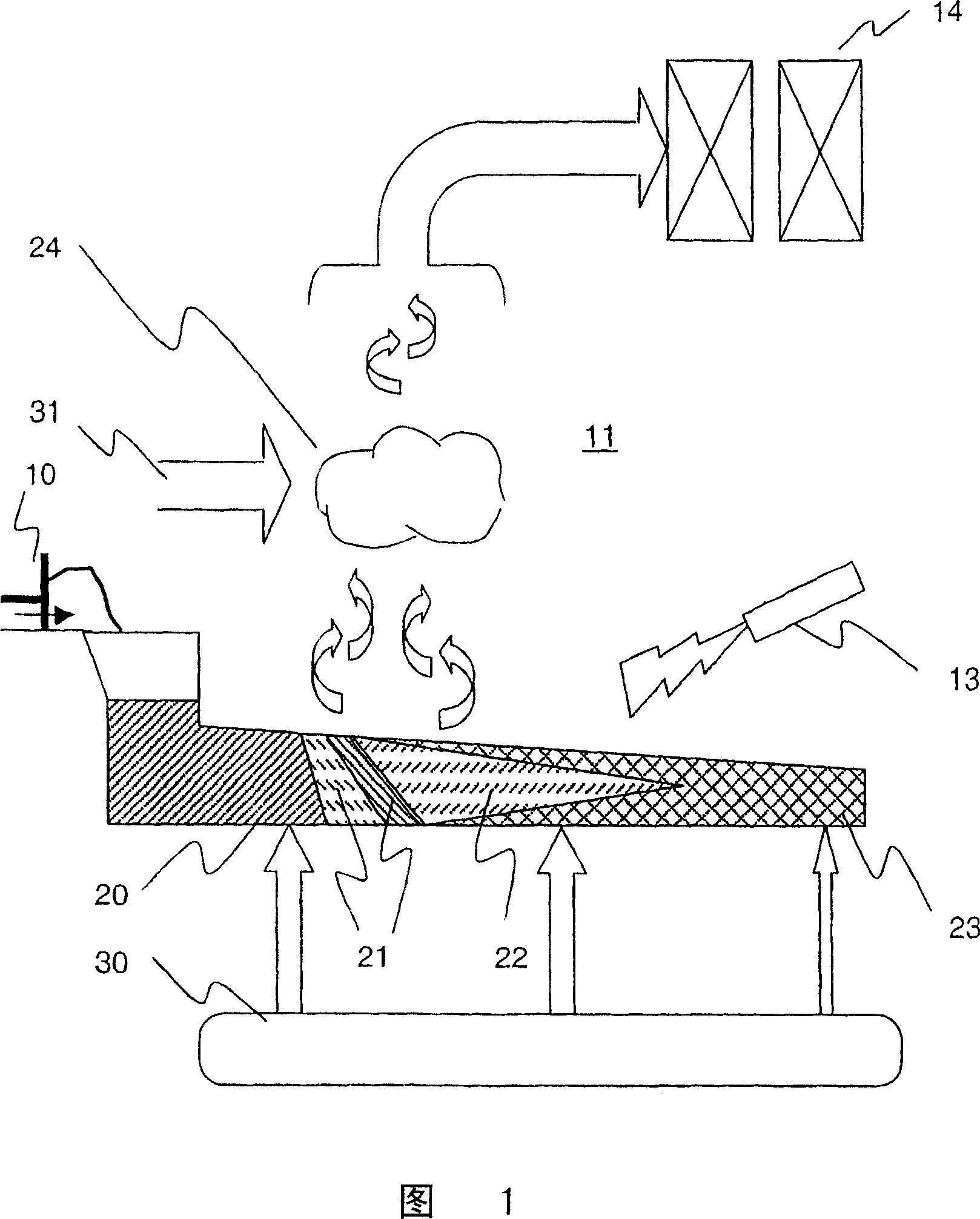

Method for drying refuse of refuse burning generating plant using solar hot-air device

InactiveCN1912514AShorten the timeImprove thermal efficiencyDrying solid materials with heatDrying gas arrangementsPower stationWater vapor

A method of using hot air unit of solar energy to dry garbage used in garbage incineration power plant utilizes hot air generated by solar energy unit to carry out predrying treatment on garbage to be used by garbage power plant in order to raise heat valve of garbage incineration and to raise wind blowing temperature of firepot as well as to ensure high temperature in incinerator.

