Zero-discharge method for strong brine containing high-concentration heavy metals

A technology of heavy metals and concentrated brine, applied in chemical instruments and methods, water pollutants, water softening, etc., can solve the problems of small water volume, difficult treatment, high pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

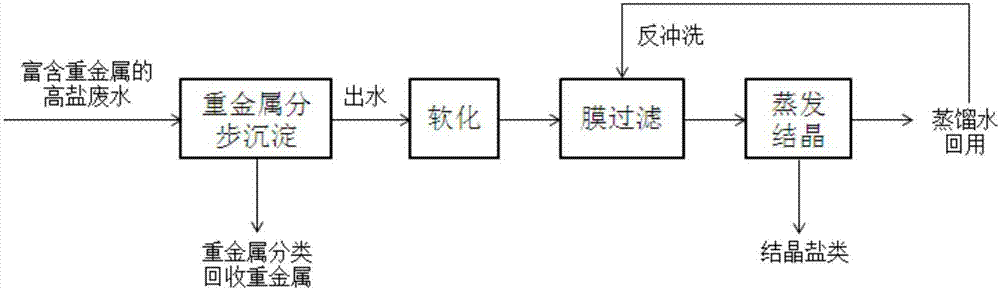

[0033] As shown in the figure, the treatment system for near-zero discharge of heavy metal-rich high-salt wastewater includes a sequential heavy metal step-by-step precipitation pretreatment system, wastewater softening system, and membrane filtration system (internal pressure, single-tube microfiltration membrane module) ) and evaporation crystallization system, heavy metal step-by-step precipitation system is used to remove heavy metal ions in high-salt wastewater step by step; wastewater softening system is used to remove calcium and magnesium ions in high-salt wastewater; membrane filtration system is used to treat high-salt wastewater after pretreatment Wastewater is filtered; the evaporation and crystallization system evaporates and crystallizes the high-salt wastewater after membrane filtration to obtain industrial salt and distilled water; during wastewater treatment, the wastewater flows through the above devices in sequence.

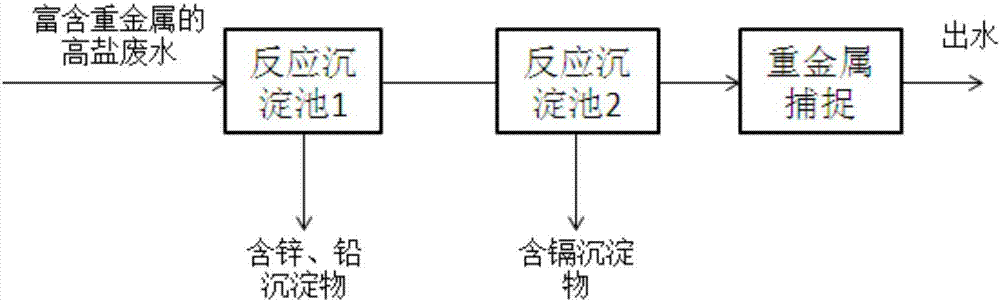

[0034] The heavy metal step-by-step preci...

Embodiment 2

[0042] The entire process was tested with 26 tons of treated water per day:

[0043] The high-salt wastewater rich in heavy metals in a power plant has a sodium chloride content of 6.2%, a potassium chloride content of 8.2%, a zinc content of 15.4g / L, a lead content of 5.6g / L, a copper content of 1.7g / L, and a nickel content of 0.1g / L, the cadmium content is 0.2g / L, the calcium content is 1.5g / L, and the chemical oxygen demand COD is 10mg / L.

[0044] Step-by-step precipitation of heavy metals + heavy metal scavenger treatment: After flocculation and precipitation of pH 9.0 to 10.0 in reaction sedimentation tank 1 with 10%wt sodium hydroxide solution, the effluent of reaction sedimentation tank 1 enters reaction sedimentation tank 2, and its pH The value is adjusted to 11.0-12.0 for flocculation and sedimentation. The effluent of reaction sedimentation tank 2 enters the heavy metal capture system, and TMT-18 heavy metal capture agent 2.6kg / d is added. After the heavy metal cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com