Circulating fluidized bed refuse incineration boiler and refuse incineration method thereof

A circulating fluidized bed and waste incineration technology, which is applied in the combustion method, incinerator, combustion type, etc., can solve the problems of loss, inability to judge, and the structure and composition of the sanitation belt are not specified in detail, so as to reduce operating costs and improve Flue gas temperature, the effect of increasing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Below in conjunction with accompanying drawing, structure principle and working principle of the present invention are described in detail:

[0081] In order to solve the problems of low calorific value and large fluctuation of garbage, poor combustion stability, low combustion temperature in the furnace, which affects the decomposition of dioxins, and strong corrosive acid gas in the flue gas, the invention adopts a different type of conventional garbage in the overall structure of the boiler. Structural design of coal-fired mixed fuel circulating fluidized bed boiler.

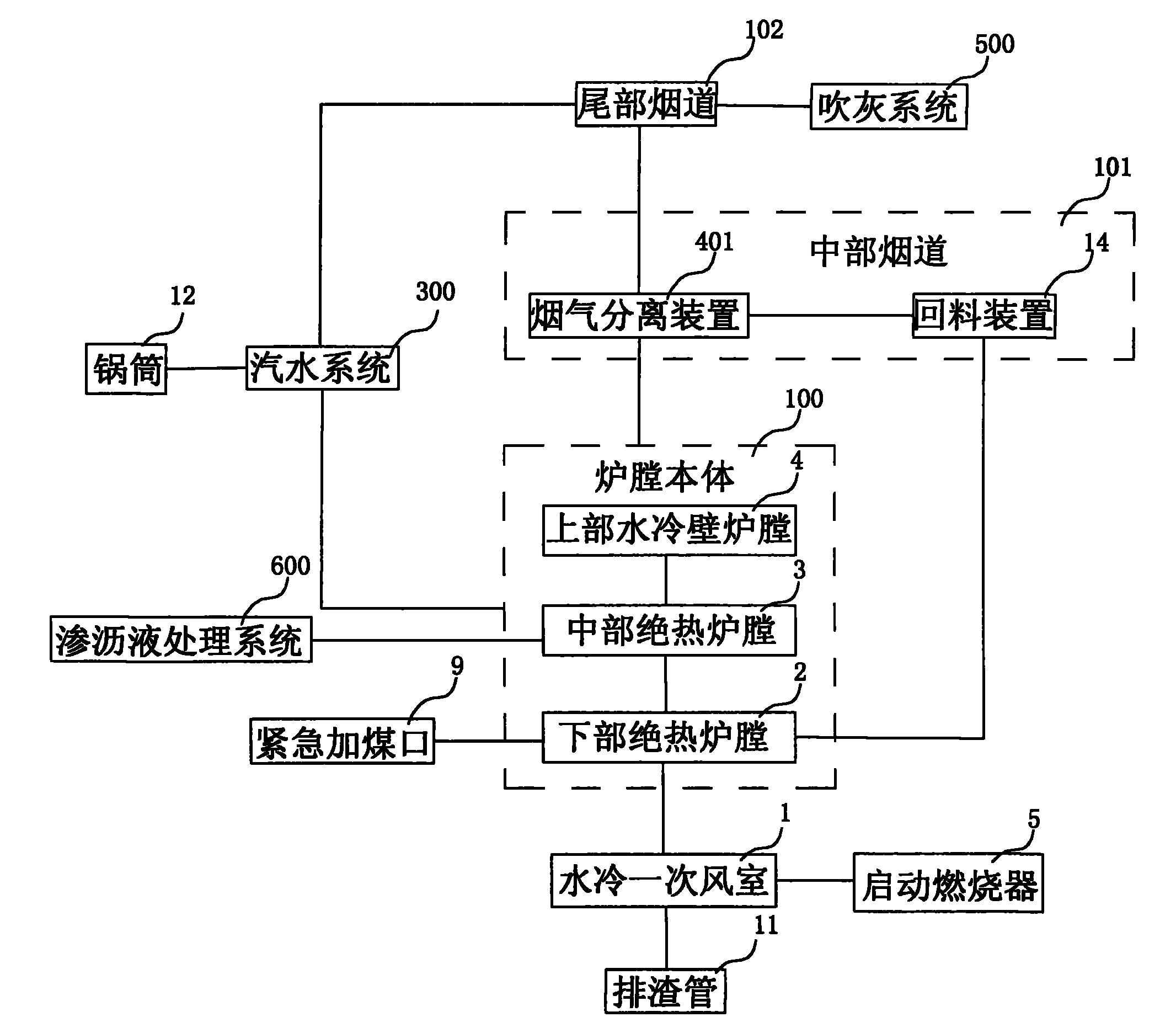