Owner:彭坚宁

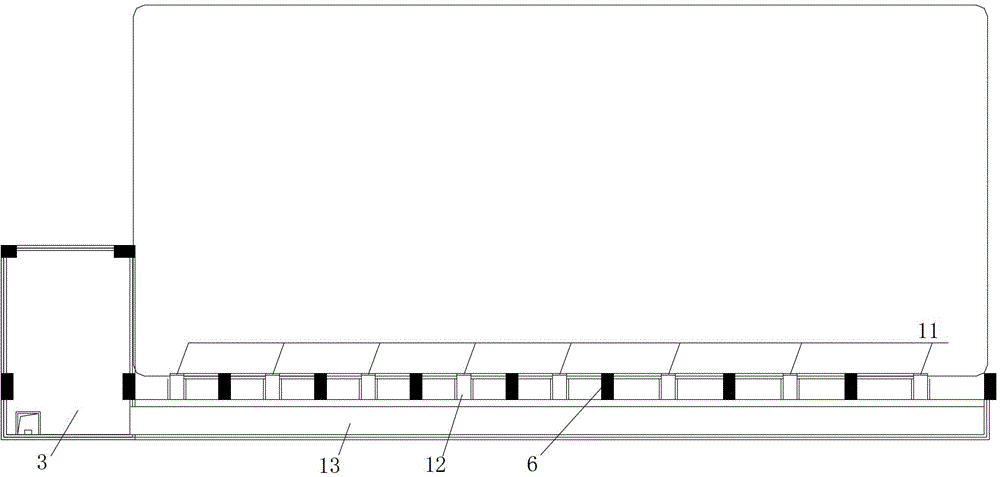

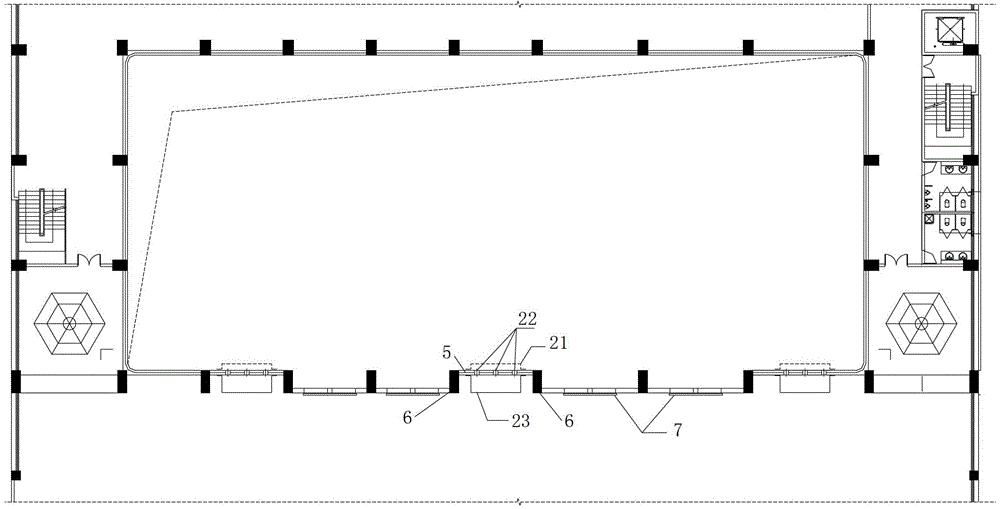

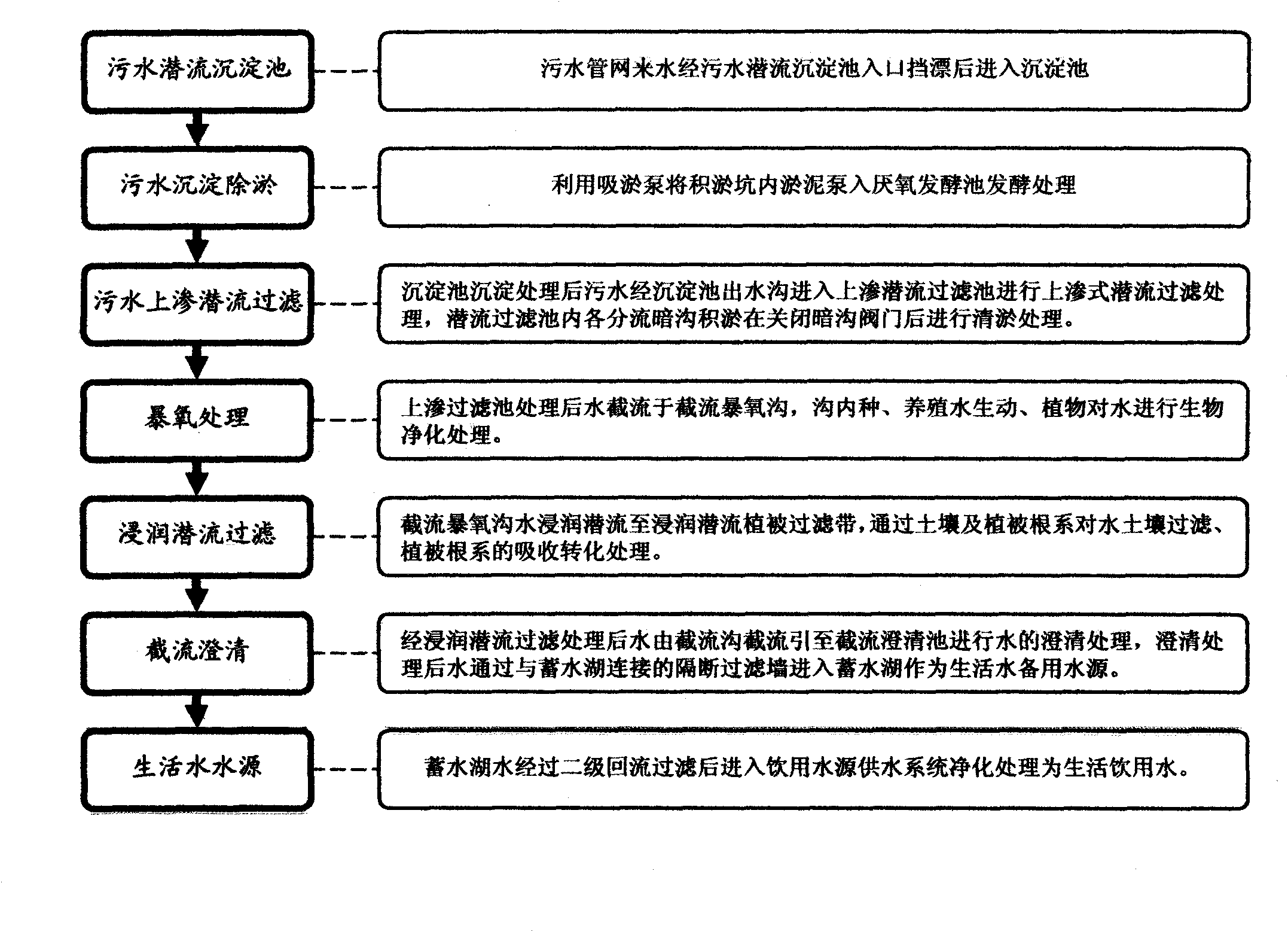

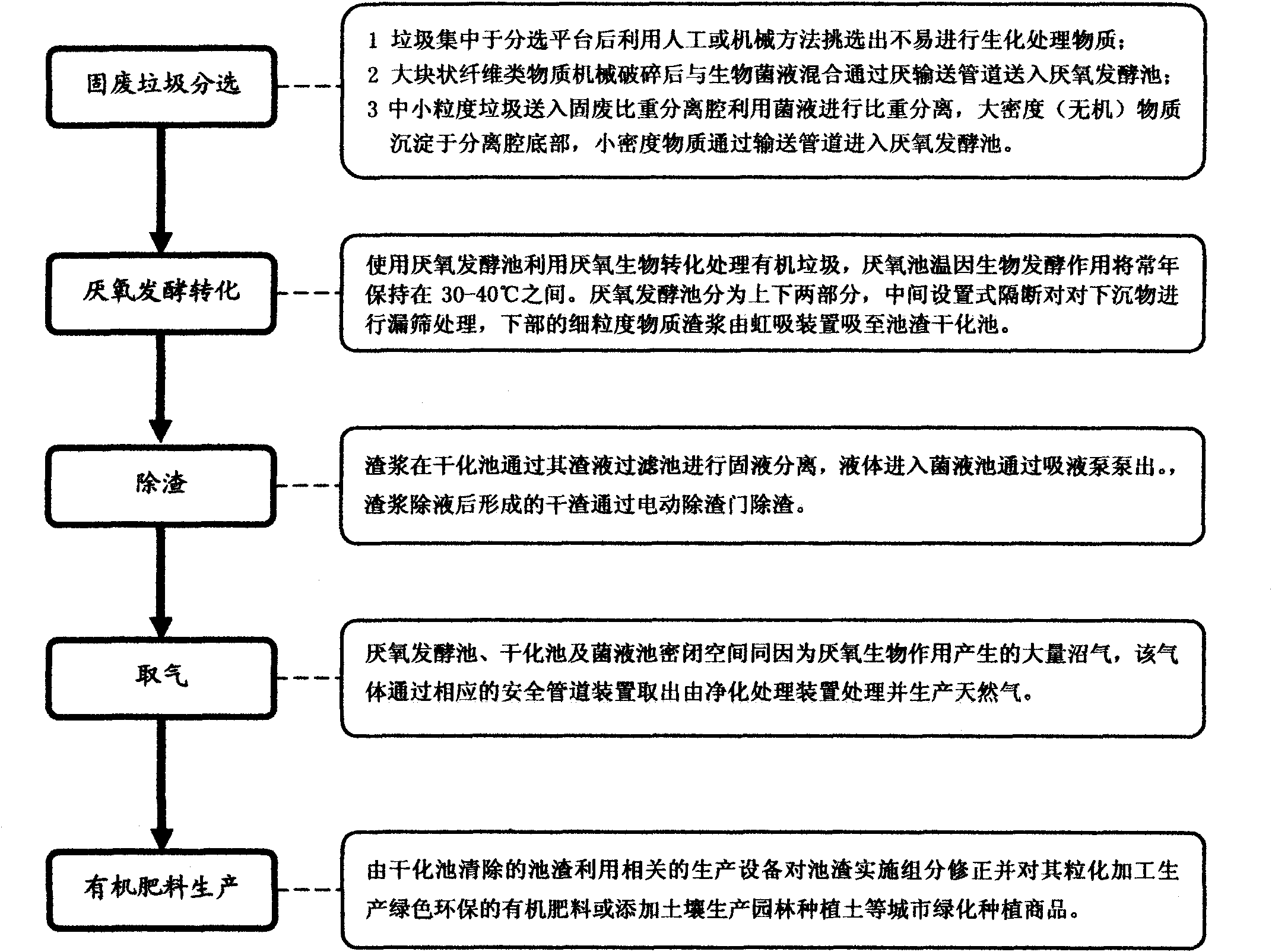

Comprehensive treatment system of urban river water area ecological environment

InactiveCN101811799AImprove the living environmentReasonable designBio-organic fraction processingSolid waste disposalEcological environmentEngineering

The invention relates to a comprehensive treatment system of a urban river water area ecological environment, which is an effective ecological environment control measure implemented on the basis of the support of a state environmental protection policy and the financial support. The invention is widely suitable for ecological environment treatment of surrounding rivers of mountainous and plain cities. Under the same treatment scale, the construction investment due to the adoption of the technology of the comprehensive treatment system of the urban river water area ecological environment is much lower than that due to the adoption of the environment control mode of the traditional large-scale sewage treatment plants, garbage power plants, and the like, and the comprehensive treatment system is an ecological circulation control measure which is more effective and economical than all traditional environment control methods and is also an only environment control method by which the control output is much larger than the construction investment at present. The construction investment can also be input stage by stage according to a mode demanding treating water firstly and treating solids later, the treatment scale can be adjusted according to demands, and the invention has strong regional adaptability.

