Processing method and equipment of complexing agent containing heavy metal waste water

A treatment method and technology of treatment equipment, applied in the direction of metallurgical wastewater treatment, water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problems of small application range and high cost, and achieve easy removal and less sludge generation , The effect of reducing the cost of sludge disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

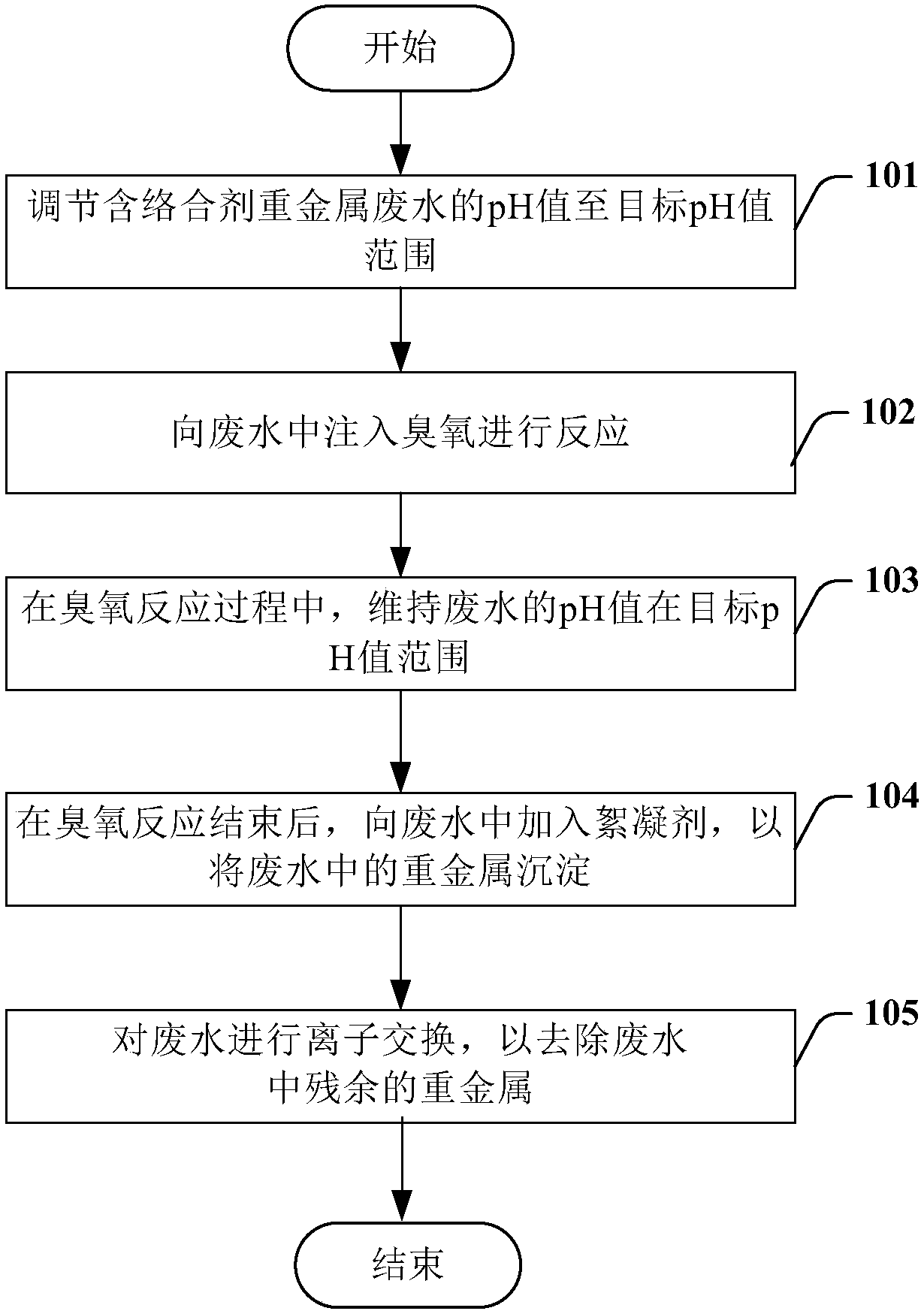

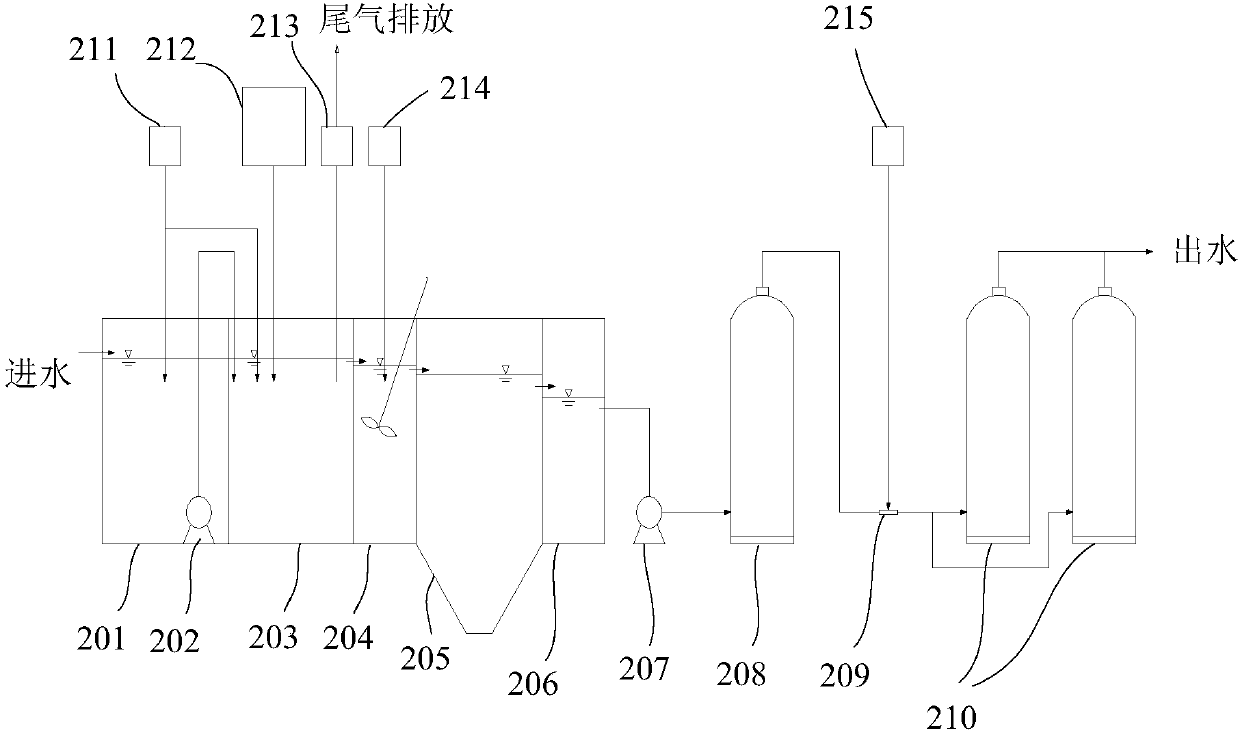

Method used

Image

Examples

example 1

[0053] Get the chemical nickel plating waste water of certain electroplating factory, nickel concentration is 144mg / L in the waste water, and pH value is 8.3. Add 10% (mass ratio) sodium hydroxide solution to the waste water to adjust the pH value of the waste water to 11.0. An oxygen source ozone generator is used to produce ozone, and an aeration head located at the bottom of the reactor is used to inject ozone-containing gas into the wastewater. The tail gas decomposes the undissolved ozone into oxygen through the tail gas decomposer and then is emptied. During the reaction process, sodium hydroxide solution was added intermittently to keep the pH value of the system between 10.9 and 11.1. The ozone reaction time is 30min. After the ozone reaction, the flocculant polyacrylamide was added to the wastewater, and the concentration of nickel in the effluent after flocculation and precipitation was 1.921mg / L. After treatment with an ion-exchange resin column, the concentratio...

example 2

[0055] Get another zinc-nickel alloy rinsing wastewater from an electroplating factory. In the wastewater, the zinc concentration is 12.30 mg / L, the nickel concentration is 8.64 mg / L, and the pH value is 11.8. Wastewater pH is not adjusted. The ozone-containing gas generated by the ozone generator is injected into the wastewater through the aeration head. During the ozone reaction process, the pH value of the wastewater will gradually decrease. The pH value of the wastewater is controlled around 11.0 by adding sodium hydroxide solution. Ozone reaction for 1 hour. After the ozone reaction is completed, flocculants are added to the wastewater. After flocculation and precipitation, the concentration of zinc in the effluent is 0.069mg / L, and the concentration of nickel is 0.453mg / L. After being treated with an ion exchange resin column, the concentration of zinc in the effluent is 0.017mg / L, and the concentration of nickel is 0.040mg / L, meeting the requirements in Table 3 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com