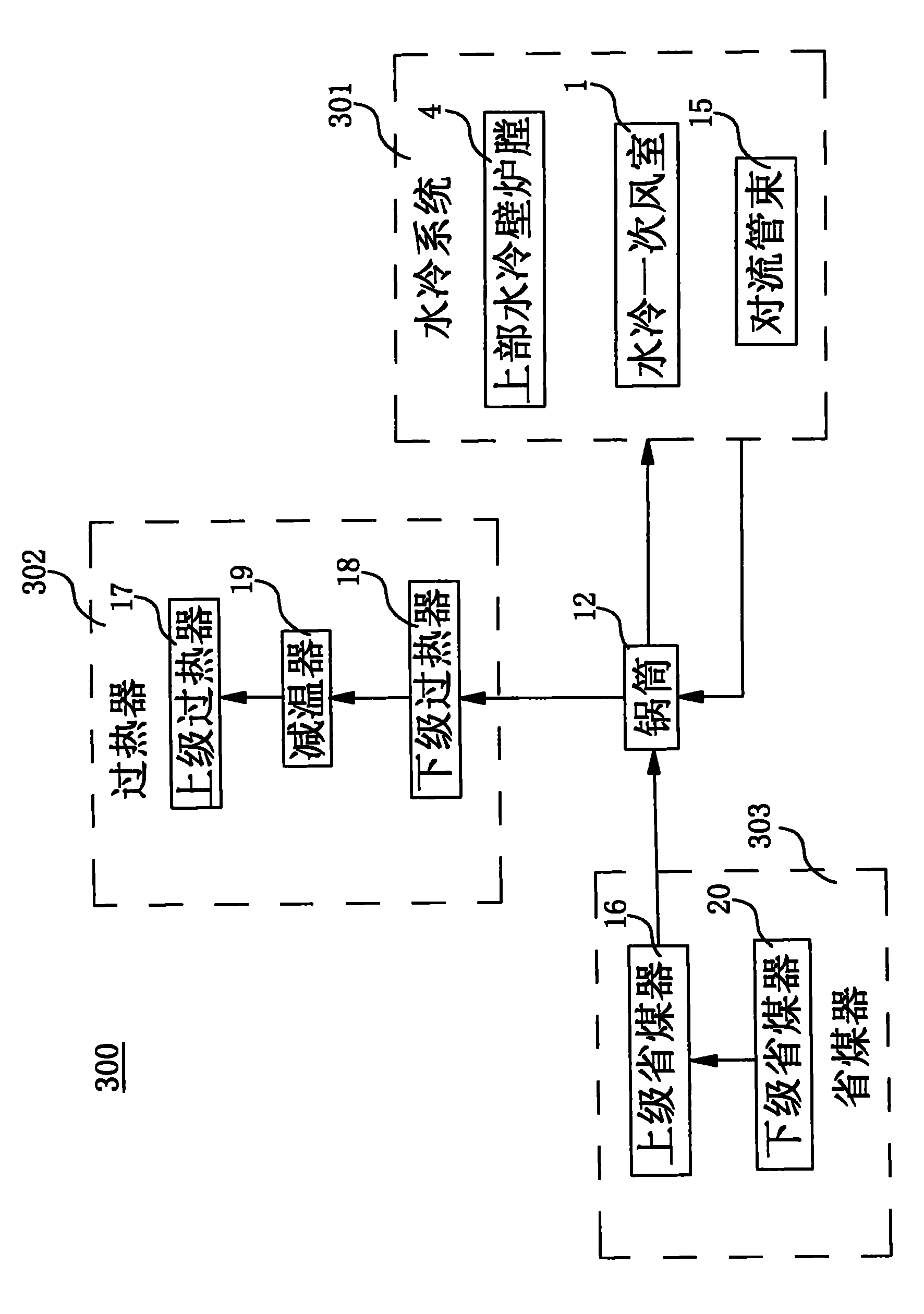

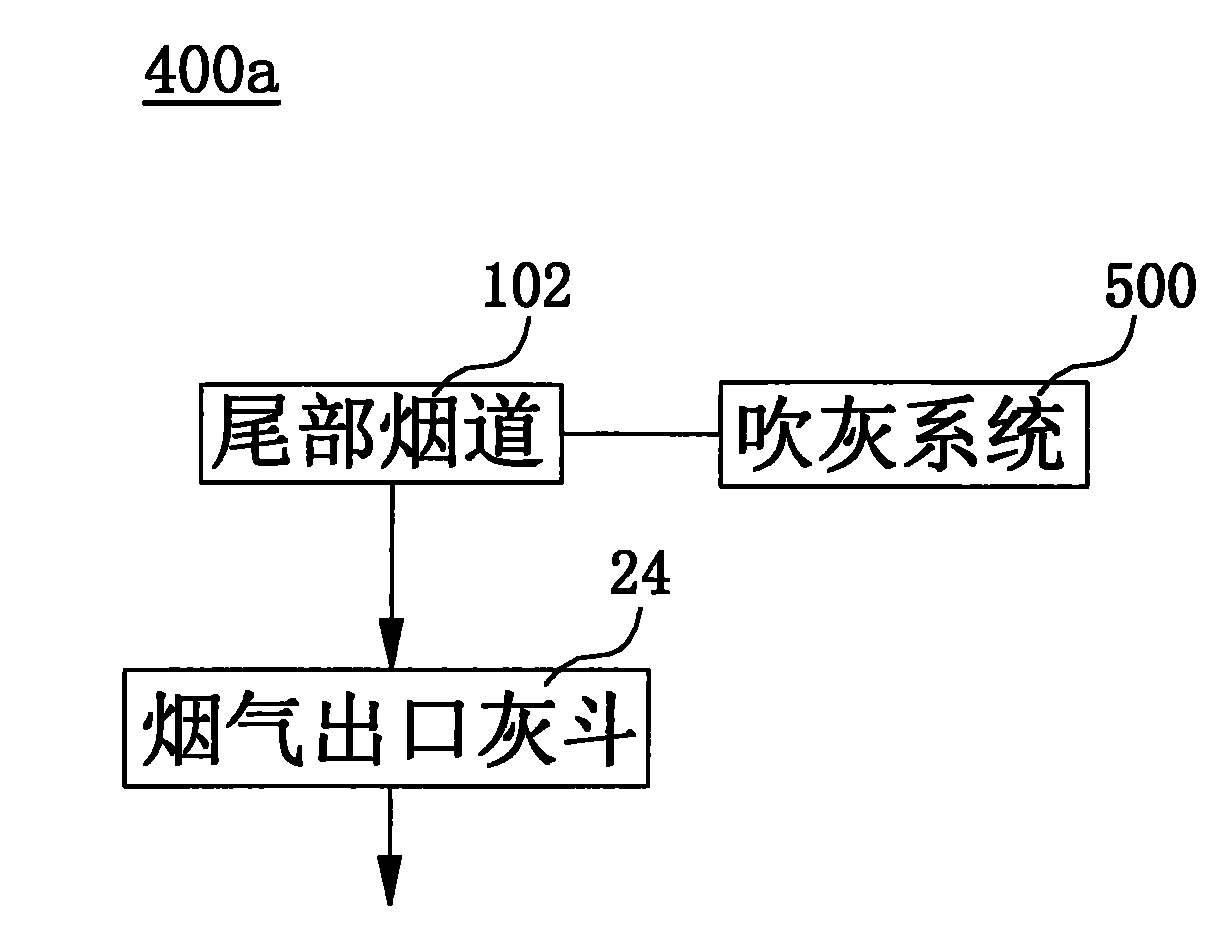

[0082] see figure 1 and Image 6 , figure 1 It is a structural block diagram of the circulating fluidized bed waste incineration boiler of the present invention, Image 6 It is a schematic structural diagram of the circulating fluidized bed waste incineration boiler of the present invention. The circulating fluidized bed waste incineration boiler of the present invention includes a steel frame 25 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com