Owner:杨欣

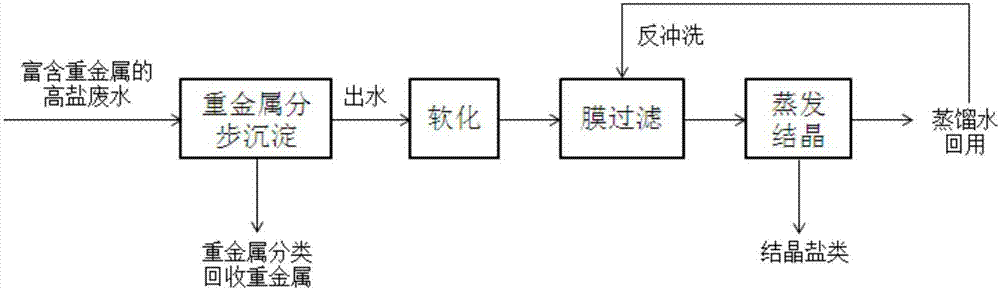

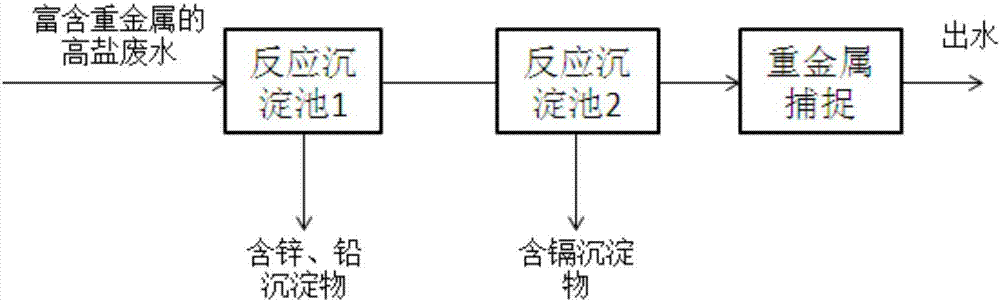

Zero-discharge method for strong brine containing high-concentration heavy metals

InactiveCN107162299AHigh in heavy metalsIncrease contentZinc oxides/hydroxidesWater contaminantsHigh concentrationFiltration

The invention discloses a zero-discharge method for strong brine containing high-concentration heavy metals. The zero-discharge method comprises the following steps: firstly, precipitation of heavy metals; secondly, softening; thirdly, tubular micro-filtration; fourthly, evaporation and crystallization. The zero-discharge method for the strong brine containing the high-concentration heavy metals, disclosed by the invention, is characterized in that in effluent obtained by fractional precipitation, namely evaporated and crystallized incoming water, the content of zinc is smaller than 1.0mg / L, the content of lead is smaller than 1.0mg / L, the content of cadmium is smaller than 1.0mg / L, the content of copper is smaller than 0.5mg / L, and the content of nickel is smaller than 1.0mg / L. In heavy metal sludge precipitated by the method disclosed by the invention, the contents of zinc and lead are high; the method can be used for recovering zinc oxide and lead oxide; in an evaporation and crystallization system disclosed by the invention, the salt separating rate is higher than or equal to 95 percent, the recovery rate of water is higher than or equal to 95 percent, and salts obtained by evaporating and crystalizing can be used as industrial salts for selling; distilled water is recycled for backwash of a water treatment system, medicine preparation and the like. According to the zero-discharge method disclosed by the invention, resources are recovered to the maximum extent while the difficult problems of high pollution and difficulty in discharge of high-salinity wastewater rich in the heavy metals generated by post treatment of a garbage power plant are solved, and near-zero discharge is realized.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Method for hydration preparation of autoclaved fly ash-lime brick from PO saponification waste residues, garbage power plant slag and fly ash

The invention discloses a method for hydration preparation of an autoclaved fly ash-lime brick from PO saponification waste residues, garbage power plant slag and fly ash. The method comprises 1, preparing building blocks with the size of 70mm*50mm*20mm from 100g of concrete, 2, breaking and screening garbage power plant slag and selecting slag with particle sizes of 2-3mm as a concrete aggregate, 3, dissolving additive accessory materials such as sodium silicate as an activator, sodium sulfate and triethanolamine as early strength agents and sodium abietate as a dispersant through a certain amount of water, adding PO saponification waste residues into the solution, orderly adding garbage power plant slag, PO42.5 cement and fly ash into the solution and fully stirring the mixture to obtain slurry, 4, taking out the slurry and carrying out repeated compaction to obtain fly ash building blocks, 5, standing to maintain the fly ash building blocks obtained by the step 4 for 24h, and 6, steaming the fly ash building blocks through an autoclaved reaction kettle with water in the bottom layer at a temperature of 165-195 DEG C for 5-9h, carrying out natural cooling to the room temperature and discharging the products. The autoclaved fly ash-lime brick realizes change of waste into valuables.

Owner:福建洋屿环保科技股份有限公司

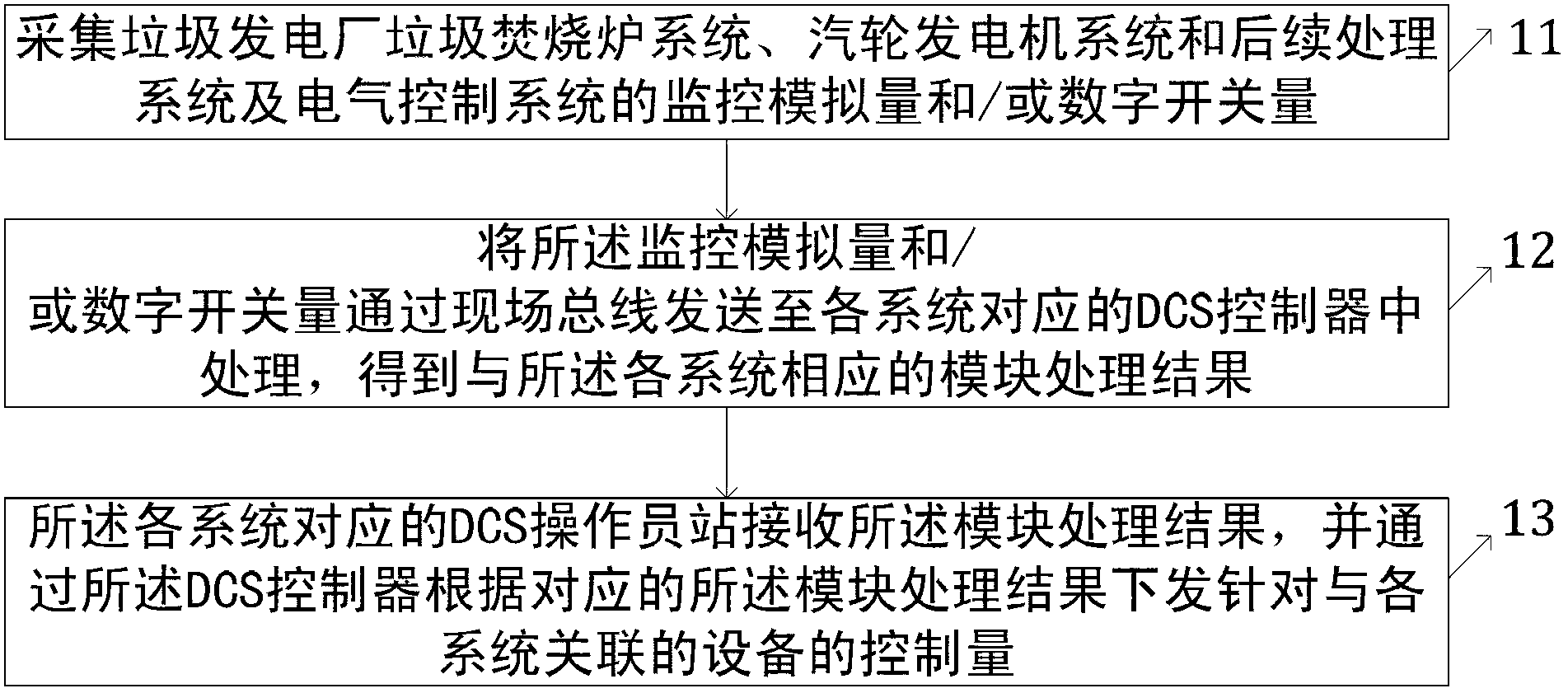

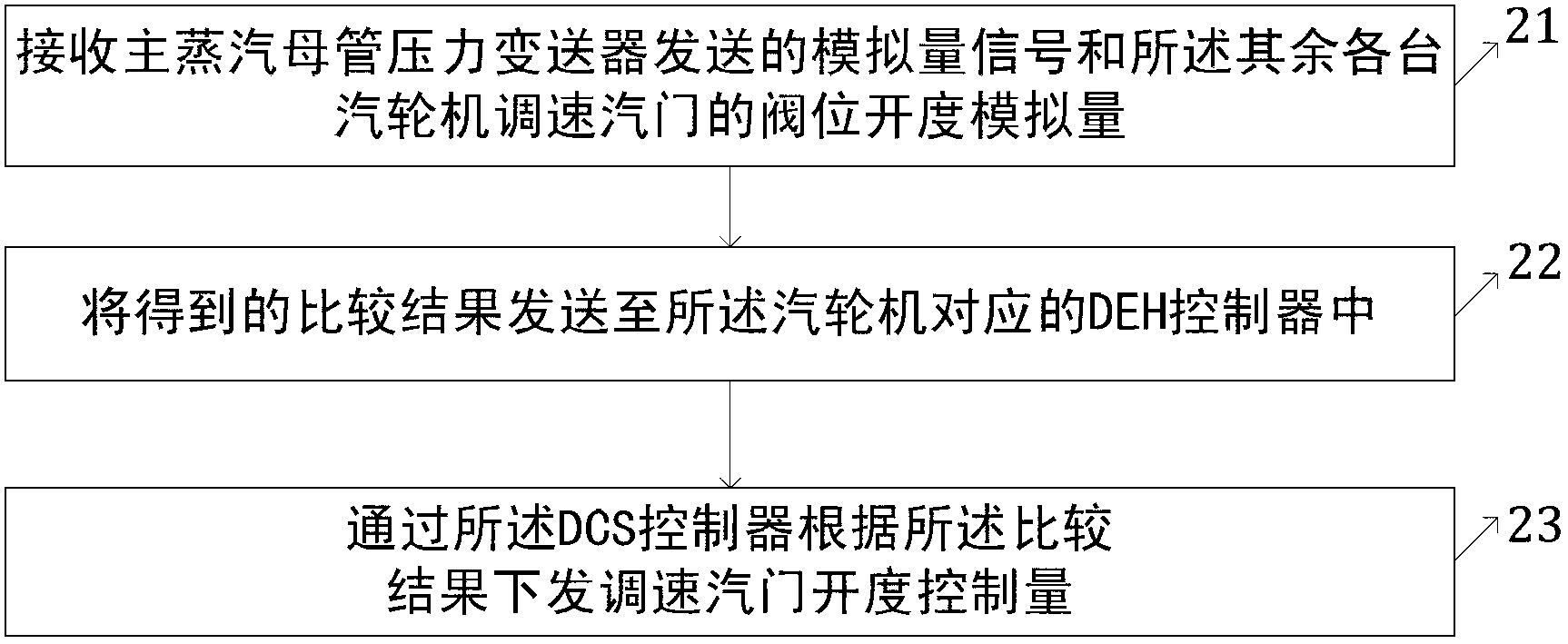

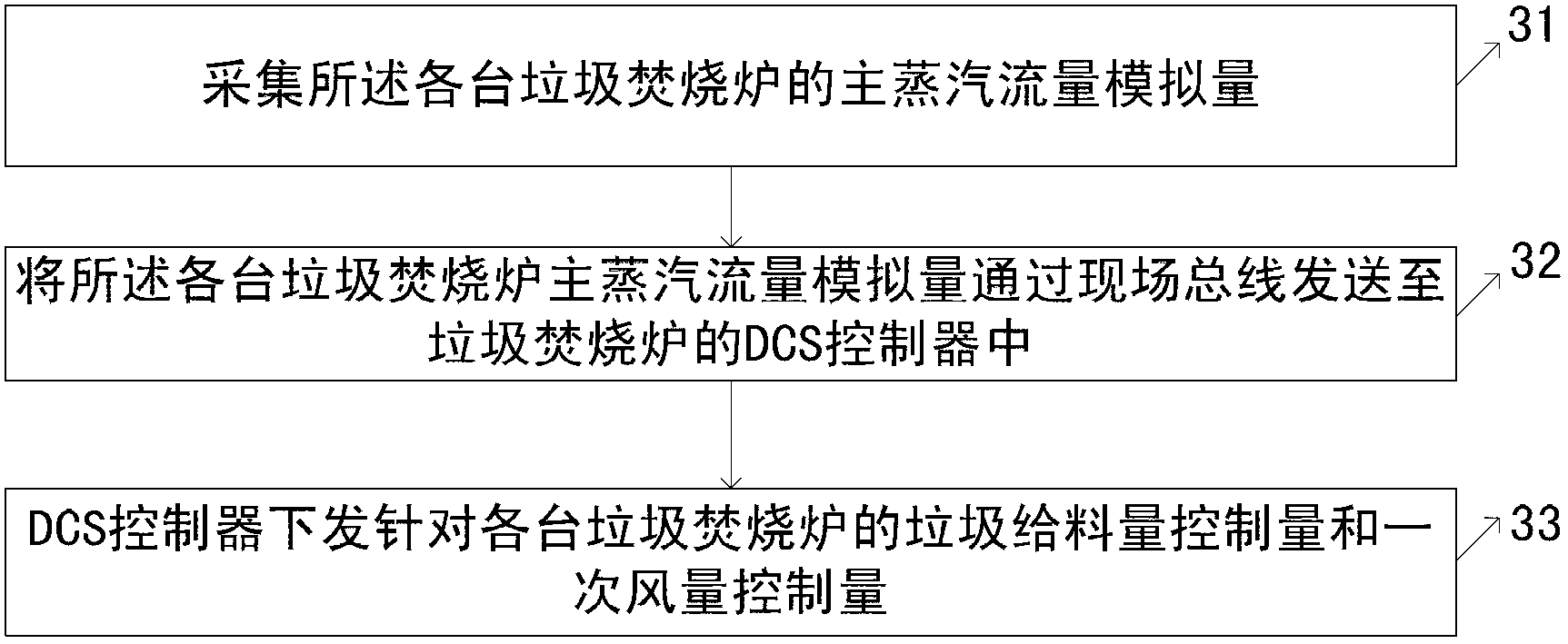

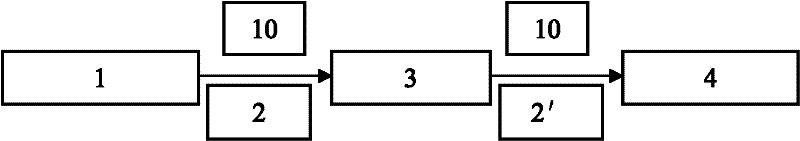

Power plant, method and system for controlling garbage incineration power plant equipment based on DCS (Distributed Control System)

ActiveCN102707692ATotal factory controlProgramme total factory controlElectric controlHandling system

The embodiment of the invention discloses a method for controlling garbage incineration power plant equipment based on DCS. The method comprises the following steps of: acquiring monitoring analog quantities and / or digital switching quantities of a garbage incinerator system, a turbine generator system, a subsequent processing system and an electric control system in a garbage power plant; transmitting the monitoring analog quantities and / or the digital switching quantities to corresponding DCS controllers of the systems to process, and obtaining module processing result corresponding to the systems; receiving the module processing result by the corresponding DCS operator stations of the systems and transmitting control quantities for the associated equipment of the systems by the DSC controllers according to the module processing result. According to the power plant, the method and the system for controlling the garbage incineration power plant equipment based on DCS, problems of a large number of communication points of the DCS and the PLC (Programmable Logic Controller) and many faults are solved; regulations on feeding quantity, primary air quantity and secondary air quantity of the equipment in parallel operation, such as many garbage incinerators in parallel operation can be realized, and the coordinated control of the garbage incinerator and a turbine generator unit in the turbine generator system can be realized.

Owner:HANGZHOU HOLLYSYS AUTOMATION +1

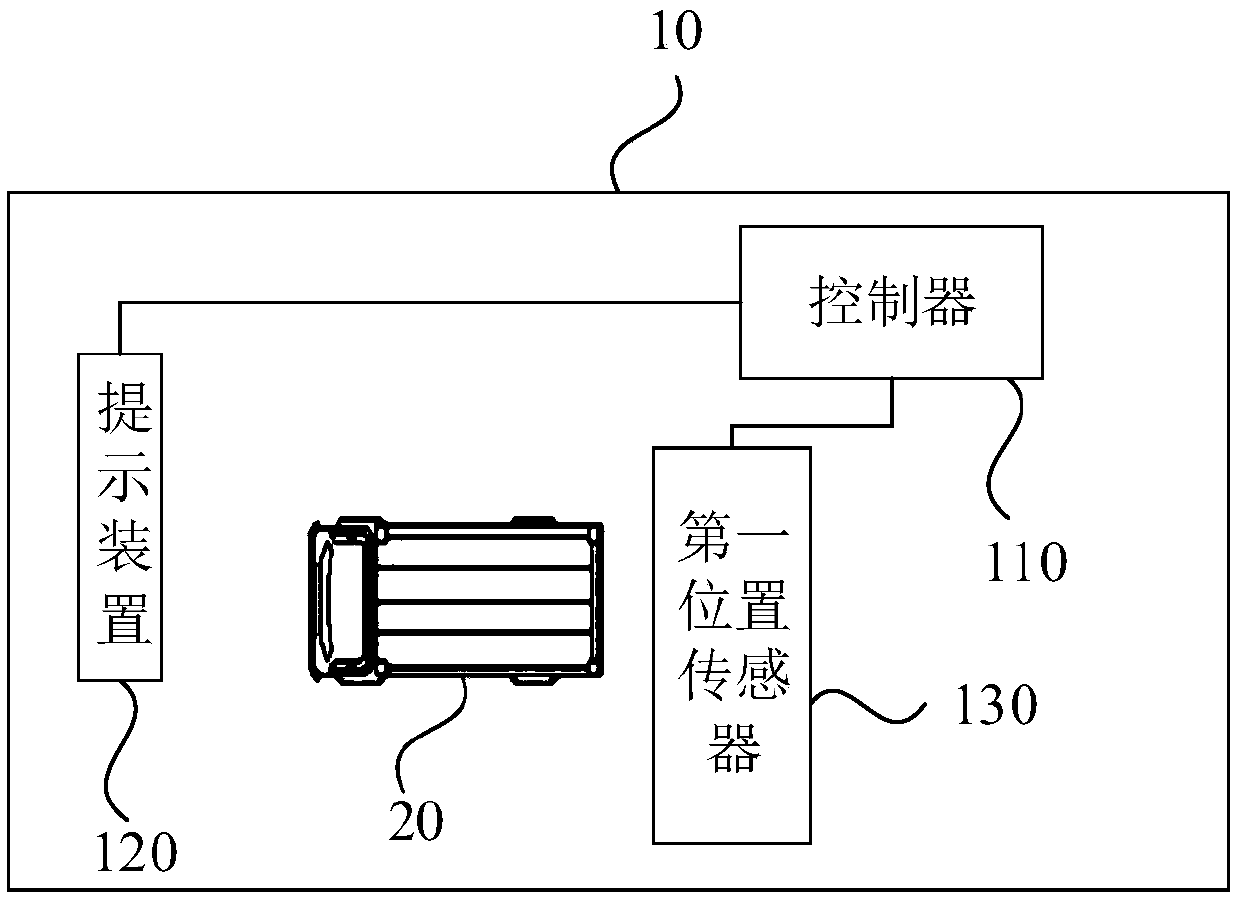

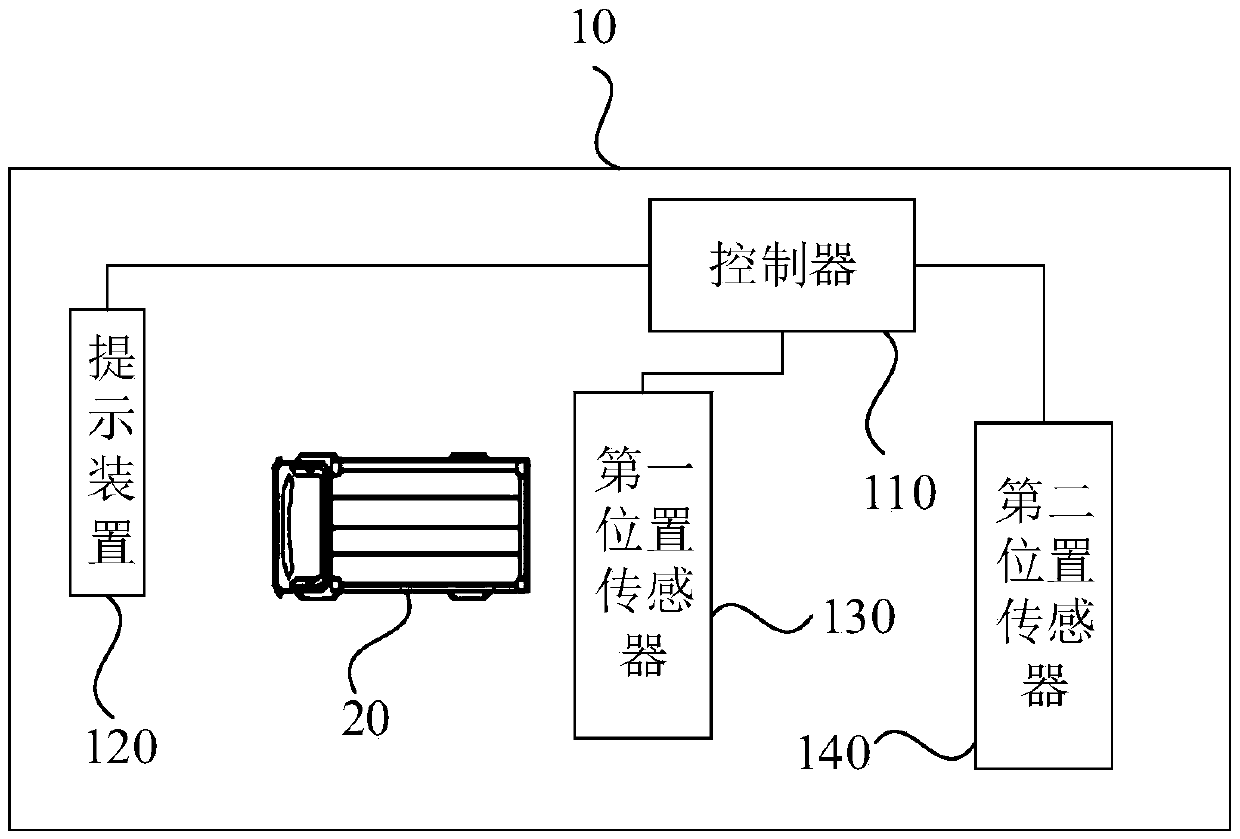

Unloading indication device for garbage power plant, and control system

InactiveCN109677958AImprove unloading efficiencyImprove securityConveyorsControl devices for conveyorsPower stationControl system

The embodiment of the invention relates to an unloading indication device for a garbage power plant, and a control system. The indication device comprises a controller, a prompting device and a firstposition sensor, wherein the first position sensor is connected with the controller, and used for detecting whether a garbage truck reverses to arrive at a set position or not, and sending a first detection result to the controller; the controller is connected with the prompting device, and used for sending a first control instruction to the prompting device according to the first detection result; and the prompting device is used for receiving the first control instruction, and carrying out information prompting according to the first control instruction. According to the technical scheme, reversing and unloading are carried out independent of the commanding of commanding personnel, so that the garbage unloading efficiency is increased, and the garbage unloading safety is improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Method for improving garbage fermentation effect of garbage power plant

PendingCN110170505AFast filtrationBreed fastSolid waste disposalIncinerator apparatusFermentationNutrients substances

The invention discloses a method for improving garbage fermentation effect of a garbage power plant. The method comprises the steps that 1), a leachate pool is built in a garbage pool, and leachate generated by a garbage pile is collected; 2), garbage is poured into the leachate pool and is stacked for a period of time; 3), the garbage is fished out and stacked on an inclined surface, and the generated leachate is automatically returned into the leachate pool; 4), new garbage is continuously poured into the leachate pool, the step 2 and the step 3 are repeated; and 5), after the garbage pile is stacked on the inclined surface for a period of time, the fermented garbage is transferred to be used for incinerating power generation. The fresh leachate in the pool contains a large number of microbial populations and nutrient substances, the new garbage is fully in contact and mixed with the leachate, the water content of the new garbage is adjusted, the number of the microbial populations and small molecule nutrient substances in the new garbage are increased, the reproduction of microorganisms is accelerated, so that the fermentation time of the garbage is shortened; and meanwhile, thewater in the garbage is separated out, the fermentation effect is improved, and the heat value of the garbage is improved.

Owner:CHONGQING UNIV

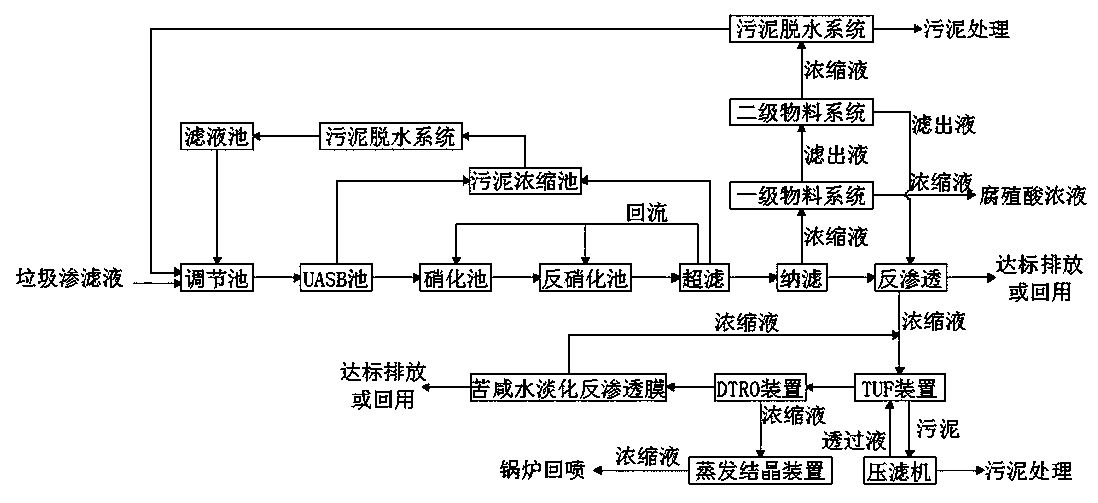

Landfill power plant leachate treatment system

InactiveCN109205900AImplement classification processingHigh recovery rateWater treatment parameter controlGeneral water supply conservationFiltrationUltrafiltration

The invention discloses a landfill power plant leachate treatment system which adopts a biochemical and membrane filtration combined process; nanofiltration concentrate and reverse osmosis concentratecan be obtained by treatment processes such as a regulating tank, a UASB tank, a nitrification tank, a denitrification tank, ultrafiltration, nanofiltration and reverse osmosis; humic acid is extracted from the nanofiltration concentrate through a material membrane separation system; the reverse osmosis concentrate is softened by a TUF tubular softening membrane to obtain permeate, the permeate passes through a DTRO device for reverse osmosis treatment to obtain a concentrated liquid, the concentrated liquid is crystallized by MVR evaporation, finally a small amount of the concentrated liquidis sprayed back to a boiler, and DTRO permeate is treated by a brackish water desalination reverse osmosis membrane unit to be discharged up to the standard or reused. The landfill power plant leachate treatment system has high recovery rate and can achieve zero discharge of the concentrated liquid.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

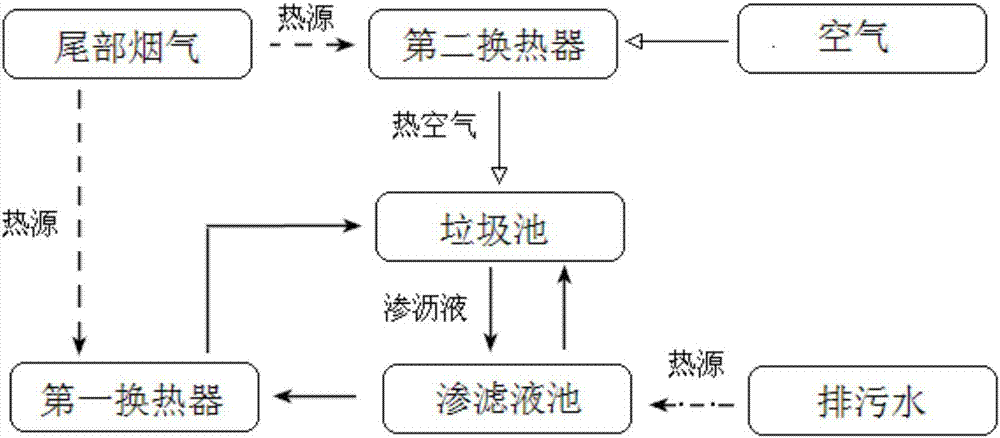

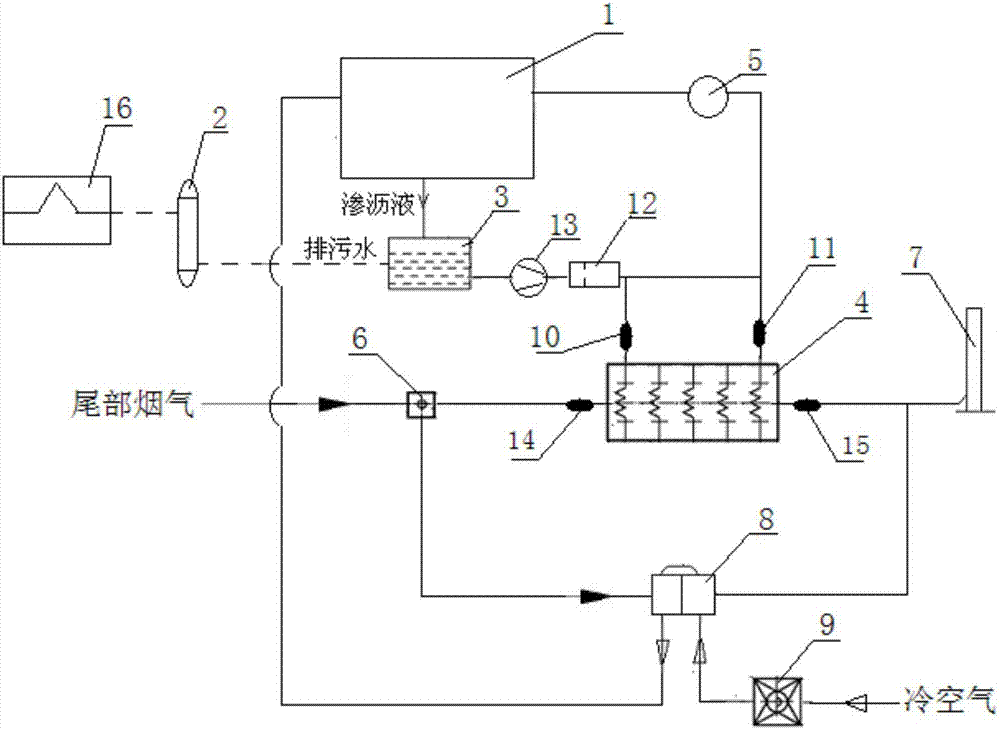

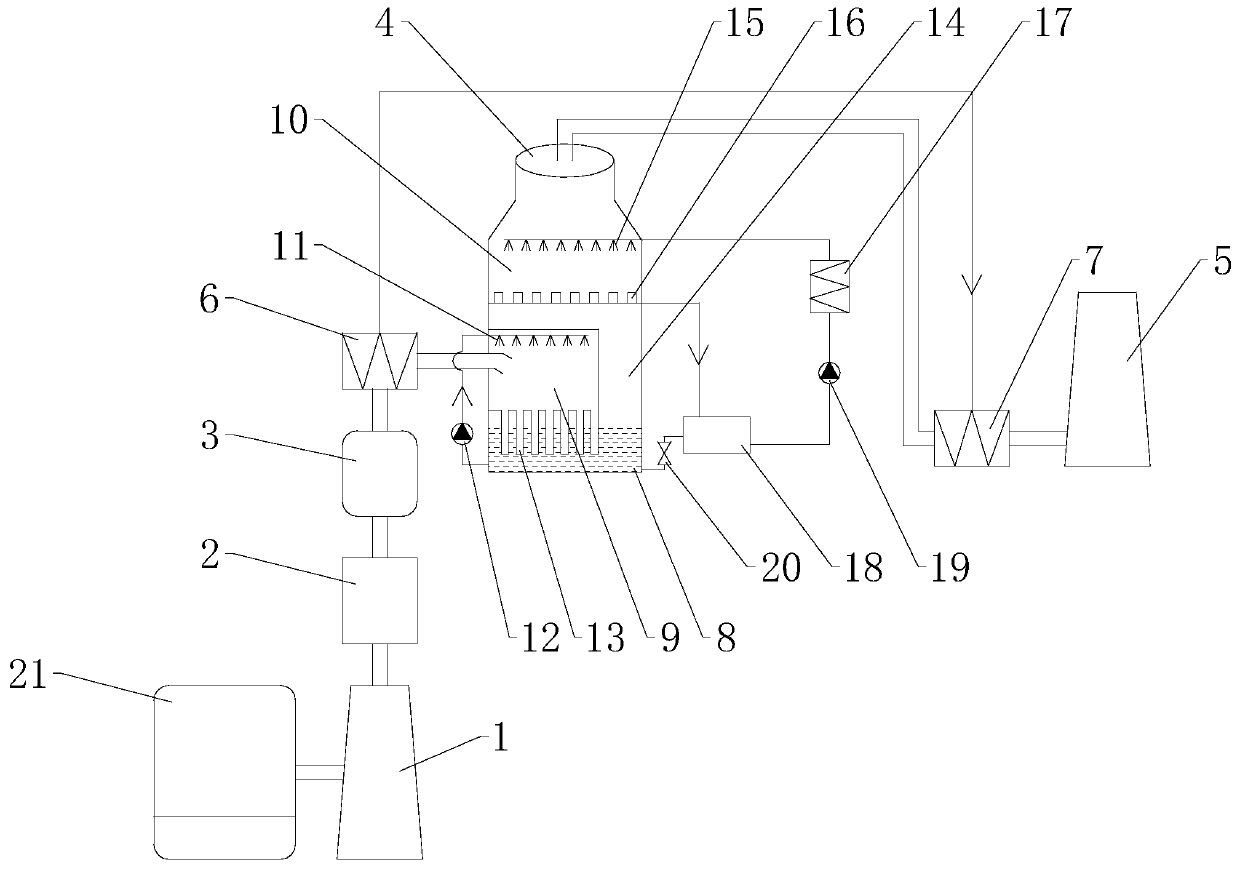

Method and system for increasing calorific value of garbage by virtue of waste heat of garbage incineration plant

ActiveCN106907719AIncrease the degree of filtrationIncrease the ambient temperatureIncinerator apparatusPower stationSewage

The invention discloses a method and system for increasing the calorific value of garbage by virtue of waste heat of a garbage incineration plant and belongs to the field of power generation by garbage incineration. The method comprises the steps: carrying out heat exchange on a leachate by virtue of tail smoke waste heat treated by smoke purification and / or sewage water waste heat in a garbage incineration system; and then, spraying the leachate subjected to heat exchange back to a garbage pool. By carrying out heat exchange on the leachate by virtue of the tail smoke waste heat treated by smoke purification and / or the sewage water waste heat in the garbage incineration system, and then, spraying the leachate back to a garbage pile of the garbage pool, the temperature of the garbage pile in the garbage pool of a low-calorific-value garbage incineration power plant can be effectively increased, and the fermentation and leaching of the garbage pile in the garbage pool can be favorably realized, so that the calorific value of the garbage incinerated in the furnace can be increased, furthermore, the on-grid energy is increased, and finally, the stable and continuous operation of a garbage power plant is favorably realized.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

Method for preparing autoclaved fly ash brick through hydration with PO saponification waste residue, garbage power plant slag and coal-fired power plant fly ash

InactiveCN105948635ASolve the problem of comprehensive utilization of resourcesSolve the home problemSolid waste managementCeramic shaping apparatusSlagFlexural strength

The invention discloses a method for preparing an autoclaved fly ash brick through hydration with PO saponification waste residue, garbage power plant slag and coal-fired power plant fly ash. The method is characterized in comprising the following steps: (1) 100g of concrete is prepared into a building block with a size of 70mm*50mm*20mm; (2) garbage power plant slag is crushed; slag particles with sizes of 2-3mm are selected as an aggregate of the concrete; (3) water is added for dissolving additive auxiliary materials including an activating agent Na2SiO3, early strength agents Na2SO4 and triethanolamine, and a dispersing agent sodium rosinate; the PO saponification waste residue is added; the garbage power plant slag, PO42.5 cement and coal-fired power plant fly ash are sequentially added; the mixture is well mixed, such that a slurry is prepared; (4) the slurry obtained in the step (3) is fetched and pressed into building blocks; (5) the building blocks obtained in the step (4) are allowed to stand for curing for 24h; (6) the building blocks obtained in the step (5) are steamed in an autoclave reactor, wherein the temperature is controlled at 230-250 DEG C and autoclave is carried out for 5-9h; the material is discharged after natural cooling; and (7) compression strength tests and flexural strength tests are carried out. According to the invention, the above three solid waste resources are used or preparing the autoclaved fly ash bricks, such that waste is turned valuable.

Owner:福建洋屿环保科技股份有限公司

Filtering device for dust and other pollutants

ActiveUS20170291136A1Efficient purificationLow constructionHuman health protectionUsing liquid separation agentDust particlesMaterials science

The present invention relates to the filtering of fumes emitted by industrial processes such as those used in iron and steel works, refineries, waste-to-energy plants and the like and in particular relates to a filtering device for fine and ultrafine dust particles and other polluting agents.

Owner:RIZZO ROCCO

Percolate treating system for garbage incineration power plant

InactiveCN107244782AIncrease water production rateGuaranteed normal consumptionWaste based fuelTreatment with anaerobic digestion processesRefluxPower station

The invention discloses a percolate treating system for a garbage incineration power plant. The percolate treating system comprises an adjusting tank, a medium temperature tank, an anaerobic reactor and a two-stage denitrification / nitrification system. The percolate treating system is characterized by further comprising a sand basin and a filtering system; the sand basin, the adjusting tank, the medium temperature tank, the anaerobic reactor, the two-stage denitrification / nitrification system and the filtering system are sequentially connected through pipelines; the filtering system comprises an outer tubular ultrafiltration membrane system; the sand basin, the anaerobic reactor and the outer tubular ultrafiltration membrane system are connected with a sludge storage tank through pipelines; the sludge storage tank is connected with a sludge dewatering system, a reflux pipeline is arranged between the sludge dewatering system and the adjusting tank, liquid out of the sludge dewatering system can return to the adjusting tank. A water yield of the percolate treating system of the garbage incineration power plant disclosed by the invention is improved, residual concentrated liquid can be completely consumed in the garbage incineration power plant, and the concentrated liquid is prevented from being emitted and seriously polluting environment.

Owner:佛山市银禾工业设计有限公司

Deep deacidification and white smoke removing system and method for flue gas of garbage power plant

InactiveCN110115924AReduce the temperatureReduce moisture contentCombination devicesGas treatmentSlurryWater content

The invention discloses a deep deacidification and white smoke removing system and method for flue gas of a garbage power plant. The system comprises a temperature reducing tower. The flue gas is introduced into a wet tower after preliminary deacidification by means of a semi-drying method, first deacidification is completed in a spraying bin, and then the flue gas is introduced into a slurry tankfor a gas-liquid reaction to complete second deacidification so that the deacidification efficiency of the flue gas can reach 90% or above; at the same time, the flue gas is condensed and dehumidified in a dehumidifying layer to reduce the water content in the flue gas, so that the two processes including deacidification and white smoke removing are integrally completed in the wet tower; during spraying deacidification, a certain guarantee is provided for the reaction time of spraying slurry and the flue gas, the slurry is in full contact with the flue gas, the demand for the height of a tower body is not high, and the energy consumption of the system is reduced; the flue gas is introduced into the slurry tank through a descending pipe after being subjected to spraying deacidification inthe spraying bin, acid gas removal and deep dust removal are further carried out through a slurry reaction, and ultra-low emission requirements are met.

Owner:凤阳海泰科能源环境管理服务有限公司

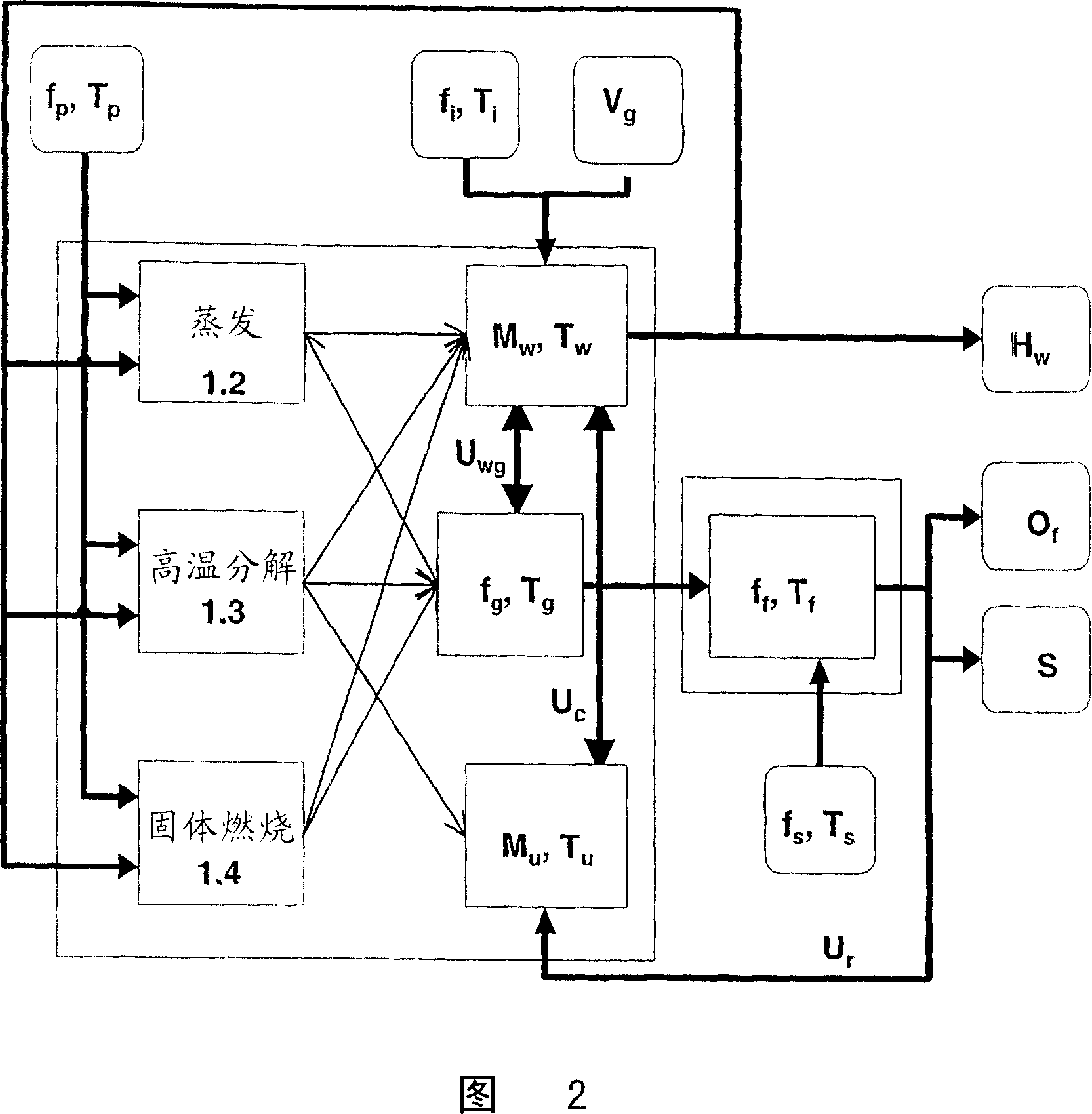

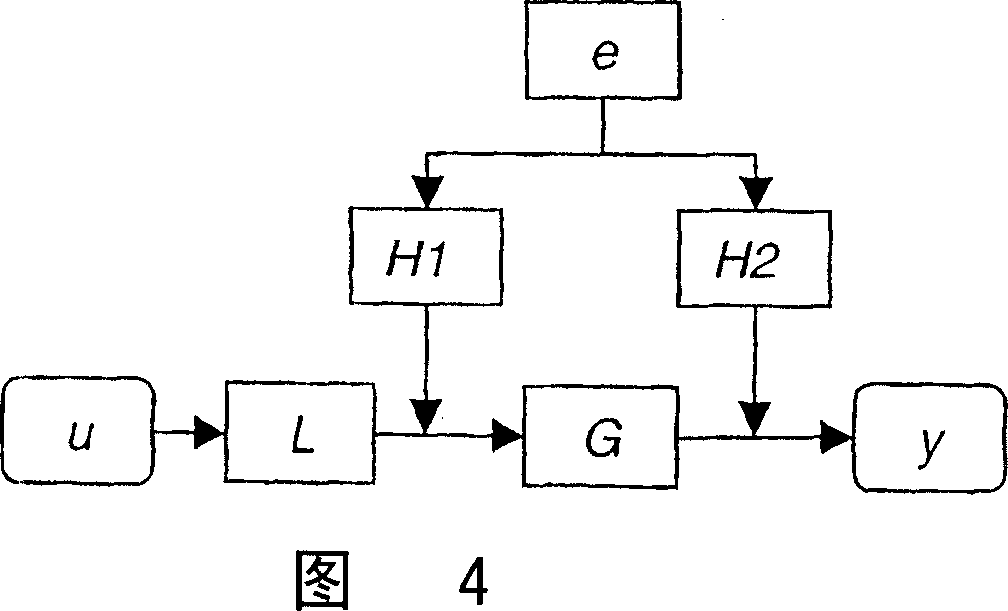

Model and control of a waste combustion process

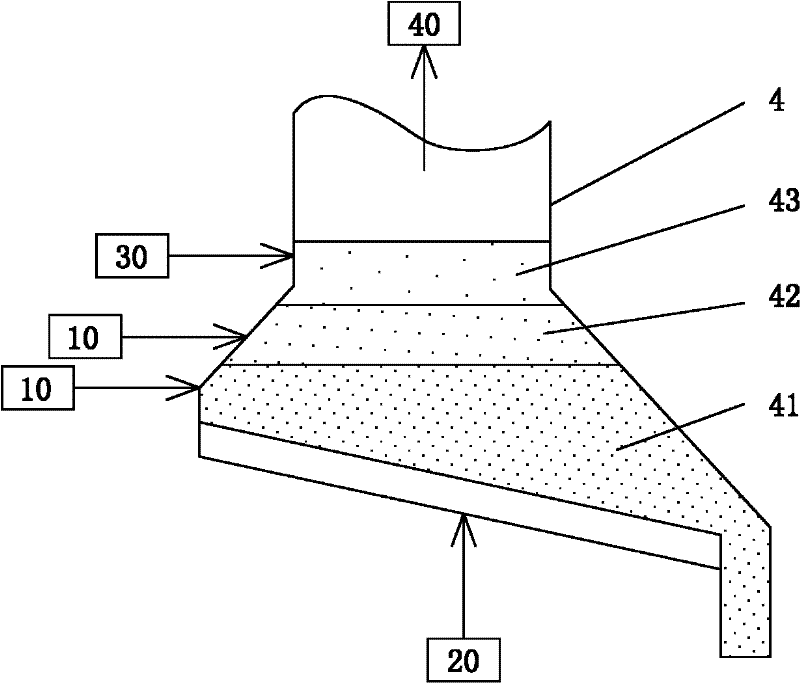

InactiveCN1947073APrecise regenerationReliable regenerationCombustion signal processingIncinerator apparatusComputation complexityModel based controller

The present invention is concerned with a model of a waste combustion process which is accurate and of limited computational complexity at the same time and thus is suitable for controlling or simulating a waste incineration plant. A pile of waste is represented by two layers, and the heat transfer from a gas combustion phase or flame above the pile is limited to a heat radiation interaction between the flame and upper one of the layers. The resulting model-based controller for a waste incineration grate takes into account a variability of the waste composition via filtered white noise. The controller can assist the operator in maintaining constant process conditions and maximizing the throughput of the plant at constant energy output, or realize a training simulator to educated operators in running a waste to energy plant secure, reliable and efficient.

Owner:ABB RES LTD

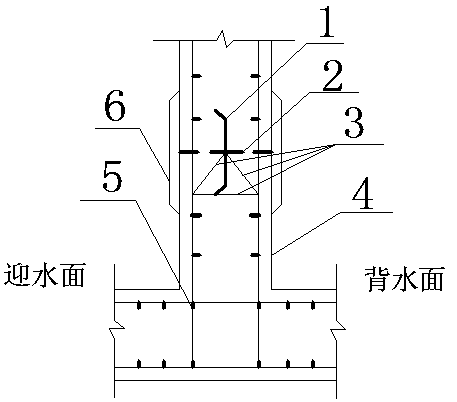

Horizontal construction seam construction method of refuse incineration power plant structure pool project

PendingCN108560608AEasy to pourAvoid corrosionArtificial islandsProtective foundationPower stationSlag

The invention discloses a horizontal construction seam construction method of a refuse incineration power plant structure pool project. The horizontal construction seam construction method comprises the following steps that a steel plate waterproof belt is mounted at the horizontal position of a construction seam, the steel plate waterproof belt is fixed by adopting reinforcing steel bars, the lower part is borne by adopting rebar cross braces, the two sides are slantly welded and fixed by adopting rebars, the mixed concrete is poured in a form board on the lower part of the construction seam,the surface of the concrete on the lower part of the construction seam is subjected to scabbling, laitance removal and water wetting, a paper sponge strip is pasted to the concrete below the construction seam, square timber is horizontally mounted on the lower face of the sponge strip, the form board on the upper part is placed on the square timber, the form board is tightly adhered to the papersponge strip, the upper layer concrete must be poured before the lower layer concrete is initially set, and after the upper form board is removed, waterproof mortar is applied on the inner side and the outer side of the horizontal construction seam. The horizontal construction seam construction method meets the anti-leakage construction requirement of the horizontal construction seam, can be applied to structure projects such as rubbish bins, slag bins and percolate pools in various refuse incineration power plants, and is safe and reliable, short in construction period, and outstanding in economic benefit.

Owner:POWER CHINA HENAN ENG CO LTD

Regeneration process for solid waste of garbage power plants

The invention discloses a regeneration process for solid waste of garbage power plants. According to the regeneration process, combustible materials, metal and sand in the solid waste are separated. A separation process comprises a dry separation process and a wet separation process; facilities related to the dry separation process comprise a vibrating mesh screen, a feeding bin, a conveyor, a cylinder screen, a jaw crusher, a material storage bin, an electromagnetic absorption machine and a wet type cylinder magnetic separator. Materials are subjected to coarse separation through dry type breaking and electromagnetic adsorption and then subjected to the wet separation process. The facilities related to the wet separation process comprise a wet type crusher, a U-shaped groove, a washbox, a cylinder fine screen, a water filtering screen, a shaking table, a bailing machine, a water extractor, a sand pool and a water pool. The materials are subjected to fine separation through the wet separation process, and finally the waste solid materials are divided into the combustible materials, metal and sand; the combustible materials are sent back to a combustion furnace to burn, the metal is regenerated and utilized after being classified, and the sand is used for manufacturing wall bricks and / or other construction materials.

Owner:晋江市冠兴建材有限责任公司

Method and treatment system for reducing nitrogen oxides by using incineration of refuse landfill gas

InactiveCN102252333AEfficient collectionNo pollution in the processIncinerator apparatusPower stationNitrogen oxides

The invention relates to a refuse landfill gas burning and re-burning technology, and in particular relates to a method and a treatment system for reducing nitrogen oxides by using incineration of refuse landfill gas. The treatment system mainly consists of a refuse landfill, an air pipe, a fan, the other air pipe and an incinerator connected sequentially; during working, the landfill gas of the refuse landfill is led out by the fan through the air pipe, delivered to the incinerator through the other air pipe, and burnt and re-burnt by the incinerator; and the landfill gas is used for reducing NOx in the incinerator, so that the NOx content of the flue gas exhausted by the incinerator is effectively reduced. The method and the system solve the problem of air pollution caused by stench of the refuse landfill and the problem of NOx concentration in the flue gas exhausted by the refuse incinerator, and are particularly suitable for a newly built refuse power plant, particularly a refuse burning power plant which is built nearby the refuse landfill and can provide the landfill gas more conveniently and effectively.

Owner:福建省丰泉环保控股有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com